Abstract

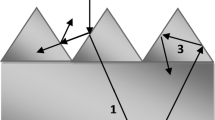

In this work we report the fabrication of ordered arrays of sub and micron-scale silicon pyramids and pillars by simple electrochemical etching of a p-type silicon substrate through Pd deposition. The Pd was deposited on Si substrate by evaporation technique using a mask (mPd/Si) and without a mask (wPd/Si). The morphology and dimensions of the silicon nano or micro-structure were controlled by the electrochemical etching time, dimension and shape of Pd structure. Then; ordered pyramids, inverted pyramids or mixed pyramids and pillars structure are formed depending on the etching time. The morphologies obtained have been attributed to two etching: chemical and electrochemical.

Finally, total reflectance spectra show a low reflectance value less than 5% in the region 350–1050 nm for anodized (mPd/Si) structures. Such result would be very interesting for both solar cells and optical filters applications.

Similar content being viewed by others

Data Availability

Not applicable.

References

Canham LT (1990) Silicon quantum wire array fabrication by electrochemical and chemical dissolution of wafers. Appel Phys Lett 57:1046–1048

Shao MW, Shan YY, Wong NB, Lee ST (2005) Silicon nanowire sensors for bioanalystical applications: glucose and hydrogen peroxide detection. Adv Funct Mater 15:1478–1482

Scheible DV, Blick RH (2004) Silicon nanopillars for mechanical single-electron transport. Appl Phys Lett 84:4632–4634

Cluzel B, Pauc N, Calvo V, Charvolin T, Hadji E (2006) Nanobox array for silicon-on-isulator luminescence enhancement at room temperature. Appl Phys Let 88:133120

R. Giuly, J.A. Corno, J.L. Gole,“A simple method for generating nano-pillars and uniformly separated nano-needle arrays on silicon” Mater Lett, 62, 17–18, pg. 2704–2706 (2008)

Schneider BW, Lal NN, Baker-Finch S, White TP (2014) Pyramidal surface textures for light trapping and antireflection in perovskite-on-silicon tandem solar cells. Opt Express 22(S6):A1422–A1430

Mavrokefalos A, Han SE, Yerci S, Branham MS, Chen G (2012) Efficient light trapping in inverted Nanopyramid thin crystalline silicon membranes for solar cell applications. Nano Lett 12(6):2792–2796. https://doi.org/10.1021/nl2045777

Wang X, Yang Z, Gao P, Yang X, Zhou S, Wang D, Liao M et al (2017) Improved optical absorption in visible wavelength range for silicon solar cells via texturing with nanopyramid arrays. Opt Express 25:10464–10472

Iqbal S, Zhang L-J, Xing-Chang F, Dan S, Zhou H-L, Weiping W, Zhang T (2018) Highly-efficient low cost anisotropic wet etchingof silicon wafers for solar cells application. AIP Adv 8:025223

Vazsonyi E, De Clercq K, Einhans R, van Kerschaver E, Said K, Poortmans J, Szlufcik J, Nijs J (1999). Sol Energy Mater Sol Cells 57:179–188

Slimani A, Iratni A, Chazalviel J-N, Gabouze N, Ozanam F (2009) Experimental study of macropore formation in p-type silicon in a fluoride solution and the transition between macropore formation and electropolishing. Electrochim Acta 54:3139–3144

Lehmann V (1993). J Electrochem Soc 140:2836–2843

Lehmann V, Föll H (1990). J Electrochem Soc 137:653–659

Smith RL, Collins SD (1992). J Appl Phys 71:R1–R22

Petrii OA, Khomchenko IG (1980) Electrochemical properties of platinum and palladium electrodes in acetonitrile solutions. J Electroanal Chem 106:277–286

John. K . Foley, Carol Korzniewki, Stanle pons, anodic and cathodic reactions in acetonitrileltetra-n-butylammonium tetrafluoroborate: an electrochemical and infrared spectroelectrochemical study , Can J Chem 66,000 (1988)

Seo H-S, Li X, Um H-D, Yoo B, Cho YW, Lee J-H (2009). Electrochem Solid-State Lett 12(12):D89–D91. https://doi.org/10.1149/1.3231135

Zhang XG (1991) Mechanism of pore formation on n-type silicon. J Electrochem Soc 138(12):3750. https://doi.org/10.1149/1.2085494

Searson PC, Macaulay JM, S. M. (1992) Prokes the formation, morphology, and optical properties of porous silicon structures. J Electrochem Soc 139(11):3373. https://doi.org/10.1149/1.2069080

Lehmann V, Gösele U (1991) Porous silicon formation: a quantum wire effect. Appl Phys Lett 58(8):856–858. https://doi.org/10.1063/1.104512

Rieger MM, Kohl PA (1995). J Electrochem Soc 142(5):1490–1495

Kang C-G, Kang M-S, Yang J-H (2003) Comparision of Nano-porous silicon prepared by Photoelectrochemical etching in HF-ethanol and HF-acetonitrile solutions. J Korean Phys Soc 42:S693–S697

Hadjersi T, Gabouze N, Yamamoto N, Benazzouz C, Cheraga H (2005). Vacuum 80:366–370

