Abstract

Purpose

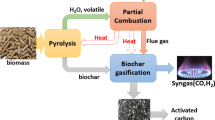

China is a big agricultural country and generates a large amount of biomass wastes every year. Biomass is the only renewable carbon source, which can produce biochar through pyrolysis under anaerobic or hypoxic conditions. Biochar has a rich pore structure, large specific surface area and special adsorption properties, and has been widely used in different industries. Different raw materials and pyrolysis conditions influence its yield and pore structure.

Methods

In our study, a flow chart was established in Aspen Plus V8.4 software to simulate the pyrolysis process of rice straw and sugarcane bagasse, and the feasibility of the model was verified by experiment. Finally, the Life Cycle Cost (LCC) method was used to evaluate the economics of the process of preparing biochar from 1 t rice straw and sugarcane bagasse.

Results

The simulated value of biochar yield is different from the experimental value. The difference is small at low temperature (300–500 °C), and relatively large at high temperature (600–800 °C), but both remain between 0.55 and 8.93%. Calculations indicate that the costs of rice straw and sugarcane bagasse biochar were 0.79 and 0.93 USD/kg, respectively.

Conclusion

Considering from the aspects of yield, pore structure, energy consumption, and economy of biochar, compared with sugarcane bagasse, rice straw has a more competitive advantage in the preparation of biochar.

Graphical Abstract

Similar content being viewed by others

References

Zhu, Z., Xu, Z.: The rational design of biomass-derived carbon materials towards next-generation energy storage: a review. Renew. Sustain. Energy Rev. 134, 110308 (2020). https://doi.org/10.1016/j.rser.2020.110308

Zhang, Z., Zhu, Z., Shen, B., Liu, L.: Insights into biochar and hydrochar production and applications: a review. Energy 171, 581–598 (2019). https://doi.org/10.1016/j.energy.2019.01.035

Zhu, Z., Rezende, C.A., Simister, R., McQueen-Mason, S.J., Macquarrie, D.J., Polikarpov, I., Gomez, L.D.: Efficient sugar production from sugarcane bagasse by microwave assisted acid and alkali pretreatment. Biomass Bioenergy 93, 269–278 (2016). https://doi.org/10.1016/j.biombioe.2016.06.017

Doula, M.K., Sarris, A., Hliaoutakis, A., Kydonakis, A., Papadopoulos, N.S., Argyriou, L.: Building a strategy for soil protection at local and regional scale-the case of agricultural wastes landspreading. Environ. Monit. Assess. 188, 141 (2016). https://doi.org/10.1007/s10661-016-5139-0

Abnisa, F., Wan Daud, W.M.A.: A review on co-pyrolysis of biomass: an optional technique to obtain a high-grade pyrolysis oil. Energy Convers. Manage. 87, 71–85 (2014). https://doi.org/10.1016/j.enconman.2014.07.007

Liu, Z., Zhou, X., Chen, X., Dai, C., Zhang, J., Zhang, Y.: Biosorption of clofibric acid and carbamazepine in aqueous solution by agricultural waste rice straw. J. Environ. Sci. 25, 2384–2395 (2013). https://doi.org/10.1016/S1001-0742(12)60324-6

Arregi, A., Amutio, M., Lopez, G., Bilbao, J., Olazar, M.: Evaluation of thermochemical routes for hydrogen production from biomass: a review. Energy Convers. Manage. 165, 696–719 (2018). https://doi.org/10.1016/j.enconman.2018.03.089

Yan, N., Chen, X.: Don’t waste seafood waste. Nature 524, 155–157 (2015). https://doi.org/10.1038/524155a

Lenihan, P., Orozco, A., O’Neill, E., Ahmad, M.N.M., Rooney, D.W., Walker, G.M.: Dilute acid hydrolysis of lignocellulosic biomass. Chem. Eng. J. 156, 395–403 (2016). https://doi.org/10.1016/j.cej.2009.10.061

Deng, L., Zhong, W., Wang, J., Zhang, P., Fang, H., Yao, L., Liu, X., Ren, X., Li, Y.: The enhancement of electrochemical capacitance of biomass-carbon by pyrolysis of extracted nanofibers. Electrochim. Acta 228, 398–406 (2017). https://doi.org/10.1016/j.electacta.2017.01.099

