Abstract

The valorization of agroindustrial wastes has drawn attention, since there is an increasing demand for energy aligned with obtaining bioproducts with higher added-value. In this regard, the residues generated during cassava processing are practically unexplored materials with enormous potential for bioconversion. Cassava peel is a lignocellulosic material that can be treated to remove components such as lignin and starch in order to produce hemicellulosic-based compounds. Different classical pretreatments can be used on cassava peel, in particular alkaline, acidic and hydrothermal, and modern ones such as ultrasonic, microwave and steam explosion. In addition, environmentally friendly techniques such as non-thermal plasma and ionic liquids are promising pretreatments. In general, pretreatments are used to modify the lignocellulosic chemical structure of wood biomass, i.e., physical, chemical, and biological pretreatments change the structure of lignin by breaking its chemical bonds, exposing the internal content (cellulose and hemicellulose), making it possible to obtain hemicellulosic-based bioproducts such as xylooligosaccharides (XOS). XOS are prebiotics that can be obtained from xylan-rich sources such as cassava peels and other biomasses. In this context, this review aims to critically discussed the current production of XOS based on cassava peels, including the most promising and efficient pretreatments applied on lignocellulosic wastes to obtain higher value-added bioproducts. In addition, it addresses the challenges on the change of lignocellulosic chemical structures of different biomass. Regarding traditional alkaline pretreatments, there are some advantages, such as high yield in XOS production, low by-product formation, high lignin removal yield and milder operating conditions. Thus, the use of agro-industrial wastes is a promising strategy that encompasses biorefinery concepts, such as the bioconversion of cassava peels to XOS.

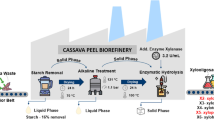

Graphical Abstract

Similar content being viewed by others

Data Availability

Not applicable.

Code Availability

Not applicable.

References

Jain, A., Sarsaiya, S., Kumar Awasthi, M., Singh, R., Rajput, R., Mishra, U.C., Chen, J., Shi, J.: Bioenergy and bio-products from bio-waste and its associated modern circular economy: current research trends, challenges, and future outlooks. Fuel. 307, 121859 (2022). https://doi.org/10.1016/j.fuel.2021.121859

Raina, D., Kumar, V., Saran, S.: A critical review on exploitation of agro-industrial biomass as substrates for the therapeutic microbial enzymes production and implemented protein purification techniques. Chemosphere. 294, 133712 (2022). https://doi.org/10.1016/j.chemosphere.2022.133712

Zevallos Torres, L.A., Lorenci Woiciechowski, A., de Andrade Tanobe, V.O., Karp, S.G., Guimarães Lorenci, L.C., Faulds, C., Soccol, C.R.: Lignin as a potential source of high-added value compounds: a review. J. Clean. Prod. 263 (121499), 1–18 (2020). https://doi.org/10.1016/j.jclepro.2020.121499

Patrizi, N., Bruno, M., Saladini, F., Parisi, M.L., Pulselli, R.M., Bjerre, A.B., Bastianoni, S.: Sustainability assessment of biorefinery systems based on two food residues in Africa. Front. Sustain. Food Syst 4, 1–13 (2020). https://doi.org/10.3389/fsufs.2020.522614

Dai, L., Huang, T., Jiang, K., Zhou, X., Xu, Y.: A novel recyclable furoic acid-assisted pretreatment for sugarcane bagasse biorefinery in co-production of xylooligosaccharides and glucose. Biotechnol. Biofuels. 14, 1–8 (2021). https://doi.org/10.1186/s13068-021-01884-3

Andrade, C.J., De, Barros, F.C., Andrade, L.M., De, Rocco, S.A., Sforça, L., Pastore, M., Jauregi, P.: Ultrafiltration based purification strategies for surfactin produced by Bacillus subtilis LB5A using cassava wastewater as substrate. J. Chem. Technol. Biotechnol. (2016). https://doi.org/10.1002/jctb.4928

Paula, A., Rêgo, B., Santana, H., Teixeira, I., Gilvani, A., Matias, C., Conceição, A.A.: Tratamento de efluentes resultantes do processamento da mandioca e seus principais usos effluent treatment resulting from the processing of cassava and its main uses. Rev. Meio Ambient. e Sustentabilidade. 4, 118–130 (2013)

Potivichayanon, S., Toensakes, R., Supromin, N., Seaung, K.: Removal of high levels of cyanide and COD from cassava industrial wastewater by a fixed-film sequencing batch reactor. Air. Soil. Pollut. Water. (2020). https://doi.org/10.1007/s11270-020-04642-7

