Abstract

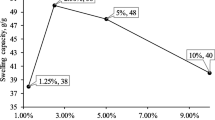

Chitin and glucan in the cell wall of Ganoderma lucidum have various biological activities, but are usually not effectively utilized or discarded as insoluble waste. The aim of this study is to characterize the chitin-glucan complex extracted from Ganoderma lucidum residues and to access its application potential as a hemostatic material. Ganoderma lucidum chitin-glucan complex (GLCGC) was extracted from Ganoderma lucidum, and GLCGC was prepared into a novel Ganoderma lucidum chitin-glucan complex hydrogel (GLCGCH) with ionic liquid [AMIM]Cl. GLCGC and lyophilized GLCGCH was characterized by fourier transform infrared spectroscopy, scanning electron microscope, swelling capacity, rheological properties and hemostatic properties. Our results showed that the extracted GLCGC mainly consisted of glucan (76.7 ± 2.9%) and chitin (3.85 ± 0.55%). The hydrogel GLCGCH had three-dimensional porous structure with good performance in swelling behavior (with swelling ratios of 1181.0–1891.0%). With no cytotoxicity against mouse fibroblast cells, GLCGCH showed good blood compatibility (with hemolysis ratios of 0.9–1.5%) and in vitro blood coagulation property (with blood clotting indices of 35.3–41.9%), indicating GLCGCH has great hemostatic effect. This work provided new insight into the integrated utilization of Ganoderma lucidum residues. The prepared hydrogel could be used as a promising material for hemostatic application.

Graphical Abstract

Similar content being viewed by others

Data Availability

All data generated or analysed during this study are included in this published article and its supplementary information files.

Code Availability

Not applicable.

References

Li, Z., Zhou, J., Lin, Z.: Development and innovation of ganoderma industry and products in China. Adv. Exp. Med. Biol. 1181, 187–204 (2019). https://doi.org/10.1007/978-981-13-9867-4_7

Jiang, D., et al.: Restoration of the tumor-suppressor function to mutant p53 by ganoderma lucidum polysaccharides in colorectal cancer cells. Oncol. Rep. 37(1), 594–600 (2017). https://doi.org/10.3892/or.2016.5246

Zhang, J., et al.: Toxicology and immunology of ganoderma lucidum polysaccharides in Kunming mice and wistar rats. Int. J. Biol. Macromol. 85, 302–310 (2016). https://doi.org/10.1016/j.ijbiomac.2015.12.090

Gill, B.S., Gill, N., Kumar, S.: Ganoderma lucidum targeting lung cancer signaling: a review. Tumor Biol. 39(6), 1–10 (2017). https://doi.org/10.1177/1010428317707437

Kurita, K.: Chitin and chitosan: functional biopolymers from marine crustaceans. Mar. Biotechnol. 8(3), 203–226 (2006). https://doi.org/10.1007/s10126-005-0097-5

Jones, M.P., et al., Crab vs. mushroom: A review of crustacean and fungal chitin in wound treatment. Marine Drugs, 2020. 18(1): p. 64–88. http://dx.doi.org/https://doi.org/10.3390/md18010064.

Nawawi, W.M.F.B.W., et al.: Nanomaterials derived from fungal sources—is it the new hype? Biomacromolecules 21(1), 30–55 (2020). https://doi.org/10.1021/acs.biomac.9b01141

Nawawi, W.M., et al.: Plastic to elastic: fungi-derived composite nanopapers with tunable tensile properties. Compos. Sci. Technol. 198, 108327 (2020). https://doi.org/10.1016/j.compscitech.2020.108327

Abdel-Mohsen, A.M., et al.: Novel chitin/chitosan-glucan wound dressing: isolation, characterization, antibacterial activity and wound healing properties. Int. J. Pharm. 510(1), 86–99 (2016). https://doi.org/10.1016/j.ijpharm.2016.06.003

Janesch, J., et al.: Mushroom-derived chitosan-glucan nanopaper filters for the treatment of water. React. Funct. Polym. 146, 1–10 (2020). https://doi.org/10.1016/j.reactfunctpolym.2019.104428

Yousefi, N., et al.: Fungal chitin-glucan nanopapers with heavy metal adsorption properties for ultrafiltration of organic solvents and water. Carbohyd. Polym. 253, 117273 (2021). https://doi.org/10.1016/j.carbpol.2020.117273

Narayanan, K.B., Zo, S.M., Han, S.S.: Novel biomimetic chitin-glucan polysaccharide nano/microfibrous fungal-scaffolds for tissue engineering applications. Int. J. Biol. Macromol. 149, 724–731 (2020). https://doi.org/10.1016/j.ijbiomac.2020.01.276