Imtiaz, S., Zhang, J., Zafar, Z.A., Ji, S., Huang, T., Anderson, J.A., Zhang, Z., Huang, Y.: Biomass-derived nanostructured porous carbons for lithium-sulfur batteries. Sci. China Mater. 59, 389–407 (2016). https://doi.org/10.1007/s40843-016-5047-8

Bird, M.I., Wurster, C.M., Silva, P.H.D.P., Bass, A.M., Nys, R.D.: Algal biochar-production and properties. Bioresour. Technol. 102, 1886 (2011). https://doi.org/10.1016/j.biortech.2010.07.106

Liang, B., Lehmann, J., Solomon, D., Kinyangi, J., Grossman, J., O’Neill, B., Skjemstad, J.O., Thies, J., LuizO, F.J., Petersen, J.: Black carbon increases cation exchange capacity in soils. Soil Sci. Soc. Am. J. 70, 1719–1730 (2006). https://doi.org/10.2136/sssaj2005.0383

Lin, X.W., Xie, Z.B., Zheng, J.Y., Liu, Q., Bei, Q.C., Zhu, J.G.: Effects of biochar application on greenhouse gas emissions, carbon sequestration and crop growth in coastal saline soil. Eur. J. Soil Sci. 66, 329–338 (2015). https://doi.org/10.1111/ejss.12225

Li, Y., Hu, H., Song, J., Wu, Y., Chen, Y.: An excellent Fe, N Co-doped porous biomass carbon oxygen reduction reaction electrocatalyst: effect of zinc-based activators on catalytic activity. Energy Technol. 80, 96–104 (2020). https://doi.org/10.1002/ente.202000625

Hou, J., University, T.R.: Study on the acid-reducing effect of biomass carbon on acid soil in new zanthoxylum orchard. Anhui Agric. Sci. Bull. 25, 106–107 (2019). https://doi.org/10.16377/j.cnki.issn1007-7731.2019.11.044

Plaza, M.G., García, S., Rubiera, F., Pis, J.J., Pevida, C.: Evaluation of ammonia modified and conventionally activated biomass based carbons as CO2 adsorbents in postcombustion conditions. Sep. Purif. Technol. 80, 96–104 (2011). https://doi.org/10.1016/j.seppur.2011.04.015

Xu, X., Meng, Z., Zhu, X., Zhang, S., Han, W.Q.: Biomass carbon composited FeS2 as cathode materials for high-rate rechargeable lithium-ion battery. J. Power Sources 380, 12–17 (2018). https://doi.org/10.1016/j.jpowsour.2018.01.057

Zhang, L., Xu, C., Champagne, P.: Overview of recent advances in thermo-chemical conversion of biomass. Energy Convers. Manage. 51, 969–982 (2010). https://doi.org/10.1016/j.enconman.2009.11.038

Gaskin, J.W., Steiner, C., Harris, K., Das, K.C., Bibens, B.: Effect of low-temperature pyrolysis conditions on biochar for agricultural use. Trans. ASABE 51, 2061–2069 (2008). https://doi.org/10.13031/2013.25409

Singh, B., Singh, B.P., Cowie, A.L.: Characterisation and evaluation of biochars for their application as a soil amendment. Soil Res. 48, 516–525 (2010). https://doi.org/10.1071/SR10058

Choi, H.S., Choi, Y.S., Park, H.C.: Fast pyrolysis characteristics of lignocellulosic biomass with varying reaction conditions. Renew. Energy 42, 131–135 (2012). https://doi.org/10.1016/j.renene.2011.08.049

Cao, J., Xiao, G., Xu, X., Jin, B.S.: Functional groups evolvement and charcoal formation during lignin pyrolysis/carbonization. J. Southeast Univ. (Engl. Ed.) 42, 83–87 (2012). https://doi.org/10.3969/j.issn.1001-0505.2012.01.016

Kazmerski, L.: Renewable and sustainable energy reviews. Renew. Sustain. Energy Rev. 38, 834–847 (2016). https://doi.org/10.1016/j.rser.2014.07.023

