Abstract

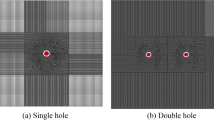

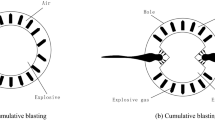

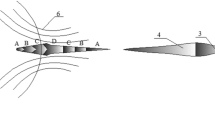

In order to increase the permeability of low permeability and high gas coal seam and improve the efficiency and utilization of gas extraction, the permeability enhancement technology of deep hole pre-splitting blasting is proposed, and the mechanism of blasting induced cracking of deep hole pre-splitting blasting is analyzed. ANSYS/LS-DYNA is used to simulate the propagation law of blasting stress wave and crack propagation under different process parameters. At the same time, the field industrial test was carried out on the 16,071 working face of Jiulishan Mine, in order to verify the effect of gas drainage and permeability improvement after deep hole pre-splitting blasting technology for low permeability and high gas seam. The results show that with the decrease of the decoupling coefficient, the number and density of cracks in the fracture zone gradually increase, and the number of coal failure units obviously increases. However, the increase range of the number and density of fringes in the fracture zone weakens when the value exceeds a certain value. By setting control holes, cracks can be formed through blasting holes and control holes to promote the expansion of cracks in the coal body, and then improve the permeability of the coal seam. When the distance between the blasting hole and the control hole is set to 3 m, the permeability improvement is the most ideal. Compared with natural extraction, the limit gas extraction amount of drilling hole after deep hole pre-splitting blasting is 3.71 times that of ordinary drilling hole. The results of numerical simulation and industrial field tests prove that the proposed deep hole pre-cracking blasting can effectively increase the permeability of low permeability coal strata, improve the gas extraction rate, and reduce gas disasters, which provides theoretical reference and field guidance for other low permeability coal seam.

Similar content being viewed by others

References

Badal R (1994) Controlled blasting in jointed rocks. Int J Rock Mech Min Sci Geomechan Abstracts 31:79–84

Baiquan L (1995) Experimental study on deep hole controlled relief blasting and its anti-outburst action mechanism. J Fuxin Min Institute (Natural Science Edition) 16–21

Feng XQ, Yu SW (1995) Micromechanical modelling of tensile response of elastic-brittle materials. Int J Solids Struc 32:3359–3372

Feng C, Zegong L, Chaoju Z, Baiquan L (2007) Numerical simulation on anti-reflection of deep hole pre-cracking blasting in high gas and low permeability coal seam. J China Coal Soc 499–503

Harries G (1979) Use of a computer to describe blasting. 15th APCOM Symposium. Int J Rock Mech Min Sci Geomech Abstracts, Brisbane

Guanglong D, Youqing W, Chang I, Qingming L, Guangyin S (2007) Prediction of gas emission in Mining face of protective layer. J China Coal Soc 382–385

Guozhong H, Hongtu W, Xiaogang F, Xiaohong L, Yin D, Yonghong S (2008) Study on gas pressure in the protection area of overlying false slope protective layer. J China University Mining Technol 328–332

Hanukayev A (1980) Blasting process of ore and rock. Metallurgical Industry Press, Beijing

Harries G (1973) A mathematical model of cratering and blasting. National symposium on rock fragmentation, Adelaide. pp 41–54

Huaibao C, Xiaolin Y, Weimin L, Yongqiang Y (2011a) Simulation test on blasting mechanism of coal mass. J China Coal Soc 36:1451–1456

Huaibao C, Xiaolin Y, Weimin L, Yongqiang Y, Liping W (2011b) Simulation test study on blasting damage law of coal. J Min Safety Eng 28:488–492

Huaibao C, Xiaolin Y, Aijun H, Yongqiang Y, Weimin L (2012) Experimental simulation of stress wave propagation and attenuation in coal. Explos Shock Waves 32:185–189

Huili T, Maopu Z (2004) Experimental study on medium-deep hole blasting in large section rock Roadway. Coal Eng 62–64

Institute CCSR (1976) Current situation and trends of coal and gas outburst prevention measures at home and abroad. Safety Environm Protect Min Industry 30–48

Jinglan P, Weidong L (1996) Development of pre-splitting blasting technology. Metal Mine 12–14

Jinkui L, Shihai C (2005) Experimental study on pressure relief of high stress soft rock roadway foundation by angular deep hole Blasting. Railway Construct 79–80

Kang C, Kaiguang Z (2001) Research on the formula for calculating the charge quantity of horizontal pre splitting line. Soil Mech 224–225

Khandelwal M, Singh TN (2006) Prediction of blast induced ground vibrations and frequency in opencast mine: a neural network approach. J Sound Vib 289:711–725

Kumar M, Ghosh PK, Singh AK (2003) Management of hard roof under Indian geo-mining conditions. J Mines Metals Fuels 51:143–146

Langefors (1963) The modern technique of rock blasting. New York: John Wiley and Sons Incorporation

