Abstract

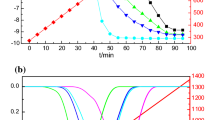

The influence of the gasification temperature and Equivalence Ratio (ER) on the behavior of an industrial low-grade Solid Recovered Fuel (SRF) was investigated in an air bubbling fluidized bed. The studied SRF exhibits an intermediate composition between biomass-rich SRF and plastic-rich SRF. Its Lower Heating Value (14 MJ/kg) is low since its ash content is very high (35 wt%). But surprisingly, the Cold Gas Efficiency and the Carbon Conversion were relatively high with this type of low-grade SRF. As a result, the syngas produced is quite rich (LHV > 8 MJ/m3 STP) and it may be valorized in gas engines. H2S, HCl, HCN and NH3 in the syngas were analyzed. These results confirm that inorganic gases are an important issue for the valorization of SRF as fuel in gasification processes, even if significant parts of S, N and Cl are not converted into inorganic gases.

Graphic Abstract

Similar content being viewed by others

Availability of Data and Materials

All the data published in these articles are available for the scientific community.

References

Kaza, S., Yao, L., Bhada-Tata, P., Van Woerden, F.: What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050. Urban Development Series. World Bank Group, Washington, DC (2018)

Kang, P., Zhang, H., Duan, H.: Characterizing the implications of waste dumping surrounding the Yangtze River economic belt in China. J. Hazard. Mater. 383, 121207 (2020). https://doi.org/10.1016/j.jhazmat.2019.121207

Hafeez, S., Mahmood, A., Syed, J.H., Li, J., Ali, U., Malik, R.N., Zhang, G.: Waste dumping sites as a potential source of POPs and associated health risks in perspective of current waste management practices in Lahore city, Pakistan. Sci. Total Environ. 562, 953–961 (2016). https://doi.org/10.1016/j.scitotenv.2016.01.120

Rego, R.F., Moraes, L.R.S., Dourado, I.: Diarrhoea and garbage disposal in Salvador, Brazil. Trans. R. Soc. Trop. Med. Hyg. 99, 48–54 (2005). https://doi.org/10.1016/j.trstmh.2004.02.008

Kupchik, G.J., Franz, G.J.: Solid waste, air pollution and health. J. Air Pollut. Control Assoc. 26, 116–118 (1976). https://doi.org/10.1080/00022470.1976.10470229

Triassi, M., Alfano, R., Illario, M., Nardone, A., Caporale, O., Montuori, P., Triassi, M., Alfano, R., Illario, M., Nardone, A., Caporale, O., Montuori, P.: Environmental pollution from illegal waste disposal and health effects: a review on the “Triangle of Death.” Int. J. Environ. Res. Public Health 12, 1216–1236 (2015). https://doi.org/10.3390/ijerph120201216

Plaza, P.I., Lambertucci, S.A.: How are garbage dumps impacting vertebrate demography, health, and conservation? Glob. Ecol. Conserv. 12, 9–20 (2017). https://doi.org/10.1016/j.gecco.2017.08.002

Schweitzer, L., Noblet, J.: Chapter 36—water contamination and pollution. In: Török, B., Dransfield, T. (eds.) Green Chemistry, pp. 261–290. Elsevier, Amsterdam (2018)

Lebreton, L., Slat, B., Ferrari, F., Sainte-Rose, B., Aitken, J., Marthouse, R., Hajbane, S., Cunsolo, S., Schwarz, A., Levivier, A., Noble, K., Debeljak, P., Maral, H., Schoeneich-Argent, R., Brambini, R., Reisser, J.: Evidence that the Great Pacific Garbage Patch is rapidly accumulating plastic. Sci. Rep. 8, 4666 (2018). https://doi.org/10.1038/s41598-018-22939-w

Haward, M.: Plastic pollution of the world’s seas and oceans as a contemporary challenge in ocean governance. Nat. Commun. 9, 667 (2018). https://doi.org/10.1038/s41467-018-03104-3

