Abstract

In this paper we present the reactive extrusion process as a method of lipids extraction from by-products of fish. The study focuses on two essential points which are by-product enzymatic hydrolysis efficiency of three fish types, and the technical feasibility of producing a biodiesel from the fish lipids. The parameters of extrusion process were optimized in order to extract the more important percentage of oil. The results of the extracted oil from the three fish types were compared with other techniques such as batch process. Following the enzymatic hydrolysis, the chemical composition and the total fatty acids percentage are determined for each fish oil types in order to select the suitable oil for biodiesel production. Then the selected oil goes through transesterification, and we recover the methyl esters. The results of this study show that the enzymatic hydrolysis of the fish by-products by using the reactive extrusion process is interesting. Moreover, the valorization of fish by-products allows the marine waste recycling while producing biofuel. The produced biofuel can be used as an additive in a diesel fuel.

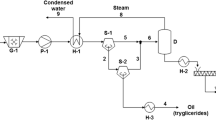

Graphical abstract

Similar content being viewed by others

References

Guy, R.: Extrusion Cooking: Technologies and Applications. Woodhead Publishing in Food Science and Technology Elsevier, Amsterdam (2001)

Duffossé, P., Delamare, L., Berzin, F., Vergnes, B.: Modeling of peroxide initiated controlled degradation of polypropylene in a twin-screw extruder. Polym. Eng. Sci. 40, 344–356 (2000)

Choulak, S.E.: Modélisation et commande d’un procédé d’extrusion réactive.Thèse de doctorat, Université Claude Bernard – Lyon 1 (2004)

Berzin, F., Hu, G.H., Procédés d’extrusion réactive. Tech L’ingénieur, no. AM3654 (2004)

Colak, B.Y.: Utilisation du caséinate de sodium pour la fabrication de films actifs pour l'emballage alimentaire : étude des propriétés barrières aux gaz, de l'activité antimicrobienne et de la biodégradabilité. Université Jean Monnet, Saint-Etienne, Thèse de doctorat (2014)

Sahyoun, J.: Développement de nouveaux matériaux polymères ignifugeants par la voie extrusion réactive. Thèse de doctorat, Université Claude Bernard – Lyon 1 (2014)

Gutierrez, N.C.: Incorporation et liberation de composes organiques volatils dans une matrice d’agromateriaux par extrusion bi-vis. Université de Toulouse, Thèse de doctorat (2016)

Le Roux, K.: Purification de la chitine par hydrolyse enzymatique à partir de coproduits de crevette Penaeus vannamei. Université de Nantes, Caractérisations des produits et optimisation du procédé. Thèse de doctorat (2012)

Vauchel, P.: Optimisation de procédés innovants pour l’obtention de phycocolloides. Université de Nantes, Thèse de doctorat (2007)

Makoure, D., Arhaliass, A., Echchelh, A., Baron, R., Legrand, J.: Reactive and / or enzymatic extrusion process for phycocolloids extraction: application to sea products. in ISTE OpenScience.London,UK (2019)

Fodil-Pacha, F.: Contribution à l’identification dynamique et à la commande de l'extrudeuse BC21 Clextral. Université de Nantes, Thèse de doctorat (2007)

Andrieux, G.: La filière française des co-produits de la pêche et de l’aquaculture: état des lieux et analyse. Etude de l’OFIMER. p 63 (2004)

Rago, D., Rasmussen, M.A., Lee-Sarwar, K.A., Weiss, S.T., Lasky-Su, J., Stokholm, J., Bønnelykke, K., Chawes, B.L., Bisgaard, H.: Fish-oil supplementation in pregnancy, child metabolomics and asthma risk. EBioMedicine. 46, 399–410 (2019)

Yorulmaz, E., Yorulmaz, H., Gökmen, E.S., Altınay, S., Küçük, S.H., Zengi, O., Çelik, D.S., Şit, D.: Therapeutic effectiveness of rectally administered fish oil and mesalazine in trinitrobenzenesulfonic acid-induced colitis. Biomed. Pharmacother. 118, 109247 (2019)

Royon, D., Daz, M., Ellenrieder, G., Locatelli, S.: Enzymatic production of biodiesel from cotton seed oil using t-butanol as a solvent. Bioresour. Technol. 98(3), 648–653 (2007)

