Abstract

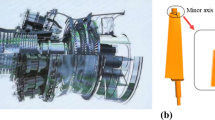

This investigation elucidates failure of a land based 6FA gas turbine compressor 2nd stage blade. During discussions with site officials, it was learnt that this particular compressor operated in good condition for over 20,000 h at two other sites. In this power station, this was second such failure with less operation duration. Due to failure of blades, it was requested for a detailed root cause analysis by the utility officials in order to avert such failures in future. Failed blade samples were collected from the site and cut into the suitable sizes for investigation procedures. Investigation techniques like visual observation, stereomicroscopic, metallographic, scanning electron microscopic examinations (SEM), etc. are employed to ascertain the root cause for failure. During the investigation it was noticed that there is no degradation in the material. During stereomicroscopic examination, a number of beach marks were observed to be present on the fractured surface of the blade. It was also noticed from both stereomicroscopic and SEM examinations that the blade failed due to fatigue. The cracks have originated from micro-cracks developed at the trailing edge during shot peening process in the blade root. These cracks grew as the blades have vibrated beyond their natural frequency due to air surge during operation. It was recommended to examine the air filtration mechanism of the compressor regularly.

Similar content being viewed by others

References

A564/A564M-13 (S45000 XM-25), Standard Specification for Hot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and Shapes, ASTM International, USA (2013).

Standard E45-13; Standard Test Methods for Determining the Inclusion Content of Steel; ASTM International, USA (2013).

Saqib Hameed M, and Manarvi I A, “Using FEM and CFD to Locate Cracks in Compressor Blades for Non Destructive Inspections” IEEEAC paper# 1651, Version 4, Updated Nov 19 (2008).

Carole Teolis, David Gent, Christine Kim, Teolis A, Paduano J, and Bright M, Eddy Current Sensor Signal Processing for Stall Detection, IEEEAC paper #1255, Version 3, Updated Dec 10 (2004).

Acknowledgments

Authors are grateful to the management of BHEL (R&D), BHEL (HPEP) Hyderabad and BGGTS for giving the opportunity to carry out this investigation and funding this study. Authors would like to express their gratitude to the staff of Metallurgy department, BHEL (R&D) for rendering services during tensile testing and metallographic examination.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Swamy, M., Singh, K., Pavan, A.H.V. et al. Failure Investigation of Frame 6FA Gas Turbine Compressor Blades. Trans Indian Inst Met 69, 647–651 (2016). https://doi.org/10.1007/s12666-015-0775-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-015-0775-6