Solid Waste Management, http://www.worldbank.org/en/topic/urbandevelopment/brief/solid-waste-management

Martignon, G.: Trends on use of solid recovered fuels. In: Johansson, I., Edo, M. (eds.) IEA Bioenergy (2020)

Vonk, G., Piriou, B., Wolbert, D., Cammarano, C., Vaïtilingom, G.: Analysis of pollutants in the product gas of a pilot scale downdraft gasifier fed with wood, or mixtures of wood and waste materials. Biomass Bioenergy 125, 139–150 (2019). https://doi.org/10.1016/j.biombioe.2019.04.018

Combustibles solides de récupération (CSR) - Caractérisation et évaluation de leurs performances en combustion. FEDEREC et COMPTE-R (2015)

Consommation d’énergie primaire - Eurostat, https://ec.europa.eu/eurostat/fr/web/products-datasets/-/T2020_33

Brunner, P.H., Morf, L., Rechberger, H.: VI.3—thermal waste treatment—a necessary element for sustainable waste management. In: Twardowska, I. (ed.) Waste Management Series, pp. 783–806. Elsevier, Amsterdam (2004)

Porteous, A.: Why energy from waste incineration is an essential component of environmentally responsible waste management. Waste Manag. 25, 451–459 (2005). https://doi.org/10.1016/j.wasman.2005.02.008

Arena, U.: Process and technological aspects of municipal solid waste gasification. A review. Waste Manag. 32, 625–639 (2012). https://doi.org/10.1016/j.wasman.2011.09.025

Enerkem produces renewable alternative solution to diesel fuel. Focus Catal. 2018, 6 (2018). https://doi.org/10.1016/j.focat.2018.11.097

Barba, A., Le Cadre, E., Forsgren, H., Gaillard, M., Gunnarsson, I., Guerrini, O., Hoff, M.V., Kara, Y., Mollema, E., Moretti, I., Ourliac, M., Overwijk, M., Peureux, G., Peltenburg, A., Tengberg, F., De Vries, T., Winjstra, S.: Europe move towards industrialization of 2G biomethane from biomass gasification and methanation. Presented at the International Gas Research Conference Proceedings (2017)

Ramos, A., Monteiro, E., Silva, V., Rouboa, A.: Co-gasification and recent developments on waste-to-energy conversion: a review. Renew. Sustain. Energy Rev. 81, 380–398 (2018). https://doi.org/10.1016/j.rser.2017.07.025

Sansaniwal, S.K., Pal, K., Rosen, M.A., Tyagi, S.K.: Recent advances in the development of biomass gasification technology: a comprehensive review. Renew. Sustain. Energy Rev. 72, 363–384 (2017). https://doi.org/10.1016/j.rser.2017.01.038

Campoy, M., Gómez-Barea, A., Ollero, P., Nilsson, S.: Gasification of wastes in a pilot fluidized bed gasifier. Fuel Process. Technol. 121, 63–69 (2014). https://doi.org/10.1016/j.fuproc.2013.12.019

Karatas, H., Olgun, H., Engin, B., Akgun, F.: Experimental results of gasification of waste tire with air in a bubbling fluidized bed gasifier. Fuel 105, 566–571 (2013). https://doi.org/10.1016/j.fuel.2012.08.038

Xiao, G., Ni, M.-J., Chi, Y., Cen, K.-F.: Low-temperature gasification of waste tire in a fluidized bed. Energy Convers. Manag. 49, 2078–2082 (2008). https://doi.org/10.1016/j.enconman.2008.02.016

Di Gregorio, F., Santoro, D., Arena, U.: The effect of ash composition on gasification of poultry wastes in a fluidized bed reactor. Waste Manag. Res. 32, 323–330 (2014). https://doi.org/10.1177/0734242X14525821

Mastellone, M.L., Zaccariello, L., Arena, U.: Co-gasification of coal, plastic waste and wood in a bubbling fluidized bed reactor. Fuel 89, 2991–3000 (2010). https://doi.org/10.1016/j.fuel.2010.05.019

