Abstract

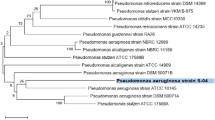

The production, purification, and characterization of thermostable-alkaline keratinase from Bacillus halodurans SW-X (keratinase_SW-X), and its applicability towards the production of white chicken feather hydrolysate and bioplastic starch/keratin production were investigated. A maximal keratinase activity of 16.05 ± 0.25 U/mL was achieved by cultivation of B. halodurans SW-X in 5 L stirred tank bioreactor at 47 °C, 200 rpm, and 2 vvm for 48 h. Keratinase_SW-X was purified as a monomeric protein with the estimated MW of 25 kDa, 14.4-fold, and 20% recovery yield. The protein was classified as thermostable-alkaline keratinase due to its optimal pH (pH 10) and temperature (70 °C), pH stability (pH 9.0–11), thermostability (> 3 h at 50–60 °C), and it showed the highest specificity towards chicken feather keratin with Km of 0.45 mg/mL, and Vmax of 3.51 μmol/min/mg. Crude keratinase_SW-X biodegraded white chicken feathers into two types of low (10–20 kDa) and high (≥ 30 kDa) chicken feather (keratin) hydrolysates, with total recovery yields of 30%. The bioplastic starch/keratin was synthesized using cassava starch (70%, w/w), glycerol (30%, w/w), and keratin hydrolysate (0–0.30%, w/w). The optimal concentration of keratin hydrolysate was 0.10% (w/w), resulting in improved strength and elongation at break, with a good appearance of the bioplastic starch/keratin. Our study suggests that B. halodurans SW-X is a potential strain for thermostable-alkaline keratinase production. Moreover, from environmental perspectives, keratinases_SW-X is a promising candidate enzyme that valorizes low cost chicken feather waste to a high value added product, indicating a novel approach for feather waste treatment and utilization.

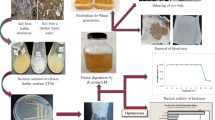

Graphic Abstract

Similar content being viewed by others

Data Availability

Data availability all data generated or analyzed during this study are included in this published article and its supplementary information files.

References

Chinta, S., Landage, S., Yadav, K.: Application of chicken feathers in technical textiles. Int. J. Innov. Res. Sci. Eng. Technol. 2(4), 1158–1165 (2013)

Reddy, N., Yang, Y.: Structure and properties of chicken feather barbs as natural protein fibers. J. Polym. Environ. 15(2), 81–87 (2007)

Abdel-Fattah, A.M., El-Gamal, M.S., Ismail, S.A., Emran, M.A., Hashem, A.M.: Biodegradation of feather waste by keratinase produced from newly isolated Bacillus licheniformis ALW1. J. Genet. Eng. Biotechnol. 16(2), 311–318 (2018)

Tronina, P., Bubel, F.: Production of organic fertilizer from poultry feather wastes excluding the composting process. Pol. J. Chem. Technol. 10(2), 33–36 (2008)

Tesfaye, T., Sithole, B., Ramjugernath, D., Mokhothu, T.: Valorisation of chicken feathers: Characterisation of thermal, mechanical and electrical properties. Sustain. Chem. Pharm. 9, 27–34 (2018)

Lange, L., Huang, Y., Busk, P.K.: Microbial decomposition of keratin in nature-a new hypothesis of industrial relevance. Appl. Microbiol. Biotechnol. 100(5), 2083–2096 (2016)

Ramakrishnan, N., Sharma, S., Gupta, A., Alashwal, B.Y.: Keratin based bioplastic film from chicken feathers and its characterization. Int. J. Biol. Macromol. 111, 352–358 (2018)

Ni, N., Dumont, M.: Protein-based hydrogels derived from industrial byproducts containing collagen, keratin, zein and soy. Waste Biomass Valorization. 8(2), 285–300 (2017)

Van den Berg, L.E.: Development of 2nd generation proteinous bioplastics, UOW (2009)

Azevedo, V.M., Carvalho, R.A., Borges, S.V., Claro, P.I.C., Hasegawa, F.K., Yoshida, M.I., Marconcini, J.M.: Thermoplastic starch/whey protein isolate/rosemary essential oil nanocomposites obtained by extrusion process: Antioxidant polymers. J. Appl. Polym. Sci. 136(23), 1–12 (2019)