Babayemi, O.J., Ifut, O.J.: Quality and chemical composition of cassava wastes ensiled with Albizia saman pods. Agric. J 5, 225–228 (2010). https://doi.org/10.3923/aj.2010.225.228

Aruwajoye, G.S., Faloye, F.D., Kana, E.G.: Soaking assisted thermal pretreatment of cassava peels wastes for fermentable sugar production: process modelling and optimization. Energy Convers. Manag. 150, 558–566 (2017). https://doi.org/10.1016/j.enconman.2017.08.046

Versino, F., García, M.A.: Particle size distribution effect on Cassava Starch and Cassava Bagasse biocomposites. ACS Sustain. Chem. Eng 7, 1052–1060 (2019). https://doi.org/10.1021/acssuschemeng.8b04700

Vázquez, M.J., Alonso, J.L., Domínguez, H., Parajó, J.C.: Xylooligosaccharides: manufacture and applications. Trends Food Sci. Technol. 11, 387–393 (2000). https://doi.org/10.1016/S0924-2244(01)00031-0

Grafulin, V.Y.: Xilo-oligossacarídeos - aplicação em alimentos e produção a partir de resíduos lignocelulósicos: uma revisão da literatura. Federal University of Rio Grande do Sul. https://www.lume.ufrgs.br/handle/10183/200381 (2016). Acessed 10 Dec 2022

Poletto, P., Pereira, G.N., Monteiro, C.R.M., Pereira, M.A.F., Bordignon, S.E., de Oliveira, D.: Xylooligosaccharides: transforming the lignocellulosic biomasses into valuable 5-carbon sugar prebiotics. Process. Biochem. 91, 352–363 (2020). https://doi.org/10.1016/j.procbio.2020.01.005

Courtin, C.M., Swennen, K., Verjans, P., Delcour, J.A.: Heat and pH stability of prebiotic arabinoxylooligosaccharides, xylooligosaccharides and fructooligosaccharides. Food Chem. 112, 831–837 (2009). https://doi.org/10.1016/j.foodchem.2008.06.039

Otieno, D.O., Ahring, B.K.: The potential for oligosaccharide production from the hemicellulose fraction of biomasses through pretreatment processes: xylooligosaccharides (XOS), arabinooligosaccharides (AOS), and mannooligosaccharides (MOS). Carbohydr. Res. 360, 84–92 (2012). https://doi.org/10.1016/j.carres.2012.07.017

Wright, A., Bandulasena, H., Ibenegbu, C., Leak, D., Holmes, T., Zimmerman, W., Shaw, A., Iza, F.: Dielectric barrier discharge plasma microbubble reactor for pretreatment of lignocellulosic biomass. AIChE J. 64, 3803–3816 (2018). https://doi.org/10.1002/aic.16212

Nascimento, V.M., Manrich, A., Tardioli, P.W., de Campos Giordano, R., de Moraes Rocha, G.J., de Giordano, R.: L.C.: Alkaline pretreatment for practicable production of ethanol and xylooligosaccharides. Bioethanol. (2016). https://doi.org/10.1515/bioeth-2016-0008

Miranda, F.S., Rabelo, S.C., Pradella, J.G.C., Carli, C., Di, Petraconi, G., Maciel, H.S., Pessoa, R.S., Vieira, L.: Plasma in-liquid using non-contact electrodes: a method of pretreatment to enhance the enzymatic hydrolysis of Biomass. Waste and Biomass Valorization. 11, 4921–4931 (2020). https://doi.org/10.1007/s12649-019-00824-5

Ethaib, S.: Microwave-assisted pretreatment of lignocellulosic biomass: a review. J. Eng. Sci. Technol. 10, 97–109 (2015)

Bussemaker, M.J., Zhang, D.: Effect of ultrasound on lignocellulosic biomass as a pretreatment for biorefinery and biofuel applications. Ind. Eng. Chem. Res. 52, 3563–3580 (2013)

Menezes, C.R., De, Durrant, L.R.: Xilooligossacarídeos: produção, aplicações e efeitos na saúde humana. Ciência Rural. 38, 587–592 (2008)

Bastos, J.A., Remor, P.V., Lofhagen, J.C.P., Hawkins, C.A., Edwiges, T.: Sustainable research methodology on the effect of the reuse of black liquor in the alkaline pre-treatment of garden residues for the production of biogas. Rev. Gestão Ambient e Sustentabilidade. 8, 554–567 (2019). https://doi.org/10.5585/geas.v8i3.15780

Wan Azelee, N.I., Jahim, J.M., Ismail, A.F., Fuzi, S.F.Z.M., Rahman, R.A., Illias, M.: High xylooligosaccharides (XOS) production from pretreated kenaf stem by enzyme mixture hydrolysis. Ind. Crops Prod. 81, 11–19 (2016). https://doi.org/10.1016/j.indcrop.2015.11.038