Arena, U., Di Gregorio, F.: Energy generation by air gasification of two industrial plastic wastes in a pilot scale fluidized bed reactor. Energy 68, 735–743 (2014). https://doi.org/10.1016/j.energy.2014.01.084

Wilk, V., Hofbauer, H.: Co-gasification of plastics and biomass in a dual fluidized-bed steam gasifier: possible interactions of fuels. Energy Fuels 27, 3261–3273 (2013). https://doi.org/10.1021/ef400349k

Dunnu, G., Panopoulos, K.D., Karellas, S., Maier, J., Touliou, S., Koufodimos, G., Boukis, I., Kakaras, E.: The solid recovered fuel Stabilat®: characteristics and fluidised bed gasification tests. Fuel 93, 273–283 (2012). https://doi.org/10.1016/j.fuel.2011.08.061

Pinto, F., André, R.N., Carolino, C., Miranda, M., Abelha, P., Direito, D., Perdikaris, N., Boukis, I.: Gasification improvement of a poor quality solid recovered fuel (SRF). Effect of using natural minerals and biomass wastes blends. Fuel 117, 1034–1044 (2014). https://doi.org/10.1016/j.fuel.2013.10.015

Milne, T.A., Evans, R.J., Abatzoglou, N.: Biomass Gasifier Tars: Their Nature, Formation and Conversion. National Renewable Energy Laboratory, Golden (1998)

Vonk, G., Piriou, B., Felipe Dos Santos, P., Wolbert, D., Vaïtilingom, G.: Comparative analysis of wood and solid recovered fuels gasification in a downdraft fixed bed reactor. Waste Manag. 85, 106–120 (2019). https://doi.org/10.1016/j.wasman.2018.12.023

Arena, U., Di Gregorio, F.: Gasification of a solid recovered fuel in a pilot scale fluidized bed reactor. Fuel 117, 528–536 (2014). https://doi.org/10.1016/j.fuel.2013.09.044

Recari Ansa, J.: Gasification of biomass and solid recovered fuels (SRFs) for the synthesis of liquid fuels, PhD Thesis, Univ. Rovira I Virgili, Italia (2017)

Lardier, G., Kaknics, J., Dufour, A., Michel, R., Cluet, B., Authier, O., Poirier, J., Mauviel, G.: Gas and bed axial composition in a bubbling fluidized bed gasifier: results with miscanthus and olivine. Energy Fuels 30, 8316–8326 (2016). https://doi.org/10.1021/acs.energyfuels.6b01816

Horvat, A., Kwapinska, M., Xue, G., Rabou, L.P.L.M., Pandey, D.S., Kwapinski, W., Leahy, J.J.: Tars from fluidized bed gasification of raw and torrefied Miscanthus x giganteus. Energy Fuels 30, 5693–5704 (2016). https://doi.org/10.1021/acs.energyfuels.6b00532

Valin, S., Ravel, S., Pons de Vincent, P., Thiery, S., Miller, H.: Fluidized bed air gasification of solid recovered fuel and woody biomass: influence of experimental conditions on product gas and pollutant release. Fuel 242, 664–672 (2019). https://doi.org/10.1016/j.fuel.2019.01.094

Woolcock, P.J., Brown, R.C.: A review of cleaning technologies for biomass-derived syngas. Biomass Bioenergy 52, 54–84 (2013). https://doi.org/10.1016/j.biombioe.2013.02.036

Torres, W., Pansare, S.S., Jr., Goodwin, J.G.: Hot gas removal of tars, ammonia, and hydrogen sulfide from biomass gasification gas. Catal. Rev. 49, 407–456 (2007). https://doi.org/10.1080/01614940701375134

Asadullah, M.: Biomass gasification gas cleaning for downstream applications: a comparative critical review. Renew. Sustain. Energy Rev. 40, 118–132 (2014). https://doi.org/10.1016/j.rser.2014.07.132