Noureddini, H., Zhu, D.: Kinetics of Transesterification of Soybean Oil. J. Am. Oil Chem. 74(11), 1457–1463 (1997)

Watanabe, Y., Shimada, Y., Sugihara, A., Tominaga, Y.: Conversion of degummed soybean oil to biodiesel fuel with immobilized Candida antarctica lipase. J. Mol. Catal. B Enzym. 17, 151–155 (2002)

Zhang, Y., Dubé, M.A., McLean, D.D., Kates, M.: Biodiesel production from waste cooking oil: 2. Economic assessment and sensitivity analysis. Bioresour Technol 90(3), 229–240 (2003)

Acaroglu, M., Oguz, H., Ögüt, H.: An investigation of the use of rapeseed oil in agricultural tractors as engine oil. Energy Sources 23(9), 823–830 (2001)

Kusdiana, D., Saka, S.: Kinetics of transesteri®cation in rapeseed oil to biodiesel fuel as treated in supercritical methanol. Fuel 80, 693–698 (2001)

Harrington, K.J., D’Arcy-Evans, C.: Transesterification in Situ of Sunflower Seed Oil. Ind Eng Chem Prod Res Dev 24(2), 314–318 (1985)

Saifuddin, N., Chua, K.H.: Production of ethyl ester (biodiesel) from used frying oil: optimization of transesterification process using microwave irradiation. Malaysian J. Chem. 6(1), 77–82 (2004)

Tomasevic, A.V., Siler-Marinkovic, S.S.: Methanolysis of used frying oil. Fuel Process. Technol. 81(1), 1–6 (2003)

Otera, J.: Transesterification. Chem. Rev. 93, 1449–1470 (1993)

Gervajio, G.C.: Fatty Acids and Derivatives from Coconut Oil. in Bailey’s Industrial Oil and Fat Products, Ed. Wiley (2005)

Awad, S.: Contribution à l'étude de la valorisation énergétique des résidus graisseux et de leur combustion dans les moteurs à combustion interne. Université de Nantes, Thèse de doctorat (2011)

Awad, S., Paraschiv, M., Varuvel, E.G., Tazerout, M.: Optimization of biodiesel production from animal fat residue in wastewater using response surface methodology. Bioresour. Technol. 129, 315–320 (2013)

Esteban, M.B., García, A.J., Ramos, P., Márquez, M.C.: Evaluation of fruit-vegetable and fish wastes as alternative feedstuffs in pig diets.Waste Manag. 27, 193–200 (2007)

Coward-Kelly, G., Agbogbo, F.K., Holtzapple, M.T.: Lime treatment of shrimp head waste for the generation of highly digestible animal feed. Bioresour. Technol. 97, 1515–1520 (2006)

Kim, Y.S., Park, J.W., Choi, Y.J.: New approaches for the effective recovery of fish proteins and their physicochemical characteristics. Fish. Sci. 69, 1231–1239 (2003)

Dorado, M.P., Ballesteros, E., Lo, F.J., Mittelbach, M.: Optimization of Alkali-catalyzed transesterification of brassica carinata oil for biodiesel production. Energy Fuels 18, 77–83 (2004)

Tacon, A.G.J., Metian, M.: Global overview on the use of fish meal and fish oil in industrially compounded aquafeeds: trends and future prospects. Aquaculture 285(1–4), 146–158 (2008)

Tarhouni, A., Ben, M., Talbi, O., Elbour, M., Sadok, S., Mihoubi, N.: New integrated process for production of edible and fishmeal powders from sardines: drying kinetics and quality attributes. Process Saf. Environ. Prot. 122, 352–365 (2019)

Funding

This study was funded by CAMPUS FRANCE (PHC TOUBKAL 201X (French-Morocco bilateral program) Grant Number: 12345AB.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Makoure, D., Arhaliass, A., Echchelh, A. et al. Valorization of Fish By-Products Using Reactive Extrusion for Biodiesel Production and Optimization. Waste Biomass Valor 11, 6285–6293 (2020). https://doi.org/10.1007/s12649-019-00840-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-019-00840-5