Basha, R.Y., Sampath Kumar, T.S., Doble, M.: Electrospun nanofibers of Curdlan (β-1,3 Glucan) blend as a potential skin scaffold material. Macromol. Mater. Eng. 302(4), 1600417 (2017). https://doi.org/10.1002/mame.201600417

Park, J.-S., et al.: Preparation and evaluation of β-glucan hydrogel prepared by the radiation technique for drug carrier applications. Int. J. Biol. Macromol. 118(15), 333–339 (2018). https://doi.org/10.1016/j.ijbiomac.2018.06.068

Shalumon, K.T., et al.: Electrospinning of carboxymethyl chitin/poly(vinyl alcohol) nanofibrous scaffolds for tissue engineering applications. Carbohyd. Polym. 77(4), 863–869 (2009). https://doi.org/10.1016/j.carbpol.2009.03.009

Muzzarelli, R.A.A.: Chitins and chitosans for the repair of wounded skin, nerve, cartilage and bone. Carbohyd. Polym. 76(2), 167–182 (2009). https://doi.org/10.1016/j.carbpol.2008.11.002

Klokkevold, P.R., et al.: The effect of chitosan (poly-N-acetyl glucosamine) on lingual hemostasis in heparinized rabbits. J. Oral Maxillofac. Surg. 57(1), 49–52 (1999). https://doi.org/10.1016/S0278-2391(99)90632-8

Zhang, W., Sun, Y.-L., Chen, D.-H.: Effects of chitin and sepia ink hybrid hemostatic sponge on the blood parameters of mice. Mar. Drugs 12(4), 2269–2281 (2014). https://doi.org/10.3390/md12042269

Usami, Y., et al.: Influence of chain length of N-acetyl-D-glucosamine and D-glucosamine residues on direct and complement-mediated chemotactic activities for canine polymorphonuclear cells. Carbohyd. Polym. 32(2), 115–122 (1997). https://doi.org/10.1016/S0144-8617(96)00153-1

Ueno, H., et al.: Accelerating effects of chitosan for healing at early phase of experimental open wound in dogs. Biomaterials 20(15), 1407–1414 (1999). https://doi.org/10.1016/S0142-9612(99)00046-0

Zhou, H.Y., et al.: Glycerophosphate-based chitosan thermosensitive hydrogels and their biomedical applications. Carbohyd. Polym. 117(6), 524–536 (2015). https://doi.org/10.1016/j.carbpol.2014.09.094

Lan, G., et al.: Chitosan/gelatin composite sponge is an absorbable surgical hemostatic agent. Colloids Surf. B 136, 1026–1034 (2015). https://doi.org/10.1016/j.colsurfb.2015.10.039

Liu, J.-Y., et al.: Hemostatic porous sponges of cross-linked hyaluronic acid/cationized dextran by one self-foaming process. Mater. Sci. Eng. C 83, 160–168 (2018). https://doi.org/10.1016/j.msec.2017.10.007

Ferreira, I.C., et al.: Chitin-glucan complex - based biopolymeric structures using biocompatible ionic liquids. Carbohyd. Polym. 247, 116679 (2020). https://doi.org/10.1016/j.carbpol.2020.116679

Farinha, I., et al.: Chitin–glucan complex production by Komagataella pastoris: downstream optimization and product characterization. Carbohyd. Polym. 130, 455–464 (2015). https://doi.org/10.1016/j.carbpol.2015.05.034

Hu, X., et al.: Solubility and property of chitin in NaOH/urea aqueous solution. Carbohyd. Polym. 70(4), 451–458 (2007). https://doi.org/10.1016/j.carbpol.2007.05.002

Zhang, J., et al.: Application of ionic liquids for dissolving cellulose and fabricating cellulose-based materials: state of the art and future trends. Mater. Chem. Front. 1, 1273–1290 (2017). https://doi.org/10.1039/C6QM00348F

Poirier, M., Charlet, G.: Chitin fractionation and characterization in N, N-dimethylacetamide/lithium chloride solvent system. Carbohyd. Polym. 50(4), 363–370 (2002). https://doi.org/10.1016/S0144-8617(02)00040-1

Yao, Z.C., et al.: Ganoderma lucidum polysaccharide loaded sodium alginate micro-particles prepared via electrospraying in controlled deposition environments. Int. J. Pharm. 524(1), 148–158 (2017). https://doi.org/10.1016/j.ijpharm.2017.03.064