Ajala, E.O., Ajala, M.A., Tijani, I.A., Adebisi, A.A., Suru, I.: Journal of king saud university – science kinetics modelling of acid hydrolysis of cassava (Manihot esculanta Cranz) peel and its hydrolysate chemical characterisation. J. King Saud Univ. - Sci 32, 2284–2292 (2020). https://doi.org/10.1016/j.jksus.2020.03.003

Balagopalan, C., Padmaja, G., Nanda, S.K., Moorthy, S.N.: Cassava in food, feed and industry. CRC Press, Boca Raton (2018)

Phoncharoen, P., Banterng, P., Vorasoot, N., Jogloy, S., Theerakulpisut, P.: Crop Sci. | Res. Article Clim. 9, 376–388 (2019)

Montagnac, J.A., Davis, C.R., Tanumihardjo, S.A.: Nutritional value of Cassava for use as a staple food and recent advances for improvement. Compr. Rev. Food Sci. Food Saf 8, 181–194 (2009). https://doi.org/10.1111/j.1541-4337.2009.00077.x

Medeiros, A., Ferreira, E., Keiko, A., Ishida, N., Cleiton, A., Pinho, S., Regina, C., Souza, B., De: Physiological and molecular plant pathology expression pro fi les of defense genes in cassava storage roots upon exposure to phytopythium sp., causal agent of soft root rot disease. Physiol. Mol. Plant. Pathol 104, 23–30 (2018). https://doi.org/10.1016/j.pmpp.2018.09.001

Mohd Isa, M.H., Shamsudin, N.H., Al-Shorgani, N.K.N., Alsharjabi, F.A., Kalil, M.S.: Evaluation of antibacterial potential of biosurfactant produced by surfactin-producing Bacillus isolated from selected malaysian fermented foods. Food Biotechnol. 34, 1–24 (2020). https://doi.org/10.1080/08905436.2019.1710843

Kayiwa, R., Kasedde, H., Lubwama, M., Kirabira, J.B.: Current research in green and sustainable chemistry characterization and pre-leaching effect on the peels of predominant cassava varieties in Uganda for production of activated carbon. Curr. Res. Green. Sustain. Chem 4, 100083 (2021). https://doi.org/10.1016/j.crgsc.2021.100083

Yang, W., Bai, Y., Yang, P., Luo, H., Huang, H., Meng, K., Shi, P., Wang, Y., Yao, B.: A novel bifunctional GH51 exo-α-l-arabinofuranosidase/endo-xylanase from Alicyclobacillus sp. A4 with significant biomass-degrading capacity. Biotechnol. Biofuels. 8, 197 (2015). https://doi.org/10.1186/s13068-015-0366-0

Xu, L., Zhang, J., Zong, Q.J., Wang, L., Xu, T., Gong, J., Liu, Z.H., Li, B.Z., Yuan, Y.J.: High-solid ethylenediamine pretreatment to fractionate new lignin streams from lignocellulosic biomass. Chem. Eng. J. (2022). https://doi.org/10.1016/j.cej.2021.130962

Ruiz, H.A., Rodríguez-Jasso, R.M., Fernandes, B.D., Vicente, A.A., Teixeira, J.A.: Hydrothermal processing, as an alternative for upgrading agriculture residues and marine biomass according to the biorefinery concept: a review. Renew. Sustain. Energy Rev. 21, 35–51 (2013). https://doi.org/10.1016/j.rser.2012.11.069

Axelsson, L., Franzén, M., Ostwald, M., Berndes, G., Lakshmi, G., Ravindranath, N.H.: Jatropha cultivation in southern India: assessing farmers’ experiences. Biofuels Bioprod. Biorefining. 6, 246–256 (2012). https://doi.org/10.1002/bbb.1324

Jiwuba, P.C., Jiwuba, L.C., Ogbuewu, I.P., Mbajiorgu, C.A.: Enhancement values of cassava by-product diets on production and haemato-biochemical indices of sheep and goats: a review. Trop. Anim. Health Prod. 53, 207 (2021). https://doi.org/10.1007/s11250-021-02656-9

Dos Santos, D.M., De Lacerda Bukzem, A., Ascheri, D.P.R., Signini, R., De Aquino, G.L.B.: Microwave-assisted carboxymethylation of cellulose extracted from brewer’s spent grain. Carbohydr. Polym. 131, 125–133 (2015). https://doi.org/10.1016/j.carbpol.2015.05.051

