Abstract

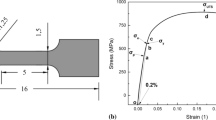

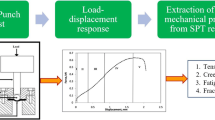

Extraction of mechanical properties of in-service materials through small specimen test techniques has become attractive in the recent years. Of the available small specimen test techniques, automated ball indentation (ABI) and small punch test (SPT) methods have proved to be more promising. These test methods are basically non-destructive in nature and are proficient enough to extract the flow properties of the materials using small volume specimen. In this work, tensile properties of a pressure vessel steel (P12) have been estimated through ABI and SPT. The objective is to compare the capability of these test methods in determining the tensile properties. The influence of lubrication (between the indenter and the specimen) on the ABI response is also investigated. The ABI response is found to be similar and the effect on the tensile properties was under 2 %. The tensile properties estimated from ABI and SPT are found to be in good agreement with conventional tensile test results. Nevertheless, in case of SPT, the error in the estimation of yield strength and ultimate tensile strength using empirical correlations is significantly high. However, the use of analytical formulations to convert the SPT load–displacement response to stress–strain curve are found to be reliable, since the error in the estimated properties is considerably less. The ABI process is numerically simulated to study the stress–strain field beneath the indenter. The maximum strain occurs at the edge of the contact indicating the material displacement along the radial direction. The plastic zone beneath the indenter resemble hemispherical shape which is in agreement with the expanding cavity model. The nature of stress changes from compressive (right below the indentation axis) to tensile at the edge of contact. This indicates that radial cracks may initiate on the specimen and propagate outwards. The pile-up is significantly higher in the case of frictionless contact between the indenter and the specimen but found to converge for a value of around 0.2.

Similar content being viewed by others

References

ASTM E8/E8M-13a, Standard Test Methods for Tension Testing of Metallic Materials, Annual Book of ASTM Standards, ASTM International, West Conshohocken, PA (2013).

Barbadikar D R, Ballal A R, Peshwe D R, Ganeshkumar J, Laha K, and Mathew M D, Mater Sci Eng A 624 (2015) 92.

Patil D C, Das M, Das G, Kori S A, and Venkateswarlu K, Procedia Mater Sci 5 (2014) 379.

Das G, Das M, Sinha S, Gupta K K, Chakrabarty S, and Ray A K, Mater Sci Eng A 513–514 (2009) 389.

Prakash R V, Trans Indian Inst Met 63 (2010) 173.

Prakash R V, and Ghosh S, in Proceedings of the ASTM Symposium on Creep, Creep-Fatigue Interactions, San Antonio, TX, Nov. 17 (2010).

Rasche S, Kuna M, Int J Press Vessels Pip 125 (2014) 23.

Zhao L, Jing H, Xu L, Han Y, Xiu J, and Qiao Y, Mater Des 47 (2013) 677.

Eskner M, and Sandstrom R, J Test Eval 32 ( 2004) 11504.

Budzakoska E, Carr D G, Stathers, P A, Li H, Harrison R P, Hellier A K, and Yeung, W Y, Fatigue Fract Eng Mater Struct 30 (2007) 796.

Murty K L, Mathew M D, Wang Y, Shah V N, and Haggag F M, Int J Press Vessels Pip 75 (1998) 831.

Xu Y, Ning G, Zhang C, Yu Q, and Xu Y, Int J Press Vessels Pip 77 (2000) 715.

Tabor D, Proc R Soc Lond Ser A 192 (1948) 247.

Johnson K L, J Mech Phys Solids 18 (1970) 115.

Oliver W C, Pharr GM, J Mater Res 7 (1992) 1564.

Herbert E G, Pharr G M, Oliver W C, Lucas B N, and Hay JL, Thin Solid Films 398–399 (2001) 331.

Talzat B, Zacharia T, and Kosel F, Int J Solids Struct 35 (1998) 4411.

Haggag F M, in Small Specimen Test Techniques Applied to Nuclear Reactor Thermal Annealing and Plant Life Extension. ASTM STP 1204, American Society for Testing and Materials, Philadelphia (1993), p 27.

Underwood J H, O’Hara G P, and Zalinka J J Exp Mech 26 (1985) 379.

Sundararajan G, and Tirupataiah Y, Bull Mater Sci 7 (1994) 747.

Talzat B, and Pharr G M, Int J Solids Struct 41 (2004) 3891.

Ahn J-H, and Kwon D, J Mater Res 16 (2001) 3170.

Fischer-Cripps A C, J Mater Sci 34 (1999) 139.

Samuels L E, in Microindentation Techniques in Materials Science and Engineering, ASTM STP 889, (eds) Blau P J, and Lawn B R, ASTM (1986), p 5.

Samuels L E, and Mulhearn T O, J Mech Phys Solids 5 (1957) 125.

Shaw M C, and DeSalvo D J, Trans the Am Soc Mech Eng Ser B 92 (1970) 480.

Johnson K L, J Mech Phys Solids 18 (1970) 115.

Loubet J L, Georges J M, and Meille G, in Microindentation Techniques in Materials Science and Engineering, ASTM STP889, (eds) Blau P J, and Lawn B R, American Society for Testing and Materials, Philadelphia (1986), p 72.

Haggag F M, in Small Specimen Test Techniques Applied to Nuclear Reactor Vessel Thermal Annealing Plant Life Extension, ASTM STP 1204, (eds) Corwin W R, Haggag F M, and Server W L, American Society for Testing and Materials, Philadelphia (1993) p 27.

García T E, Rodríguez C, Belzunce F J, and Suárez C, J Alloy Compd 582 (2014) 708.

Fleury E, and Ha J S, KSME Int J 12 (1998) 827.

Eskner M, and Sandstrom R, J Test Eval 32 (2004), 282.

Xu Y, Ning G, Zhang C, Yu Q, and Xu Y, Int J Press Vessels Pip 77 (2000) 715.

Prakash R V, and Arunkumar S, in Small Specimen Test Techniques: 6th Volume, STP 1576, (eds) Sokolov M A, and Lucon E, STP157620140011, ASTM International, West Conshohocken, PA (2014), p 1.

Poor H Z, and Moosavi H, Int J Mech Syst Eng 3 (2013) 89.

Contreras M A, Rodriguez C, Belzunce F J, and Betegon C, Fatigue Fract Eng Mater Struct 31 (2008), 727.

Karthik V,Visweswaran P, Bhushan A, Pawaskar D N, Kasiviswanathan K V, Jayakumar T, and Raj B, Int J Mech Sci 54 (2012) 74.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Arunkumar, S., Prakash, R.V. Estimation of Tensile Properties of Pressure Vessel Steel Through Automated Ball Indentation and Small Punch Test. Trans Indian Inst Met 69, 1245–1256 (2016). https://doi.org/10.1007/s12666-015-0680-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-015-0680-z