Abstract

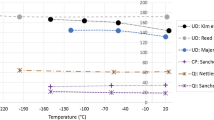

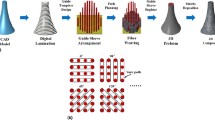

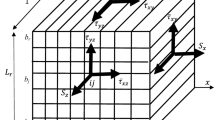

The need for materials for high-temperature applications has always been a topic of research for various engineering applications. The need for materials for high-temperature applications is an important need specifically for defense and space applications where they are subjected to very high temperatures during reentry into the earth’s atmosphere. Carbon/Carbon composites are promising materials for various fields of engineering. These materials are increasingly opted for due to their ability to withstand high temperatures above 3000 °C. Engineering designers have an important role in designing the components and sub-systems using these materials for high-temperature applications. Prediction of elastic constants for these materials is a significant step in the design of the components. The current work is aimed at the prediction of elastic constants. Elastic constants of unidirectional carbon/carbon composites are predicted in this work. Unit cell models of unidirectional carbon/carbon composites containing random positioning of fibers were created. Elastic constants were evaluated by applying periodic boundary conditions. The carbon/carbon test samples were fabricated to validate the predicted elastic constants. The PAN-based carbon fiber with carbon matrix was used for the fabrication of unidirectional carbon/carbon test samples. The uncertainty of measurement for the experiments was estimated using guide to the expression of uncertainty of measurement. The predicted values of elastic constants agree closely with the experimental results.

Similar content being viewed by others

Abbreviations

- A :

-

Area of the sample

- C i :

-

Sensitivity coefficient

- d(\({K}_{\mathrm{ran}})\) :

-

Mean random distance to \(K\mathrm{th}\) nearest neighbor

- d ij :

-

Distance between points i and j

- E 11 :

-

Longitudinal modulus

- E22, E33:

-

Transverse modulus of the fiber

- Em :

-

Young’s modulus of the matrix

- g(h):

-

Pair distribution function

- \({G}_\text{ij}\) :

-

Shear Modulus of the Fiber

- h :

-

Radius of circle

- K(h):

-

Ripley’s K function

- N :

-

No of fibers

- V :

-

Volume fraction

- \({v}_\text{ij}\) :

-

Poisson ratio of the fiber

- wij:

-

Weight function

- Kp(h):

-

Ripley’s K function for complete spatial randomness

- f :

-

Fiber

- m :

-

Matrix

References

C.T. Sun and R.S. Vaidya, Prediction of composite properties from a representative volume element. Comp. Sci. Technol., 56(2) (1996) 171–179.

S. Li, General unit cells for micromechanical analyses of unidirectional composites. Comp. Part A Appl. Sci. Manuf., 32(6) (2001) 815–826.

S. Li and A. Wongsto, Unit cells for micromechanical analyses of particle-reinforced composites. Mech. Mater., 36(7) (2004) 543–572.

J. Aboudi, Micromechanical analysis of composites by the method of cells.

J. Aboudi, Mechanics of composite materials-A unified micromechanical approach. NASA STI Recon Technical Report A., 93 (1991) 29778.

S. Ghosh and S. Moorthy, Elastic-plastic analysis of arbitrary heterogeneous materials with the Voronoi Cell finite element method. Comput. Methods Appl. Mech. Eng., 121(1–4) (1995) 373–409.

G.J. Dvorak, Y. Benveniste, On transformation strains and uniform fields in multiphase elastic media. In: Proceedings of the Royal Society of London. Series A: Mathematical and Physical Sciences,8 May 1992, 437 (1992) 291–310 .

G.J. Dvorak, On uniform fields in heterogeneous media. In: Proceedings of the Royal Society of London. Series A: Mathematical and Physical Sciences. 8 Oct 1990 431 (1881) 89–110.

G.J. Dvorak, Transformation field analysis of inelastic composite materials. In: Proceedings of the Royal Society of London. Series A: Mathematical and Physical Sciences. 1992 May 8 437 (1900) 311–27.