Diarra, S.S.: Peel meals as feed ingredients in poultry diets: chemical composition, dietary recommendations and prospects. J. Anim. Physiol. Anim. Nutr. (Berl) 102, 1284–1295 (2018). https://doi.org/10.1111/jpn.12954

Awoyale, A.A., Lokhat, D.: Harnessing the potential of bio-ethanol production from lignocellulosic biomass in Nigeria – a review. Biofuels Bioprod. Biorefining. 13, 192–207 (2019). https://doi.org/10.1002/bbb.1943

Adekunle, A., Orsat, V., Raghavan, V.: Lignocellulosic bioethanol: a review and design conceptualization study of production from cassava peels. Renew. Sustain. Energy Rev. 64, 518–530 (2016). https://doi.org/10.1016/j.rser.2016.06.064

Sivamani, S., Pandian, A., Muthusamy, C., Hosseini-bandegharaei, M.S.A., Biogas, B.: Evaluation of the potential of cassava-based residues for biofuels production. Rev. Environ. Sci. Bio/Technol 17, 553–570 (2018). https://doi.org/10.1007/s11157-018-9475-0

Giwa, A., Alabi, A., Yusuf, A., Olukan, T.: A comprehensive review on biomass and solar energy for sustainable energy generation in Nigeria. Renew. Sustain. Energy Rev. 69, 620–641 (2017). https://doi.org/10.1016/j.rser.2016.11.160

Abass, A.B., Awoyale, W., Alenkhe, B., Malu, N., Asiru, B.W., Manyong, V., Sanginga, N.: Can food technology innovation change the status of a food security crop? a review of cassava transformation into “bread” in Africa. Food Rev. Int 34, 87–102 (2018). https://doi.org/10.1080/87559129.2016.1239207

Okonko, I.O., Ogun, A.A., Shittu, O.B., Ogunnusi, T.A.: Waste utilization as a means of ensuring enviromental safety-an overview. Electron. J. Environ. Agric. Food Chem. 8, 836–855 (2009)

Oghenejoboh, K.M., Orugba, H.O., Oghenejoboh, U.M., Agarry, S.E.: Value added cassava waste management and environmental sustainability in Nigeria: a review. Environ. Challenges. 4, 100127 (2021). https://doi.org/10.1016/j.envc.2021.100127

Awoyale, A.A., Lokhat, D.: Experimental determination of the effects of pretreatment on selected nigerian lignocellulosic biomass in bioethanol production. Sci. Rep. 11, 1–16 (2021). https://doi.org/10.1038/s41598-020-78105-8

Uthumporn, U., Nadiah, I., Izzuddin, I., Cheng, L.H., Aida, H.: Physicochemical characteristics of non-starch polysaccharides extracted from cassava tubers. Sains Malaysiana. 46, 223–229 (2017). https://doi.org/10.17576/jsm-2017-4602-06

Rodrigues, C., Woiciechowski, A.L., Letti, L.A.J., Karp, S.G., Goelzer, F.D., Sobral, K.C.A., Coral, J.D., Campioni, T.S., Maceno, M.A.C., Soccol, C.R.: Materiais lignocelulósicos como matéria-prima para a obtenção de biomoléculas de valor comercial. Biotecnologia. Aplicada à Agro. Indústria 4, 283–314 (2017)

Orellana, B.B.M.A.: Utilização de resíduos de biomassa do distrito federal para fins energéticos. University of Brasilia. https://www.repositorio.unb.br/bitstream/10482/35299/1/2019_BrunaB%C3%A1rbaraMacielAmorasOrellana.pdf (2019). Acessed 9 Dec 2022

Mohammed, A.: Pretreatment and hydrolysis of cassava peels for fermentable Sugar production. Asian J. Biochem. 9, 65–70 (2014). https://doi.org/10.3923/ajb.2014.65.70

Alrefai, A.M., Alrefai, R., Benyounis, K.Y., Stokes, J.: Impact of Starch from Cassava Peel on Biogas produced through the anaerobic digestion process. Energies 13, 2713 (2020). https://doi.org/10.3390/en13112713

Karp, S.G., Woiciechowski, A.L., Soccol, V.T., Soccol, C.R.: Pretreatment strategies for delignification of sugarcane bagasse: a review. Brazilian Arch. Biol. Technol. 56, 679–689 (2013). https://doi.org/10.1590/S1516-89132013000400019

Zhang, J., Wang, Y.H., Wei, Q.Y., Du, X.J., Qu, Y.S.: Investigating desorption during ethanol elution to improve the quality and antioxidant activity of xylo-oligosaccharides from corn stalk. Bioresour Technol. 249, 342–347 (2018). https://doi.org/10.1016/j.biortech.2017.09.203

