Abstract

The chemical looping technology is an emerging technology for the efficient conversion of biomass to heat, power, fuel, and value-added chemicals. Chemical looping uses a metal oxide oxygen carrier to fully or partially oxidize the biomass feedstock, which avoids N2 dilution to the CO2 or syngas product. Thus, chemical looping technology can convert biomass to sequestration-ready CO2 or high purity syngas, which leads to the potential for negative carbon emission and enhanced energy efficiency in biomass conversions. Various chemical looping processes for biomass conversions, using different oxygen carrier materials and reactor designs, have been studied ranging from lab scale to pilot scale. This article reviews the current state of development in the scale-up of chemical looping technology for biomass conversions. It also provides perspectives on the chemical looping technology of relevance to various biomass conversion issues including CO2 capture, utilization and sequestration, biomass feedstock collection, handling and conversion enhancement, choice of reaction schemes, fuel and air reactor designs and operation, operational load variation, fate of pollutants and effect of ashes. Representative process configurations, reactor designs, oxygen carrier material selections, and the testing results are described along with the technology challenges, their potential solutions, and future research needs.

Graphic Abstract

Similar content being viewed by others

Data Availability

Not applicable.

Code Availability

Not applicable.

Abbreviations

- AR:

-

Air reactor

- ASU:

-

Air separation unit

- CCUS:

-

Carbon capture, utilization, and sequestration

- CFB:

-

Circulating fluidized bed

- CLC:

-

Chemical looping combustion

- CLG:

-

Chemical looping gasification

- CLOU:

-

Chemical looping with oxygen uncoupling

- CLR:

-

Chemical looping reforming

- FR:

-

Fuel reactor

- GHG:

-

Green-house gas

- iG-CLC:

-

In-situ gasification CLC

- kW:

-

Kilowatt

- MW:

-

Megawatt

- SR:

-

Steam reactor

- \({X}_{C}\) :

-

FR carbon conversion

- \({x}_{SG}\) :

-

Syngas purity

- \({X}_{O}\) :

-

Oxygen carrier conversion

- \({Y}_{{\rm H}_{2}}, {Y}_{\rm CO}, {Y}_{SG}\) :

-

H2/CO/synthesis gas yield

- \({\eta }_{CC}\) :

-

Carbon capture efficiency

- \({\eta }_{SF}\) :

-

Solid fuel conversion, carbon conversion efficiency

- \({\eta }_{C,FR}\) :

-

Fuel gasification portion

- \({\eta }_{C,AR}\) :

-

Fuel combustion portion

- \({\eta }_{OO}\) :

-

Oxide oxygen efficiency

- \({\eta }_{gas}\) :

-

Gas conversion

- \({\eta }_{comb,O}\) :

-

FR combustion efficiency (oxygen based)

- \({\eta }_{fuel}\) :

-

Degree of fuel oxidation

- \({\eta }_{comb,HV}\) :

-

FR combustion efficiency (heating value based)

- \({\eta }_{{\rm CO}_{2}}\) :

-

CO2 yield, CO2 conversion efficiency

- \({\eta }_{CG}\) :

-

Cold gas efficiency

- \(\Phi\) :

-

Oxygen carrier to fuel ratio

- \(\lambda\) :

-

Air excess ratio

- \({\Omega }_{T}\) :

-

Total oxygen demand

- \({\Omega }_{OD}\) :

-

FR oxygen demand

References

Stocker, T.F., Qin, D., Plattner, G.-K., Tignor, M.M.B., Allen, S.K., Boschung, J., Nauels, A., Xia, Y., Bex, V., Midgley, P.M.: Climate Change 2013 The Physical Science Basis Working Group I Contribution to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change (2013)

Edenhofer, O., Pichs-Madruga, R., Sokona, Y., Minx, J.C., Farahani, E., Kadner, S., Seyboth, K., Adler, A., Baum, I., Brunner, S., Eickemeier, P., Schlömer, S., von Stechow, C., Zwickel, T.: Climate Change 2014 Mitigation of Climate Change Working Group III Contribution to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change (2014)