Chen, B., Zhou, D., Zhu, L.: Transitional adsorption and partition of nonpolar and polar aromatic contaminants by biochars of pine needles with different pyrolytic temperatures. Environ. Sci. Technol. 42, 5137–5143 (2008). https://doi.org/10.1021/es8002684

Niu, M., Liu, H., Zhang, Y., Zhou, J.: Relationship between the corn straw carbon and the carbonization temperature and time. J. Anhui Agric. Sci. 12, 25–27 (2016). https://doi.org/10.3969/j.issn.0517-6611.2016.12.008

Sun, X.F., Chen, Z.W., Li, Y.X., Ma, H.L., Gao, R., Yin, Y.F.: Influence of different pyrolysis temperatures on eight elements content of biochar. J. Fujian Normal Univ. (Natural Science Edition) 35, 55–61 (2019). https://doi.org/10.12046/j.issn.1000-5277.2019.01.008

Cantrell, K.B., Hunt, P.G., Uchimiya, M., Novak, J.M., Ro, K.S.: Impact of pyrolysis temperature and manure source on physicochemical characteristics of biochar. Bioresour. Technol. 107, 419–428 (2012). https://doi.org/10.1016/j.biortech.2011.11.084

Gai, X., Wang, H., Jian, L., Zhai, L., Liu, S., Ren, T., Liu, H., Coles, J.A.: Effects of feedstock and pyrolysis temperature on biochar adsorption of ammonium and nitrate. PLoS ONE 9, e113888 (2014). https://doi.org/10.1371/journal.pone.0113888

Pan, M.J., Sun, J., Qiang, H.E., Chen, W.Y.: The effect of pyrolysis temperature and heating rate on biochar obtained from pyrolysis of cotton stalk. J. Hebei Univ. Technol. 43, 60–66 (2014). https://doi.org/10.14081/j.cnki.hgdxb.2014.05.011

Chen, H., Lin, G., Wang, X., Chen, Y., Liu, Y., Yang, H., Shao, J.: Physicochemical properties and hygroscopicity of tobacco stem biochar pyrolyzed at different temperatures. J. Renew. Sustain. Energy 8, 1812 (2016). https://doi.org/10.1063/1.4942784

Saeed, S., Shafeeq, A., Raza, W., Ijaz, A., Saeed, S.: Thermal performance analysis of ionic liquid pretreated spent coffee ground using Aspen Plus. Chem. Eng. Technol. 43, 661 (2020). https://doi.org/10.1002/ceat.202000002

Treeyawetchakul, C.: Preliminary modified biodiesel production by coupling reactive distillation with a steam reformer via Aspen Plus. IOP Conf. Ser. Mater. Sci. Eng. 778, 012064 (2020). https://doi.org/10.1088/1757-899X/778/1/012064

Alnouss, A., Parthasarathy, P., Mackey, H.R., Al-Ansari, T., Mckay, G.: Pyrolysis study of different fruit wastes using an Aspen Plus model. Front. Sustain. Food Syst. 5, 4 (2021). https://doi.org/10.3389/fsufs.2021.604001

Quintero, J.A., Cardona, C.A.: Process simulation of fuel ethanol production from lignocellulosics using Aspen Plus. J. Ind. Eng. Chem. 50, 6205–6212 (2011). https://doi.org/10.1021/ie101767x

Oladokun, O., Nyakuma, B.B., Ivase, T.J.: Gasification of nigerian lignite coals under air-steam conditions using Aspen Plus for the production of hydrogen and syngas. Pet. Coal 63, 332–339 (2021)

María Pilar, G.V., Fernando, R., Covadonga, P., Daniel, T.P., Tarelho, L.A.C.: Thermodynamic analysis of biomass gasification using Aspen Plus: comparison of stoichiometric and non-stoichiometric models. Energies 14, 189 (2021). https://doi.org/10.3390/en14010189

Shi, X.: Study on the application of Aspen Plus in control of flue gas pollution. Energy Convers. Manage. 5, 2–5 (2017). https://doi.org/10.3969/j.issn.2095-0802.2017.05.002

