Abstract

The research proposed an effective approach for recycling of waste plastics and agro-industrial waste as a source of energy optimizing the economic viability of the waste products and reducing environmental issues. The composites were developed by utilizing eight different types of waste plastics, rice hush husk, and sand. The density, water absorption, compressive strength, and flexural strength of the composites were evaluated. Moreover, the tribological characterizations as sliding wear rate and three-body abrasive wear were performed under the conditions of loads and speeds. The composites attained a maximum density of 1.9833 g/cm3 and a minimum percentage of water absorption of 0.261. The optimal values of the compressive strength and flexural strength were obtained to be 9.628 and 28.081 (MPa), respectively. The sliding wear rate was in the range of 2.655 × 10–8 -12.896 × 10–8 (kg/m). Whereas the ranges for abrasives wear were obtained to be 0.0309–0.6459 (cm3) and 0.0386–0.1257 (cm3), under the conditions of loads and sliding speeds, respectively. The study suggested the incorporation of 25 wt. % of rice husk ash and 25 wt. % of sand with 50 wt. % of polycarbonates in composites for tribological applications. The work contributes towards the attainment of circular economy in the composite manufacturing industries.

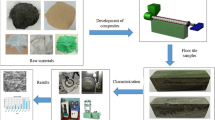

Graphical Abstract

Similar content being viewed by others

Data Availability

All data generated or analyzed during the study are included in this published article.

References

Haas, W., et al.: Spaceship earth’s odyssey to a circular economy-a century long perspective. Resour. Conserv. Recycl. 163, 105076 (2020)

Qureshi, F., Yusuf, M., Kamyab, H., Vo, D.V.N., Chelliapan, S., Joo, S.W., Vasseghian, Y.: Latest eco-friendly avenues on hydrogen production towards a circular bioeconomy: Currents challenges, innovative insights, and future perspectives. Renew. Sustain. Energy Rev. 168, 112916 (2022). https://doi.org/10.1016/j.rser.2022.112916

Stefanakis, A.I., Calheiros, C.S., Nikolaou, I.: Nature-based solutions as a tool in the new circular economic model for climate change adaptation. Circ. Econ. Sustain. 1(1), 303–318 (2021)

Evertsen, P.H., Rasmussen, E., Nenadic, O.: Commercializing circular economy innovations: A taxonomy of academic spin-offs. Technol. Forecast. Soc. Chang. 185, 122102 (2022)

Ruokamo, E., et al.: Exploring the potential of circular economy to mitigate pressures on biodiversity. Glob. Environ. Chang. 78, 102625 (2023)

King, S., Locock, K.: A circular economy framework for plastics: a semi-systematic review. J. Clean. Prod. (2022). https://doi.org/10.1016/j.jclepro.2022.132503

Sheldon, R.A., Norton, M.: Green chemistry and the plastic pollution challenge: towards a circular economy. Green Chem. 22(19), 6310–6322 (2020)

Meys, R., et al.: Towards a circular economy for plastic packaging wastes–the environmental potential of chemical recycling. Resour. Conserv. Recycl. 162, 105010 (2020)

Sanchez, F.A.C., et al.: Plastic recycling in additive manufacturing: a systematic literature review and opportunities for the circular economy. J. Clean. Prod. 264, 121602 (2020)

Khadke, S., et al.: Efficient plastic recycling and remolding circular economy using the technology of trust–blockchain. Sustainability 13(16), 9142 (2021)

Payne, J., McKeown, P., Jones, M.D.: A circular economy approach to plastic waste. Polym. Degrad. Stab. 165, 170–181 (2019)

Tesfaye, W., Kitaw, D.: Conceptualizing reverse logistics to plastics recycling system. Soc. Responsib. J. (2020). https://doi.org/10.1108/SRJ-12-2019-0411

Singh, R., et al.: Environmental hazards and biodegradation of plastic waste: challenges and future prospects. Bioremed. Environ. Sustain. (2021). https://doi.org/10.1016/B978-0-12-820524-2.00009-2

Liu, X., et al.: Evolution of global plastic waste trade flows from 2000 to 2020 and its predicted trade sinks in 2030. J. Clean. Prod. 376, 134373 (2022)

Almohana, A.I., et al.: Producing sustainable concrete with plastic waste: a review. Environ. Chall. (2022). https://doi.org/10.1016/j.envc.2022.100626

Zhang, F., et al.: Current technologies for plastic waste treatment: a review. J. Clean. Prod. 282, 124523 (2021)

