Abstract

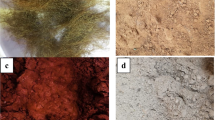

The traditional firing process to manufacture building bricks is not sustainable because of the high firing temperature and greenhouse gas emission. Therefore, there is a growing incentive to invest in green technologies with minimal environmental impacts. This study ascertained the potential use of Spent Coffee Grounds (SCG) and Tea Waste (TW) as additives to manufacture unfired clay bricks through alkali-activation. The ambition of this study is to divert SCG and TW from landfills and promote sustainable construction practice. An alkali-activated binder was used in this study by activating mill clay residues (precursor) with a liquid mixture of NaOH and Na2SiO3 solutions at a fixed Na2SiO3/NaOH ratio of 0.7. Small amounts (1, 2.5, 5, 10 and 15 wt%) of SCG and TW were added to the binder and mechanically blended for 2.5 min. Block samples were moulded by compressing the slurry in a steel mould. Once demoulded, the block samples were dried in an oven temperature at 110 °C for 24 h, then cured at ambient temperature. Fabricated samples were subjected to unconfined compressive strength test, moisture absorption test and tested samples were also characterised by Optical and Scanning Electron Microscopy (SEM). SEM micrographs showed the discovery of active fungi in the samples containing high SCG content (5 wt% and above) but not in the samples made with TW. The results showed that the samples with up to 2.5 wt% SCG and 10 wt% TW met the minimum compressive strength requirement (8.6 MPa) for structural applications with satisfactory moisture absorption values, as per ASTM C62.

Graphic Abstract

Similar content being viewed by others

References

Zaman, A.U.: Measuring waste management performance using the ‘Zero Waste Index’: the case of Adelaide, Australia. J. Clean. Prod. 66, 407–419 (2014)

Pandey, L.M.S., Shukla, S.K.: An insight into waste management in Australia with a focus on landfill technology and linear leak detection. J. Clean. Prod. 225, 1147–1154 (2019)

Li, R.Y.M., Du, H.: Sustainable construction waste management in Australia: a motivation perspective. In: Construction Safety and Waste Management, Risk Engineering. Springer, Cham (2015)

Sampe, F., Pakiding, D.L.: Perception of traditional small scale brick-making owner on firewood usage for brick-making process. Procedia-Soc Behav Sci 211, 653–659 (2015)

Weyant, C., Kumar, S., Maithel, S., Thompson, R., Baum, E., Floess, E., Bond, T.: Brick Kiln Measurement Guidelines: Emissions and Energy Performance, University of Illinois Urbana-Champaign (2017)

Arulrajah, A., Maghoolpilehrood, F., Disfani, M.M., Horpibulsuk, S.: Spent coffee grounds as a non-structural embankment fill material: engineering and environmental considerations. J. Clean. Prod. 72, 181–186 (2014)

Mussatto, S.I., Carneiro, L.M., Silva, J.P.A., Roberto, I.C., Teixeira, J.A.: A study on chemical constituents and sugars extraction from spent coffee grounds. Carbohyd. Polym. 83(2), 368–374 (2011)

Kua, T.A., Arulrajah, A., Horpibulsuk, S., Du, Y.J., Suksiripattanapong, C.: Engineering and environmental evaluation of spent coffee grounds stabilised with industrial by-products as a road subgrade material. Clean Technol. Environ. Policy 19(1), 63–75 (2017)

Kua, T.A., Arulrajah, A., Mohammadinia, A., Horpibulsuk, S., Mirzababaei, M.: Stiffness and deformation properties of spent coffee grounds based geopolymers. Constr. Build. Mater. 138, 79–87 (2017)

Arulrajah, A., Kua, T.A., Phetchuay, C., Horpibulsuk, S.: Spent coffee grounds-fly ash geopolymer used as an embankment structural fill material. J. Mater. Civ. Eng. 28(5), 4015197 (2016)

Kua, T.A., Arulrajah, A., Horpibulsuk, S., Du, Y.J., Shen, S.L.: Strength assessment of spent coffee grounds-geopolymer cement utilising slag and fly ash precursors. Constr. Build. Mater. 115, 565–575 (2016)

