Abstract

The Salman Farsi Dam is constructed on the Ghareh Aghaj River at the northern limb of Changal Anticline, SW Iran. The anticline is composed of the calcareous Asmari Formation (AF) sandwiched between two marly formations, the Pabdeh–Gurpi (PGF) and Razak (RF). The AF is divided into three units: lower (LAF) marl and limestone, middle (MAF) karstified limestone, and upper (UAF) marl and marly limestone. The dam is constructed on the MAF, and the reservoir is in direct contact with the MAF, UAF and RF. A huge relict cave was discovered during excavation of grouting galleries in the MAF. In this research, the potential leakage passage (PLP) is defined as parts of the karst aquifer located lower than the normal water level (NWL) of reservoir, in which the reservoir water has potential to be leaked toward downstream, assuming no grout curtain construction. The PLP is composed of the inlet windows, transfer passage, and discharge zones. At the Salman Farsi Dam, the PLP is determined by three alternative schematic models considering hydrogeological and geological settings. At this dam site, the grout curtain was properly designed from the MAF toward the downstream LAF, at the narrowest part of the PLP and bypassing the huge cave. The grout curtain was successful in blocking the PLP based on the negligible leakage, and high differences between water level in the pair piezometers at the upstream and downstream sides of the grout curtain. It is recommended to determine the PLP in future dam construction in karst terrains.

Similar content being viewed by others

Introduction

Leakage problem occurs often during operation of dams and reservoirs in karst regions all around the world. Difficulties in dam construction on a karst terrain were first reported at the Hales Bar Dam (USA) in 1913, in which despite the existence of karstified rocks in the foundation, little treatment was performed and huge leakage was occurred (Donnelly et al. 2009). Because of insoluble problem, the dam was replaced by the Nickajack Dam, located to 10 km downstream (Bruce 2003). The basic experiences in various methods of karst foundation grouting have been obtained by the projects of the Tennessee Valley Authority (USA), before 1950 (Milanovic 2004). After that, numerous dams and reservoirs were built in the karst regions all around the World, most of them function successfully, but a few have problems with unacceptable leakage from reservoirs (Gunn 2004; Milanovic 2004).

A considerable number of articles are published about leakage from karst dam sites, mostly focus on the leakage routes and remediation methods. Hansen and Teter (1970) used radioisotopes for leakage velocity determination at the Anchor Dam (USA). Due to the leakage problem, the Anchor Reservoir has barely stored enough water despite the extensive remedial efforts. Sinkholes and earth fissures within the reservoir area allowed drainage of the reservoir to underlying karstic formations (Jarvis 2003). Sahuquillo (1985) reviewed the difficulties found in Montejaque, Camarasa and Canelles dams in Spain by emphasis on geology and hydrogeological characters. In case of the Montejaque Dam (1920), about 4 m3 s−1 leakage was occurred through a 3.8 km long conduit, while the average inflow to the reservoir was 0.8 m3 s−1. In the Camarasa Dam (1920), leakage amounted to 11.26 m3 s−1 was reduced to 2.6 m3 s−1 after treatment works. In case of Canelles Dam, a water loss of 0.8 m3 s−1 was detected due to high permeability of the left abutment characterized by numerous caves and solution apertures. The dams of Polyphyton, Perdika and Mornos in Greece were presented by Pantzartzis et al. (1993) as examples of the typical reservoirs with major karst problems. The problems included of the submersion of karstic springs, occurrence of karst features in reservoirs, development of swallow holes and even complete failure of a project. Turkmen et al. (2002) determined the seepage direction and karstification pattern through the karstified limestone foundation of Kalecik Dam in Turkey by analyzing of borehole water levels, hydrochemistry and dye tracer tests. At this dam site, leakage through the right bank decreased significantly after additional grouting measures (Turkmen 2003). Ghobadi et al. (2005) identified seepage paths in the karstified limestone at the right abutment of Shahid Abbaspour Dam, SW Iran, using piezometers, hydrochemistry, dye tracer, and XRF test. Unal et al. (2007) investigated leakage problem at Ataturk Dam in Turkey by means of hydrometric measurements. Results showed that seepage levels were within design limits and therefore have no serious effect on the dam stability. Mohammadi et al. (2007) proposed a method for leakage study at the karstic dam sites by means of karst configuration and functioning approaches at local and regional scales. Mohammadi and Raeisi (2007) stated that uncertainty in delineation of leakage could be decreased if a detailed study be carried out on the stratigraphic and tectonic settings, karst hydrogeology, geomorphology, and speleogenesis at karst dam sites. Al-Omosh et al. (2008) applied geologic and geomagnetic investigations at the site of Bayer dam in Jordan and revealed that leakage occurred through a shallow karstic limestone bedrock under an alluvium cover which forms the unsealed floor of the dam. Schaefer (2009) summarized the primary failure modes and the methodology developed to perform risk analysis associated with dams built on karst foundations by the U.S. Army Corps of Engineers. Mozafari et al. (2012) studied leakage problem at the right abutment of Doosti Dam, NE Iran, using geological setting, dye tracer test, hydrochemistry, boreholes water level, and grout curtain characters. Results revealed that reservoir leakage occurred under diffuse flow conditions, confirming the proper performance of the grout curtain. At La Loteta Dam in Spain, it was concluded that leakage essentially occurs through the beneath and next to the left edge of the dam body by using multiple data included in the leakage discharge measured in the different zones of the drainage system, seepage points mapped downstream of the dam, borehole and piezometric data, and an equipotential map (Gutiérrez et al. 2015). Mozafari and Raeisi (2015) presented a schematic model for leakage route at the Kowsar Dam Site, SW Iran, using geological setting, water balance calculation, piezometers, springs discharge, and grout curtain characters. They concluded that water leakage at the Kowsar Dam could be significantly reduced by extension of grout curtain further into the upstream aquitard. Most recent on the leakage problem at the karst dam sites is given by Milanovic (2015) in which some of prominent case studies are briefly explained and grouped according to the some generalized seepage problems and success of remedial works.