Xue, Y., et al.: Co-hydrothermal carbonization of lignocellulose biomass and polyvinyl chloride: the migration and transformation of chlorine. Chem. Eng. J. (2022). https://doi.org/10.1016/j.cej.2022.137155

Browning, S., Beymer-Farris, B., Seay, J.R.: Addressing the challenges associated with plastic waste disposal and management in developing countries. Curr. Opin. Chem. Eng. 32, 100682 (2021)

Noor, A., Rehman, M.A.U.: A mini-review on the use of plastic waste as a modifier of the bituminous mix for flexible pavement. Clean. Mater. (2022). https://doi.org/10.1016/j.clema.2022.100059

Editorial, Chemistry Can Help Make Plastics Sustainable─but It Isn’t the Whole Solution. Nature, 2021. 590(7846): p. 363–364.

Soni, A., Das, P.K., Kumar, P.: A review on the municipal solid waste management status, challenges and potential for the future Indian cities. Environ. Dev. Sustain. (2022). https://doi.org/10.1007/s10668-022-02688-7

Prata, J.C., et al.: Solutions and integrated strategies for the control and mitigation of plastic and microplastic pollution. Int. J. Environ. Res. Public Health 16(13), 2411 (2019)

Soni, A., et al.: Challenges and opportunities of utilizing municipal solid waste as alternative building materials for sustainable development goals: a review. Sustain. Chem. Pharm. 27, 100706 (2022). https://doi.org/10.1016/j.scp.2022.100706

Valavanidis, A., 2018 Technological Challenges in Plastic Recycling. Can technological innnovation tackle the problem of plastic waste?

Aragaw, T.A., Mekonnen, B.A.: Current plastics pollution threats due to COVID-19 and its possible mitigation techniques: a waste-to-energy conversion via pyrolysis. Environ. Sys. Res. 10(1), 1–11 (2021)

Azevedo, A.R., et al.: Development of mortar for laying and coating with pineapple fibers. Rev. Bra. de Eng. Agríc. e Ambient. 24, 187–193 (2020)

Caviglia-Harris, J., et al.: The color of water: the contributions of green and blue water to agricultural productivity in the Western Brazilian Amazon. World Dev. 146, 105607 (2021)

Becker, N., Kimhi, A., Argaman, E.: Costs and benefits of waste soils removal. Land Use Policy 99, 104877 (2020)

Ferrero, G.O., Faba, E.M.S., Eimer, G.A.: Biodiesel production from alternative raw materials using a heterogeneous low ordered biosilicified enzyme as biocatalyst. Biotechnol. Biofuels 14(1), 1–11 (2021)

Bayapureddy, Y., Muniraj, K., Mutukuru, M.R.G.: Sugarcane bagasse ash as supplementary cementitious material in cement composites: strength, durability, and microstructural analysis. J. Korean Ceram. Soc. 57(5), 513–519 (2020)

Rithuparna, R., Jittin, V., Bahurudeen, A.: Influence of different processing methods on the recycling potential of agro-waste ashes for sustainable cement production: a review. J. Clean. Prod. 316, 128242 (2021)

de Azevedo, A.R., et al.: Possibilities for the application of agro-industrial wastes in cementitious materials: a brief review of the Brazilian perspective. Clean. Mater. 3, 100040 (2022)

Das, O., et al.: Natural and industrial wastes for sustainable and renewable polymer composites. Renew. Sustain. Energy Rev. 158, 112054 (2022)

Das, O., et al.: The effect of carbon black on the properties of plasticised wheat gluten biopolymer. Molecules 25(10), 2279 (2020)

Sundarababu, J., Anandan, S.S., Griskevicius, P.: Evaluation of mechanical properties of biodegradable coconut shell/rice husk powder polymer composites for light weight applications. Mater. Today: Proceed. 39, 1241–1247 (2021)

Soni, A., Das, P., Yusuf, M.: An experimental investigation on physical-mechanical-tribological performance of thermoplastic composites with partial sand replacements. Materialwiss. Werkstofftech. 53(9), 1028–1042 (2022). https://doi.org/10.1002/mawe.202100375

Soni, A., et al.: Synergy of RHA and silica sand on physico-mechanical and tribological properties of waste plastic–reinforced thermoplastic composites as floor tiles. Environ. Sci. Pollut. Res. (2022). https://doi.org/10.1007/s11356-022-20915-6

Soni, A., et al.: Tribological behavior of particulates reinforced sustainable composites: effect of composition, load, and sliding speed. Sustain. Chem. Pharm. 29, 100748 (2022). https://doi.org/10.1016/j.scp.2022.100748