Mokhtari-Hosseini, Z.B., et al.: Chitin and chitosan biopolymer production from the Iranian medicinal fungus ganoderma lucidum: optimization and characterization. Prep. Biochem. Biotechnol. 48(7), 662–670 (2018). https://doi.org/10.1080/10826068.2018.1487847

Wu, T., et al.: Chitin and chitosan value-added products from mushroom waste. J. Agric. Food Chem. 52(26), 7905–7910 (2004). https://doi.org/10.1021/jf0492565

Elson, L.A., Morgan, W.T.: A colorimetric method for the determination of glucosamine and chondrosamine. Biochem. J. 27(6), 1824–1828 (1933). https://doi.org/10.1042/bj0271824

Dimzon, I.K.D., Knepper, T.P.: Degree of deacetylation of chitosan by infrared spectroscopy and partial least squares. Int. J. Biol. Macromol. 72, 939–945 (2015). https://doi.org/10.1016/j.ijbiomac.2014.09.050

Sluiter, A., et al.: Determination of structural carbohydrates and lignin in biomass, Technical Report NREL/TP-510–42618, National Renewable Energy Laboratory, Golden, CO. 2010.

Zhang, F., et al.: Fibrous aramid hydrogel supported antibacterial agents for accelerating bacterial-infected wound healing. Mater. Sci. Eng., C 121, 111833 (2021). https://doi.org/10.1016/j.msec.2020.111833

Wang, S., et al.: Study of double-bonded carboxymethyl chitosan/cysteamine-modified chondroitin sulfate composite dressing for hemostatic application. Eur. Polymer J. 162, 110875 (2022). https://doi.org/10.1016/j.eurpolymj.2021.110875

Liu, X., et al.: Rapid hemostatic and mild polyurethane-urea foam wound dressing for promoting wound healing. Mater. Sci. Eng. C 71, 289–297 (2017). https://doi.org/10.1016/j.msec.2016.10.019

Su, C.H., et al.: Fungal mycelia as the source of chitin and polysaccharides and their applications as skin substitutes. Biomaterials 18(17), 1169–1174 (1997). https://doi.org/10.1016/S0142-9612(97)00048-3

Vetter, J.: Chitin content of cultivated mushrooms agaricus bisporus, pleurotus ostreatus and lentinula edodes. Food Chem. 102(1), 6–9 (2007). https://doi.org/10.1016/j.foodchem.2006.01.037

Zhang, P., Sutheerawattananonda, M.: Kinetic models for glucosamine production by acid hydrolysis of chitin in five mushrooms. Int. J. Chem. Eng. 2020, 1–8 (2020). https://doi.org/10.1155/2020/5084036

Sun, C., et al.: Chitin isolated from yeast cell wall induces the resistance of tomato fruit to Botrytis cinerea. Carbohyd. Polym. 199, 341–352 (2018). https://doi.org/10.1016/j.carbpol.2018.07.045

Paulino, A.T., et al.: Characterization of chitosan and chitin produced from silkworm crysalides. Carbohyd. Polym. 64(1), 98–103 (2006). https://doi.org/10.1016/j.carbpol.2005.10.032

Hong, Y., Ying, T.: Characterization of a chitin-glucan complex from the fruiting body of Termitomyces albuminosus (Berk.) Heim. Int. J. Biol. Macromol. (2019). https://doi.org/10.1016/j.ijbiomac.2019.04.198

Boureghda, Y., Satha, H., Bendebane, F.: Chitin-glucan complex from Pleurotus ostreatus mushroom: physicochemical characterization and comparison of extraction methods. Waste Biomass Valoriz. (2021). https://doi.org/10.1007/s12649-021-01449-3

Zhang, H., et al.: 1-allyl-3-methylimidazolium chloride room temperature ionic liquid: a new and powerful nonderivatizing solvent for cellulose. Macromolecules 38(20), 8272–8277 (2005). https://doi.org/10.1021/ma0505676

Zainal, S.H., et al.: Preparation of cellulose-based hydrogel: a review. J. Market. Res. 10, 935–952 (2021). https://doi.org/10.1016/j.jmrt.2020.12.012

Liao, J., Huang, H.: A fungal chitin derived from hericium erinaceus residue: dissolution, gelation and characterization. Int. J. Biol. Macromol. 152(1), 456–464 (2020). https://doi.org/10.1016/j.carbpol.2019.05.074

Liao, J., Huang, H.: Magnetic chitin hydrogels prepared from hericium erinaceus residues with tunable characteristics: a novel biosorbent for Cu2+ removal. Carbohyd. Polym. 220(15), 191–201 (2019). https://doi.org/10.1016/j.carbpol.2019.05.074