Reservoir leakage varies from 5 to 10 % of average annual flow of the river to completely dried reservoir (Merritt 1995). The amount of leakage depends on the kind of water flow system. There are two end-member flow types in karst aquifers, laminar or slow flow and turbulent or rapid flow (White 1969, 1977; Ford and Williams 1989; Martin and Screaton 2001). The laminar flow system occurs through matrix or narrow fractures, while turbulent flow occurs within conduits or connected fractures (Pitty 1968). Reservoir leakage could be through laminar or turbulent flow system, or a combination of both. Depending on which flow system is governed, the amount of leakage is different. Under laminar flow system, the amount of leakage is predominantly negligible, while at the turbulent flow system, the leakage amount is significant and the risk of leakage problem is high. For normal hydraulic gradients, the turbulent flow occurs in conduits when apertures exceed about 0.01 m (White 2002). By increasing of hydraulic gradient due to reservoir filling, turbulent flow could be occurred even in conduits with smaller apertures. Therefore, existing of high diameter conduits at the dam foundation presents a high risk of leakage problem. At these conditions and to decrease the risk of leakage problem, the deep and extensive grouting works and caves filling are expected. Milanovic (2004, 2015) explained the practical solutions for waterproofing of several cavernous dam sites including: Lar and Marun Dams (Iran), Great Falls, Douglas, and Hales Bar dams (USA), Keban Dam (Turkey), Sklope Dam (Croatia), Camarasa and Canelles dams (Spain), El Cajon Dam (Honduras) and Khao Laem Dam (Thailand). Karst caves with volume higher than 50,000 m3 were cut by grout curtain at the Lar and Keban dams, more than 200 m below the riverbed. Plugging of caves was cost and time consuming and needed huge amounts of rock blocks, gravel, sand, and clay. Changing of the grout curtain route and depth was inevitable in some cases. Despite long-time extensive treatment works at the cavernous foundation, in some cases, as like as the Lar Dam in Iran, reservoirs were failed to fill up to an acceptable level.

The Salman Farsi Dam, a 125 m high concrete gravity arch dam with a reservoir capacity of 950 hm3, was built on the Ghareh Aghaj River, SW Iran (Fig. 1). The function of this dam is to generate electrical power and provide downstream drinking and irrigation water. The elevation of the riverbed at the dam site is 735 m. The designed NWL of the reservoir was 853 m asl, reduced to 835 m asl during construction. The dam is constructed on a karstified foundation, characterized by the presence of numerous karst conduits. Despite the karstified foundation, no significant water leakage was reported. The objective of this paper is to explain how a successful reservoir can be constructed in a karst terrain, using the example of the Salman Farsi Reservoir.

Hydrogeological settings

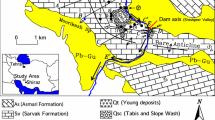

The study area is situated in the SW Iran, in Simply Folded Zagros, an Alpine tectono-sedimentary zone of Iran, characterized by long trending NW–SE antiformal and synformal folds (Falcon 1961). The structural characteristics and stratigraphy of the Zagros sedimentary sequence have been described in detail by Stocklin and Setudehnia (1977) and Alavi (2004). Generally at this zone, anticlines are cylindrical in form and well-exposed as high mountains, while the synclines form valleys and plains (Raeisi and Karimi 1997; Miliaresis 2001). At the study area, the exposed geological formations from the oldest to the youngest age are (Fig. 1): Pabdeh–Gurpi shale and marl (Santonian-Oligocene), Asmari limestone, marly limestone and marl (Oligo-Miocene), Razak marl and shale (Early Miocene), Mishan marl and shale (Miocene), and Bakhtiari calcareous conglomerate (Late Pliocene–Pleistocene).

