Abstract

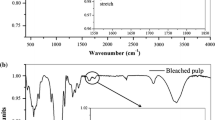

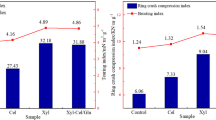

The low environmental impact NH4OH–KOH pulping process was used to extract pulp from banana pseudostem waste (BNW). The extracted BNW pulp was then single-stage bleached using a mixture of NaOH and H2O2 to increase brightness of the pulp. The Valley beater was further used to refine the obtained pulp (at a speed of 500 and 700 rpm) which resulted in fiber delamination, fibrillation, cutting, shortening as well as creation of fines leading to considerable higher total surface area for fiber–fiber bonding as revealed by SEM. XRD patterns of the bleached and refined BNW pulps indicated unchanged cellulose I structure with a minor increase in the crystallinity index (79–82%). The Canadian Standard Freeness (CSF) of the refined BNW pulps was sharply decreased, suggesting a much greater swelling ability of fibers from internal fibrillation after refining. Still, it was found that only a speed of 700 rpm in refining could dominate positive effects on the pulp fiber characteristics and enhance overall mechanical properties of the pulp sheets, exhibiting the highest tensile index of 76.66 Nm/g and tear index of 10.89 mNm2/g. In addition, the molded sheet prepared with BNW pulp refined at 700 rpm, having smoother surface and denser structure (reduced porosity), showed a visible increase in surface water resistance (as confirmed by dynamic contact angle measurement).

Graphical Abstract

Similar content being viewed by others

Data Availability

The data in this current study are available on request from the authors.

References

Zhang, Y., Duan, C., Bokka, S.K., He, Z., Ni, Y.: Molded fiber and pulp products as green and sustainable alternatives to plastics: a mini review. J. Bioresour. Bioprod. 7, 14–25 (2022). https://doi.org/10.1016/j.jobab.2021.10.003

Abd El-Sayed, E.S., El-Sakhawy, M., El-Sakhawy, M.A.M.: Non-wood fibers as raw material for pulp and paper industry. Nord Pulp Pap Res. J. 35, 215–230 (2020). https://doi.org/10.1515/npprj-2019-0064

Ramdhonee, A., Jeetah, P.: Production of wrapping paper from banana fibres. J. Environ. Chem. Eng. 5, 4298–4306 (2017). https://doi.org/10.1016/j.jece.2017.08.011

Alzate Acevedo, S., Díaz Carrillo, Ã.J., Flórez-López, E., Grande-Tovar, C.D.: Recovery of banana waste-loss from production and processing: a contribution to a circular economy. Molecules 26, 5282 (2021). https://doi.org/10.3390/molecules26175282

Subagyo, A., Chafidz, A.: Banana pseudo-stem fiber: preparation, characteristics, and applications banana nutrition - function and processing kinetics. IntechOpen (2018). https://doi.org/10.5772/intechopen.82204

Ersoy Kalyoncu, E.: Eco-friendly pulping of banana pseudo-stem wastes with potassium-based processes. Cellul. Chem. Technol. 56, 131–140 (2022). https://doi.org/10.35812/CelluloseChemTechnol.2022.56.12

Ferdous, T., Quaiyyum, M.A., Jin, Y., Bashar, M.S., Yasin Arafat, K.M., Jahan, M.S.: Pulping and bleaching potential of banana pseudo stem, banana leaf and banana peduncle. Biomass Conv. Bioref. 13, 893–904 (2023). https://doi.org/10.1007/s13399-020-01219-6

Kumar, A., Singh, B.P., Jain, R.K., Sharma, A.K.: Banana fibre (Musa sapientum): a suitable raw material for handmade paper industry via enzymatic refining. Int. J. Eng. Res. Technol. 2, 1338–1350 (2013)

Tripathi, S.K., Bhardwaj, N.K., Chechi, S., Varadhan, R.: Suitability of banana stem pulp as replacement of softwood pulp for making superior grade unbleached paper from agro residue pulp. Appita J. 72, 163–178 (2019). https://doi.org/10.3316/informit.695406825143869

Nassar, M., Ebrahim, E.E., Sherif, H.M., Ali, M.A.: Optimization of banana stem pulp to substitute softwood pulp for high quality paper. Egypt. J. Chem. 64, 1461–1469 (2021). https://doi.org/10.21608/EJCHEM.2020.46294.2954

Malone Rubright, S.L., Pearce, L.L., Peterson, J.: Environmental toxicology of hydrogen sulfide. Nitric Oxide Biol. Chem. 71, 1–13 (2017). https://doi.org/10.1016/j.niox.2017.09.011

Huang, G.L., Shi, J.X., Langrish, T.A.: Environmentally friendly bagasse pulping with NH4OH–KOH–AQ. J. Clean Prod. 16, 1287–1293 (2008). https://doi.org/10.1016/j.jclepro.2007.06.011

Huang, G., Peng, W., Yang, S., Yang, C.: Delignification kinetic modeling of NH4OH–KOH–AQ pulping for bagasse. Ind. Crops Prod. 123, 740–745 (2018). https://doi.org/10.1016/j.indcrop.2018.07.040