Rhodes, J.S., Keith, D.W.: Engineering economic analysis of biomass IGCC with carbon capture and storage. Biomass Bioenerg. 29, 440–450 (2005). https://doi.org/10.1016/j.biombioe.2005.06.007

Kraxner, F., Nilsson, S., Obersteiner, M.: Negative emissions from BioEnergy use, carbon capture and sequestration (BECS): the case of biomass production by sustainable forest management from semi-natural temperate forests. In: Biomass and Bioenergy. pp. 285–296. Pergamon (2003)

Tilman, D., Hill, J., Lehman, C.: Carbon-negative biofuels from low-input high-diversity grassland biomass. Science 314, 1598–1600 (2006). https://doi.org/10.1126/science.1133306

Sanchez, D.L., Nelson, J.H., Johnston, J., Mileva, A., Kammen, D.M.: Biomass enables the transition to a carbon-negative power system across western North America. Nat. Clim. Chang. 5, 230–234 (2015). https://doi.org/10.1038/nclimate2488

Share of renewable energy in gross final energy consumption in Europe—European Environment Agency, https://www.eea.europa.eu/data-and-maps/indicators/renewable-gross-final-energy-consumption-4/assessment-4

Energy Information Administration, U.: International Energy Outlook 2019 (2019)

Facts and figures on bioenergy in the EU | EU Science Hub, https://ec.europa.eu/jrc/en/science-update/facts-and-figures-bioenergy-eu

Khan, A.A., de Jong, W., Jansens, P.J., Spliethoff, H.: Biomass combustion in fluidized bed boilers: potential problems and remedies. Fuel Process. Technol. 90, 21–50 (2009). https://doi.org/10.1016/j.fuproc.2008.07.012

Koppejan, J., Van Loo, S.: The handbook of biomass combustion and co-firing. Routledge (2012)

Sikarwar, V.S., Zhao, M., Clough, P., Yao, J., Zhong, X., Memon, M.Z., Shah, N., Anthony, E.J., Fennell, P.S.: An overview of advances in biomass gasification, www.rsc.org/ees (2016)

Saxena, R.C., Adhikari, D.K., Goyal, H.B.: Biomass-based energy fuel through biochemical routes: a review (2009)

Srirangan, K., Akawi, L., Moo-Young, M., Chou, C.P.: Towards sustainable production of clean energy carriers from biomass resources. Appl. Energy. 100, 172–186 (2012). https://doi.org/10.1016/j.apenergy.2012.05.012

Paisley, M.A., Anson, D.: Biomass gasification for gas turbine-based power generation. J. Eng. Gas Turbines Power. 120, 284–288 (1998). https://doi.org/10.1115/1.2818118

Maniatis, K.: Progress in biomass gasification: an overview. Prog. Thermochem. biomass Convers. 1 (2008)

Nieminen, J., Kivela, M.: Biomass CFB gasifier connected to a 350 MW(TH) steam boiler fired with coal and natural gas—thermie demonstration project in lahti in Finland. In: Biomass and Bioenergy. pp. 251–257. Elsevier Sci Ltd (1998)

Ciferno, J.P., Marano, J.J.: Benchmarking biomass gasification technologies for fuels, chemicals and hydrogen production prepared for (2002)

Basu, P.: Biomass Gasification, Pyrolysis and Torrefaction: Practical Design and Theory. Academic Press, London (2018)

Zhao, X., Zhou, H., Sikarwar, V.S., Zhao, M., Park, A.H.A., Fennell, P.S., Shen, L., Fan, L.-S.: Biomass-based chemical looping technologies: the good, the bad and the future. Energy Environ. Sci. 10, 1885–1910 (2017). https://doi.org/10.1039/c6ee03718f

Mendiara, T., García-Labiano, F., Abad, A., Gayán, P., de Diego, L.F., Izquierdo, M.T., Adánez, J.: Negative CO2 emissions through the use of biofuels in chemical looping technology: a review (2018)