Reh, A., et al.: Efficient wound healing composite hydrogel using Egyptian Avena sativa L. polysaccharide containing β-glucan. Int. J. Biol. Macromol. 149, 1331–1338 (2020). https://doi.org/10.1016/j.ijbiomac.2019.11.046

Abdel-Mohsen, A., et al.: Chitosan-glucan complex hollow fibers reinforced collagen wound dressing embedded with Aloe vera. Part I: preparation and characterization. Carbohyd. Polym. 230, 115708 (2020). https://doi.org/10.1016/j.carbpol.2019.115708

Abdel-Mohsen, A., et al.: Chitosan-glucan complex hollow fibers reinforced collagen wound dressing embedded with Aloe vera. II. Multifunctional properties to promote cutaneous wound healing. Int. J. Pharm. 582, 119349 (2020). https://doi.org/10.1016/j.ijpharm.2020.119349

Ahmad, S.I., et al.: Chitin and its derivatives: structural properties and biomedical applications. Int. J. Biol. Macromol. 164(1), 526–539 (2020). https://doi.org/10.1016/j.ijbiomac.2020.07.098

Khan, A.A., et al.: Biological and pharmaceutical activities of mushroom β-glucan discussed as a potential functional food ingredient. Bioactive Carbohydr. Dietary Fibre 16, 1–13 (2018). https://doi.org/10.1016/j.bcdf.2017.12.002

Han, F., et al.: Preparation, characteristics and assessment of a novel gelatin–chitosan sponge scaffold as skin tissue engineering material. Int. J. Pharm. 476(1), 124–133 (2014). https://doi.org/10.1016/j.ijpharm.2014.09.036

Yang, X., et al.: Fabricating antimicrobial peptide-immobilized starch sponges for hemorrhage control and antibacterial treatment. Carbohyd. Polym. 222, 115012 (2019). https://doi.org/10.1016/j.carbpol.2019.115012

Huang, M.H., Yang, M.C.: Evaluation of glucan/poly(vinyl alcohol) blend wound dressing using rat models. Int. J. Pharm. 346(1), 38–46 (2008). https://doi.org/10.1016/j.ijpharm.2007.06.021

Howling, G.I., et al.: The effect of chitin and chitosan on the proliferation of human skin fibroblasts and keratinocytes in vitro. Biomaterials 22(22), 2959–2966 (2001). https://doi.org/10.1016/S0142-9612(01)00042-4

Hattori, H., Ishihara, M.: Changes in blood aggregation with differences in molecular weight and degree of deacetylation of chitosan. Biomed. Mater. 10(1), 1015014 (2015)

Acknowledgements

This work was supported by the National Key R&D Program of China (2019YFD0901805), the 111 Project (B18022), the Fundamental Research Funds for the Central Universities, and the Open Project Funding of the State Key Laboratory of Bioreactor Engineering, ECUST (ZDXM2019). We acknowledge Yuan Li for the assistance in performing the cytotoxicity experiments.

Author information

Authors and Affiliations

Contributions

Liming Zhao conceived and supervised the project. Yanqiong Liu and Chunyue Zhang designed the experiments. Yanqiong Liu, Chunyue Zhang, Xingxing Zhang and Yanying Hou performed the experiments. Yanqiong Liu, Chunyue Zhang, Lujie Liu wrote the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

12649_2022_1711_MOESM2_ESM.tif

Fig. S1 Chromatograms of glucosamine (GlcN, A), Chitobiose ([GlcN]2, B), Chitotrise ([GlcN]3, C), Chitotetraose ([GlcN]4, D) in Ganoderma lucidum chitin-glucan complex (GLCGC). In this mode, the molecular mass of [GlcN]1-4 was 180.1, 341.2, 502.2 and 663.3, respectively. Supplementary file2 (TIF 15451 kb)

12649_2022_1711_MOESM3_ESM.tif

Fig. S2 ATR-FTIR spectra of Ganoderma lucidum chitin-glucan complex (GLCGC) and Ganoderma lucidum chitin-glucan complex hydrogels GLCGCH 3, 4, 5. Supplementary file3 (TIF 475 kb)

Rights and permissions

About this article

Cite this article

Liu, Y., Zhang, C., Liu, L. et al. Characterization of Chitin-Glucan Complex of Ganoderma lucidum Extract and Its Application as Hemostatic Hydrogel. Waste Biomass Valor 13, 3297–3308 (2022). https://doi.org/10.1007/s12649-022-01711-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-022-01711-2