Miao S (2019) Research and application of hydraulic punching anti-reflection technology in coal seam in yuwu mine. Coal Technol 38:111–114

Min G, Benliang X, Chuhan W, Hua W (2012a) Dynamic stress distribution and drainage effect of coal seam in through-layer blasting. Chin J Rock Mech Eng 31:2989–2996

Min G, Bin W, Desheng W (2012b) Application and numerical simulation of through-layer blasting in gas drainage of Nantong Mine. Rock Soil Mech 33:1822–1828

Min G, Chuhan W, Hua W (2012c) Stress field Characteristics of fan-shaped deep-hole blasting in multi-layer coal-rock medium. J Univ Sci Technol Beijing 34:614–619

Min G, Desheng W, Yihua H, Lidonghai (2008a) Effect of control hole in deep hole controlled blasting of outburst coal seam. Explos Shock Waves 28:310-315

Min G, Yihua H, Desheng W, Lidonghai (2008b) Numerical analysis of mechanical properties of deep hole pre-cracking blasting in soft coal seam. Chinese J Rock Mechan Eng 1674–1681

Nilson RH (1986) An integral method for predicting hydraulic fracture propagation driven by gases or liquids. Int J Numer Analyt Methods Geomechan 10:191–211

Nilson RH, Proffer WJ, Duff RE (1985) Modelling of gas driven fractures induced by propellant combustion within a borehole. Int J Numer Analyt Methods Geomechan 22:3–19

Platt JC (1998) Sequential minimal optimization: a fast algorithm for training support vector machines. Microsoft Res

Qi Z, Guangbao C, Jugen F (1994) Calculation of propagation length of crack induced by detonation gas. J Fuxin Mining Institute (Natural Science Edition) 13:18–21

Qun Z, Sanli F, Xilu Y (2001) Discussion on the basic reservoir characteristics and development strategies of coalbed methane. J China Coal Soc 230–235

Shilong Z, Minbo Z, Renhao Z, Qingling M (2021) Characteristics of coal mine accidents in Recent 5 Years and countermeasures. Coal Chem Ind 44:101–106+109

Shugang C, Yong L, Yanbao L, Liqiang Z, Jun W (2009) The effect of deep hole controlled presplitting blasting on the microstructure of coal body. J Rock Mech Eng 28:673–678

Si C, Biming S, Chaomin M, Zhanjin L (2013) Study on anti-reflection effect and pressure relief range of protective layer mining. Coal Sci Technol 41:45–49

Statistics NBo (2022) China Energy Statistical Yearbook 2022. In: Statistics NBo (ed). pp 4–5

Taylor LM, Chen EP, Kuszmaul JS (1986) Microcrack induced damage accumulation in brittle rock under dynamic loading. J Comput Methods Appl Mech Eng 55:301–320

Wang Z, Wu G, Zhou LJAS (2022) Optimization of pre-splitting blasting hole network parameters and engineering applications in open pit mine. Appl Sci 12:4930

Wang L, Sun Y, Zheng S, Shu L, Zhang XJJoCP (2023) How efficient coal mine methane control can benefit carbon-neutral target: Evidence from China.138895

Wu H, Gong M, Wu X, Guo YJE (2022) Effect and response of coal and rock media conditions on deep-hole pre-splitting blasting techniques for gas drainage. Energies 15:8733

Xiao L, Sail S, Geng M (2018) Effect of hydraulic punching on permeability evolution of coal reservoir. Coal Sci Technol 46:76–81

Yang L, Yang A, Chen S, Fang S, Huang C, Xie HJIJoRM, Sciences M, (2021) Model experimental study on the effects of in situ stresses on pre-splitting blasting damage and strain development. Int J Rock Mech Mining Sci 138:104587

Yingwei X, Zijian D (1997) Control of coal and gas outburst in Fully mechanized mining face by long borehole controlled loose blasting. Safety Environm Protect Min Ind 3:6–52

Yixian W (2019a) Numerical simulation of blasting cracking of soft stratified coal with hole location. China Min Ind 28:142–146

Yixian W (2019b) Numerical simulation of soft layer thickness on blasting cracking effect of coal. China Min Ind 28:97–101

Yuanping C, Deyong Z, Qixiang Y, Hongxing Z, Haifeng W (2006) Study on gas extraction and gushing regularity of pressure relief layer. J Min Safety Eng 12–18

Yun L, Chuan Y, Jianwei Z (2019) Optimization and application of Hydraulic punching parameters in single thick coal Seam drilling. Safety Coal Mine 50:176–180

Author information

Authors and Affiliations

Contributions

Li Hui, Zhang Kanglin, Zu Haodong and Qian Jifa wrote the main manuscript text. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Competing interest

The authors declare that they have no known competing financial interest or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, H., Zhang, K., Zu, H. et al. Study on the technology of permeability enhancement of deep hole pre-splitting blasting in a low-permeability coal seam. Environ Earth Sci 83, 40 (2024). https://doi.org/10.1007/s12665-023-11332-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12665-023-11332-0