Song, T., Shen, L.: Review of reactor for chemical looping combustion of solid fuels (2018)

Lin, Y., Wang, H., Wang, Y., Huo, R., Huang, Z., Liu, M., Wei, G., Zhao, Z., Li, H., Fang, Y.: Review of biomass chemical looping gasification in China. Energy Fuels (2020). https://doi.org/10.1021/acs.energyfuels.0c01022

Kobayashi, N., Fan, L.-S.: Biomass direct chemical looping process: a perspective. Biomass Bioenerg. 35, 1252–1262 (2011). https://doi.org/10.1016/j.biombioe.2010.12.019

Li, F., Zeng, L., Fan, L.-S.: Biomass direct chemical looping process: process simulation. Fuel 89, 3773–3784 (2010). https://doi.org/10.1016/j.fuel.2010.07.018

Lyngfelt, A., Brink, A., Langørgen, Ø., Mattisson, T., Rydén, M., Linderholm, C.: 11,000 h of chemical-looping combustion operation—where are we and where do we want to go? (2019)

Mattisson, T., Keller, M., Linderholm, C., Moldenhauer, P., Rydén, M., Leion, H., Lyngfelt, A.: Chemical-looping technologies using circulating fluidized bed systems: status of development (2018)

Fan, L.-S.: Chemical looping systems for fossil energy conversions. Wiley, Chichester (2010)

Lyngfelt, A., Linderholm, C.: Chemical-looping combustion of solid fuels: status and recent progress. In: Energy Procedia. pp. 371–386. Elsevier Ltd (2017)

Breault, R.W.: Handbook of Chemical Looping Technology. Wiley, Chichester (2018)

Udomsirichakorn, J., Salam, P.A.: Review of hydrogen-enriched gas production from steam gasification of biomass: the prospect of CaO-based chemical looping gasification (2014)

Fan, L.-S.: Chemical Looping Partial Oxidation: Gasification, Reforming, and Chemical Syntheses. Cambridge University Press, Cambridge (2017)

Hsieh, T.L., Xu, D., Zhang, Y., Nadgouda, S., Wang, D., Chung, C., Pottimurphy, Y., Guo, M., Chen, Y.Y., Xu, M., He, P., Fan, L.-S., Tong, A.: 250 kWth high pressure pilot demonstration of the syngas chemical looping system for high purity H2 production with CO2 capture. Appl. Energy. 230, 1660–1672 (2018). https://doi.org/10.1016/j.apenergy.2018.09.104

Fan, L.-S., Zeng, L., Luo, S.: Chemical-looping technology platform. AIChE J. 61, 2–22 (2015). https://doi.org/10.1002/aic.14695

Cormos, C.C.: Biomass direct chemical looping for hydrogen and power co-production: process configuration, simulation, thermal integration and techno-economic assessment. Fuel Process. Technol. 137, 16–23 (2015). https://doi.org/10.1016/j.fuproc.2015.04.001

Ekström, C., Schwendig, F., Biede, O., Franco, F., Haupt, G., de Koeijer, G., Papapavlou, C., Røkke, P.E.: Techno-economic evaluations and benchmarking of pre-combustion CO2 capture and oxy-fuel processes developed in the European ENCAP project. In: Energy Procedia. pp. 4233–4240. Elsevier (2009)

Vargas, L.: Commercialization of an atmospheric iron-based CDCL process for power production. Phase I: technoeconomic analysis. Babcock & Wilcox Power Generation Group, Incorporated (2013)

Kathe, M., Xu, D., Hsieh, T.-L., Simpson, J., Statnick, R., Tong, A., Fan, L.-S.: Chemical looping gasification for hydrogen enhanced syngas production with in-situ CO2 capture (2014)