Guolin, H., Chengfang, Z., Zhongsheng, C.: Pulping of wheat straw with caustic potash-ammonia aqueous solutions and its kinetics. Chin. J. Chem. Eng. 14, 729–733 (2006). https://doi.org/10.1016/S1004-9541(07)60003-2

Sarkar, A.M., Farzana, M., Rahman, M.M., Jin, Y., Jahan, S.: Future cellulose based industries in Bangladesh: A mini review. Cell. Chem. Technol. 55, 443–459 (2021). https://doi.org/10.35812/CelluloseChemTechnol.2021.55.41

Berhanu, H., Kiflie, Z., Neiva, D., Gominho, J., Feleke, S., Yimam, A., Pereira, H.: Optimization of ethanol–alkali delignification of false banana (Ensete ventricosum) fibers for pulp production using response surface methodology. Ind. Crops Prod. 126, 426–433 (2018). https://doi.org/10.1016/j.indcrop.2018.08.093

Saberikhah, E., Rovshandeh, M., Rezayati-Charani, J.: Organosolv pulping of wheat straw by glycerol. Cell. Chem. Technol. 45, 67–75 (2011)

Ferdous, T., Quaiyyum, M.A., Jahan, M.S.: Chlorine dioxide bleaching of nineteen non-wood plant pulps. Nord Pulp Pap Res. J. 35, 569–576 (2020). https://doi.org/10.1515/npprj-2020-0043

Sharma, N., Bhardwaj, N.K., Singh, R.B.P.: Environmental issues of pulp bleaching and prospects of peracetic acid pulp bleaching: a review. J. Clean Prod. 256, 120338 (2020). https://doi.org/10.1016/j.jclepro.2020.120338

Mamaye, M., Kiflie, Z., Feleke, S., Yimam, A.: Evaluation of soda delignification and single-stage hydrogen peroxide bleaching for the ethiopian sugarcane bagasse for paper production. Sugar Tech. 22, 706–717 (2020). https://doi.org/10.1007/s12355-019-00793-y

Motamedian, H.R., Halilovic, A.E., Kulachenko, A.: Mechanisms of strength and stiffness improvement of paper after PFI refining with a focus on the effect of fines. Cellulose 26, 4099–4124 (2019). https://doi.org/10.1007/s10570-019-02349-5

Sable, I., Grinfelds, U., Vikele, L., Rozenberga, L., Zeps, M., Neimane, U., Jansons, A.: Effect of refining on the properties of fibres from young scots (Pinus sylvestris) and Lodgepole pines (Pinus contorta). Balt For. 23, 529–533 (2017)

Gharehkhani, S., Sadeghinezhad, E., Kazi, S.N., Yarmand, H., Badarudin, A., Safaei, M.R., Zubir, M.N.M.: Basic effects of pulp refining on fiber properties—A review. Carbohydr. Polym. 115, 785–803 (2015). https://doi.org/10.1016/j.carbpol.2014.08.047

El-Sakhawy, M., Nassar, M.A., Madkour, H.M.F., El-Ziaty, A.K., Mohamed, S.A.: Bagasse packaging board by cold soda pulping methods. Res. J. Chem. Sci. 4, 15–19 (2014)

Somboon, P.: Quality developments in pulp fibers using conventional papermaking laboratory beaters and an industrial pilot refiner. Agric. Nat. Resour. 45, 883–890 (2011)

Goswami, T., Kalita, D., Rao, P.G.: Greaseproof paper from banana (Musaparadisica L.) pulp fibre. Indian J. Chem. Technol. 15, 457–461 (2008)

Amiri, A., Triplett, Z., Moreira, A., Brezinka, N., Alcock, M., Ulven, C.A.: Standard density measurement method development for flax fiber. Ind. Crops Prod. 96, 196–202 (2017). https://doi.org/10.1016/j.indcrop.2016.11.060

Kandhola, G., Djioleu, A., Rajan, K., Labbé, N., Sakon, J., Carrier, D.J., Kim, J.W.: Maximizing production of cellulose nanocrystals and nanofibers from pre-extracted loblolly pine kraft pulp: a response surface approach. Bioresour. Bioprocess. 7, 1–16 (2020). https://doi.org/10.1186/s40643-020-00302-0

Moral, A., Aguado, R., Tijero, A., Tarrés, Q., Delgado-Aguilar, M., Mutjé, P.: High-yield pulp from Brassica napus to manufacture packaging paper. BioResources 12, 2792–2804 (2017)

Pelletier, A.L., Zhao, Y., Lei, X., Li, K.: Improved fiber separation and energy reduction in thermomechanical pulp refining using enzyme-pretreated wood. BioResources 8, 3385–3398 (2013)

Fernando, D., Muhic, D., Engstrand, P., Daniel, G.: Fundamental understanding of pulp property development during different TMP refining conditions using the application of new Simons’ stain method and fibre surface ultrastructure. Holzforschung 65, 777–786 (2011). https://doi.org/10.1515/HF.2011.076