Efeovbokhan, V.E., Egwari, L., Alagbe, E.E., Adeyemi, J.T., Taiwo, O.S.: Production of bioethanol from hybrid cassava pulp and peel using microbial and acid hydrolysis. BioResources. 14, 2596–2609 (2019). https://doi.org/10.15376/biores.14.2.2596-2609

Salihu, A., Abbas, O., Sallau, A.B., Alam, M.Z.: Agricultural residues for cellulolytic enzyme production by Aspergillus niger: effects of pretreatment. 3 Biotech 5, 1101–1106 (2015). https://doi.org/10.1007/s13205-015-0294-5

Onilude, A.A.: Effect of cassavar cultivar, age and pretreatment processes of cellulase and xylanase production from cassava waste by Trichoderma harzianum. J. Basic. Microbiol 36, 421–431 (1996). https://doi.org/10.1002/jobm.3620360607

Ona, J.I., Halling, P.J., Ballesteros, M.: Enzyme hydrolysis of cassava peels: treatment by amylolytic and cellulolytic enzymes. Biocatal Biotransform. 37, 77–85 (2019). https://doi.org/10.1080/10242422.2018.1551376

Moshi, A.P., Temu, S.G., Nges, I.A., Malmo, G., Hosea, K.M.M., Elisante, E., Mattiasson, B.: Combined production of bioethanol and biogas from peels of wild cassava Manihot glaziovii. Chem. Eng. J. 279, 297–306 (2015). https://doi.org/10.1016/j.cej.2015.05.006

Barati, Z., Latif, S., Müller, J.: Enzymatic hydrolysis of cassava peels as potential pre-treatment for peeling of cassava tubers. Biocatal. Agric. Biotechnol. 20, 101247 (2019). https://doi.org/10.1016/j.bcab.2019.101247

Pooja, N.S., Padmaja, G.: Enhancing the enzymatic saccharification of agricultural and processing residues of cassava through pretreatment techniques. Waste. Biomass Valorization 6, 303–315 (2015). https://doi.org/10.1007/s12649-015-9345-8

Czaikoski, A., Lopes, R., Menegalli, F.C.: Rheological behavior of cellulose nano fi bers from cassava peel obtained by combination of chemical and physical processes. Carbohydr. Polym. 248, 116744 (2020). https://doi.org/10.1016/j.carbpol.2020.116744

Hermansyah, A., Xayasene, T., Tho, N.H., Fatma, N., Panagan, A.T: Bioethanol production from cassava (Manihot esculenta) peel using yeast isolated from durian (Durio zhibetinus). J. Physics: Conference Series. 1095, 1–8 (2018). https://doi.org/10.1088/1742-6596/1095/1/012016

Papathoti, N.K., Laemchiab, K., Megavath, V.S., Keshav, P.K., Numparditsub, P., Le Thanh, T., Buensanteai, N.: Augmented ethanol production from alkali-assisted hydrothermal pretreated cassava peel waste. energy sources, part A recover. Util. Environ. Eff 00, 1–11 (2021). https://doi.org/10.1080/15567036.2021.1928338

Sudha, A., Sivakumar, V., Sangeetha, V., Priyenka Devi, K.S.: Physicochemical treatment for improving bioconversion of cassava industrial residues. Environ. Prog Sustain. Energy. 37, 577–583 (2018). https://doi.org/10.1002/ep.12702

Kongkiattikajorn, J., Sornvoraweatn, B.: Comparative study of bioethanol production from cassava peels by monoculture and co-culture of yeast jirasak. Kasetsart J. - Nat. Sci. 45, 268–274 (2011)

Zhang, J., Liu, J., Kou, L., Zhang, X., Tan, T.: Bioethanol production from cellulose obtained from the catalytic hydro- deoxygenation (lignin- fi rst re fi ned to aviation fuel) of apple wood. Fuel. 250, 245–253 (2019). https://doi.org/10.1016/j.fuel.2019.03.020

Samanta, A.K., Kolte, A.P., Elangovan, A.V., Dhali, A., Senani, S., Sridhar, M., Suresh, K.P., Jayapal, N., Jayaram, C., Roy, S.: Value addition of corn husks through enzymatic production of xylooligosaccharides. Brazilian Arch. Biol. Technol. 59, 1–8 (2016). https://doi.org/10.1590/1678-4324-2016160078

Ávila, P.F., Martins, M., Goldbeck, R.: Enzymatic production of Xylooligosaccharides from alkali-solubilized arabinoxylan from sugarcane straw and coffee husk. Bioenergy Res (2020). https://doi.org/10.1007/s12155-020-10188-7