Brandin, J., Tunér, M., Odenbrand, I.: Small scale gasification: gas engine CHP for biofuels, Swedish Energy Agency Report (2011)

Gupta, R.P., Turk, B.S., Portzer, J.W., Cicero, D.C.: Desulfurization of syngas in a transport reactor. Environ. Prog. 20, 187–195 (2001)

Lee, J., Feng, B.: A thermodynamic study of the removal of HCl and H2S from syngas. Front. Chem. Sci. Eng. 6, 67–83 (2012). https://doi.org/10.1007/s11705-011-1162-4

Tijmensen, M.J.A., Faaij, A.P.C., Hamelinck, C.N., van Hardeveld, M.R.M.: Exploration of the possibilities for production of Fischer Tropsch liquids and power via biomass gasification. Biomass Bioenergy 23, 129–152 (2002). https://doi.org/10.1016/S0961-9534(02)00037-5

Chiche, D., Diverchy, C., Lucquin, A.-C., Porcheron, F., Defoort, F.: Synthesis gas purification. Oil Gas Sci. Technol. Rev. D’IFP Energ. Nouv. 68, 707–723 (2013). https://doi.org/10.2516/ogst/2013175

Kaufman Rechulski, M.D., Schildhauer, T.J., Biollaz, S.M.A., Ludwig, Ch.: Sulfur containing organic compounds in the raw producer gas of wood and grass gasification. Fuel 128, 330–339 (2014). https://doi.org/10.1016/j.fuel.2014.02.038

Arena, U., Di Gregorio, F.: Fluidized bed gasification of industrial solid recovered fuels. Waste Manag. 50, 86–92 (2016). https://doi.org/10.1016/j.wasman.2016.02.011

Wilk, V., Hofbauer, H.: Conversion of fuel nitrogen in a dual fluidized bed steam gasifier. Fuel 106, 793–801 (2013). https://doi.org/10.1016/j.fuel.2012.12.056

Berrueco, C., Recari, J., Abelló, S., Farriol, X., Montané, D.: Experimental investigation of solid recovered fuel (SRF) gasification: effect of temperature and equivalence ratio on process performance and release of minor contaminants. Energy Fuels 29, 7419–7427 (2015). https://doi.org/10.1021/acs.energyfuels.5b02032

Berrueco, C., Recari, J., Güell, B.M., del Alamo, G.: Pressurized gasification of torrefied woody biomass in a lab scale fluidized bed. Energy 70, 68–78 (2014). https://doi.org/10.1016/j.energy.2014.03.087

Gas analysis in gasification of biomass and waste—guideline report document 1. IEA Bioenergy Task 33 (2018)

Aljbour, S.H., Kawamoto, K.: Bench-scale gasification of cedar wood—part II: effect of operational conditions on contaminant release. Chemosphere 90, 1501–1507 (2013). https://doi.org/10.1016/j.chemosphere.2012.08.030

Recari, J., Berrueco, C., Abelló, S., Montané, D., Farriol, X.: Gasification of two solid recovered fuels (SRFs) in a lab-scale fluidized bed reactor: influence of experimental conditions on process performance and release of HCl, H2S, HCN and NH3. Fuel Process. Technol. 142, 107–114 (2016). https://doi.org/10.1016/j.fuproc.2015.10.006

Arena, U., Zaccariello, L., Mastellone, M.L.: Fluidized bed gasification of waste-derived fuels. Waste Manag. 30, 1212–1219 (2010). https://doi.org/10.1016/j.wasman.2010.01.038

Pels, J.R., Kapteijn, F., Moulijn, J.A., Zhu, Q., Thomas, K.M.: Evolution of nitrogen functionalities in carbonaceous materials during pyrolysis. Carbon 33, 1641–1653 (1995). https://doi.org/10.1016/0008-6223(95)00154-6