Flagiello, D., Natale, F.D., Erto, A., Lancia, A.: Wet oxidation scrubbing (WOS) for flue-gas desulphurization using sodium chlorite seawater solutions. Fuel 277, 118055 (2020). https://doi.org/10.1016/j.fuel.2020.118055

Yang, Y., Brammer, J.G., Wright, D.G., Scott, J.A., Serrano, C., Bridgwater, A.V.: Combined heat and power from the intermediate pyrolysis of biomass materials: performance, economics and environmental impact. Appl. Energy 191, 639–652 (2017). https://doi.org/10.1016/j.apenergy.2017.02.004

Homagain, K., Shahi, C., Luckai, N., Sharma, M.: Life cycle cost and economic assessment of biochar-based bioenergy production and biochar land application in Northwestern Ontario, Canada. For. Ecosyst. 3, 21 (2017). https://doi.org/10.1186/s40663-016-0081-8

Sahoo, K., Upadhyay, A., Runge, T., Bergman, R., Puettmann, M., Bilek, E.: Life-cycle assessment and techno-economic analysis of biochar produced from forest residues using portable systems. Int. J. Life Cycle Assess. 26, 189–213 (2020). https://doi.org/10.1007/s11367-020-01830-9

Alhashimi, H.A., Aktas, C.B.: Life cycle environmental and economic performance of biochar compared with activated carbon: a meta-analysis. Resour. Conserv. Recycl. 118, 13–26 (2017). https://doi.org/10.1016/j.resconrec.2016.11.016

Harsono, S.S., Grundman, P., Lau, L.H., Hansen, A., Salleh, M.A.M., Meyer-Aurich, A., Idris, A., Ghazi, T.I.M.: Energy balances, greenhouse gas emissions and economics of biochar production from palm oil empty fruit bunches. Resour. Conserv. Recycl. 77, 108–115 (2013). https://doi.org/10.1016/j.resconrec.2013.04.005

Abbie, C., Andrew, B., John, M.D., Simon, S.: From rhetoric to reality: farmer perspectives on the economic potential of biochar in China. Int. J. Agric. Sustain. 12, 440–458 (2014). https://doi.org/10.1080/14735903.2014.927711

Adeniyi, A.G., Ighalo, J.O., Aderibigbe, F.A.: Modelling of integrated processes for the pyrolysis and steam reforming of rice husk (Oryza sativa). SN Appl. Sci. 1, 841 (2019). https://doi.org/10.1007/s42452-019-0877-6

Ward, J., Rasul, M.G., Bhuiya, M.M.K.: Energy recovery from biomass by fast pyrolysis. Proced. Eng. 90, 669–674 (2014). https://doi.org/10.1016/j.proeng.2014.11.791

Adeniyi, A.G., Ighalo, J.O., Amosa, M.K.: Modelling and simulation of banana (Musa spp.) waste pyrolysis for bio-oil production. Biofuels (2019). https://doi.org/10.1080/17597269.2018.1554949

Adeniyi, A.G., Ighalo, J.O., Abdulsalam, A.: Modeling of integrated processes for the recovery of the energetic content of sugar cane bagasse. Biofuels Bioprod. Biorefin. 13, 1–11 (2019). https://doi.org/10.1002/bbb.1998

Adeniyi, A.G., Otoikhian, K.S., Ighalo, J.O.: Steam reforming of biomass pyrolysis oil: a review. Int. J. Chem. React. Eng. (2019). https://doi.org/10.1515/ijcre-2018-0328

Peters, J.F., Iribarren, D., Dufour, J.: Predictive pyrolysis process modelling In Aspen Plus. In: European biomass conference and exhibition, (2014)

Cao, S.H., Hu, W.R., Fan, L.: Progress in the structure of lignin and its analyzing methods. Polym. Bull. 3, 8–13 (2012). https://doi.org/10.14028/j.cnki.1003-3726.2012.03.011

Zhang, Y., Ye, Y.Y., Fan, J., Chang, J.: Selective production of phenol, guaiacol and 2,6-dimethoxyphenol by alkaline hydrothermal conversion of lignin. J. Biobased Mater. Bioenergy 7, 696–701 (2013). https://doi.org/10.1166/jbmb.2013.1397