The main geological structure of the study area is the 30 km long Changal Anticline, with a NW–SE trending parallel to the general structure of the Simply Folded Zagros Zone (Fig. 1). Geometrically, this anticline shows a cylindrical form, plunges down at both the ends. The Karzin Valley is cut in the anticline by the Ghareh Aghaj River almost perpendicular to the fold axis. The annual average discharge of the river is 16.5 m3 s−1. The Changal Anticline is composed mainly of the calcareous AF and the marly PGF and RF (Figs. 1, 2). The core of the anticline is made of about 800 m of shale and marlstone, belonging to the PGF (Fig. 2). Overlying the PGF, the calcareous AF with 650 m thickness crops out in most parts of the anticline. The AF is underlain by about 900 m marl and marlstone of the RF. The RF has been eroded at the top of the Changal Anticline and mostly exposed all around the anticline or buried under a thin alluvium at the adjacent plains. This formation covers the most parts of the reservoir area (Fig. 1). Hydrostratigraphically, the carbonate units form the karst aquifers, while the shale beds are interpreted as aquitards (Bachu et al. 2000; Filipponi and Jeannin 2006; Goldscheider and Neukum 2010; Bella and Bosák 2012). Therefore, at the Changal Anticline, both the marly PGF and RF form aquitards over and under the AF karst aquifer.

Geological cross section, elaborated perpendicular to the anticline axis. The cross section is located in Fig. 1

The Salman Farsi Dam is constructed on the AF at the entrance of the Karzin Valley on the northern limb of the Changal Anticline. The reservoir is formed at the foot of this limb and in the adjacent plain (Figs. 1, 2). At the dam site, the AF is divided into three lower (LAF), middle (MAF) and upper (UAF) units (Figs. 3, 4) (Stucky-Electrowatt 1996–2004; Fazeli 2007). The LAF is made of 230 m of well-stratified fine-grained limestone and marls. The MAF, with approximate thickness of 270 m, is composed of thickly well-stratified limestone, dolomite, and dolomitic limestone. The UAF consists of 150 m of thinly well-stratified limestone, marl and marly limestone. Based on the surface karst features, the MAF was more karstified than the LAF and UAF. While a few isolated small cavities were observed in the limestone layers of the LAF and UAF, several conduits and big caves were observed on the MAF, in addition to enlarged bedding planes and fractures, at both the abutments (Fars Regional water Authority 1999; Mahab Ghods Consulting Engineering Company 2000; Koleini et al. 2012).

Stratigraphic column of the Asmari Formation (AF) at the Salman Farsi Dam Site (After Koleini et al. 2012). Lithologically, the AF is divided into three units: upper (UAF), middle (MAF) and lower (LAF) units

At the dam site, the principal sets of discontinuities are bedding planes (N19°E/55°SE), and joint systems: J1 (N131°E/81NE), J2 (N115°E/85°NE), J3 (N280°E/77°SE), J4 (N294°E/89°SW), and J5 (N149°E/63°SE). The discontinuity apertures vary from millimeters up to 1.2 m, partly filled with sand and clay. On the left abutment (SE side of the river), joints generally belong to systems J1 and J2 with uniform orientation, while the joints distribution is more scattered on the right abutment (NW side of the river) (Koleini 2013).

Before the dam construction, water table dipped toward the Ghareh Aghaj River at the area of the dam axis in both the abutments, while the hydraulic gradient was steeper on the left bank than the right one (Nazari et al. 2010). Karst water emerged from the MAF into the river through 10 and 30 small karst springs on the right and left banks, respectively. There was no individual discharge measurement, but total discharge of the springs was around 0.008 m3 s−1. On the left bank, springs emerged from two different groundwater sources based on water temperature, a shallow phreatic source with temperature of 28 °C and a deeper source with temperature of 42 °C. By excavation of the dam foundation pit, groundwater inflow, almost hot water, estimated to be 0.08 m3 s−1 (Stucky-Electrowatt 1996–2004). Moreover, after excavation of the 370 m long and 15 m wide diversion tunnel in the left abutment (Fig. 3), water with temperature around 37.5 °C and discharge of 0.062 m3 s−1 was emerged from the MAF (Amirhoseini 2010). The existed oil field in vicinity of the study area could be considered as the source of hot water (Stucky-Electrowatt 1996–2004).

Before the dam construction, six kilograms of Rhodamine were injected into the Borehole QR51, a 100 m deep borehole drilled in the MAF unit at the left abutment, about 850 m far from the dam axis (Fig. 3). The dye was moved toward the river and detected in a spring at the outlet of the diversion tunnel (Fig. 3). The groundwater velocity based on the first and peak arrival time of the tracer was calculated to be about 3 and 1 m h−1, respectively (Amirhoseini 2010).