Prachayawarakorn, J., Hwansanoet, W.: Effect of silk protein fibers on properties of thermoplastic rice starch. Fibers Polym. 13(5), 606–612 (2012)

Benkiar, A., Nadia, Z.J., Badis, A., Rebzani, F., Soraya, B.T., Rekik, H., Naili, B., Ferradji, F.Z., Bejar, S., Jaouadi, B.: Biochemical and molecular characterization of a thermo- and detergent-stable alkaline serine keratinolytic protease from Bacillus circulans strain DZ100 for detergent formulations and feather-biodegradation process. Int. Biodeterior. Biodegradation. 83, 129–138 (2013)

Takenaka, S., Nomura, R., Minegishi, A., Yoshida, K.I.: Enrichment and characterization of a bacterial culture that can degrade 4-aminopyridine. BMC Microbiol. 13(1), 1–10 (2013)

Kumar, C.G., Takagi, H.: Microbial alkaline proteases: from a bioindustrial viewpoint. Biotech Adv. 17(7), 561–594 (1999)

Secades, P., Guijarro, J.: Purification and characterization of an extracellular protease from the fish pathogen Yersinia ruckeri and effect of culture conditions on production. Appl. Environ. Microbiol. 65(9), 3969–3975 (1999)

Kunitz, M.: Crystalline soybean trypsin inhibitor: II General properties. J. Gen. Physiol. 30(4), 291–310 (1947)

Lowry, O.H., Rosebrough, N.J., Farr, A.L., Randall, R.J.: Protein measurement with the Folin phenol reagent. J. Biol. Chem. 193, 265–275 (1951)

He, F.: Laemmli-SDS-PAGE. Bio-protocol 101, 80 (2011)

Blum, H., Beier, H., Gross, H.J.: Improved silver staining of plant proteins, RNA and DNA in polyacrylamide gels. Electrophoresis 8(2), 93–99 (1987)

Moore, S., Spackman, D.H., Stein, W.H.: Automatic recording apparatus for use in the chromatography of amino acids. Federation Proceedings. 4, 1107–1115 (1958)

Jantanasakulwong, K., Leksawasdi, N., Seesuriyachan, P., Wongsuriyasak, S., Techapun, C., Ougizawa, T.: Reactive blending of thermoplastic starch, epoxidized natural rubber and chitosan. Eur. Polym. J. 84, 292–299 (2016)

Singh, S., Bajaj, B.K.: Agroindustrial/forestry residues as substrates for production of thermoactive alkaline protease from Bacillus licheniformis K-3 having multifaceted hydrolytic potential. Waste Biomass Valorization. 8(2), 453–462 (2017)

Kshetri, P., Ningthoujam, D.S.: Keratinolytic activities of alkaliphilic Bacillus sp. MBRL 575 from a novel habitat, limestone deposit site in Manipur. India. Springerplus. 5(1), 1–16 (2016)

Cai, C.G., Chen, J.S., Qi, J.J., Yin, Y., Zheng, X.D.: Purification and characterization of keratinase from a new Bacillus subtilis strain. J. Zhejiang Univ. Sci. B. 9(9), 713–720 (2008)

Salaheen, S., Mamun, M.A., Khan, S., Hoq, M.: Improvement of Bacillus licheniformis MZK05 by mutation for increased production of keratinase. Dhaka Univ. J. Biol. Sci. 24(1), 17–23 (2015)

Dong, Y.Z., Chang, W.S., Chen, P.T.: Characterization and overexpression of a novel keratinase from Bacillus polyfermenticus B4 in recombinant Bacillus subtilis. Bioresour. Bioprocess. 4(1), 47 (2017)

Kim, J.M., Choi, Y.M., Suh, H.J.: Preparation of feather digests as fertilizer with Bacillus pumilis KHS-1. J. Microbiol. Biotechnol. 15(3), 472–476 (2005)