Keller, M., Kaibe, K., Hatano, H., Otomo, J.: Techno-economic evaluation of BECCS via chemical looping combustion of Japanese woody biomass. Int. J. Greenh. Gas Control. 83, 69–82 (2019). https://doi.org/10.1016/j.ijggc.2019.01.019

Ohlemüller, P., Ströhle, J., Epple, B.: Chemical looping combustion of hard coal and torrefied biomass in a 1 MWth pilot plant. Int. J. Greenh. Gas Control. 65, 149–159 (2017). https://doi.org/10.1016/j.ijggc.2017.08.013

Jiang, S., Shen, L., Niu, X., Ge, H., Gu, H.: Chemical looping co-combustion of sewage Sludge and Zhundong coal with natural hematite as the oxygen carrier. Energy Fuels 30, 1720–1729 (2016). https://doi.org/10.1021/acs.energyfuels.5b02283

Adánez-Rubio, I., Pérez-Astray, A., Abad, A., Gayán, P., De Diego, L.F., Adánez, J.: Chemical looping with oxygen uncoupling: an advanced biomass combustion technology to avoid CO2 emissions. Mitig. Adapt. Strateg. Glob. Chang. 24, 1293–1306 (2019). https://doi.org/10.1007/s11027-019-9840-5

Penthor, S., Mayer, K., Kern, S., Kitzler, H., Wöss, D., Pröll, T., Hofbauer, H.: Chemical-looping combustion of raw syngas from biomass steam gasification—coupled operation of two dual fluidized bed pilot plants. Fuel 127, 178–185 (2014). https://doi.org/10.1016/j.fuel.2014.01.062

Niu, X., Shen, L., Gu, H., Jiang, S., Xiao, J.: Characteristics of hematite and fly ash during chemical looping combustion of sewage sludge. Chem. Eng. J. 268, 236–244 (2015). https://doi.org/10.1016/j.cej.2015.01.063

Gu, H., Shen, L., Xiao, J., Zhang, S., Song, T.: Chemical looping combustion of biomass/coal with natural iron ore as oxygen carrier in a continuous reactor. Energy Fuels 25, 446–455 (2011). https://doi.org/10.1021/ef101318b

Shen, L., Wu, J., Xiao, J., Song, Q., Xiao, R.: Chemical-looping combustion of biomass in a 10 kWth reactor with iron oxide as an oxygen carrier. Energy Fuels 23, 2498–2505 (2009). https://doi.org/10.1021/ef900033n

Jiang, S., Shen, L., Yan, J., Ge, H., Song, T.: Performance in coupled fluidized beds for chemical looping combustion of CO and biomass using hematite as an oxygen carrier. Energy Fuels 32, 12721–12729 (2018). https://doi.org/10.1021/acs.energyfuels.8b02861

Yan, J., Shen, L., Jiang, S., Wu, J., Shen, T., Song, T.: Combustion performance of sewage sludge in a novel CLC system with a two-stage fuel reactor. Energy Fuels 31, 12570–12581 (2017). https://doi.org/10.1021/acs.energyfuels.7b02493

Mendiara, T., Pérez-Astray, A., Izquierdo, M.T., Abad, A., de Diego, L.F., García-Labiano, F., Gayán, P., Adánez, J.: Chemical looping combustion of different types of biomass in a 0.5 kWth unit. Fuel 211, 868–875 (2018). https://doi.org/10.1016/j.fuel.2017.09.113

Adánez-Rubio, I., Abad, A., Gayán, P., De Diego, L.F., García-Labiano, F., Adánez, J.: Biomass combustion with CO2 capture by chemical looping with oxygen uncoupling (CLOU). Fuel Process. Technol. 124, 104–114 (2014). https://doi.org/10.1016/j.fuproc.2014.02.019

Adánez-Rubio, I., Pérez-Astray, A., Mendiara, T., Izquierdo, M.T., Abad, A., Gayán, P., de Diego, L.F., García-Labiano, F., Adánez, J.: Chemical looping combustion of biomass: CLOU experiments with a Cu-Mn mixed oxide. Fuel Process. Technol. 172, 179–186 (2018). https://doi.org/10.1016/j.fuproc.2017.12.010