Grout curtain and discovered caves

At the dam axis, the sides of the valley are composed of the karstified MAF. The low permeable LAF and the PGF aquitards are exposed downstream of the dam, but extended below the MAF toward the reservoir area due to dip of bedding planes. Based on the Lugeon tests, the LAF and UAF show low permeable, but the permeability in the MAF was high. The permeability of the MAF, inferred by water pressure tests in 104 sections of five pilot boreholes (Fig. 3), was less than 10 Lu, between 10 and 100 Lu, and more than 100 Lu in 64, 31 and 5 % of sections, respectively (Stucky-Electrowatt 1996–2004; Fazeli 2007; Koleini 2013). The grout curtain was constructed mostly in the MAF, extended to the impermeable marlstone layers of the LAF in both the abutments (Fig. 5). The extension of the grout curtain was 140 m in depth at the central section and 400 and 470 m laterally into the right and left abutments, respectively (Fars Regional water Authority 1999; Mahab Ghods Consulting Engineering Company 2000). To construct the grout curtain, a five-level galleries system with vertical distance varied from 18 to 36 m was excavated in the MAF, extended into the LAF at the end in some levels (Fig. 6). The grouting galleries provide access for grouting the deep rock mass in abutments and foundation and also facilitate future grouting if it would be needed. From top to down, galleries were located at the elevations of 853, 835, 802, 769, and 738 m in the right abutment, and at the 853, 835, 802, 775, and 738 m in the left abutment (Stucky-Electrowatt 1996–2004). During drilling of exploratory boreholes in the MAF, no caves were discovered, but at the time of excavations in the MAF, galleries encountered with numerous relict caves in both the abutments (Fig. 6). The caves and conduits were mostly developed along the two sets of sub-vertical joint systems, J1 and J2, and the steep bedding planes (Vuckovic´ and Milanovic´ 2001; Fazeli 2007). Two largest caves were Golshan and Saidi Caves, discovered at the right and left banks, respectively (Figs. 5, 6). The approximate length, height, and width of the Golshan Cave are 130, 70, and 25 m, respectively, with estimated volume of 150,000 m3. This cave is accessible by two galleries on the elevations of 769 and 802 m (Milanovic 2015). The deepest point of the cave was located on an elevation of 758 m and was covered by fallen limestone blocks. More than five upward chimneys had been observed at the ceiling, but not speleologically investigated. Inside the cave, temperature was around 35 °C. The Saidi Cave, with 40 m length and approximate volume of 5000 m3, was discovered during excavation of a gallery on the elevation of 835 m. The bottom of this cave was also covered by limestone blocks (Dolder et al. 2001; Vuckovic´ and Milanovic´ 2001; Fazeli 2007).

The grout curtain was constructed in one row with split spacing method, while the final borehole spacing was 0.5 m. Grouting was carried out in 5-m sections in downward direction. The final grouting pressure was 40 bars. The water/cement ratio of grout mix varies from 1:1 to 1:1.5. To reduce viscosity and cohesion of grouting mix, superplasticizer to the extent of 1 % of the cement weight was used (Fazeli 2007; Nazari et al. 2010). The discussed alternative methods for water-tightening of the Golshan Cave include: filling the cave by concrete; building a concrete wall in the cave; and bypassing the cave by change in azimuth of grout curtain. Before cave filling or building a concrete wall, it was necessary to clean the cave, a complicated and time and cost consuming phase. Moreover, building a 70 m high concrete wall in the cave contains numerous problems as instabilities, transport of material, equipping and carrying special instrument. Considering these conditions, the bypassing of the cave from the upstream side was chosen and applied as the best method to watertight the Golshan Cave (Fig. 5) (Fars Regional water Authority 1999; Mahab Ghods Consulting Engineering Company 2000; Milanovic 2004). In the case of small caves, including Saidi Cave in the left abutment, the grout curtain route was not changed. The appropriate watertight was achieved by: reducing space of grouting boreholes; applying high grouting pressure; reducing the water/cement ratio to 1:2; and adding of maximum 6 % 0.001 m size clean sand into grouting materials, in addition to the superplasticizer. Generally, 100 tons of cement had been considered as a basis for grouting the medium scale caves at this project (Fazeli 2007; Nazari et al. 2010; Beynen 2011; Milanovic 2015).

Methodology

The AF aquifer in the Changal Anticline is classified into two sub-aquifers, namely the northern AF sub-aquifer and the southern AF sub-aquifer, since the hydraulic relation between the northern and southern limbs is disconnected by the elevated PGF in the core of the anticline. The general groundwater flow direction in the northern AF sub-aquifer is presented using the methods proposed by Ashjari and Raeisi (2006) and Raeisi (2008). The following equation is used to determine the mean recharge of the sub-aquifer during one hydrological year (Q in m3/year):

where A is the aquifer area (m2), P is the mean annual rainfall (mm), I is the recharge coefficient, and t is a 1 year period. The mean rainfall over the sub-aquifer surface is calculated based on the relationship between the elevations and 20 years mean rainfall of the adjacent climatologic stations.

The potential leakage passage (PLP) is defined as the parts of the karst aquifer, with elevations lower than the NWL of the reservoir, in which the reservoir water has potential to be leaked through it toward downstream. The PLP is composed of an inlet window, discharge zone(s), and the transfer passage between them. The inlet window is restricted to the area where the reservoir water could be seeped into the karst aquifer. The PLP is determined by the geological and hydrogeological settings, general flow direction, and base level of erosion in the karst aquifer. The efficiency of the executed grout curtain is determined based on the water level differences in the pair piezometers located at the upstream and downstream sides of the grout curtain, and drainage from galleries and seepage zone.