Seo, J.K., Jung, J.K., Seo, S.W.: Evaluation of nutritional and economic feed values of spent coffee grounds and Artemisia princeps residues as a ruminant feed using invitro ruminal fermentation. PeerJ. 9 (2015)

Tsai, W.T., Liu, S.C., Hsieh, C.H.: Preparation and fuel properties of biochars from the pyrolysis of exhausted coffee residue. J. Anal. Appl. Pyrol. 93, 63–67 (2012)

Sanchez-Hernandez, J.C., Dominguez, J.: Vermicompost derived from spent coffee grounds: Assessing the potential for enzymatic bioremediation. In: Handbook of Coffee processing by-Products, vol. 1(12), pp. 369–398 (2017)

Velasco, P.M., Mendivil, M.A., Morales, M.P., Munoz, L.: Eco-fired clay bricks made by adding spent coffee grounds: a sustainable way to improve buildings insulation. Mater. Struct. 49, 641–650 (2015)

Eliche-Quesada, D., Perez-Villarejo, L., Iglesias-Godino, F.J., Martinez-Garcia, C., Corpas-Iglesias, F.A.: Incorporation of coffee grounds into clay brick production. Adv. Appl. Ceram. 110(4), 225–232 (2011)

Mierzwinski, D., Korniejenko, K., Lach, M., Mikula, J., Krzywda, J.: Effect of coffee grounds addition on efflorescence in fly ash-based geopolymer. IOP Conf. Ser. 416, 012035 (2018)

Demir, I.: An investigation on the production of construction brick with processed waste tea. Build. Environ. 41(9), 1274–1278 (2006)

Alastair, H.: Current status and future development of global tea production and tea products. AU J.T. 12(4), 251–264 (2009)

Tea-Australia: Statista Market Forecast, Australia (2018)

Ozturk, S., Sutcu, M., Erdogmus, E., Gencel, O.: Influence of tea waste concentration in the physical, mechanical and thermal properties of brick clay mixtures. Constr. Build. Mater. 217, 592–599 (2019)

Saman, N.S.M., Deraman, R., Hamzah, M.H.: Development of low thermal conductivity brick using rice husk, corn cob and waste tea in clay brick manufacturing. AIP Conf. Proc. 1901(1), 130007 (2017)

Shakir, A., Naganathan, S., Mustapha, K.N.: Development of bricks from waste material: a review paper. Aust. J. Basic Appl. Sci. 7(8), 812–818 (2013)

Liew, Y.M., Heah, C.Y., Bakri, M.M.A., Kamarudin, H.: Structure and properties of clay-based geopolymer cements: a review. Prog. Mater Sci. 83, 595–629 (2016)

ASTM C136/C136M-14: Standard test methods for sieve analysis of fine and coarse aggregates, ASTM International, United States (2019)

Zhang, Z.P., Wong, Y.C., Arulrajah, A.: Compressive Strength of Non-fired Bricks Produced from Mill Residues in brick Production by Alkali-Activation. Swinburne University of Technology (2019)

Yao, X., Zhang, Z.H., Zhu, H.J., Chen, Y.: Geopolymerization process of alkali-metakaolinite characterised by isothermal calorimetry. Thermochim. Acta 493(1–2), 49–54 (2009)

ASTM C67-17: Standard test methods for sampling and testing brick and structural clay tile, ASTM International, United States (2017)

Esmeray, E., Atis, M.: Utilisation of sewage sludge, oven slag and fly ash in clay brick production. Constr. Build. Mater. 194, 110–121 (2019)

Xing, J., Zhao, Y.L., Qiu, J.P., Sun, X.G.: Microstructural and mechanical properties of alkali activated materials from two types of blast furnace slags. Materials 12(13), 2089 (2019)

Criado, M., Aperador, W., Sobrados, I.: Microstructural and mechanical properties of alkali activated Colombian raw materials. Materials 9(3), 158 (2016)

Slaty, F., Khoury, H., Wastiels, J., Rahier, H.: Characterisation of alkali activated kaolinitic clay. Appl. Clay Sci. 75–76, 120–125 (2013)

Clarke, R.J.: Storage and Stability, Encyclopedia of Food Sciences and Nutrition, 2nd ed. (2003)