Mendiara, T., Abad, A., de Diego, L.F., García-Labiano, F., Gayán, P., Adánez, J.: Biomass combustion in a CLC system using an iron ore as an oxygen carrier. Int. J. Greenh. Gas Control. 19, 322–330 (2013). https://doi.org/10.1016/j.ijggc.2013.09.012

Schmitz, M., Linderholm, C.: Chemical looping combustion of biomass in 10- and 100-kW pilots: analysis of conversion and lifetime using a sintered manganese ore. Fuel 231, 73–84 (2018). https://doi.org/10.1016/j.fuel.2018.05.071

Moldenhauer, P., Linderholm, C., Rydén, M., Lyngfelt, A.: Experimental investigation of chemical-looping combustion and chemical-looping gasification of biomass-based fuels using steel converter slag as oxygen carrier. In: Proceedings of the international conference on negative CO2 emissions. pp. 1–17 (2018)

Gogolev, I., Soleimanisalim, A.H., Linderholm, C., Lyngfelt, A.: Commissioning, performance benchmarking, and investigation of alkali emissions in a 10 kWth solid fuel chemical looping combustion pilot. Fuel 287, 119530 (2021). https://doi.org/10.1016/j.fuel.2020.119530

Mei, D., Soleimanisalim, A.H., Linderholm, C., Lyngfelt, A., Mattisson, T.: Reactivity and lifetime assessment of an oxygen releasable manganese ore with biomass fuels in a 10 kWth pilot rig for chemical looping combustion. Fuel Process. Technol. 215, 106743 (2021). https://doi.org/10.1016/j.fuproc.2021.106743

Gogolev, I., Pikkarainen, T., Kauppinen, J., Linderholm, C., Steenari, B.M., Lyngfelt, A.: Investigation of biomass alkali release in a dual circulating fluidized bed chemical looping combustion system. Fuel 297, 120743 (2021). https://doi.org/10.1016/j.fuel.2021.120743

Gogolev, I., Linderholm, C., Gall, D., Schmitz, M., Mattisson, T., Pettersson, J.B.C., Lyngfelt, A.: Chemical-looping combustion in a 100 kW unit using a mixture of synthetic and natural oxygen carriers: operational results and fate of biomass fuel alkali. Int. J. Greenh. Gas Control. 88, 371–382 (2019). https://doi.org/10.1016/j.ijggc.2019.06.020

Corcoran, A., Marinkovic, J., Lind, F., Thunman, H., Knutsson, P., Seemann, M.: Ash properties of ilmenite used as bed material for combustion of biomass in a circulating fluidized bed boiler. Energy Fuels 28, 7672–7679 (2014). https://doi.org/10.1021/ef501810u

Berdugo Vilches, T., Lind, F., Rydén, M., Thunman, H.: Experience of more than 1000 h of operation with oxygen carriers and solid biomass at large scale. Appl. Energy. 190, 1174–1183 (2017). https://doi.org/10.1016/j.apenergy.2017.01.032

Thunman, H., Lind, F., Breitholtz, C., Berguerand, N., Seemann, M.: Using an oxygen-carrier as bed material for combustion of biomass in a 12-MWth circulating fluidized-bed boiler. Fuel 113, 300–309 (2013). https://doi.org/10.1016/j.fuel.2013.05.073

Samprón, I., Luis, F., García-Labiano, F., Izquierdo, M.T., Abad, A., Adánez, J.: Biomass chemical looping gasification of pine wood using a synthetic Fe2O3/Al2O3 oxygen carrier in a continuous unit. Biores. Technol. (2020). https://doi.org/10.1016/j.biortech.2020.123908

Condori, O., García-Labiano, F., Luis, F., Izquierdo, M.T., Abad, A., Adánez, J.: Biomass chemical looping gasification for syngas production using ilmenite as oxygen carrier in a 1.5 kWth unit. Chem. Eng. J. (2021). https://doi.org/10.1016/j.cej.2020.126679