Results and discussion

The AF karst aquifer

The AF in the Changal Anticline is sandwiched between two PGF and RF aquitards, forms a karst aquifer located in the limbs of the fold. The underlain PGF aquitard represents the lower limit of the aquifer, preventing vertical hydraulic relation with the deeper formations. The surrounding RF aquitard forms a barrier of permeability all around the anticline, blocking lateral hydraulic relation with the adjacent aquifers. The northern and southern limbs of the anticline are hydraulically disconnected since the contact between the PGF and AF in the core of anticline is higher than the contact between the RF and AF at the foot of the limbs (Fig. 2). In this manner, every limb is an independent sub-aquifer which its catchment area is limited by the crest of the anticline. The general groundwater flow direction in the northern AF sub-aquifer is in agreement with the general flow direction in most of the anticlines in the Simply Folded Zagros (Ashjari and Raeisi 2006; Raeisi 2008). In the northern AF sub-aquifer, the general groundwater flow direction is from both the plunges toward the Ghareh Aghaj River, the deepest point in the anticline (Fig. 1). After infiltration into the AF, water flows along the joints and bedding planes down to phreatic zone at the foot of the limb. Here, water cannot be emerged from the AF because the water table is lower than the contact elevations of the AF and RF, confirming by the lack of spring. The contacts between the RF and AF are located about 1070 and 980 m asl in the SE and NW plunges of the anticline, respectively. These contacts are 335 and 245 m higher than the Ghareh Aghaj River. This proposed flow direction is confirmed by dipping of groundwater toward the river, emerging of springs at both the banks of the river, and results of the dye tracer test before the dam construction (Amirhoseini 2010). As mentioned earlier, there were a shallow phreatic and a deep groundwater sources at the left bank of the river before the dam construction. Hot water could be come from the deep aquifers following a deep fault that cross the PGF. This situation is similar to the aquifers studied by many authors (e.g. Luhmann et al. 2011; Sauro et al. 2013). The shallow groundwater sources at both the abutments are mainly recharged by precipitation on the karstified surface of the AF sub-aquifer. Since there was no spring discharge measurement, the annual discharge of the karst sub-aquifer was estimated based on Eq. (1). The recharge coefficient of the aquifer is estimated to be 0.5, according to previous studies on karstic regions of Iran (Pezeshkpour 1991; Karst Research Centre of Iran 1993; Raeisi and Kowsar 1997; Karimi et al. 2005), and the mean annual rainfall on the aquifer is calculated to be 530 mm. The discharge of the northern AF sub-aquifer during one hydrological year is calculated to be 0.4 and 10.0 hm3 at the right and left sides of the river, respectively.

The alternative leakage routes

In a schematic model, three alternative leakage routes (Route I, II and III in Fig. 7) are presented based on the geological and hydrogeological settings of the Changal Anticline. The inlet window is a same area for three proposed leakage routes. The dam is constructed on the MAF, and the reservoir is in direct contact with this unit near the dam body, and to a greater extent with the UAF and RF in other areas. The RF aquitard with up to 900 m thickness is extended in the most areas of the reservoir (Figs. 1, 7), acts as a barrier and prevents significant water seeping into the AF. Therefore, the inlet window at the dam site is an extended area at both the abutments, where the reservoir water comes into direct contact with the UAF and MAF units (Fig. 3). Seeping through the low permeable UAF is unlikely because flow path is perpendicular to numerous marly interlayers of this unit. Even considering water seeping into this unit, its preferred discharge zone is the underlain MAF. The reservoir water has significant potential to seep directly into the highly karstified MAF, where the water is in direct contact with this unit. The MAF is the main transfer passage for the reservoir leakage. After reservoir water seeping into the MAF, three alternative leakage routes could be proposed (Fig. 7). In the Route I, groundwater flow is toward the southern limb of the anticline, perpendicular to the fold axis. Leakage through this route is unlikely because: (a) At downstream of the dam body, the elevations of the PGF aquitard in the core of the anticline are much higher than the NWL of the reservoir; (b) Reservoir water must move perpendicular to the bedding planes, through the numerous impermeable marl interlayers of the LAF and the thick PGF aquitard; and (c) Bedding planes dip steeply to upstream, against the direction of this proposed route. In the Route II, groundwater flow is along the bedding planes strike toward the plunges of the anticline. Flow through this proposed route is unlikely because by moving toward the plunges, the contact elevations of the RF and AF increase and reach to much higher levels than the NWL of the reservoir; therefore, there is no potential discharge zone at the plunges area or foot of the limb. In the Route III, flow direction is toward the downstream discharge zone, the Ghareh Aghaj River at the downstream of the dam body where the river is in direct contact with the MAF. The Route III is the PLP for the Salman Farsi Reservoir. The length of the inlet window is at least 2.3 km, while the length of the discharge zone is about 320 m at each abutments. In spite of the extensive inlet window and transfer passage, the discharge zones have a short length. The grout curtain was not designed along the inlet window because it has an extensive length, but it was properly constructed at a shallow and narrow part of the PLP near the discharge zone, blocking the transfer passage toward the river (Figs. 3, 5).