Hargaten, V.B., Kuhn, M., Briesen, H.: Swelling properties of roasted coffee particles. J. Sci. Food Agric. 100(10), 3960–3970 (2020)

Gorhan, G., Simsek, O.: porous clay bricks manufactured with rice husks. Constr. Build. Mater. 40, 390–396 (2013)

Sangma, S., Tripura, D.D.: Experimental study on shrinkage behaviour of earth walling materials with fibers and stabiliser for cob building. Constr. Build. Mater. 256, 119449 (2020)

Ghavami, K., Filho, R.D.T., Barbosa, N.P.: Behaviour of composite soil reinforced with natural fibers. Cement Concr. Compos. 21, 39–48 (1999)

Monika, H., Unnikrishnan, S.: Characterisation of jute fibre reinforced adobe brick and brick masonry. Int. J. Adv. Res. Trends Eng. Technol. 4(22), 16–22 (2017)

Sumathi, A., Mohan, K.S.R.: Study on the effect of compressive strength of brick masonry with admixed mortar. Int. J. ChemTech Res. 6, 3437–3450 (2014)

Bouhicha, M., Aouissi, F., Kenai, S.: Performance of composite soil reinforced with barley straw. Cement Concr. Compos. 27(5), 617–621 (2005)

Xu, H., Deventer, J.S.J.V.: The geopolymerization of alumino-silicate minerals. Int. J. Miner. Process. 59(3), 247–266 (2000)

ASTM C62-17: Standard specification for building brick (solid masonry units made from clay or shale), ASTM International, United States (2017)

Heah, C.Y., Kamarudin, H., Bakri, A.M.M.A., Binhussain, M., Luqman, M., Nizar, I.K., Ruzaidi, C.M., Liew, Y.M.: Study on solids-to-liquid and alkaline activator ratios on kaolin-based geopolymers. Constr. Build. Mater. 35, 912–922 (2012)

Liew, Y.M., Kamarudin, H., Bakri, A.M.M.A., Binhussain, M., Luqman, M., Nizar, I.K., Ruzaidi, C.M., Heah, C.Y.: Influence of solids-to-liquid and activator ratios on calcined kaolin cement powder. In: 2011 International Conference on Physics Science and Technology. Physics Procedia, vol. 22, pp. 312–317 (2011)

Criado, M., Fernandez-Jimenez, A., Palomo, A.: Alkali activation of fly ash: effect of the SiO2/Na2O ratio: part I: FTIR study. Microporous Mesoporous Mater. 106(1–3), 180–191 (2007)

Arulrajah, A., Kua, T.A., Suksiripattanapong, C., Horpibulsuk, S., Shen, J.S.L.: Compressive strength and microstructural properties of spent coffee grounds-bagasse ash based geopolymers with slag supplements. J. Clean. Prod. 162, 1491–1501 (2017)

Gupta, P., Attri, R., Kumar, R.: Utilisation of WTP sludge & Tea waste in brick manufacturing. Int. J. Adv. Technol. Eng. Sci. 3(1), 1663–1670 (2015)

Dorioz, J.M., Robert, M., Chenu, C.: The role of roots, fungi and bacteria on clay particle organisation. An experimental approach. Soil Struct. 56, 179–194 (1993)

Soma, G., Mahadevamma, S., Sudha, M.L.: Characterisation of tea fiber and its utilisation as a functional ingredient in the preparations of biscuits. Int. Food Res. J. 23(6), 2525–2533 (2016)

Freyburg, S., Schwarz, A.: Influence of the clay type on the pore structure of structural ceramics. J. Eur. Ceram. Soc. 27(2), 1727–1733 (2007)

Reygaert, W.C.: The antimicrobial possibilities of green tea. Front. Microbiol. (2014). https://doi.org/10.3389/fmicb.2014.00434

Acknowledgements

The authors gratefully thank Austral Bricks, Wollert, Victoria, Australia for providing the mill clay residues.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chung, L.L.P., Wong, Y.C. & Arulrajah, A. The Application of Spent Coffee Grounds and Tea Wastes as Additives in Alkali-Activated Bricks. Waste Biomass Valor 12, 6273–6291 (2021). https://doi.org/10.1007/s12649-021-01453-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-021-01453-7