Abstract

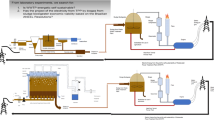

Anaerobic biotechnology offers both economic and ecological benefits for sustainable renewable energy production and sustainable agriculture practice. In this study, a novel bioreactor configuration, which is a combination of a continuous flow stirred-tank reactor (CSTR) and an up flow sludge blanket reactor (UASB), was used in order to valorize the residual organic content in the effluent of a conventional CSTR reactor. Thereby, maximum utilization of total COD potential was aimed by further processing of the residual COD from conventional farm based CSTR type digester effluent. The effluent of the CSTR reactor (dry matter 10%, HRT: 30 days) was fed into UASB reactors under varying HRT and Organic Loading Rate (OLR) conditions. Up to 98% COD removal was achieved in 4 L UASB reactor corresponding to maximum biogas production of 0.7 m3 biogas/kg CODremoved in UASB reactor. To the best of our knowledge, this integrated system is used for the first time to maximize the COD conversion into bio-methane during biogas production from laying hen litters. Thereby, a novel approach was presented a promising solution for the maximum valorization of animal manure as an alternative to conventional farm based biogas digester systems.

Similar content being viewed by others

References

Turkish Statistical Institute (TUIK): tuik.gov.tr (2016). Accessed 16 Jan 2016

Bengtson, L.P., Whitaker, J.H.: Farm structures in tropical climates. Food and Agriculture Organization of the United Nations, Rome (1988)

Akkaya, E., Demir, A., Varank, G.: Estimation of biogas generation from a uasb reactor via multiple regression model. Int. J. Green Energy. 12(2), 185–189 (2015)

World Energy Council-Turkish National Committee (WEC-TNC): Energy Report 2014. ISSN: 1301–6318, 84–90 (2014)

Yetilmezsoy, K.: Integration of kinetic modeling and desirability function approach for multi-objective optimization of uasb reactor treating poultry manure wastewater. Bioresour. Technol. 118, 89–101 (2012)

Waskom, R.M.: Best management practices for manure utilization. 568 A, Colorado State University Cooperative Extension, Fort Collins (1999)

Chong, S., Sen, T.K., Kayaalp, A., Ang, H.M.: The performance enhancements of upflow anaerobic sludge blanket (uasb) reactors for domestic sludge treatment—a state of the art review. Water Resour. 46, 3434–3470 (2012)

Pandey, P.K., Ndegwa, P.M., Soupir, M.L., Alldredge, J.R., Pitts, M.J.: Efficacies of inocula on the startup of anaerobic reactors treating dairy manure under stirred and unstirred conditions. Biomass Bioenerg. 35, 2705–2720 (2011)

Sakar, S., Yetilmezsoy, K., Kocak, E.: Anaerobic digestion technology ın poultry and livestock waste treatment- a literature review. Waste Manag. Res. 27(3), 18 (2009)

Yaldiz, O., Sozer, S., Caglayan, N., Ertekin, C., Kaya, D.: Methane production from plant wastes and chicken manure at different working conditions of a one-stage anaerobic digester. Energy Sources Part A: Recovery Util. Environ. Eff. 33(19), 1802–1813 (2011)

Salminen, E., Rintala, J.: Anaerobic digestion of organic solid poultry slaughterhouse waste—a review. Bioresour. Technol. 83, 13–26 (2002)

Rao, A.G., Reddy, T.S.K., Prakash, S.S., Vanajakshi, J., Joseph, J., Jetty, A., Reddy, A.R., Sarma, P.N.: Biomethanation of poultry litter leachate ın uasb reactor coupled with ammonia stripper for enhancement of overall performance. Bioresour. Technol. 99, 8679–8684 (2008)

Calli, B., Mertoglu, B., Inanc, B., Yenigun, O.: Effects of high free ammonia concentrations on the performances of anaerobic bioreactors. Process Biochem. 40, 1285–1292 (2005)

Abouelenien, F., Nakashimada, Y., Nishio, N.: Dry mesophilic fermentation of chicken manure for production of methane by repeated batch culture. J. Biosci. Bioeng. 107 (3), 293–295 (2009)

Nasir, I.M., Ghazi, R., Omar, R.: Anaerobic digestion technology in livestock manure treatment for biogas production: a review. Eng. Life Sci. 12(3), 258–269 (2012)

Abouelenien, F., Fujiwara, W., Namba, Y., Kosseva, M., Nishio, N., Nakashimada, Y.: Improved methane fermentation of chicken manure via ammonia removal by biogas recycle. Bioresour. Technol. 101, 6368–6373 (2010)

Niu, Q., Qiao, W., Qiang, H., Hojo, T., Li, Y.Y.: Mesophilic methane fermentation of chicken manure at a wide range of ammonia concentration: stability, ınhibition and recovery. Bioresour. Technol. 137, 358–367 (2013)

Yetilmezsoy, K., Sapci-Zengin, Z.: Recovery of ammonium nitrogen from the effluent of uasb treating poultry manure wastewater by map precipitation as a slow release fertilizer. J. Hazard. Mater. 166, 260–269 (2009)

Yamamoto, T., Wakamatsu, S., Qiao, S., Hira, D., Fujii, T., Furukawa, K.: Partial nitritation and anammox of a livestock manure digester liquor and analysis of its microbial community. Bioresour. Technol. 102, 2342–2347 (2011)