Reservoir impounding and operation of the grout curtain

The impoundment of the reservoir started in March 2007. Due to low precipitation and consequently low inflow to the reservoir, rising of water level up to the NWL was not possible and after a continuous rising and falling, the reservoir water level reached a maximum elevation of 822.4, 12.6 m below the NWL, by the end of April 2013 (Fig. 8). At this reservoir level, no spring or seepage was observed around the Changal Anticline at the contact between the AF and RF, but a seepage zone was identified downstream of the dam on the left bank of the river (Fig. 5). Also, water started to emerge from a few grouting galleries. The maximum discharge of the seepage zone and galleries was estimated to be 0.65 and 0.05 m3 s−1, respectively.

Water levels recorded in the pair boreholes: a VPR-9–VPR-10, b VPY2-1–VPY2-2, c VPY2-3–VPY2-4, and d VPY3-11–VPY3-12. The locations of these boreholes are shown in Fig. 5

The operation of grout curtain in blocking the PLP at the Salman Farsi Dam was successful based on the piezometric data, drainage from galleries and seepage measurements. The recorded water levels in the pair piezometers, drilled at the downstream and upstream sides of the grout curtain in the grouting galleries, confirm the proper operation of the grout curtain. For the example, water levels recorded in the pair piezometers VPR-9–VPR-10, VPY2-1–VPY2-2, VPY2-3–VPY2-4, and VPY3-11–VPY3-12, located at the right abutment where the biggest caves are located (Fig. 5), are shown in Fig. 8. Although water level of the pair boreholes had a similar response to the reservoir water level variations, significant head losses occurred through the route from the reservoir to upstream of the grout curtain, and also across the grout curtain (Fig. 8). At the reservoir level of 822.4 m asl, water level differences in the reservoir and upstream of the grout curtain, and also in the presented pair boreholes were at least 30 and 15 m, respectively.

The annual leakage through the galleries and seepage zone was negligible regarding the annual inflow into the reservoir. At the year of the maximum historical level of the reservoir, the total discharge of the galleries and seepages was calculated to be less than 15 hm3, which was <4 % of the annual inflow into the reservoir.

Conclusion

The experience of the Salman dam reservoir demonstrates that it is possible to make successful engineering projects in karstified bedrocks depending on general hydrogeological settings and designation of the water-tightness system of the reservoir. The dam was constructed on a karstified formation at the northern limb of the Changal Anticline, but no significant leakage was reported after the reservoir maximum historical level. The main reasons for water tightness of the reservoir are hydrogeological settings, and proper layout and construction of the grout curtain. The main positive hydrogeological parameters are: (a) Construction of the dam at the northern limb of the anticline; (b) No hydraulic relation between the upstream and downstream limbs of the anticline due to the elevated PGF aquitard at the core of the anticline; (c) No spring or potential discharge zone at the contact of the AF and RF, all around the anticline; (d) The AF is sandwiched between two aquitards, the PGF and RF, preventing vertical and lateral leakage toward the adjacent aquifers; (e) The karstified MAF is sandwiched between the low permeable LAF and UAF; and (f) The general flow direction in the AF was toward the Ghareh Aghaj River, the base level of erosion in the anticline.

In this research, the PLP is defined as a passage of leakage in a karst aquifer at the NWL of the reservoir. It is composed of inlet windows, transfer passage, and discharge zones. The PLP is determined considering the hydrological and geological settings at the designed NWL of the reservoir. The grout curtain layout must be located inside the PLP where: (a) the grout curtain area is minimum; (b) the route is less karstified; and (c) the grout curtain is connected to the impermeable formations. Despite an extended water inlet window at the Salman Farsi Dam Site, the length of the grout curtain was significantly reduced by selecting the narrowest part of the PLP nearby the downstream discharge zones. The depth, extension, and route of the grout curtain were designed properly to block the PLP. The grout curtain penetrated into the low permeable LAF in both the abutments. The small space of grouting boreholes (0.5 m) and modification of the grout curtain route to bypass the huge Golshan Cave have a main role in reducing the risk of leakage problem.

Water leakage problems have been reported for many dams, constructed on karst terrains in Iran, which have caused water and economic loss. To reduce the risk of leakage problems in future dam projects, it is recommended to determine the PLP, and to properly design the grout curtain location for blocking the PLP, before the dam construction.