Soni, A., et al.: Experimental investigations on the workability of sustainable composite by recycling waste plastics and agro-waste. Zaštita Materijala 63(4), 493–501 (2022). https://doi.org/10.5937/zasmat2204493S

Block, C., et al.: Co-pyrogasification of plastics and biomass, a review. Waste Biomass Valoriz. 10(3), 483–509 (2019)

Kumi-Larbi Jnr, A., et al.: Reuse of waste plastics in developing countries: properties of waste plastic-sand composites. Waste Biomass Valoriz. (2022). https://doi.org/10.1007/s12649-022-01708-x

El Hajj, N., et al.: Recycling of plastic mixture wastes as carrier resin for short glass fiber composites. Waste Biomass Valoriz. 11(5), 2261–2271 (2020)

Cascone, S., Gagliano, A.: Recycled agricultural plastic waste as green roof drainage layer within the perspective of ecological transition for the built environment. J. Clean. Prod. 380, 135032 (2022)

Boom, Y.J., et al.: Analysis of possible carcinogenic compounds in recycled plastic modified asphalt. Sci. Total Environ. 858, 159910 (2023)

Dong, C., et al.: Fresh and hardened properties of recycled plastic fiber reinforced self-compacting concrete made with recycled concrete aggregate and fly ash, slag, silica fume. J. Build. Eng. 62, 105384 (2022)

Fard, P.M., Alkhansari, M.G.: Innovative fire and water insulation foam using recycled plastic bags and expanded polystyrene (EPS). Constr. Build. Mater. 305, 124785 (2021)

Tulashie, S.K., et al.: Recycling of plastic wastes into alternative fuels towards a circular economy in Ghana. Clean. Chem. Eng. 4, 100064 (2022)

Turku, I., et al.: Characterization of wood plastic composites manufactured from recycled plastic blends. Compos. Struct. 161, 469–476 (2017)

Khalid, M.Y., et al.: Recent trends in recycling and reusing techniques of different plastic polymers and their composite materials. Sustain. Mater. Technol. (2021). https://doi.org/10.1016/j.susmat.2021.e00382

Nasir, N.H.M., Usman, F., Saggaf, A.: Development of composite material from recycled polyethylene terephthalate and fly ash: four decades progress review. Curr. Res. Green Sustain. Chem. (2022). https://doi.org/10.1016/j.crgsc.2022.100280

Istrate, O.M., Chen, B.: Structure and properties of clay/recycled plastic composites. Appl. Clay Sci. 156, 144–151 (2018)

Babatunde, Y., et al.: Influence of material composition on the morphology and engineering properties of waste plastic binder composite for construction purposes. Heliyon 8(10), e11207 (2022)

Alyousef, R., et al.: Potential use of recycled plastic and rubber aggregate in cementitious materials for sustainable construction: a review. J. Clean. Prod. 329, 129736 (2021)

Ehrenbring, H., et al.: Bending behavior of engineered cementitious composites (ECC) with different recycled and virgin polymer fibers. Constr. Build. Mater. 346, 128355 (2022)

Akbar, A., Liew, K.: Assessing recycling potential of carbon fiber reinforced plastic waste in production of eco-efficient cement-based materials. J. Clean. Prod. 274, 123001 (2020)

Yorseng, K., et al.: Accelerated weathering studies of kenaf/sisal fiber fabric reinforced fully biobased hybrid bioepoxy composites for semi-structural applications: morphology, thermo-mechanical, water absorption behavior and surface hydrophobicity. Constr. Build. Mater. 235, 117464 (2020)

Rivas, A., et al.: Phase transformation of amorphous rice husk silica. In: Frontiers in materials processing, applications, research and technology, pp. 17–26. Springer (2018)

Acknowledgements

The authors would like to thank Universiti Teknologi PETRONAS for providing facilities in carrying out this research

Author information

Authors and Affiliations

Contributions

AS, conceptualization, experimentation, and writing of the manuscript. PKD supervised and provided resources, facilities, and funding for this work. MY helped in refining, reviewing, editing, and proofreading of the manuscript. SR, HK, SC, IK, ZHM helped in review and editing of this manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Ethical Approval

Not applicable since there were no human or animal subjects.

Consent for Publication

All authors agree to the submission of manuscript to Waste and Biomass Valorization.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Soni, A., Das, P.K., Yusuf, M. et al. Valorization of Post-Consumers Plastics and Agro-Waste in Sustainable Polymeric Composites for Tribological Applications. Waste Biomass Valor 15, 1739–1755 (2024). https://doi.org/10.1007/s12649-023-02103-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-023-02103-w