Amorim, C., Silvério, S.C., Rodrigues, L.R.: One-step process for producing prebiotic arabino-xylooligosaccharides from brewer ’ s spent grain employing Trichoderma species. Food Chem 270, 86–94 (2019). https://doi.org/10.1016/j.foodchem.2018.07.080

Kaur, R., Uppal, S.K., Sharma, P.: Production of Xylooligosaccharides from Sugarcane Bagasse and evaluation of their prebiotic potency in Vitro. Waste. Biomass. Valorization 10, 2627–2635 (2019). https://doi.org/10.1007/s12649-018-0266-1

Agung, A., Ratnadewi, I., Budi, A., Sulistyaningsih, E.: Application of Cassava Peel and waste as raw materials for xylooligosaccharide production using endoxylanase from Bacillus subtilis of soil Termite Abdomen. Procedia. Chem 18, 31–38 (2016). https://doi.org/10.1016/j.proche.2016.01.007

Pondja, E.A., Jr., Persson, K.M., Matsinhe, N.P.: The potential use of Cassava Peel for treatment of mine water in Mozambique. J. Environ. Prot. (Irvine Calif) 08, 277–289 (2017). https://doi.org/10.4236/jep.2017.83021

Aguilar, R., Ramírez, J.A., Garrote, G., Vázquez, M.: Kinetic study of the acid hydrolysis of sugar cane bagasse. J. Food Eng. 55, 309–318 (2002). https://doi.org/10.1016/S0260-8774(02)00106-1

Vancov, T., Alston, A., Brown, T., Mcintosh, S.: Use of ionic liquids in converting lignocellulosic material to biofuels. Renew. Energy. 45, 1–6 (2012). https://doi.org/10.1016/j.renene.2012.02.033

Monteiro, C.R.M., Ávila, P.F., Pereira, M.A.F., Pereira, G.N., Bordignon, S.E., Zanella, E., Stambuk, B.U., de Oliveira, D., Goldbeck, R., Poletto, P.: Hydrothermal treatment on depolymerization of hemicellulose of mango seed shell for the production of xylooligosaccharides. Carbohydr. Polym. (2021). https://doi.org/10.1016/j.carbpol.2020.117274

Jacquet, N., Maniet, G., Vanderghem, C., Delvigne, F., Richel, A.: Application of steam explosion as pretreatment on lignocellulosic material: a review. Ind. Eng. Chem. Res. (2015). https://doi.org/10.1021/ie503151g

Pereira, G.N., Cesca, K., Vieira Cubas, A.L., de Oliveira, D.: Use of non-thermal plasma in lignocellulosic materials: a smart alternative. Trends Food Sci. Technol. 109, 365–373 (2021). https://doi.org/10.1016/j.tifs.2021.01.047

de Freitas, C., Carmona, E., Brienzo, M.: Xylooligosaccharides production process from lignocellulosic biomass and bioactive effects. Bioact. Carbohydr. Diet. Fibre. (2019). https://doi.org/10.1016/j.bcdf.2019.100184

Cipriani, T.R.: Extração, purificação e caracterização estrutural de polissacarídeos de Maytenus ilicifolia (espinheira-santa). Federal University of Paraná. https://www.acervodigital.ufpr.br/handle/1884/68399 (2003). Acessed 8 Dec 2022

Haghighi Mood, S., Hossein Golfeshan, A., Tabatabaei, M., Salehi Jouzani, G., Najafi, G.H., Gholami, M., Ardjmand, M.: Lignocellulosic biomass to bioethanol, a comprehensive review with a focus on pretreatment. Renew. Sustain. Energy Rev. 27, 77–93 (2013). https://doi.org/10.1016/j.rser.2013.06.033

Rabemanolontsoa, H., Kuninori, Y., Saka, S.: High conversion efficiency of japanese cedar hydrolyzates into acetic acid by co-culture of Clostridium thermoaceticum and Clostridium thermocellum. J. Chem. Technol. Biotechnol 91, 1040–1047 (2016). https://doi.org/10.1002/jctb.4679

Poletto, P., Pereira, G.N., Monteiro, C.R.M., Pereira, M.A.F., Bordignon, S.E., de Oliveira, D.: Xylooligosaccharides: transforming the lignocellulosic biomasses into valuable 5-carbon sugar prebiotics. Process. Biochem. 91, 352–363 (2020). https://doi.org/10.1016/j.procbio.2020.01.005

Pereira Ramos, L.: The chemistry involved in the steam treatment of lignocellulosic materials. Quim. Nova. 26, 863–871 (2003). https://doi.org/10.1590/s0100-40422003000600015

