Abstract

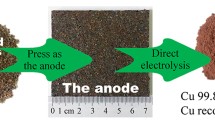

In order to extend the duration of the electrolyte solution in which copper granules recovered from waste printed circuit board are refined through electrolysis to obtain copper foil with high purity and which is contaminated by the accumulation of metallic impurities along with the refinery of waste printed circuit board, the leaching and electrowinning processes are used to pretreat the copper granules. The effects of impurities of copper granules as well as H2SO4 mole ratio, leaching temperature, liquid-solid ratio, and operation time on the removing efficiencies of Zn, Sn, Fe and Al, were studied. The results showed that more than 95% of impurities can be removed when the mole ratio of impurities to H2SO4 was 1:4, the temperature was 70 °C, the liquid-solid ratio was 20 mL/g, along with the leaching time of 180 min. After 1440 min electrolysis of the pretreated granules with the electric current density of 40 mA/cm2, the purity of refined copper foil maintained at 99% in contrast with 95% which copper granules are without pretreatment. The maximal concentration of the accumulated ions of impurities is less than 60 mg/L, which suggests that sulfuric acidic pretreatment is a promising approach to increase the duration of the electrolyte solution.

Similar content being viewed by others

Data Availability

The datasets generated during and/or analysed during the current study are not publicly available due to Confidentiality Agreement but are available from the corresponding author on reasonable request.

References

Ghosh, B., et al.: Waste printed circuit boards recycling: an extensive assessment of current status. J. Clean. Prod. 94, 5–19 (2015)

Huang, K., et al.: Recycling of waste printed circuit boards: a review of current technologies and treatment status in China. J. Hazard. Mater. 164, 399–408 (2009)

Cui, J., et al.: Metallurgical recovery of metals from electronic waste: a review. J. Hazard. Mater. 158, 228–256 (2008)

Wang, H., et al.: Recovery of waste printed circuit boards through pyrometallurgical processing: a review. Resour. Conserv. Recycl. 126, 209–218 (2017)

Satyro, W.C., et al.: Planned obsolescence or planned resource depletion? A sustainable approach. J. Clean. Prod. 195, 744–752 (2018)

Zeng, X.L., et al.: Measuring the recyclability of e-waste: an innovative method and its implications. J. Clean. Prod. 131, 156–162 (2016)

Wang, J.B., et al.: An environmentally friendly technology of disassembling electronic components from waste printed circuit boards. Waste Manag. 53, 218–224 (2016)

Park, S., et al.: Apparatus for electronic component disassembly from printed circuit board assembly in e-wastes. Int. J. Miner. Process 144, 11–15 (2015)

Shuey, S.A., et al.: Review of pyrometallurgical treatment of electronic scrap. Min. Eng. 57, 67–70 (2005)

Ishak, K.E.H.K., et al.: Recovery of copper and valuable metals from E-waste via hydrometallurgical method. Mater. Today 66, 3077–3081 (2022)

Havlik, T., et al.: Leaching of copper and tin from used printed circuit boards after thermal treatment. J. Hazard. Mater. 183, 866–873 (2010)

Liu, X.N., et al.: Copper recovery from waste printed circuit boards concentrated metal scraps by electrolysis. Front. Environ. Sci. Eng. 11, 10 (2017)

Chu, Y.Y., et al.: Micro-copper powders recovered from waste printed circuit boards by electrolysis. Hydrometallurgy 156, 152–157 (2015)

Rene, E.R., et al.: Electronic waste generation, recycling and resource recovery: technological perspectives and trends. J. Hazard. Mater. 416, 125664 (2021)

Mecucci, A., et al.: Leaching and electrochemical recovery of copper, lead and tin from scrap printed circuit boards. J. Chem. Technol. Biotechnol. 77, 449–457 (2002)

Xiu, F.R., et al.: Electrokinetic recovery of cd, cr, as, Ni, Zn and Mn from waste printed circuit boards: effect of assisting agents. J. Hazard. Mater. 170, 191–196 (2009)