Müller, V.: Bacterial fermentation, In Encyclopedia of Life Sciences, pp 1–7, Nature Publishing, New York (2001)

Borowski, S., Weatherley, L.: Co-digestion of solid poultry manure with municipal sewage sludge. Bioresour. Technol. 142, 345–352 (2013)

González, C.G., Barrios, X.G.: Anaerobic digestion of livestock wastes: vegetable residues as co-substrate and digestate posttreatment, Universidad De Valladolid, Valladolid (2010)

Callaghan, F.J., Wase, D.A.J., Thayanithy, K., Forster, C.F.: Continuous co-digestion of cattle slurry with fruit and vegetable wastes and chicken manure. Biomass Bioenerg. 27, 71–77 (2002)

Gungor-Demirci, G., Demirer, G.N.: Effect of initial cod concentration, nutrient addition, temperature and microbial acclimation on anaerobic treatability of broiler and cattle manure. Bioresour. Technol. 93, 109–117 (2004)

Bertin, L., Grilli, S., Spagni, A., Fava, F.: Innovative two-stage anaerobic process for effective codigestion of cheese whey and cattle manure. Bioresour. Technol. 128, 779–783 (2013)

Liu, K., Tang, Y.Q., Matsui, T., Morimura, S., Wu, X.L., Kida, K.: Thermophilic anaerobic co-digestion of garbage, screened swine and dairy cattle manure. J. Biosci. Bioeng. 107(1), 54–60 (2009)

Abouelenien, F., Elsaidy, N., Nakashimada, Y.: Simultaneous ammonia removal and methane production from chicken manure under dry thermophilic condition. J. Am. Sci. 9, 10 (2013)

APHA, AWWA, WPCF: Standard methods for the examination of water and wastewater. American Public Health Association, Washington, D.C (2001)

Speece, R.E.: Anaerobic biotechnology for ındustrial wastewaters, pp. 3-6-36. Archae Press, Nashville (1996)

Kata, M.T., Rebac, S., Lettinga, G.: The anaerobic treatment of low strength brewery wastewater in expanded granular sludge bed. Appl. Biochem. Biotechnol. 76, 15–32 (1999)

Bujoczek, G., Oleszkiewicz, J., Sparling, R., Cenkowski, S.: High solid anaerobic digestion of chicken manure. J. Agric. Eng. Res. 76, 5160 (2000)

Turkish Statistical Institute: Animal Production Statistics. http://www.turkstat.gov.tr/PreHaberBultenleri.do?id=21821 (2015). Accessed 1 Nov 2016

OECD/FAO: Agricultural Outlook 2012–2021. (2012). Accessed 1 Nov 2016. doi: 10.1787/agr_outlook-2012-en

Khanal, S.K.: Anaerobic biotechnology for bioenergy production: principles and applications, First Ed. Willey, USA. ISBN: 978-0-8138-2346-1 (2008)

Demirci, Y., Saatçi, Y.: Bir anaerobik çamur çürütme sisteminde çeşitli yük parametrelerinin sistem verimine etkileri. Fen ve Mühendislik Bilimleri Dergisi. 15(3), 337–348 (2003)

Öztürk, E.: Peyniraltı suyunun anaerobik arıtma çamuru reaktöründe arıtımında en uygun koşulların belirlenmesi, Yüksek Lisans Tezi, Gazi Üniversitesi Fen Bilimleri Enstitüsü, Ankara. pp. 34,48–49,76–79 (2007)

Converse, J.C., Evans, G.W., Verhoeven, C.R., Gibbon, W.: Performance of a large size anaerobic digester for poultry manure. ASAE Publication. pp. 15 (1977)

Kalyuzhnyi, S., Fedorovich, V., Nozhevnikova, A.: Anaerobic treatment of liquid fraction of hen manure in uasb reactors. Bioresour. Technol. 65, 221–225 (1998)

Atuanya, E.I., Aigbirior, M.: Mesophilic Biomethanation and treatment of poultry wastewater using pilot scale uasb reactor. Environ. Monit. Assess. 77, 139–147 (2002)

Anozie, A.N., Layokun, S.K., Okeke, C.U.: An evaluation of a batch pilot-scale digester for gas production from agricultural wastes. Energy Source. 27, 1301–1311 (2005)

Mahmoud, M.: High strength sewage treatment in a uasb reactor and an integrated uasb-digester system. Bioresour. Technol. 99, 7531–7538 (2008)

Abouelenien, F., Nakashimada, Y., Nishio, N.: Dry mesophilic fermentation of chicken manure for production of methane by repeated batch culture. J. Biosci. Bioeng. 107(3), 293–295 (2009)

Acknowledgements

The authors wish to thank Ege University, BAP (Bilimsel Araştırma Projesi) office under the grant No 13MUH002, for the financial support of this study. The data presented in this article was produced within the projects above, however it is only the authors of this article who are responsible for the results and discussions made herein. This article has been prepared within the context of Master Thesis studies of Gülizar Çalışkan.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Çalışkan, G., Azbar, N. Energy Recovery From Conventional Biogas Digester Effluent with a Novel Bioreactor Configuration. Waste Biomass Valor 8, 2371–2381 (2017). https://doi.org/10.1007/s12649-016-9827-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-016-9827-3