Huang Z, Geyer N, Werner P, de Boor J, Gösele U (2011). Adv Mater 23:285–308

Peng K, Xu Y, Wu YY, Lee S-T, Zhu J (2005) Aligned single-crystalline Si nanowire arrays for photovoltaic applications. Small 1:1062–1067

Han H, Huang Z, Lee W (2014) Metal-assisted chemical etching of silicon and nanotechnology applications. Nano Today 9(3):271–304

Asoh H, Arai F, Ono S (2009). Electrochim Acta 54:5142

Li X, Xiao Y, Yan C, Zhou K, Schweizer SL, Sprafke A, Lee J-H, Lee J-H, Wehrspohn RB (2013) Influence of the mobility of Pt nanoparticles on the anisotropic etching properties of silicon. ECS Solid State Lett 2(2):P22–P24

Lounas A, Nait Bouda A, Menari H, Belkacem Y, Gabouze N (2014) Texture etching of monocrystalline silicon surface with sodium hypochlorite. Surf Eng 30(02):148–151

Wijekoon K, Weidman T, Paak S, Williams KM (2010) Production ready novel texture etching process for fabrication of single crystalline silicon solar cells. Appl Mater IEEE 003635–003641

Acknowledgments

We are grateful to the financial support of the National Research Fund (DGRSDT/MESRS).

Author information

Authors and Affiliations

Contributions

The authors confirm contribution to the paper as follows:

- Study conception and design: Kahina Lasmi, Noureddine Gabouze, Lamia Amena;

- Data collection: Kahina Lasmi, Noureddine Gabouze, Lamia Amena, Amar Manseri, Hamid Menari, Maha Ayat;

- Analysis and interpretation of results: Noureddine Gabouze, Kahina Lasmi, Katia Ayouz-Chebout;

- Draft manuscript preparation: Noureddine Gabouze, Katia Ayouz-Chebout;

- All authors reviewed the results and approved the final version of the manuscript.

- All authors confirm their responsibility for the following: study conception and design, data collection, analysis and interpretation of results, and manuscript preparation.

Corresponding author

Ethics declarations

Ethical Statement for Current Silicon

Hereby, I AYOUZ-CHEBOUT KATIA, consciously assure that for the manuscript “Fabrication of Lithography-Free Silicon Sub-Micro-Pyramids” the following is fulfilled:

1) The paper was submitted for publication in Applied Physics A journal, this latter suggested transferred it to the Silicon journal.

2) The paper reflects the authors’ own research and analysis in a truthful and complete manner.

3) The paper properly credits the meaningful contributions of co-authors and co-researchers.

4) The results are appropriately placed in the context of prior and existing research.

5) All sources used are properly disclosed (correct citation). Literally copying of text must be indicated as such by using quotation marks and giving proper reference.

6) All authors have been personally and actively involved in substantial work leading to the paper, and will take public responsibility for its content.

I agree with the above statements and declare that this submission follows the policies of the Silicon as outlined in the Guide for Authors and in the Ethical Statement.

Consent for Publication

The authors, the undersigned, give her consent for the publication of identifiable details, which can include details within the text, to be published in the above Journal and Article.

Consent to Participate

Informed consent was obtained from all individual participants included in the study. The authors have consented to the submission of this research for publication in the journal.

Competing Interests

The authors declare that they have no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Additifs

Additifs

Generally, it is reported that the ethanol does not participate in the anodization process [5]. However, acetonitrile participates in the anodization process as shown in formula (3).

In addition, molecular structures of ethanol and acetonitrile are shown in Fig. 8. The nitrogen (N) in the acetonitrile has an unshared electron pair, so that the nitrogen combines with H2O which has a permanent dipole moment to form a weak hydrogen bond. Therefore, we present the possibility that acetonitrile prevents water molecules from participating in the anodization process as in anhydrous solution [5, 6, 12]. Therefore, with the reaction mechanism of silicon in anhydrous solution, hydrogen gas is produced little in the HF-acetonitrile solution in a HF-ethanol solution. Also, due to electron injection into the silicon conduction band, double currents pass to the silicon wafer so that uniform nano-PSi layers can be acquired in the same etching time.

Metal-assisted chemical etching (MACE), of silicon and nanotechnology applications, Hee Hana, Sufficient experimental evidences have been reported to support a solid mass transfer model [8, 9]. In the scenario, the oxidation of Si surface proceeds at the interface between metal and Si substrate; through HF can diffuse through the channels between Si and metal catalyst to bulk Si to facilitate the oxidative dissolution of Si, and reactants and byproducts diffuse as well through the channels (Fig. 1a). Two sets of etching experiments were carried out for comparison. Metal (Ag) stripes, including those with different lateral sizes while the same thickness and those with identical lateral size but different thicknesses were deposited onto Si substrates, and subsequently the samples were etched in an aqueous etchant comprised of HF and H2O2. The experiments showed that the etching rate decreases with the lateral size of Ag stripes, indicating the correlation between the etching rates of Si and the lateral sizes of Ag stripes.

Rights and permissions

About this article

Cite this article

Lasmi, K., Amena, L., Ayouz-Chebout, K. et al. Fabrication of Lithography-Free Silicon Sub-Micro-Pyramids. Silicon 14, 8311–8318 (2022). https://doi.org/10.1007/s12633-021-01586-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-021-01586-3