Leppälahti, J., Koljonen, T.: Nitrogen evolution from coal, peat and wood during gasification: literature review. Fuel Process. Technol. 43, 1–45 (1995). https://doi.org/10.1016/0378-3820(94)00123-B

Leppälahti, J., Kurkela, E.: Behaviour of nitrogen compounds and tars in fluidized bed air gasification of peat. Fuel 70, 491–497 (1991). https://doi.org/10.1016/0016-2361(91)90026-7

Hansson, K.-M., Samuelsson, J., Tullin, C., Åmand, L.-E.: Formation of HNCO, HCN, and NH3 from the pyrolysis of bark and nitrogen-containing model compounds. Combust. Flame 137, 265–277 (2004). https://doi.org/10.1016/j.combustflame.2004.01.005

Kelemen, S.R., Afeworki, M., Gorbaty, M.L., Kwiatek, P.J., Sansone, M., Walters, C.C., Cohen, A.D.: Thermal transformations of nitrogen and sulfur forms in peat related to coalification. Energy Fuels 20, 635–652 (2006). https://doi.org/10.1021/ef050307p

Leichtnam, J., Schwartz, D., Gadiou, R.: The behaviour of fuel-nitrogen during fast pyrolysis of polyamide at high temperature. J. Anal. Appl. Pyrol. 55, 255 (2000)

Scott, D.S., Piskorz, J.: The continuous flash pyrolysis of biomass. Can. J. Chem. Eng. 62, 404–412 (1984). https://doi.org/10.1002/cjce.5450620319

Scott, D.S., Piskorz, J., Westerberg, I.B., McKeough, P.: Flash pyrolysis of peat in a fluidized bed. Fuel Process. Technol. 18, 81–95 (1988). https://doi.org/10.1016/0378-3820(88)90076-8

Tian, F.-J., Yu, J., McKenzie, L.J., Hayashi, J., Li, C.-Z.: Conversion of fuel-N into HCN and NH3 during the pyrolysis and gasification in steam: a comparative study of coal and biomass. Energy Fuels 21, 517–521 (2007). https://doi.org/10.1021/ef060415r

Kurkela, E., Laatikainen, J., Ståhlberg, P.: Pressurized Fluidized-Bed Gasification Experiments with Wood, Peat and Coal at VTT in 1991–1992: Gasification of Danish Wheat Straw and Coal. VTT, Espoo (1996)

Glarborg, P., Jensen, A.D., Johnsson, J.E.: Fuel nitrogen conversion in solid fuel fired systems. Prog. Energy Combust. Sci. 29, 89–113 (2003). https://doi.org/10.1016/S0360-1285(02)00031-X

Ma, W., Hoffmann, G., Schirmer, M., Chen, G., Rotter, V.S.: Chlorine characterization and thermal behavior in MSW and RDF. J. Hazard. Mater. 178, 489–498 (2010). https://doi.org/10.1016/j.jhazmat.2010.01.108

Bläsing, M., Zini, M., Müller, M.: Influence of feedstock on the release of potassium, sodium, chlorine, sulfur, and phosphorus species during gasification of wood and biomass shells. Energy Fuels 27, 1439–1445 (2013). https://doi.org/10.1021/ef302093r

Corella, J., Toledo, J.M., Molina, G.: Performance of CaO and MgO for the hot gas clean up in gasification of a chlorine-containing (RDF) feedstock. Bioresour. Technol. 99, 7539–7544 (2008). https://doi.org/10.1016/j.biortech.2008.02.018

Lu, H., Purushothama, S., Hyatt, J., Pan, W.-P., Riley, J.T., Lloyd, W.G., Flynn, J., Gill, P.: Co-firing high-sulfur coals with refuse-derived fuel. Thermochim. Acta 284, 161–177 (1996). https://doi.org/10.1016/0040-6031(96)02864-X

Jazbec, M., Sendt, K., Haynes, B.S.: Kinetic and thermodynamic analysis of the fate of sulphur compounds in gasification products. Fuel 83, 2133–2138 (2004). https://doi.org/10.1016/j.fuel.2004.06.017