Prakash, P., Jayalakshmi, S.K., Sreeramulu, K.: Purification and characterization of extreme alkaline, thermostable keratinase, and keratin disulfide reductase produced by Bacillus halodurans PPKS-2. Appl. Microbiol. Biotechnol. 87(2), 625–633 (2010)

Fellahi, S., Chibani, A., Feuk-Lagerstedt, E., Taherzadeh, M.J.: Identification of two new keratinolytic proteases from a Bacillus pumilus strain using protein analysis and gene sequencing. AMB Express. 6(1), 1–8 (2016)

Shrinivas, D., Naik, G.: Characterization of alkaline thermostable keratinolytic protease from thermoalkalophilic Bacillus halodurans JB 99 exhibiting dehairing activity. Int. Biodeterior. Biodegradation. 65(1), 29–35 (2011)

Yakul, K., Takenaka, S., Nakamura, K., Techapun, C., Leksawasdi, N., Seesuriyachan, P., Watanabe, M., Chaiyaso, T.: Characterization of thermostable alkaline protease from Bacillus halodurans SE5 and its application in degumming coupled with sericin hydrolysate production from yellow cocoon. Process Biochem. 78, 63–70 (2019)

Rai, S.K., Konwarh, R., Mukherjee, A.K.: Purification, characterization and biotechnological application of an alkaline β-keratinase produced by Bacillus subtilis RM-01 in solid-state fermentation using chicken-feather as substrate. Biochem. Eng. J. 45(3), 218–225 (2009)

Poopathi, S., Thirugnanasambantham, K., Mani, C., Lakshmi, P., Ragul, K.: Purification and characterization of keratinase from feather degrading bacterium useful for mosquito control-A new report. Trop. Biomed. 31(1), 97–109 (2014)

Jayakumar, R., Jayashree, S., Annapurna, B., Seshadri, S.: Characterization of thermostable serine alkaline protease from an alkaliphilic strain Bacillus pumilus MCAS8 and its applications. Appl. Biochem. Biotechnol. 168(7), 1849–1866 (2012)

Singh, S.K., Singh, S.K., Tripathi, V.R., Garg, S.K.: Purification, characterization and secondary structure elucidation of a detergent stable, halotolerant, thermoalkaline protease from Bacillus cereus SIU1. Process Biochem. 47(10), 1479–1487 (2012)

Lo, W.H., Too, J.R., Wu, J.Y.: Production of keratinolytic enzyme by an indigenous feather-degrading strain Bacillus cereus Wu2. J. Biosci. Bioeng. 114(6), 640–647 (2012)

Counotte, G., Prins, R.: Calculation of Km and Vmax from substrate concentration versus time plot. Appl. Environ. Microbiol. 38(4), 758–760 (1979)

Yilmaz, B., Baltaci, M.O., Sisecioglu, M., Adiguzel, A.: Thermotolerant alkaline protease enzyme from Bacillus licheniformis A10: purification, characterization, effects of surfactants and organic solvents. J. Enzyme Inhib. Med. Chem. 31(6), 1241–1247 (2016)

Nadeem, M., Qazi, J.I., Syed, Q., Gulsher, M.: Purification and characterization of an alkaline protease from Bacillus licheniformis UV-9 for detergent formulations. J. Sci. Technol. 35, 187–195 (2013)

Cheong, C.W., Lee, Y.S., Ahmad, S.A., Ooi, P.T., Phang, L.Y.: Chicken feather valorization by thermal alkaline pretreatment followed by enzymatic hydrolysis for protein-rich hydrolysate production. J. Waste Manag. 79, 658–666 (2018)

Villa, A.L.V., Aragão, M.R.S., dos Santos, E.P., Mazotto, A.M., Zingali, R.B., De Souza, E.P., Vermelho, A.B.: Feather keratin hydrolysates obtained from microbial keratinases: effect on hair fiber. BMC Biotechnol. 13(1), 1–11 (2013)

Tesfaye, T., Sithole, B., Ramjugernath, D.: Valorisation of chicken feathers: a review on recycling and recovery route-current status and future prospects. Clean. Technol. Environ. Policy. 19(10), 2363–2378 (2017)

Saravanan, K., Dhurai, B.: Exploration on the amino acid content and morphological structure in chicken feather fiber. J. Text. Appar. Technol. Manag. 7(3), 1–6 (2012)