Mäki-Arvela, P., Anugwom, I., Virtanen, P., Sjöholm, R., Mikkola, J.P.: Dissolution of lignocellulosic materials and its constituents using ionic liquids-a review. Ind. Crops Prod 32, 175–201 (2010). https://doi.org/10.1016/j.indcrop.2010.04.005

Kriegseis, J., Möller, B., Grundmann, S., Tropea, C.: Capacitance and power consumption quantification of dielectric barrier discharge (DBD) plasma actuators. J. Electrostat. 69, 302–312 (2011). https://doi.org/10.1016/j.elstat.2011.04.007

Brienzo, M., Siqueira, A.F., Milagres, A.M.F.: Search for optimum conditions of sugarcane bagasse hemicellulose extraction. Biochem. Eng. J. 46, 199–204 (2009). https://doi.org/10.1016/j.bej.2009.05.012

Gullo, P., Domı, H., Parajo, J.C.: Advances in the manufacture, purification and applications of xylo-oligosaccharides as food additives and nutraceuticals. Process. Biochem 41, 1913–1923 (2006). https://doi.org/10.1016/j.procbio.2006.05.011

Khat-udomkiri, N., Sivamaruthi, B.S., Sirilun, S., Lailerd, N., Peerajan, S., Chaiyasut, C.: Optimization of alkaline pretreatment and enzymatic hydrolysis for the extraction of xylooligosaccharide from rice husk. AMB Express (2018). https://doi.org/10.1186/s13568-018-0645-9

Flavia, A., Carvalho, A., Cristina, F., Figueiredo, D., Sila, T., Maria, G., Oliva, P., De: Biomass and bioenergy improvement of some chemical and biological methods for the efficient production of xylanases, xylooligosaccharides and lignocellulose from sugar cane bagasse. Biomass. Bioenergy 143, 105851 (2020). https://doi.org/10.1016/j.biombioe.2020.105851

Suvarna, G., Rajeswari, B.U., Prakasham, R.S.: Biosynthesis of xylobiose: a strategic way to enrich the value of oil palm empty fruit bunch fiber. J. Microbiol. Biotechnol 22, 1084–1091 (2012)

Lucas, S., García-cubero, M.T., Jos, J., Juan, C.L.: A biorefinery based on brewers spent grains: Arabinoxylans recovery by microwave assisted pretreatment integrated with butanol production. Ind. Crops. Prod (2020). https://doi.org/10.1016/j.indcrop.2020.113044

Badiei, M., Asim, N., Jahim, J.M., Sopian, K.: Comparison of Chemical pretreatment methods for cellulosic biomass. Procedia - Soc. Behav. Sci. 9, 170–174 (2014). https://doi.org/10.1016/j.apcbee.2014.01.030

Chen, H., Liu, J., Chang, X., Chen, D., Xue, Y., Liu, P., Lin, H., Han, S.: A review on the pretreatment of lignocellulose for high-value chemicals. Fuel Process. Technol. 160, 196–206 (2017). https://doi.org/10.1016/J.FUPROC.2016.12.007

Ravindran, R., Sarangapani, C., Jaiswal, S., Lu, P., Cullen, P.J., Bourke, P., Jaiswal, A.K.: Improving enzymatic hydrolysis of brewer spent grain with nonthermal plasma. Bioresour Technol. 282, 520–524 (2019). https://doi.org/10.1016/j.biortech.2019.03.071

Schultz-Jensen, N., Kádár, Z., Thomsen, A.B., Bindslev, H., Leipold, F.: Plasma-assisted pretreatment of wheat straw for ethanol production. Appl. Biochem. Biotechnol. 165, 1010–1023 (2011). https://doi.org/10.1007/s12010-011-9316-x

Afolabi, F.T., Ayodele, E.O.: Comparative Study of Bioethanol Production and Reducing Sugar Yields from Cassava Peels Using Fungi. Acta Microbiol. Bulg 36, 153 (2020)

Wang, W., Luo, G., Xie, L., Zhou, Q.: Enhanced thermophilic fermentative hydrogen production from cassava stillage by chemical pretreatments. Water Sci. Technol. 68, 59–67 (2013). https://doi.org/10.2166/wst.2013.218

Barati, Z., Latif, S., Müller, J.: Biocatalysis and agricultural biotechnology enzymatic hydrolysis of cassava peels as potential pre-treatment for peeling of cassava tubers. Biocatal. Agric. Biotechnol 20, 101247 (2019). https://doi.org/10.1016/j.bcab.2019.101247