Zeng, J., Xiao, R., Zhang, H., Wang, Y., Zeng, D., Ma, Z.: Chemical looping pyrolysis-gasification of biomass for high H2/CO syngas production. Fuel Process. Technol. 168, 116–122 (2017). https://doi.org/10.1016/j.fuproc.2017.08.036

Ge, H., Guo, W., Shen, L., Song, T., Xiao, J.: Biomass gasification using chemical looping in a 25 kWth reactor with natural hematite as oxygen carrier. Chem. Eng. J. 286, 174–183 (2016). https://doi.org/10.1016/j.cej.2015.10.092

Ge, H., Guo, W., Shen, L., Song, T., Xiao, J.: Experimental investigation on biomass gasification using chemical looping in a batch reactor and a continuous dual reactor. Chem. Eng. J. 286, 689–700 (2016). https://doi.org/10.1016/j.cej.2015.11.008

Ge, H., Shen, L., Feng, F., Jiang, S.: Experiments on biomass gasification using chemical looping with nickel-based oxygen carrier in a 25 kWth reactor. Appl. Therm. Eng. 85, 52–60 (2015). https://doi.org/10.1016/j.applthermaleng.2015.03.082

Wei, G., He, F., Huang, Z., Zheng, A., Zhao, K., Li, H.: Continuous operation of a 10 kWth chemical looping integrated fluidized bed reactor for gasifying biomass using an iron-based oxygen carrier. Energy Fuels 29, 233–241 (2015). https://doi.org/10.1021/ef5021457

Wei, G., He, F., Zhao, Z., Huang, Z., Zheng, A., Zhao, K., Li, H.: Performance of Fe-Ni bimetallic oxygen carriers for chemical looping gasification of biomass in a 10 kWth interconnected circulating fluidized bed reactor. Int. J. Hydrogen Energy. 40, 16021–16032 (2015). https://doi.org/10.1016/j.ijhydene.2015.09.128

Huseyin, S., Wei, G.Q., Li, H., He, F., Huang, Z.: Chemical-looping gasification of biomass in a 10 kWth interconnected fluidized bed reactor using Fe2O3/Al2O3 oxygen carrier. J. Fuel Chem. Technol. 42, 922–931 (2014). https://doi.org/10.1016/s1872-5813(14)60039-6

Xu, D., Zhang, Y., Hsieh, T.L., Guo, M., Qin, L., Chung, C., Fan, L.-S., Tong, A.: A novel chemical looping partial oxidation process for thermochemical conversion of biomass to syngas. Appl. Energy. 222, 119–131 (2018). https://doi.org/10.1016/j.apenergy.2018.03.130

Fan, L.-S., Tong, A.: Biomass gasification for chemicals production using chemical looping techniques. In: DOE Bioenergy Technologies Office (BETO) 2019 Project Peer Review Advanced Development and Optimization: Integration and Scale-Up (2019)

Mendiara, T., Adánez-Rubio, I., Gayán, P., Abad, A., Diego, L.F., García-Labiano, F., Adánez, J.: Process comparison for biomass combustion. In situ gasification-chemical looping combustion (iG-CLC) versus chemical looping with oxygen uncoupling (CLOU). Energy Technol. 4, 1130–1136 (2016). https://doi.org/10.1002/ente.201500458

Luo, S., Majumder, A., Chung, E., Xu, D., Bayham, S., Sun, Z., Zeng, L., Fan, L.-S.: Conversion of woody biomass materials by chemical looping process—kinetics, light tar cracking, and moving bed reactor behavior. In: Industrial and Engineering Chemistry Research. pp. 14116–14124. American Chemical Society (2013)

Gu, H., Shen, L., Zhang, S., Niu, M., Sun, R., Jiang, S.: Enhanced fuel conversion by staging oxidization in a continuous chemical looping reactor based on iron ore oxygen carrier. Chem. Eng. J. 334, 829–836 (2018). https://doi.org/10.1016/j.cej.2017.10.066