Tchapda, A., Pisupati, S., Tchapda, A.H., Pisupati, S.V.: A review of thermal co-conversion of coal and biomass/waste. Energies 7, 1098–1148 (2014). https://doi.org/10.3390/en7031098

Knudsen, J.N., Jensen, P.A., Lin, W., Frandsen, F.J., Dam-Johansen, K.: Sulfur transformations during thermal conversion of herbaceous biomass. Energy Fuels 18, 810–819 (2004). https://doi.org/10.1021/ef034085b

Hervy, M., Pham Minh, D., Gérente, C., Weiss-Hortala, E., Nzihou, A., Villot, A., Le Coq, L.: H2S removal from syngas using wastes pyrolysis chars. Chem. Eng. J. 334, 2179–2189 (2018). https://doi.org/10.1016/j.cej.2017.11.162

Broer, K.M., Brown, R.C.: The role of char and tar in determining the gas-phase partitioning of nitrogen during biomass gasification. Appl. Energy 158, 474–483 (2015). https://doi.org/10.1016/j.apenergy.2015.08.100

Pinto, F., Lopes, H., André, R.N., Gulyurtlu, I., Cabrita, I.: Effect of catalysts in the quality of syngas and by-products obtained by co-gasification of coal and wastes. 1. Tars and nitrogen compounds abatement. Fuel 86, 2052–2063 (2007). https://doi.org/10.1016/j.fuel.2007.01.019

de Almeida, V.F., Gómez-Barea, A., Arroyo-Caire, J., Pardo, I.: On the measurement of the main inorganic contaminants derived from Cl, S and N in simulated waste-derived syngas. Waste Biomass Valoriz. (2020). https://doi.org/10.1007/s12649-019-00879-4

Hervy, M., Remy, D., Dufour, A., Mauviel, G.: Air-blown gasification of solid recovered fuels (SRFs) in lab-scale bubbling fluidized-bed-Influence of the operating conditions and of the SRF composition. Energy Convers. Manag. 181, 584–592 (2019)

Cluet, B., Mauviel, G., Rogaume, Y., Authier, O., Delebarre, A.: Segregation of wood particles in a bubbling fluidized bed. Fuel Process. Technol. 133, 80–88 (2015). https://doi.org/10.1016/j.fuproc.2014.12.045

Blanco, P.H., Wu, C., Onwudili, J.A., Williams, P.T.: Characterization of tar from the pyrolysis/gasification of refuse derived fuel: influence of process parameters and catalysis. Energy Fuels 26, 2107–2115 (2012). https://doi.org/10.1021/ef300031j

Morin, M., Nitsch, X., Hémati, M.: Interactions between char and tar during the steam gasification in a fluidized bed reactor. Fuel 224, 600–609 (2018). https://doi.org/10.1016/j.fuel.2018.03.050

Dufour, A., Masson, E., Girods, P., Rogaume, Y., Zoulalian, A.: Evolution of aromatic tar composition in relation to methane and ethylene from biomass pyrolysis-gasification. Energy Fuels 25, 4182–4189 (2011). https://doi.org/10.1021/ef200846g

Dufour, A., Girods, P., Masson, E., Rogaume, Y., Zoulalian, A.: Synthesis gas production by biomass pyrolysis: effect of reactor temperature on product distribution. Int. J. Hydrogen Energy 34, 1726–1734 (2009). https://doi.org/10.1016/j.ijhydene.2008.11.075

Dufour, A., Valin, S., Castelli, P., Thiery, S., Boissonnet, G., Zoulalian, A., Glaude, P.-A.: Mechanisms and kinetics of methane thermal conversion in a syngas. Ind. Eng. Chem. Res. 48, 6564–6572 (2009). https://doi.org/10.1021/ie900343b