References

Alavi M (2004) Regional stratigraphy of the Zagros folds-thrust belt of Iran and its proforeland evolution. Am J Sci 304:1–20

Al-Omosh H, Al Farajat M, Zuni F (2008) Leakage in Bayer Dam in Jordan: its causes and consequences, Jordan. J Civil Eng 2:363–375

Amirhoseini YK (2010) Investigation of water leakage from dam reservoirs, case study of Salman Farsi. In: Proceedings of the first Iranian national conference on applied research in water resources, geology, hydrogelogy and engineering of karst resources of Iran, Kermanshah, Iran (In Persian), pp. 249–258

Ashjari J, Raeisi E (2006) Influences of anticlinal structure on regional flow, Zagros, Iran. Cave Karst Sci 68:118–129

Bachu S, Brulotte M, Grobe M, Stewart S (2000) Suitability of the Alberta subsurface for carbon-dioxide sequestration in geological media. Alberta Energy and Utilities Board, Alberta Geological Survey, Earth Sciences Report 2000–2011

Bella P, Bosák P (2012) Speleogenesis along deep regional faults by ascending waters: case studies from Slovakia and Czech Republic. Acta Carsol 41:169–192

Beynen VPE (2011) Karst management. Springer, Utrecht, p 489. ISBN 978-94-007-1206-5

Bruce DA (2003) Sealing of massive water inflows through karst by grouting: principles and practice. In: Beck BF (ed) Sinkholes and the engineering and environmental impacts of karst. Geotechnical special publication no. 122. American Society of Civil Engineers, Reston, p 615

Dolder T, Kreuzer H, and Milanović P (2001) Salman Farsi Dam Project: Final Report Phase 2, Electrowatt-Econo, Zurich (unpublished)

Donnelly CR, Hinchberger S, Mohammadian E (2009) the design of foundation treatment measures for Dams on Karst foundations. Can Dam Assoc Bull 20:20–27

Falcon NL (1961) Major earth-flexing in the Zagros Mountains of southwest Iran. Quat J Geol Soc Lond 117:367–376

Fars Regional Water Authority (1999) Salman Farsi Dam (Ghir) Project. Mission Report (especially on geological and hydraulogical aspect), p. 37

Fazeli MA (2007) Construction of grout curtain in karstic environment case study: Salman Farsi Dam. Environ Geol 51(5):791–796

Filipponi M, Jeannin P-Y (2006) Is it possible to predict karstified horizons in tunneling? Aust J Earth Sci 99:24–30

Ford DC, Williams PW (1989) Karst geomorphology and hydrology. Unwin Hymam, London, p 601

Ghobadi MH, Khanlari GR, Djalaly H (2005) Seepage problems in the right abutment of the Shahid Abbaspour dam, southern Iran. Eng Geol 82:119–126

Goldscheider N, Neukum C (2010) Fold and fault control on the drainage pattern of a double-karst-aquifer system, Winterstaude, Austrian Alps. Acta Carsol 39:173–186

Gunn J (2004) Encyclopedia of caves and karst science. Fitzroy Dearborn, New York, p 430

Gutiérrez F, Mozafari M, Carbonel D, Gómez R, Raeisi E (2015) Leakage problems in dams built on evaporites. The case of La Loteta Dam (NE Spain), a reservoir in a large karstic depression generated by interstratal salt dissolution. Eng Geol 185:139–154

Hansen RL, Teter GA (1970) Use of radioisotopes in tracing reservoir leakage at Anchor Dam. U.S. Department of the Interior, Bureau of Reclamation, Office of Chief Engineer, p. 27

Jarvis T (2003) The money pit: karst failure of Anchor Dam, Wyoming. In: Johnson KS, Neal JT (eds) Evaporite karst and engineering/environmental problems in the United States: Oklahoma geological survey circular, vol 109, pp 271–278

Karimi H, Raeisi E, Zare M (2005) Physicochemical parameters time series of karst spring as a tool to differentiate the source of spring water. Carbonates Evaporites 20:138–147

Karst Research Centre of Iran (1993) Comprehensive study and research in water resource of the Maharlu Basin. Karst Research Centre of Iran Report, V, Fars, pp 1–4

Koleini M (2013) Engineering geological assessment and rock mass characterization of the Asmari formation (Zagros Range) as large dam foundation rocks in southwestern Iran. Doctoral dissertation, University of Pretoria

Koleini M, Van Rooy JL, Bumby A (2012) Hypogenic karstification and conduit system controlling by tectonic pattern in foundation rocks of the Salman Farsi Dam in South-Western Iran. Int J Civil Geol Eng 7:154–161

Luhmann A, Covington MD, Peters AJ et al (2011) Classification of thermal patterns at karst springs and cave streams. Ground Water 49:324–335

Mahab Ghods Consulting Engineering Company (2000) Salman Farsi (Ghir) Dam, Report on hydrogeology, p. 33

Martin JB, Screaton EJ (2001) Exchange of matrix and conduit water with examples from the Floridan Aquifer, U.S. Geological Survey Karst Interest Group Proceedings, Water Resources Investigations Report 01-4011, pp 38–44

Merritt AH (1995) Geotechnical aspects of the design and construction of dams and pressure tunnel in soluble rocks. In: Beck BF (ed) Karst geohazards: engineering and environmental problems in karst terranes. A.A. Balkema, Rotterdam, pp 3–7

Milanović PT (2004) Water resources engineering in karst. CRC Press, Boca Raton 312 p

Milanović PT (2015) Catalog of engineering works in karst and their effects. In: Stevanovic´ Z (ed) Karst aquifers-characterization and engineering. Springer, University of Belgrade, Belgrade, Serbia, pp 361–399

