Abstract

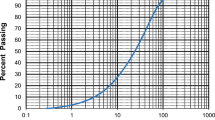

The study represents an analysis for the selection of backfill materials and backfill process for Barapukuria coal mine which is the only mining industry in the country under production state. Recently, this industry faced massive people protest due to mine-induced subsidence around the mining area. The backfill is the most emerging and developing technology in recent times in mining sectors which can be considered as a prospective option for Barapukuria coal mine in the purposes of increasing the ore recovery and mine stability, consequently reducing the subsidence. For the first time to have a backfill assessment in this underground mine, initially this study searched out the available resources to fill the mined out void as are alluvial sands, power plant fly ash, mine tailing, and Portland cement. In the subsequent steps, these samples were characterized for both cemented and uncemented option under particle size, compressive strength, shear strength, proctor test, and permeability analysis. The particle size analysis evaluates the sands and mine tailing as medium to fine grain uniform and well-graded sample, respectively. In the case of cemented backfill, the compressive strength test on different proportion mixtures of sand, cement, and ash shows compressive strength that is increased with time and cement content. The important finding is the significant influence of ash content, used as Portland cement replacement, in long-term strength. The determined permeability of sand sample is 3.60 × 10−5 m/s, which is higher than mine tailing valued at 1.11 × 10−5 m/s. Shear strength of mine tailing with friction angle of 43.19° and cohesion of 5.33 kPa is greater than cohesion less sand sample with friction angle of 37°. Standard proctor test denoted the highest dry density of sand and mine tailing as 1.74 × 103 and 2.23 × 103 kg/m3 at 18 and 11 wt% of water content, respectively. After taking into account the findings hydraulic backfill is preferred where the recommended backfill mixture for the mine is sand fill with 5–7 % cement and 8–10 % ash through the consideration of requires volume, materials characterization along with cost consideration.

Similar content being viewed by others

References

Arioglu E (1983) Design of supports in mines. Wiley, New York, p 248

Aylmer FL (1973) Cement properties related to the behavior of cemented fill, mine filling. In: Proceedings of the Jubilee Symposium, Australian Institute of Mining and Metallurgy, Queensland, 59–64

Barret JR, Coulthard MA, Dight PM (1978) Determination of fill stability, mining with backfill. 12th Canadian Rock Mechanics Symposium, Canadian Institute of Mining and Metallurgy, Quebec, 19: 85–91

Bloomfield RA (1984) Current research into the potential for utilization of mine waste. J Test Eval 12(2):119–122

Bourgoyne AT Jr, Millheim KK, Chenevert ME, Young FS Jr (1986) Applied Drilling Engineering (SPE Textbook Series), vol 2. Society of Petroleum Engineers, Richardson, pp 85–112

Brady BHG, Brown ET (1985) Rock mechanics for underground mining. George Allen & Unwin, Crows Nest, pp 351–358

Budhu M (2000) Soil mechanics and foundations. Wiley, New Jersey

Cai S (1983) A simple and convenient method for design of strength of cemented hydraulic fill. In: Balkema AA (ed) Proceedings of international symposium on mining with backfill, Rotterdam, 405–412

Cernica JN (1995) Geotechnical engineering: soil mechanics. Wiley, New York, p 453

Grice T (1998) Underground mining with backfill, the 2nd annual summit—mine tailings disposal systems, Brisbane, 24–25, p 14

Hassani F, ve Archibald J (eds) (1998) Mine Backfill. CİM, Canada, p 263

Herget G, de Korompay V (1978) In situ drainage properties of hydraulic backfills, mining with backfill. In: 12th Canadian Rock mechanics symposium, Canadian Institute of Mining and Metallurgy, Quebec, 19: 117–123

Holtz R, Kovacs W (1981) An introduction to geotechnical engineering. Prentice-Hall Inc, USA ISBN 0-13-484394-0

Imam B (2005) Energy resources of Bangladesh. University Grants Commission of Bangladesh, Dhaka, p 277

Karim MM, Howladar MF (2013) Volumetric estimation of coal resources in seam VI for require backfill materials of Barapukuria coal mine, Dinajpur, Bangladesh. Earth Sci 2(6):113–119. doi:10.11648/j.earth.20130206.11

Lamos AW, Clark IH (1989) The influence of material composition and sample geometry on the strength of cemented backfill. In: Balkema AA (ed) Proceedings of the 4th international symposium on mining with backfill innovations in mining backfill technology, Rotterdam, 89–94

Mitchell RJ (1983) Earth structures engineering. Allen and Unwin, Winchester, p 265

Palarski J (1993) The use of fly ash, tailings, rock and binding agents as consolidated backfill for coal mines. In: Glen HW (ed) Proc. Minefill 93. South African Institute of Mining and Metalurgy, Johannesburg, pp 403–408

Palarski J (1994) Design of backfill as support in polish coal mines. J S Afr Inst Min Metall 94:218–225

Schiffman RL, Vick SG, Gibson RE (1988) Behavior and properties of hydraulic fills. Hydraulic Fill Structures, ASCE Geotechnical Special Publication, vol 21, New York, 166–202

Terzaghi K, Peck B, Mesri G (1996) Soil mechanics in engineering practice. Wiley, New York, p 549

Thomas EG (1973) A review of cementing agents for hydraulic fill, mine filling. In: Proceedings of the Jubilee Symposium, Australian Institute of Mining and Metallurgy, Queensland, 65–76

Thomas EG (1978) Fill permeability and its significance in mine fill practice, mining with backfill. In: 12th Canadian Rock Mechanics Symposium, Canadian Institute of Mining and Metallurgy, Quebec, Special vol 19

Thomas EG (1983) Characteristics of cemented deslimed mill tailing fill prepared from finely ground tailing. In: Balkema AA (ed) Proceedings of international symposium on mining with backfill, Rotterdam: 59–68

Thomas EG, Cowling R (1978) Pozzolanic behavior of ground Isa mine slag in cemented hydraulic fill at high slag/cement ratios, mining with backfill. In: 12th Canadian Rock Mechanics Symposium, Canadian Institute of Mining and Metallurgy, Quebec, 19: 129–132

Wardell Armstrong (1991) Techno-economic feasibility study, Barapukuria coal project, Dinajpur District, Bangladesh, vol 1 and 2, chap 1 and 2

Thomas EG, Nantel JH, Notely KR (1979) Fill technology in underground metalliferous mines. International Academic Services Limited, Kingston, p 293

Acknowledgments

The authors are very much grateful to Professor Dr. Gunter Doerhoefer and Professor Dr. Olaf Kolditz, Editor-in-Chief for their kind co-operation for the publication of the research. The anonymous three reviewers made valuable comments, criticism, and suggestions which helped in improving the original manuscript significantly. The authors gratefully express their gratitude for the thoughtful and thorough reviews. Authors are also deeply thankful to Barapukuria Coal Mine Authority for providing necessary support for this research. At the end, authors would like to thank to the Ministry of Science and Technology, Bangladesh for the financial support for the successful completion of the research work otherwise it was completely beyond our reach.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Farhad Howladar, M., Mostafijul Karim, M. The selection of backfill materials for Barapukuria underground coal mine, Dinajpur, Bangladesh: insight from the assessments of engineering properties of some selective materials. Environ Earth Sci 73, 6153–6165 (2015). https://doi.org/10.1007/s12665-014-3841-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12665-014-3841-1