Kumar, P., Barrett, D.M., Delwiche, M.J., Stroeve, P.: Methods for pretreatment of lignocellulosic biomass for efficient hydrolysis and biofuel production. Ind. Eng. Chem. Res. 48, 3713–3729 (2009). https://doi.org/10.1021/ie801542g

Faravelli, T., Frassoldati, A., Migliavacca, G., Ranzi, E.: Detailed kinetic modeling of the thermal degradation of lignins. Biomass Bioenergy 34, 290–301 (2010). https://doi.org/10.1016/j.biombioe.2009.10.018

Yildiz, G., Ronsse, F., Venderbosch, R., Duren, R.V., Kersten, S., Prins, W.: Effect of biomass ash in catalytic fast pyrolysis of pine wood. Appl. Catal. B 168, 203–211 (2015). https://doi.org/10.1016/j.apcatb.2014.12.044

Shariff, A., Mohamad Aziz, N.S., Abdullah, N.: Slow pyrolysis of oil palm empty fruit bunches for biochar production and characterisation. J. Phys. Ther. Sci. 25, 97–112 (2014)

Kabir, M.J., Chowdhury, A.A., Rasul, M.G.: Pyrolysis of municipal green waste: a modelling, simulation and experimental analysis. Energies 8, 7522–7541 (2015). https://doi.org/10.3390/en8087522

Titiloye, J.O., Abu Bakar, M.S., Odetoye, T.E.: Thermochemical characterisation of agricultural wastes from West Africa. Ind. Crops Prod. 47, 199–203 (2013). https://doi.org/10.1016/j.indcrop.2013.03.011

Gómez, N., Banks, S.W., Nowakowski, D.J., Rosas, J.G., Cara, J., Sánchez, M., Bridgwater, A.V.: Effect of temperature on product performance of a high ash biomass during fast pyrolysis and its bio-oil storage evaluation. Fuel Process. Technol. 172, 97–105 (2017). https://doi.org/10.1016/j.fuproc.2017.11.021

Zhu, Z., Liu, Y., Gomez, L.D., Wei, T., Macquarrie, D.J.: Thermochemical pretreatments of maize stem for sugar recovery: comparative evaluation of microwave and conventional heating. Ind. Crops Prod. (2020). https://doi.org/10.1016/j.indcrop.2020.113106

Nooshin, R., Hooi Ling, F., Nor Aini Abdul, R., Arbakariya, A., Umi Kalsom, M.: Saccharification of rice straw by cellulase from a local Trichoderma harzianum SNRS3 for biobutanol production. BMC Biotechnol. (2014). https://doi.org/10.1186/s12896-014-0103-y

Zhang, Q.Z., Gai, W.M.: Enzymatic hydrolysis of alkali-pretreated rice straw by Trichoderma reesei ZM4-F3. Biomass Bioenergy 32, 1130–1135 (2008). https://doi.org/10.1016/j.biombioe.2008.02.006

Remli, N.M., Shah, U.M., Mohamad, R., Abd-Aziz, S.: Effects of chemical and thermal pretreatments on the enzymatic saccharification of rice straw for sugars production. BioResources 9, 510–522 (2014). https://doi.org/10.15376/biores.9.1.510-522

Xing, X., Sun, Z., Ma, P., Yu, J., Wu, Z.: Establishment of three components of biomass pyrolysis yield model. Energy Proced. 66, 293–296 (2015). https://doi.org/10.1016/j.egypro.2015.02.061

Liu, N., Huang, X.: Simulation and calculation for coal drying process by Aspen Plus. Coal Convers. 36, 65–67 (2013). https://doi.org/10.19726/j.cnki.ebcc.2013.01.015

Begum, S., Rasul, M., Akbar, D., Ramzan, N.: Performance analysis of an integrated fixed bed gasifier model for different biomass feedstocks. Energies 6, 6508–6524 (2013). https://doi.org/10.3390/en6126508

Tauqir, W., Zubair, M., Nazir, H.: Parametric analysis of a steady state equilibrium-based biomass gasification model for syngas and biochar production and heat generation. Energy Convers. Manage. 199, 111954 (2019). https://doi.org/10.1016/j.enconman.2019.111954