Xiu, F.R., et al.: Materials recovery from waste printed circuit boards by supercritical methanol. J. Hazard. Mater. 178, 628–634 (2010)

Diaz, L.A., et al.: Comprehensive process for the recovery of value and critical materials from electronic waste. J. Clean. Prod. 125, 236–244 (2016)

Veit, H.M., et al.: Recovery of copper from printed circuit boards scraps by mechanical processing and electrometallurgy. J. Hazard. Mater. 137, 1704–1709 (2006)

Guimarães, Y.F., et al.: Direct recovery of copper from printed circuit boards (PCBs) powder concentrate by a simultaneous electroleaching–electrodeposition process. Hydrometallurgy 149, 63–70 (2014)

Zhang, S., et al.: Superfine copper powders recycled from concentrated metal scraps of waste printed circuit boards by slurry electrolysis. J. Clean. Prod. 152, 1–6 (2017)

Wang, M.Y., et al.: Sustainable electrochemical recovery of high-purity Cu powders from multi-metal acid solution by a centrifuge electrode. J. Clean. Prod. 204, 41–49 (2018)

Awad, A., et al.: Characterization of nano/micro size copper powder by product of electropolishing process. J. Am. Sci. 6, 137–143 (2010)

Matsushima, H., et al.: Copper electrodeposition in a magnetic field. Electrochim. Acta 53, 161–166 (2007)

Nikolić, N.D., et al.: Morphologies of copper deposits obtained by the electrodeposition at high overpotentials. Surf. Coat. Technol. 201, 560–566 (2006)

Popov, K.I., et al.: Comparison of the critical conditions for initiation of dendritic growth and powder formation in potentiostatic and galvanostatic copper electrodeposition. J. Appl. Electrochem. 12, 525–531 (1982)

Somasundaram, M., et al.: Recovery of copper from scrap printed circuit board: modelling and optimization using response surface methodology. Powder Technol. 266, 1–6 (2014)

Hoffmann, J.E.: The purification of copper refinery electrolyte. J. Met. Mater. Miner. 56, 30–33 (2004)

Alam, M.S., et al.: Electrolyte purification in energy-saving monovalent copper electrowinning processes. Hydrometallurgy 87, 36–44 (2007)

Liu, W.F., et al.: Comparation on the methods of removing impurity metals from copper powder of waste printed circuit boards. J. Clean. Prod. 349, 131295 (2022)

Qiu, R.J., et al.: Recovering full metallic resources from waste printed circuit boards: a refined review. J. Clean. Prod. 244, 118690 (2020)

Pan, J.H., et al.: Recovery of rare earth elements from coal fly ash by integrated physical separation and acid leaching. Chemosphere 248, 126112 (2020)

Gargul, K., et al.: Leaching of lead and copper from flash smelting slag by citric acid. Arch. Civ. Mech. Eng. 19, 648–656 (2019)

Karimov, K.A., et al.: Sulfuric acid leaching of High-Arsenic Dust from Copper Smelting. Metallurgist 60, 456–459 (2016)

Lei, T.Y., et al.: Enhanced recovery of copper from reclaimed copper smelting fly ash via leaching and electrowinning processes. Sep. Purif. Technol. 273, 118943 (2021)

Lv, Z.Y., et al.: Synergistic removal of calcium and iron impurities from calcium-rich and high-alumina fly ash by acid leaching control. J. Environ. Chem. Eng. 10, 17268 (2022)

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by ZL, WW, XM and XL. The first draft of the manuscript was written by ZL and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, Zj., Wang, W., Jiang, Lj. et al. Effects of Acid Pretreatment on Purity of Copper Foil Recovered by Electrolytic Refining from Waste Printed Circuit Board. Waste Biomass Valor 15, 1403–1410 (2024). https://doi.org/10.1007/s12649-023-02225-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-023-02225-1