Jess, A.: Mechanisms and kinetics of thermal reactions of aromatic hydrocarbons from pyrolysis of solid fuels. Fuel 75, 1441–1448 (1996). https://doi.org/10.1016/0016-2361(96)00136-6

Phan, T.S., Sane, A.R., Rêgo de Vasconcelos, B., Nzihou, A., Sharrock, P., Grouset, D., Pham Minh, D.: Hydroxyapatite supported bimetallic cobalt and nickel catalysts for syngas production from dry reforming of methane. Appl. Catal. B 224, 310–321 (2018). https://doi.org/10.1016/j.apcatb.2017.10.063

Dupont, C., Jacob, S., Marrakchy, K.O., Hognon, C., Grateau, M., Labalette, F., Da Silva Perez, D.: How inorganic elements of biomass influence char steam gasification kinetics. Energy 109, 430–435 (2016). https://doi.org/10.1016/j.energy.2016.04.094

Bates, R.B., Altantzis, C., Ghoniem, A.F.: Modeling of biomass char gasification, combustion, and attrition kinetics in fluidized beds. Energy Fuels 30, 360–376 (2016). https://doi.org/10.1021/acs.energyfuels.5b02120

Westbrook, C.K., Dryer, F.L.: Chemical kinetic modeling of hydrocarbon combustion. Prog. Energy Combust. Sci. 10, 1–57 (1984). https://doi.org/10.1016/0360-1285(84)90118-7

Battin-Leclerc, F.: Detailed chemical kinetic models for the low-temperature combustion of hydrocarbons with application to gasoline and diesel fuel surrogates. Prog. Energy Combust. Sci. 34, 440–498 (2008). https://doi.org/10.1016/j.pecs.2007.10.002

Debono, O., Villot, A.: Nitrogen products and reaction pathway of nitrogen compounds during the pyrolysis of various organic wastes. J. Anal. Appl. Pyroly. 114, 222–234 (2015). https://doi.org/10.1016/j.jaap.2015.06.002

Chen, H., Wang, Y., Xu, G., Yoshikawa, K.: Fuel-N evolution during the pyrolysis of industrial biomass wastes with high nitrogen content. Energies 5, 5418–5438 (2012). https://doi.org/10.3390/en5125418

Recari, J., Berrueco, C., Abelló, S., Montané, D., Farriol, X.: Effect of bed material on oxygen/steam gasification of two solid recovered fuels (SRFs) in a Bench-Scale Fluidized-Bed Reactor. Energy Fuels 31, 8445–8453 (2017). https://doi.org/10.1021/acs.energyfuels.7b01507

Ephraim, A., Ngo, L., Pham Minh, D., Lebonnois, D., Peregrina, C., Sharrock, P., Nzihou, A.: Valorization of waste-derived inorganic sorbents for the removal of HCl in syngas. Waste Biomass Valoriz. (2018). https://doi.org/10.1007/s12649-018-0355-1

Delgado, J., Aznar, M.P., Corella, J.: Biomass gasification with steam in fluidized bed: effectiveness of CaO, MgO, and CaO−MgO for hot raw gas cleaning. Ind. Eng. Chem. Res. 36, 1535–1543 (1997). https://doi.org/10.1021/ie960273w

Acknowledgements

The authors acknowledge the financial support of ADEME, France –Terracotta project, n° 1606C0013. The authors also thank the EDF Company, France, especially Emmanuel Thunin and Mathieu Insa for their support on material characterizations, as well as Matthieu Debal, Pierre Girods and Yann Rogaume (LERMAB, University de Lorraine) for their tremendous work for SRF pelletization.

Funding

The research was supported by ADEME through the project ADEME Terracotta n° 1606C0013 led by EDF.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Hervy, M., Remy, D., Dufour, A. et al. Gasification of Low-Grade SRF in Air-Blown Fluidized Bed: Permanent and Inorganic Gases Characterization. Waste Biomass Valor 12, 6231–6244 (2021). https://doi.org/10.1007/s12649-021-01434-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-021-01434-w