Cai, C.G., Lou, B.G., Zheng, X.D.: Keratinase production and keratin degradation by a mutant strain of Bacillus subtilis. J. Zhejiang Univ. Sci. B. 9(1), 60–67 (2008)

Navone, L., Speight, R.: Understanding the dynamics of keratin weakening and hydrolysis by proteases. PLoS ONE 13(8), 1–21 (2018)

Kaneko, T., Thi, T.H., Shi, D.J., Akashi, M.: Environmentally degradable, high-performance thermoplastics from phenolic phytomonomers. Nat. Mater. 5(12), 966–970 (2006)

Cuevas-Carballo, Z., Duarte-Aranda, S., Canché-Escamilla, G.: Properties and biodegradability of thermoplastic starch obtained from granular starches grafted with polycaprolactone. Int. J. Polym. Sci. (2017). https://doi.org/10.1155/2017/3975692

Lin, J., Li, J., Wang, J., Guan, Y., Wang, G., Chen, L.: Effects of thermoplastic elastomer on the morphology and mechanical properties of glass fiber-reinforced polycarbonate/acrylonitrile-butadiene-styrene. Polym. Eng. Sci. 59(2), 144–151 (2019)

Poole, A.J., Lyons, R.E., Church, J.S.: Dissolving feather keratin using sodium sulfide for bio-polymer applications. J. Polym. Environ. 19(4), 995–1004 (2011)

Fernández-d’Arlas, B.: Tough and functional cross-linked bioplastics from sheep wool keratin. Sci. Rep. 9(1), 1–12 (2019)

Rejak, A., Moscicki, L., Wójtowicz, A., Oniszczuk, T., Mitrus, M., Gladyszewska, B.: Influence of keratin addition on selected mechanical properties of TPS film. TEKA. 12(1), 219–224 (2012)

Yu, J., Chen, S., Gao, J., Zheng, H., Zhang, J., Lin, T.: A study on the properties of starch/glycerine blend. Starke. 50(6), 246–250 (1998)

Petrucci, R., Dominici, F., Santulli, C., Puglial, D., Kenny, J.: Mechanical and Thermal Characterisation of Poly (Ethylene) and Thermoplastic Starch Filled with Keratin Horn Powder from Bovine Claws. Mater. Adv. Technol. 1(1), 1–4 (2015)

Pandey, A., Toda, A., Rastogi, S.: Influence of amorphous component on melting of semicrystalline polymers. Macromolecules 44(20), 8042–8055 (2011)

Acknowledgements

The authors gratefully acknowledge the financial support from the National Research Council of Thailand (NRCT) through the Royal Golden Jubilee Ph.D. Programme, Thailand (Grant No. PHD/0144/2560) to Tanyawat Kaewsalud and Thanongsak Chaiyaso. This research was also supported by CMU Mid-Career Research Fellowship program; the Biotechnology Program, Graduate School of Chiang Mai University; the Cluster of Agro Bio-Circular-Green Industry (Agro BCG); Faculty of Agro-Industry; Chiang Mai University, Thailand; and the Japan Student Services Organization (JASSO) student exchange support program (Scholarship for Short-Term Study in Japan) FY2019.

Funding

This work was financially supported by the National Research Council of Thailand (NRCT) in the framework of the Royal Golden Jubilee Ph.D. Programme (Grant No. PHD/0144/2560) to Tanyawat Kaewsalud and Thanongsak Chaiyaso, and supported by the CMU Mid-Career Research Fellowship program (Grant Year 2020); the Japan Student Services Organization (JASSO) student exchange support program (Scholarship for Short-Term Study in Japan) FY2019.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Ethical Approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Information Consent

Informed consent has been obtained from all individual participants of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Kaewsalud, T., Yakul, K., Jantanasakulwong, K. et al. Biochemical Characterization and Application of Thermostable-Alkaline Keratinase From Bacillus halodurans SW-X to Valorize Chicken Feather Wastes. Waste Biomass Valor 12, 3951–3964 (2021). https://doi.org/10.1007/s12649-020-01287-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-020-01287-9