Mims, C.A., Pabst, J.K.: Alkali-catalyzed carbon gasification kinetics: unification of H2O, D2O, and CO2 reactivities. J. Catal. 107, 209–220 (1987). https://doi.org/10.1016/0021-9517(87)90286-7

Zhang, S., Gu, H., Zhao, J., Shen, L., Wang, L.: Development of iron ore oxygen carrier modified with biomass ash for chemical looping combustion. Energy 186, 115893 (2019). https://doi.org/10.1016/j.energy.2019.115893

Yan, J., Shen, L., Ou, Z., Wu, J., Jiang, S., Gu, H.: Enhancing the performance of iron ore by introducing K and Na ions from biomass ashes in a CLC process. Energy 167, 168–180 (2019). https://doi.org/10.1016/j.energy.2018.09.075

Gu, H., Shen, L., Zhong, Z., Zhou, Y., Liu, W., Niu, X., Ge, H., Jiang, S., Wang, L.: Interaction between biomass ash and iron ore oxygen carrier during chemical looping combustion. Chem. Eng. J. 277, 70–78 (2015). https://doi.org/10.1016/j.cej.2015.04.105

Yan, J., Sun, R., Shen, L., Bai, H., Jiang, S., Xiao, Y., Song, T.: Hydrogen-rich syngas production with tar elimination via biomass chemical looping gasification (BCLG) using BaFe2O4/Al2O3 as oxygen carrier. Chem. Eng. J. 387, 124107 (2020). https://doi.org/10.1016/j.cej.2020.124107

Li, X., Wang, L., Zhang, B., Khajeh, A., Shahbazi, A.: Iron oxide supported on silicalite-1 as a multifunctional material for biomass chemical looping gasification and syngas upgrading. Chem. Eng. J. 401, 125943 (2020). https://doi.org/10.1016/j.cej.2020.125943

Abad, A., Adánez, J., Gayán, P., de Diego, L.F., García-Labiano, F., Sprachmann, G.: Conceptual design of a 100 MWthCLC unit for solid fuel combustion. Appl. Energy. 157, 462–474 (2015). https://doi.org/10.1016/j.apenergy.2015.04.043

Lyngfelt, A., Leckner, B.: A 1000 MWth boiler for chemical-looping combustion of solid fuels: discussion of design and costs. Appl. Energy. 157, 475–487 (2015). https://doi.org/10.1016/j.apenergy.2015.04.057

Zeng, L., Cheng, Z., Fan, J.A., Fan, L.-S., Gong, J.: Metal oxide redox chemistry for chemical looping processes. Nat. Rev. Chem. 2(11), 349–364 (2018). https://doi.org/10.1038/s41570-018-0046-2

Joshi, A., Shah, V., Mohapatra, P., Kumar, S., Joshi, R.K., Kathe, M., Qin, L., Tong, A., Fan, L.-S.: Chemical looping-a perspective on the next-gen technology for efficient fossil fuel utilization. Adv. Appl. Energy (2021). https://doi.org/10.1016/j.adapen.2021.100044

Qin, L., Cheng, Z., Baser, D., Goldenbaum, T., Fan, J.A., Fan, L.-S.: Cyclic redox scheme towards shale gas reforming: a review and perspectives. React. Chem. Eng. 5(12), 2204–2220 (2020). https://doi.org/10.1039/D0RE00301H

Fan, C., Cui, Z., Wang, J., Liu, Z., Tian, W.: Exergy analysis and dynamic control of chemical looping combustion for power generation system. Energy Convers. Manag. 228, 113728 (2021)

Zhang, Y., Pan, J., Wang, D., Xu, D., Tong, A., Fan, L.-S.: Design of fluidized bed combustor reactor in chemical looping combustion: hydrodynamic and heat transfer properties. In: AIChE Annual Meeting. AIChE (2019)