Guimaraes, J.L., Frollini, E., Da Silva, C.G., Wypych, F., Satyanarayana, K.G.: Characterization of banana, sugarcane bagasse and sponge gourd fibers of Brazil. Ind. Crops Prod. 30, 407–415 (2009). https://doi.org/10.1016/j.indcrop.2009.07.013

Chandrakala, R., Gundev, P., Singh, L.: Effect of different spices on enzymatic browning of banana pseudostem juice. J. Sci. Res. Rep. 17, 1–7 (2017). https://doi.org/10.9734/JSRR/2017/37919

Kunfong, N., Rattanawongkun, P., Tawichai, N., Intatha, U., Soykeabkaew, N.: NH4OH-KOH pulping and single-stage bleaching processes of banana pseudostem waste: a feasibility study for molded pulp packaging use. Mater. Sci. Forum. 1046, 77–82 (2021). https://doi.org/10.4028/www.scientific.net/MSF.1046.77

Gopinathan, P., Subramanian, K.S., Paliyath, G., Subramanian, J.: Genotypic variations in characteristics of nano-fibrillated cellulose derived from banana pseudostem. BioResources 12, 6984–7001 (2017). https://doi.org/10.15376/biores.12.4.6984-7001

Dhesinghraja, J., Mayandi, K., Rajini, N., Prakash, C.: A potential renewable energy resource from the biomass of banana pseudo-stem (Musaacuminata) wild species variety. Biomass Convers. Biorefin. (2023). https://doi.org/10.1007/s13399-023-03936-0

Faradilla, R.F., Lee, G., Arns, J.Y., Roberts, J., Martens, P., Stenzel, M.H., Arcot, J.: Characteristics of a free-standing film from banana pseudostem nanocellulose generated from TEMPO-mediated oxidation. Carbohydr. Polym. 174, 1156–1163 (2017). https://doi.org/10.1016/j.carbpol.2017.07.025

Das, D., Hussain, S., Ghosh, A.K., Pal, A.K.: Studies on cellulose nanocrystals extracted from Musasapientum: structural and bonding aspects. Cell. Chem. Technol. 52, 729–739 (2018)

Cheng, G., Varanasi, P., Li, C., Liu, H., Melnichenko, Y.B., Simmons, B.A., Kent, M.S., Singh, S.: Transition of cellulose crystalline structure and surface morphology of biomass as a function of ionic liquid pretreatment and its relation to enzymatic hydrolysis. Biomacromolecules 12, 933–941 (2011). https://doi.org/10.1021/bm101240z

Johansson, A. . Correlations between fibre properties and paper properties [Master’s thesis]. KTH Royal Institute of Technology. https://www.urn.kb.se/resolve?urn=urn:nbn:se:kth:diva-90437 (2011)

Geng, B.J., Ramle, S.F.M., Ibrahim, N.I., Zaudin, N.A.C., Young, L.J., Hamzah, Z.: Effect of beating on kraft pulp of Sesbania grandiflora. Songklanakarin J. Sci. Technol. 41, 1356–1359 (2019)

Shao, S., Wu, C., Chen, K.: Refining, dewatering, and paper properties of soda-anthraquinone (soda/AQ) pulp from rice straw. BioResources 12, 4867–4880 (2017). https://doi.org/10.15376/biores.12.3.4867-4880

Arafat, K., Nayeem, J., Quadery, A.H., Quaiyyum, M.A., Jahan, M.S.: Handmade paper from waste banana fibre. Bangladesh J. Sci. Ind. Res. 53, 83–88 (2018). https://doi.org/10.3329/bjsir.v53i2.36668

Sahu, P., Gupta, M.: Water absorption behavior of cellulosic fibres polymer composites: a review on its effects and remedies. J. Ind. Text. 51, 1–33 (2020). https://doi.org/10.1177/1528083720974424

Gao, W.H., Chen, K.F., Yang, R.D., Li, J., Yang, F., Rao, G.H., Tao, H.: Effects of beating on tobacco stalk mechanical pulp. Cell. Chem. Technol. 46, 277–282 (2012)

Acknowledgements

We are deeply grateful for the postgraduate scholarship from the National Research Council of Thailand (grant code: NRCT5-RRI63014), which is co-funded by the Composite Technology Co. Ltd., Thailand. The authors also would like to thank the Office of Postgraduate Studies and the Center of Innovative Materials for Sustainability (iMatS), Mae Fah Luang University, Thailand for their additional financial supports throughout this research. Our manuscript draft has been reviewed by Eleni G. and we greatly appreciate her kind assistance.

Funding

The financial supports were provided by the National Research Council of Thailand (Grant Code: NRCT5-RRI63014), which is co-funded by the Composite Technology Co. Ltd., Thailand.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kunfong, N., Rattanawongkun, P., Tawichai, N. et al. The Influence of Refining on Molded Pulps from Banana Pseudostem Waste After NH4OH–KOH Based Pulping and Single-Stage Bleaching. Waste Biomass Valor 15, 1565–1575 (2024). https://doi.org/10.1007/s12649-023-02253-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-023-02253-x