J.H. Lim, H. Kim, S.W. Kim and D. Sohn, A microstructure modeling scheme for unidirectional composites using signed distance function based boundary smoothing and element trimming. Adv. Eng. Softw., 1(109) (2017) 1–4.

K.P. Babu, P.M. Mohite and C.S. Upadhyay, Development of an RVE and its stiffness predictions based on mathematical homogenization theory for short fiber composites. Int. J. Solids Struct., 1(130) (2018) 80–104.

L. Iorga, Y. Pan and A. Pelegri, Numerical characterization of material elastic properties for random fiber composites. J. Mech. Mater. Struct., 3(7) (2008) 1279–1298.

P. Chowdhury, H. Sehitoglu and R. Rateick, Damage tolerance of carbon-carbon composites in aerospace application. Carbon., 1(126) (2018) 382–393.

X. Chao, L. Qi, W. Tian, X. Hou, W. Ma and H. Li, Numerical evaluation of the influence of porosity on bending properties of 2D carbon/carbon composites. Comp. Part B Eng., 1(136) (2018) 72–80.

A. Bahmani, G. Li, T.L. Willett and J. Montesano, Three-dimensional microscopic assessment of randomly distributed representative volume elements for high fiber volume fraction unidirectional composites. Comp Struc., 15(192) (2018) 153–164.

G. Li, F. Sharifpour, A. Bahmani and J. Montesano, A new approach to rapidly generate random periodic representative volume elements for microstructural assessment of high volume fraction composites. Mater. Des., 15(150) (2018) 124–138.

J. Sun, H. Li, L. Han and Q. Song, Enhancing both strength and toughness of carbon/carbon composites by heat-treated interface modification. J. Mater. Sci. Technol., 35(3) (2019) 383–393.

L. Han, K. Li, J. Sun, Q. Song and Y. Wang, Reinforcing effects of carbon nanotube on carbon/carbon composites before and after heat treatment. Mater. Sci. Eng. A, 26(735) (2018) 10–18.

X. Chao, L. Qi, J. Cheng, W. Tian, S. Zhang and H. Li, Numerical evaluation of the effect of pores on effective elastic properties of carbon/carbon composites. Comp. Struct., 15(196) (2018) 108–116.

Z. Liu, C. Zhu and P. Zhu, Generation of random fiber distributions for unidirectional fiber-reinforced composites based on particle swarm optimizer. Polym. Comp., 40(4) (2019) 1643–1653.

M.V. Pathan, S.A. Ponnusami, J. Pathan, R. Pitisongsawat, B. Erice, N. Petrinic and V.L. Tagarielli, Predictions of the mechanical properties of unidirectional fiber composites by supervised machine learning. Sci. Rep., 9(1) (2019) 1.

S.M. Park, J.H. Lim, M.R. Seong and D. Sohn, Efficient generator of random fiber distribution with diverse volume fractions by random fiber removal. Comp. Part B Eng., 15(167) (2019) 302–316.

W. Ge, L. Wang, Y. Sun and X. Liu, An efficient method to generate random distribution of fibers in continuous fiber reinforced composites. Polym. Comp., 40(12) (2019) 4763–4770.

C. Wang, M. Tang, W. Liu, T. Zhu, Study on Microstructure Characteristics and axially braided Carbon/Carbon composites based on SEM and Micro-CT. Materials. 2020 Mar 20 13 (6) (2020) 1414

K. Breuer, A. Spickenheuer and M. Stommel, Statistical Analysis of Mechanical Stressing in Short Fiber Reinforced Composites by Means of Statistical and Representative Volume Elements. Fibers., 9(5) (2021) 32.

V.N. Manchiraju, A. Bhagat and V.K. Dwivedi, Prediction of elastic properties of unidirectional carbon/carbon composites using analytical and numerical homogenisation methods. Adv. Mater. Process. Technol., 24 (2021) 1–5.

J. Liu, L. Chen, J. Xie, Z. Lin, Micro‐flow model with a new algorithm of random fiber distribution over the transverse cross-section. Polym. Comp. 41 (12) (2020) 5006–5015.