Naqvi, R., Wolf, J., Bolland, O.: Part-load analysis of a chemical looping combustion (CLC) combined cycle with CO2 capture. Energy 32, 360–370 (2007). https://doi.org/10.1016/j.energy.2006.07.011

Marx, K., Bertsch, O., Pröll, T., Hofbauer, H.: Next scale chemical looping combustion: Process integration and part load investigations for a 10MW demonstration unit. In: Energy Procedia. pp. 635–644. Elsevier Ltd (2013)

Chung, C., Pottimurthy, Y., Xu, M., Hsieh, T.L., Xu, D., Zhang, Y., Chen, Y.Y., He, P., Pickarts, M., Fan, L.S., Tong, A.: Fate of sulfur in coal-direct chemical looping systems. Appl. Energy. 208, 678–690 (2017). https://doi.org/10.1016/j.apenergy.2017.09.079

Acknowledgements

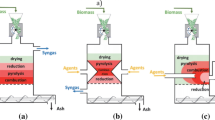

Figure 3a is reprinted from Int. J. Greenh. Gas Control., Vol 19, Mendiara, T., Abad, A., de Diego, L.F., García-Labiano, F., Gayán, P., Adánez, J. Biomass combustion in a CLC system using an iron ore as an oxygen carrier, pp. 322–330, Copyright (2013), with permission from Elsevier. Figure 3b is reprinted with permission from Shen, L., Wu, J., Xiao, J., Song, Q., Xiao, R.: Chemical-looping combustion of biomass in a 10 kWth reactor with iron oxide as an oxygen carrier. Energy and Fuels. 23, 2498–2505 (2009). https://doi.org/10.1021/ef900033n. Copyright 2009 American Chemical Society. Figure 3c is reprinted from Int. J. Greenh. Gas Control., Vol 88, Gogolev, I., Linderholm, C., Gall, D., Schmitz, M., Mattisson, T., Pettersson, J.B.C., Lyngfelt, A., Chemical-looping combustion in a 100 kW unit using a mixture of synthetic and natural oxygen carriers – Operational results and fate of biomass fuel alkali, pp. 371–382, Copyright (2019), with permission from Elsevier. Figure 3d is reprinted from Fuel, Vol 231, Schmitz, M., Linderholm, C, Chemical looping combustion of biomass in 10- and 100-kW pilots—Analysis of conversion and lifetime using a sintered manganese ore, pp 73–84, Copyright (2018), with permission from Elsevier. Figure 3e is reprinted from J., Epple, B., Vol 65, Ohlemüller, P., Ströhle, Chemical looping combustion of hard coal and torrefied biomass in a 1 MWth pilot plant, pp. 149–159, Copyright (2017), with permission from Elsevier. Figure 3f is reprinted with permission from Yan, J., Shen, L., Jiang, S., Wu, J., Shen, T., Song, T.: Combustion Performance of Sewage Sludge in a Novel CLC System with a Two-Stage Fuel Reactor. Energy and Fuels. 31, 12,570–12,581 (2017). https://doi.org/10.1021/acs.energyfuels.7b02493. Copyright 2017 American Chemical Society. Figure 5 is reprinted from Appl. Energy., Vol 190, Berdugo Vilches, T., Lind, F., Rydén, M., Thunman, H., Experience of more than 1000 h of operation with oxygen carriers and solid biomass at large scale, pp 1174–1183, Copyright (2017), with permission from Elsevier.

Funding

No funds, grants, or other support was received.

Author information

Authors and Affiliations

Contributions

Dikai Xu performed the literature search, data analysis, and drafted the manuscript. Andrew Tong and Liang-Shih Fan critically revised the work.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xu, D., Tong, A. & Fan, LS. State of Scale-Up Development in Chemical Looping Technology for Biomass Conversions: A Review and Perspectives. Waste Biomass Valor 13, 1363–1383 (2022). https://doi.org/10.1007/s12649-021-01563-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-021-01563-2