Aruwajoye, G.S., Faloye, F.D., Kana, E.G.: Soaking assisted thermal pretreatment of cassava peels wastes for fermentable sugar production: process modelling and optimization. Energy Convers. Manag. 150, 558–566 (2017). https://doi.org/10.1016/j.enconman.2017.08.046

Awoyale, W., Alamu, E.O., Chijioke, U., Tran, T., Takam, H.N., Ndjouenkeu, R.: Review a review of cassava semolina (gari and eba) end-user preferences and implications for varietal trait evaluation. Int. J. Food Sci. Technol (2021). https://doi.org/10.1111/ijfs.14867

Cebin, A.V., Ralet, M.C., Vigouroux, J., Karača, S., Martinić, A., Komes, D., Bonnin, E.: Valorisation of walnut shell and pea pod as novel sources for the production of xylooligosaccharides. Carbohydr. Polym. (2021). https://doi.org/10.1016/j.carbpol.2021.117932

Cebreiros, F., Risso, F., Cagno, M., Cabrera, M.N., Rochón, E., Jauregui, G., Boix, E., Böthig, S., Ferrari, M.D., Lareo, C.: Enhanced production of butanol and xylosaccharides from Eucalyptus grandis wood using steam explosion in a semi-continuous pre-pilot reactor. Fuel (2021). https://doi.org/10.1016/j.fuel.2020.119818

Wijaya, H., Sasaki, K., Kahar, P., Rahmani, N., Hermiati, E., Yopi, Y., Ogino, C., Prasetya, B., Kondo, A.: High enzymatic recovery and purification of xylooligosaccharides from empty fruit bunch via nanofiltration. Processes. 8, 1–9 (2020). https://doi.org/10.3390/PR8050619

Jnawali, P., Kumar, V., Tanwar, B., Hirdyani, H., Gupta, P.: Enzymatic production of Xylooligosaccharides from Brown Coconut Husk treated with Sodium Hydroxide. Waste. Biomass. Valorization 9, 1757–1766 (2018). https://doi.org/10.1007/s12649-017-9963-4

Surek, E., Buyukkileci, A.O.: Production of xylooligosaccharides by autohydrolysis of hazelnut (Corylus avellana L.) shell. Carbohydr. Polym 174, 565–571 (2017). https://doi.org/10.1016/j.carbpol.2017.06.109

Moniz, P., Pereira, H., Duarte, L.C., Carvalheiro, F.: Hydrothermal production and gel filtration purification of xylo-oligosaccharides from rice straw. Ind. Crops Prod. 62, 460–465 (2014). https://doi.org/10.1016/j.indcrop.2014.09.020

Bragatto, J., Segato, F., Squina, F.M.: Production of xylooligosaccharides (XOS) from delignified sugarcane bagasse by peroxide-HAc process using recombinant xylanase from Bacillus subtilis. Ind. Crops Prod. 51, 123–129 (2013). https://doi.org/10.1016/j.indcrop.2013.08.062

Garrote, G., Domínguez, H., Parajó, J.C.: Generation of xylose solutions from Eucalyptus globulus wood by autohydrolysis-posthydrolysis processes: posthydrolysis kinetics. Bioresour Technol 79, 155–164 (2001). https://doi.org/10.1016/S0960-8524(01)00044-X

Acknowledgements

The authors acknowledge the financial support of Foundation for the Research and Innovation Support Foundation of Santa Catarina State (FAPESC) – Programa de Apoio a Núcleos Emergentes (PRONEM) 2020TR731 and Coordination for the Improvement of Higher Education Personnel (CAPES) – Institutional Program for Internationalization (PRINT), Project numbers 88887.310560/2018-00 and 88887.310727/2018-00.

Funding

The authors acknowledge the financial support of Foundation for the Research and Innovation Support Foundation of Santa Catarina State (FAPESC) – Programa de Apoio a Núcleos Emergentes (PRONEM) 2020TR731 and Coordination for the Improvement of Higher Education Personnel (CAPES) – Institutional Program for Internationalization (PRINT), Project numbers 88887.310560/2018-00 and 88887.310727/2018-00.

Author information

Authors and Affiliations

Contributions

WR: Conceptualization, Methodology, Software, Writing - Original Draft, Writing - Review & Editing GNP: Methodology, Conceptualization, Writing - Original Draft; KC: Conceptualization, Project administration; DdO: Term, Supervision, Funding acquisition CJdA: Term, Supervision, Funding acquisition.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical Approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rogoski, W., Pereira, G.N., Cesca, K. et al. An Overview on Pretreatments for the Production of Cassava Peels-based Xyloligosaccharides: State of Art And Challenges. Waste Biomass Valor 14, 2115–2131 (2023). https://doi.org/10.1007/s12649-023-02044-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-023-02044-4