M. Nabi, S.M. Ghoreishi and M. Behpour, Uncertainty in Analytical Measurements: Approaches, Evaluation Methods and Their Comparison Based on a Case Study of Arsenic Determination in Rice. MAPAN, 36 (2021) 187–192. https://doi.org/10.1007/s12647-020-00422-0.

S. Pati, G. Mandal, N. Singh et al., A Pilot Study on the Comparison of the Methods for Uncertainty Analysis of Micropipette Calibration. MAPAN, 36 (2021) 343–347. https://doi.org/10.1007/s12647-021-00459-9x.

M. Pant, L. Nagdeve, G. Moona et al., Estimation of Measurement Uncertainty of Additive Manufacturing Parts to Investigate the Influence of Process Variables. MAPAN (2022). https://doi.org/10.1007/s12647-022-00592-z.

A.R. Melro, P.P. Camanho and S.T. Pinho, Generation of random distribution of fibers in long-fiber reinforced composites. Comp. Sci. Technol., 68(9) (2008) 2092–2102.

M.V. Mohan, R.B. Atul, V.K. Dwivedi, Effect of spatial distribution of fibers on elastic properties of unidirectional carbon/carbon composites. In E3S Web of Conferences 2021 (Vol. 309). EDP Sciences.

V. Romanov, S.V. Lomov, Y. Swolfs, S. Orlova, L. Gorbatikh, I. Verpoest, Statistical analysis of real and simulated fiber arrangements in unidirectional composites. Comp. Sci. Technol. 2013 Oct 18; 87 (2013) 126−134

V.N. Manchiraju, A.R. Bhagat and V.K. Dwivedi, Generation of random microstructure in fiber-reinforced composites and its comparison with carbon/carbon composite test samples through statistical analysis. Adv. Mater. Process. Technol., 18 (2022) 1–5.

S.L. Omairey, P.D. Dunning and S. Sriramula, Development of an ABAQUS plugin tool for periodic RVE homogenization. Eng. Comput., 35(2) (2019) 567–577.

V.M. Rao, P. Mahajan and R.K. Mittal, Effect of architecture on mechanical properties of carbon/carbon composites. Comp. Struct., 83 (2008) 131–142.

A.R. Bhagat and P. Mahajan, Homogenization and multiscale analysis of 3D carbon-carbon composites using Eigen deformation technique. J. Mater. Eng. Perform, 29 (2020) 365–376.

R. Sharma, P. Mahajan and R.K. Mittal, Elastic modulus of 3D carbon/carbon composite using image-based finite element simulations and experiments. Comp. Struct., 98 (2013) 69–78.

A.R. Bhagat and P. Mahajan, Characterization and damage evaluation of coal tar pitch carbon matrix used in carbon/carbon composites. J. Mater. Eng. Perform, 25 (2016) 3904–3911.

A.R. Bhagat and K.H. Sinnur, Characterization and Modeling of Interfaces in 3D Carbon Carbon Hybrid Composites. Comp. Interfaces (2021). https://doi.org/10.1080/09276440.2021.1949115.

B. Singh, M.R. Ranjan, A. Chauhan et al., Accreditation of conformity assessment bodies in the field of environmental testing in India. MAPAN, 37 (2022) 261–268. https://doi.org/10.1007/s12647-022-00563-4.

ISO I. 98–3: 2008 Uncertainty of measurement—part 3: Guide to the expression of uncertainty in measurement (GUM: 1995). International Organization for Standardization: Geneva, Switzerland. (2008).

W. Gabauer, The determination of uncertainties in tensile testing. Voest-Alpine Stahl Gmbh: Linz, Austria. (2000)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Manchiraju, V.N.M., Bhagat, A.R. & Dwivedi, V.K. Estimation of Elastic Constants Using Numerical Methods and Their Validation Through Experimental Results for Unidirectional Carbon/Carbon Composite Materials. MAPAN 38, 923–937 (2023). https://doi.org/10.1007/s12647-023-00669-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12647-023-00669-3