Burlington, M.: Getting started modeling processes with solids. Aspen Technol. (2010). http://profsite.um.ac.ir/~fanaei/_private/Solids%208_4.pdf. Accessed 3 Jan 2022

Yang, Y., Yan, H., Chen, R., Lee, H., Zheng, C.: Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 86, 1781–1788 (2007). https://doi.org/10.1016/j.fuel.2006.12.013

Smets, K., Roukaerts, A., Czech, J., Reggers, G., Schreurs, S., Carleer, R., Yperman, J.: Slow catalytic pyrolysis of rapeseed cake: product yield and characterization of the pyrolysis liquid. Biomass Bioenergy 57, 180–190 (2013). https://doi.org/10.1016/j.biombioe.2013.07.001

Zhao, B., O’Connor, D., Zhang, J., Peng, T., Zheng, T.: Effect of pyrolysis temperature, heating rate, and residence time on rapeseed stem derived biochar. J. Clean. Prod. 174, 977–987 (2018). https://doi.org/10.1016/j.jclepro.2017.11.013

Uchimiya, M., Wartelle, L.H., Klasson, K.T., Fortier, C.A., Lima, I.M.: Influence of pyrolysis temperature on biochar property and function as a heavy metal sorbent in soil. J. Agric. Food Chem. 59, 2501–2510 (2011). https://doi.org/10.1021/jf104206c

Wang, Y., Zhou, E., Wu, M.: Simulation analysis of natural gas auto thermal reforming to syngas by Aspen Plus. Coal Chem. Ind. 47(8–12), 22 (2019)

Sansaniwal, S.K., Pal, K., Rosen, M.A., Tyagi, S.K.: Recent advances in the development of biomass gasification technology: a comprehensive review. Renew. Sust. Energy Rev. 72, 363–384 (2017). https://doi.org/10.1016/j.rser.2017.01.038

Demirbas, A., Arin, G.N.: An overview of biomass pyrolysis. Energy Source 24, 475–482 (2002). https://doi.org/10.1016/s0140-6701(03)83069-2

Wu, S., Wang, X., Chen, C., Peng, B., Zhuang, Y.: Characterization of biochar derived from water hyacinth, rice straw and sewage sludge and their environmental implications. Acta entiae Circumstantiae 35, 4021–4032 (2015). https://doi.org/10.13671/j.hjkxxb.2015.0119

Chandra, S., Bhattacharya, J.: Influence of temperature and duration of pyrolysis on the property heterogeneity of rice straw biochar and optimization of pyrolysis conditions for its application in soils. J. Clean. Prod. 215, 1123–1139 (2019). https://doi.org/10.1016/j.jclepro.2019.01.079

Kameyama, K., Miyamoto, T., Iwata, Y., Shiono, T.: Effects of biochar produced from sugarcane bagasse at different pyrolysis temperatures on water retention of a calcaric dark red soil. Soil Sci. 181, 20–28 (2016). https://doi.org/10.1097/SS.0000000000000123

Moradi-Choghamarani, F., Moosavi, A.A., Sepaskhah, A.R., Baghernejad, M.: Physico-hydraulic properties of sugarcane bagasse-derived biochar: the role of pyrolysis temperature. Cellulose 26, 7125–7143 (2019)

Lin, X.Q., Lu, H.H., Liu, Y.X., Wang, Y.Y., Yang, S.M.: Effects of biomass and carbonization temperature on biochar yield and characteristics. Acta Agric. Univ. Zhejiang 39, 710–714 (2016). https://doi.org/10.3969/j.issn.1004-1524.2016.07.18

Altafini, C.R., Wander, P.R., Barreto, R.M.: Prediction of the working parameters of a wood waste gasifier through an equilibrium model. Energy Convers. Manage. 44, 2763–2777 (2003). https://doi.org/10.1016/s0196-8904(03)00025-6

Zheng, Z.W., Chen, B.G., Liu, G.F., Zhao, J.: Analysis of XRD spectral structure and carbonization of the biochar preparation. Spectrosc. Spectr. Anal. 36, 3355–3359 (2016). https://doi.org/10.3964/j.issn.1000-0593(2016)10-3355-05