Milanović PT, Kreuzer H, and Dolder T (2002) Salman Farsi Dam Project: report on design of the grout curtain, JV Stucky-Electrowatt (unpublished)

Miliaresis GC (2001) Geomorphometric mapping of Zagros ranges at regional scale. Comput Geosci 27:775–786

Mohammadi Z, Raeisi E (2007) Hydrogeological uncertainties in delineation of leakage at karst dam sites, the Zagros Region, Iran. J Cave Karst Stud 69:305–317

Mohammadi Z, Raeisi E, Bakalowicz M (2007) Method of leakage study at the karst dam site. A case study: Khersan 3 Dam, Iran. Environ Geol 52:1053–1065

Mozafari M, Raeisi E (2015) Understanding karst leakage at the Kowsar dam, Iran, by hydrogeological analysis. Environ Eng Geosci 21(4):325–339

Mozafari M, Raeisi E, Zare M (2012) Water leakage paths in the Doosti Dam, Turkmenistan and Iran. J Environ Earth Sci 65:103–117

National Iranian Oil Company Exploration and Production (1959) Geological quadrangle map of Iran, geological map of Jahrom, with explanatory text in Persian, Scale: 1:250,000, 1 sheet

Nazari MH, Fazeli MA, Omran ME (2010) Design and Construction of Grout Curtain at karstified Formations with special view on Salman Farsi Dam Project. The First International Applied Geological Congress, Department of Geology, Islamic Azad University - Mashad Branch, Iran

Pantzartzis P, Emmanuelidis G, Krapp L, Milanovic P (1993) Karst phenomena and dam construction in Greece. Hydrogeological Processes in Karst Terranes. In: Proceedings, antalya symposium and field seminar, IAHS Publication 207, pp 65–74

Pezeshkpour P (1991) Hydrogeological and hydrochemical evaluation of Kuhe-Gar-Barm-Firooz springs. M. Sc. thesis, University of Shiraz, Shiraz, Iran, p 282

Pitty AF (1968) Calcium carbonate content of water in relation to flow-through time. Nature 217:939–940

Raeisi E (2008) Ground-water storage calculation in karst aquifers with alluvium or no-flow boundaries. J Cave Karst Stud 70(1):62–70

Raeisi E, Karimi G (1997) Hydrodynamic of Berghan karst spring as indicators of aquifer characteristics. J Cave Karst Stud 59:112–118

Raeisi E, Kowsar N (1997) Development of Shahpour Cave, southern Iran. Cave Karst Sci 24:27–34

Sahuquillo A (1985) Spanish experience in karst water resources. In: Proceedings, international symposium on karst water resources, Ankara, Turkey, IAHS Publication 161, pp 133–147

Sauro F, Zampieri D, Filipponi M (2013) Development of a deep karst system within a transpressional structure of the Dolomites in north-east Italy. Geomorphology 184:51–63

Schaefer JA (2009) Risk evaluation of dams on karst foundations. In: Proceedings, 29th annual USSD conference Nashville, Tennessee, April 20–24, 2009

Stocklin J, Setudehnia A (1977) Stratigraphic Lexicon of Iran: Geological Survey of Iran, Report 18-1971, p 370

Stucky-Electrowatt Joint Venture (1996–2004) Salman Farsi Dam—Reports on the design of the grout curtain. Zürich

Turkmen S (2003) Treatment of the seepage problems at the Kalecik dam (Turkey). Eng Geol 68:159–169

Turkmen S, Ozgular E, Taga H, Karaogullarindan T (2002) Seepage problems in the karstic limestone foundation of the Kalecik dam (south Turkey). Eng Geol 63:147–157

Unal B, Eren M, Yalcin MG (2007) Investigation of leakage at Ataturk dam and hydroelectric power plant by means of hydrometric measurements. Eng Geol 93:45–63

Vuckovic´ D, Milanovic´ S (2001) Salman Farsi Dam—speleological report

White WB (1969) Conceptual models for limestone aquifer. Groundwater 7:15–21

White WB (1977) Conceptual models for carbonate aquifers: revisited. In: Dilamarter RR, Csallany SC (eds) Hydrologic problems in karst terrain. Western Kentucky University, Bowling Green, pp 176–187

White WB (2002) Karst hydrology: recent developments and open questions. Eng Geol 65:85–105

Acknowledgments

The authors gratefully appreciate the sincere cooperation of the Mahab Ghods Consulting Engineering Company and Fars Regional water Authority in Iran for providing useful data. Authors also would like to thank Shiraz University for providing the facilities and the leave time to work on this research. Also, thanks to Mr. Noroozi, Mr. Safarpour and Mr. Karimi for information and their sincere helps.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mozafari, M., Raeisi, E. Salman Farsi Dam reservoir, a successful project on a karstified foundation, SW Iran. Environ Earth Sci 75, 1044 (2016). https://doi.org/10.1007/s12665-016-5844-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12665-016-5844-6