Abstract

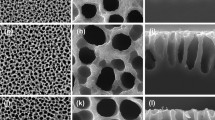

Based on importance of porous silicon in nearly all physical and chemical properties such as mechanical, electrical, and optical on one hand and its application in optoelectronic devices on the other hand, we decided to plan and construction a setup to receive a proper porous silicon in the case of uniformity in diameter and depth of pores which was confirmed by FESEM measurements. Using AFM images, topography parameters and fractal dimensions were calculated and compared. Optical band gap of silicon and porous silicon was compared. The prepared samples were applied to use as a gas sensor to exposure of ethanol and acetone vapors from 100 to 400 ppm. Interesting results of application of fabricated samples has been reported in result section.

Similar content being viewed by others

Data Availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Uhlir A (1956) Bell Syst Tech J 35:333

Fakiri S, Montagne A, Rahmoun K, Iost A, Ziouche K (2018) Mater Sci Eng A 711:470

Lachenani H, Larabi A, Gabouze N (2019) SILICON 11:2505

Chan KS, Dwight TJE (2018) Results Phys 10:5

Hajilari F, Farhadi K, Eskandari H, Allahnouri F (2020) Electrochim Acta 355:136751

Praveenkumar S, Lingaraja D, MahizMathi P, Dinesh Ram G (2019) Optik (Stuttg) 178:216

Massoudi A, Azim-Araghi ME, Keihan M (2015) Asl Adv. Ceram Prog 1:24

Black CT, Guarini KW, Breyta G, Colburn MC, Ruiz R, Sandstrom RL, Sikorski EM, Zhang Y (2006) J Vac Sci Technol B Microelectron Nanom Struct 24:3188

Föll H, Christophersen M, Carstensen J, Hasse G (2002) Mater Sci Eng R Reports 39:93

Russo L, Colangelo F, Cioffi R, Rea I, De Stefano L (2011) Materials (Basel) 4:1023

Bahar M, Gholami M, Azim-Araghi ME (2014) Mater Sci Semicond Process 26:491

Gole JL and Lewis SE (2008) Porous silicon–sensors and future applications. In Nanosilicon (pp 149–175). Elsevier.

Sailor MJ (2012) Porous silicon in practice—preparation, characterization and applications. Wiley-VCH, Weinheim, DE.

Levitsky IA (2015) Sensors (Switzerland) 15:19968

Dwivedi SBP (2023) IEEE Sensors J 23:3. https://doi.org/10.1109/JSEN.2022.3223102

Dwivedi P, Das S, Dhanekar S, Appl ACS (2017) Mater Interfaces 9(24):21017–21024

Dwivedi P, Neha Chauhan P, Vivekanandan SD, Sakthi Kumar D, Dhanekar S (2017) Sensors Actuators B Chem 249:602–610

Dwivedi P et al (2018) Nanotechnology 29:275503

Banerjee D et al (2020) Eng Res Express 2:035021

Salih E, Ayesh AI (2020) Phys E Low-Dimensional Syst Nanostructures 123:114220

Liu X, Cheng S, Liu H, Hu S, Zhang D, Ning H (2012) Sensors (Switzerland) 12:9635

Ghaderi A, Shafiekhani A, Solaymani S, Ţălu Ş, Duarte H, da Fonseca Filho NS, Ferreira RS, Matos HZ, Dejam L (2022) Sci Rep 12(1):1–9

Ramírez-González F, García-Salgado G, Rosendo E, Díaz T, Nieto-Caballero F, Coyopol A, Romano R, Luna A, Monfil K, Gastellou E (2020) Sensors (Switzerland) 20:1

Gosteva EA, Rubtsova KI, Silina MD, Starkov VV (2020) Mech Solids 55:103

Thomas T, Kumar Y, Ramos Ramón JA, Agarwal V, Sepúlveda Guzmán S, Pushpan RRS, Loredo SL, and Sanal KC (2021) Porous silicon/α-MoO3 nanohybrid based fast and highly sensitive CO2 gas sensors. Vacuum 184:109983

Choi MS, Na HG, Mirzaei A, Bang JH, Oum W, Han S, Choi SW, Kim M, Jin C, Kim SS, and Kim HW (2019) Roomtemperature NO2 sensor based on electrochemically etched porous silicon. J Alloys Compd 811:151975

Wang J, Zhou Q, Peng S, Xu L, Zeng W (2020) Front Chem 8:339

Naderi N, Hashim MR, Amran TST (2012) Superlattices Microstruct 51:626

Li C et al (2022) Sensors and Actuators: B. Chemical 367:132143

Harraz FA et al (2020) Arab J Chem 13:444–452

Riyazi S, Azim Araghi ME (2020) J Mater Sci Mater Electron 31:3539

Nečas D, Klapetek P (2012) Gwyddion: An open-source software for SPM data analysis. Cent Eur J Phys 10(1):181–188

ISO 25178–2: 2012, Geometrical product specifications (GPS) - Surface texture: Areal - Part 2: Terms, definitions and surface texture parameters

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

Emad Moghimi: Conceptualization, Methodology, Writing—original draft. Mohammad Esmaeil Azim Araghi: Data curation, Investigation, Writing—review & editing. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Financial Interests

The authors declare they have no financial interests.

Ethics Approval

Not applicable.

Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Competing Interests

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix 1

Appendix 1

The amplitude parameters of 3-D surface roughness, according with ISO 25178–2:2012 are defined as follows:

-

(Sa): Arithmetical mean height is the mean surface roughness.

-

(Sq): Root mean square height is the standard deviation of the height distribution, or RMS surface roughness.

-

(Ssk): Skewness is the third statistical moment, quantifying the symmetry of the height distribution. Negative skew indicates a predominance of valleys, while positive skew is seen on surfaces with peaks.

-

(Sku): Kurtosis is the fourth statistical moment, quantifying the flatness of the height distribution. For spiky surfaces, Sku > 3; for bumpy surfaces, Sku < 3; perfectly random surfaces have kurtosis of 3.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Moghimi, E., Azim Araghi, M.E. Ethanol and Acetone Gas Sensor Properties of Porous Silicon Based on Resistance Response. Silicon 15, 5821–5827 (2023). https://doi.org/10.1007/s12633-023-02607-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-023-02607-z