Liao, C., Wu, C., Yan, Y., Huang, H.: Chemical elemental characteristics of biomass fuels in China. Biomass Bioenergy 27, 119–130 (2004). https://doi.org/10.1016/j.biombioe.2004.01.002

Saddawi, A., Jones, J.M., Williams, A.: Influence of alkali metals on the kinetics of the thermal decomposition of biomass. Fuel Process. Technol. 104, 189–197 (2012). https://doi.org/10.1016/j.fuproc.2012.05.014

Wei, J., Guo, Q., Ding, L., Gong, Y., Yu, J., Yu, G.: Understanding the effect of different biomass ash additions on pyrolysis product distribution, char physicochemical characteristics, and char gasification reactivity of bituminous coal. Energy Fuels 33, 3068–3076 (2019). https://doi.org/10.1021/acs.energyfuels.9b00064

Zhu, Z., Liu, Y., Cong, W., Zhao, X., Fang, Z.: Soybean biodiesel production using synergistic CaO/Ag nano catalyst: process optimization, kinetic study, and economic evaluation. Ind. Crops Prod. 166, 113479 (2021). https://doi.org/10.1016/j.indcrop.2021.113479

Roschat, W., Siritanon, T., Yoosuk, B., Promarak, V.: Biodiesel production from palm oil using hydrated lime-derived CaO as a low-cost basic heterogeneous catalyst. Energy Convers. Manage. 108, 459–467 (2016). https://doi.org/10.1016/j.enconman.2015.11.036

Ahmad, M., Usman, A.R., Rafique, M.I., Al-Wabel, M.I.: Engineered biochar composites with zeolite, silica, and nano-zerovalent iron for the efficient scavenging of chlortetracycline from aqueous solutions. Environ. Sci. Pollut. Res. 26, 15136–15152 (2019). https://doi.org/10.1007/s11356-019-04850-7

Fan, X., Guo, X., Wang, X., Wang, H., Jiang, Z., Xing, Y.: Study on the modification of nutshell biochar and Its sorption mechanism for DEP. J. Soil Water Conserv. 35(336–345), 353 (2021). https://doi.org/10.13870/j.cnki.stbcxb.2021.05.045

Lu, L., Wang, J., Chen, B.: Adsorption and desorption of phthalic acid esters on graphene oxide and reduced graphene oxide as affected by humic acid. Environ. Pollut. 232, 505–513 (2018). https://doi.org/10.1016/j.envpol.2017.09.078

Liu, Y., Yang, X., Adamu, A., Zhu, Z.: Economic evaluation and production process simulation of biodiesel production from waste cooking oil. Curr. Res. Green Sustain. Chem. 4, 100091 (2021). https://doi.org/10.1016/j.crgsc.2021.100091

Sesana, M.M., Salvalai, G.: Overview on life cycle methodologies and economic feasibility for nZEBs. Build Environ. 67, 211–216 (2013). https://doi.org/10.1016/j.buildenv.2013.05.022

Li, L., Ma, X., Xie, M., Liao, Y.: Full life cycle assessment on wind power generation system. Chinese J. Turbomach. 57, 65–70 (2015). https://doi.org/10.16492/j.fjjs.2015.02.067

Wang, X.: Analysis on environmental benefit of wind turbines using life cycle assessment-case study of some wind farm in inner mongolia. Sci. Technol. Manage. Res. 32, 259–262 (2012). https://doi.org/10.3969/j.issn.1000-7695.2012.18.057

Zou, Z., Ma, X., Zhao, Z., Li, H., Chen, Y.: Life cycle assessment on the hydropower project. Water Power 30, 53–55 (2004). https://doi.org/10.3969/j.issn.0559-9342.2004.04.016

Acknowledgements

We acknowledge the financial supports from Jiangsu University of Science and Technology (1142931706) and Natural Science Foundation of the Higher Education Institution of Jiangsu Province (20KJB480009).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, Y., Yang, X., Zhang, J. et al. Process Simulation of Preparing Biochar by Biomass Pyrolysis Via Aspen Plus and Its Economic Evaluation. Waste Biomass Valor 13, 2609–2622 (2022). https://doi.org/10.1007/s12649-021-01671-z

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-021-01671-z