Abstract

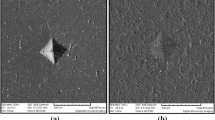

It is traditionally thought to be challenging to incorporate tougher ceramic particles into a softer aluminium matrix. Powder metallurgy has emerged as a significant fabrication technology in this context. Silicon carbide (SiC) is reinforced to aluminium with varying reinforcement, i.e., 5, 10, and 15 %. The samples were sintered in a microwave sintering furnace at 550 °C ± 5 °C. The scanning electron microscope and the field emission scanning electron microscope (FESEM) were used to inspect the microstructure (structure/shape, dislocations, and grain distribution) of prepared powders and sintered composites. Water displacement methods were used to assess the density and porosity of prepared composites. X-ray diffraction (XRD) is used to assess the existence of intermetallic compounds (if any) and contaminations. Mechanical investigations were performed on aluminium and its composites, as well as the effect of particle size on the mechanical properties of Al/15 %SiC were studied and presented. Density and porosity found to incline with the increase in SiC content. Properties such as hardness, ultimate tensile strength (UTS) and yield strength (YS) of the reinforced composites (5, 10, and 15 %) were significantly improved, whereas elongation rapidly declined compared to pure aluminium. Also, the UTS and YS increases with the decrease in reinforcement particle size. The dominant mechanisms are ascertained to be dislocation density, refined grain size, and porosity.

Similar content being viewed by others

Data Availability

As this manuscript is a part of ongoing research at this point of time data cannot be shared.

References

Chen HS, Wang WX, Nie HH, Zhou J, Li YL, Liu RF, Zhang YY (2018) Microstructure evolution and mechanical properties of B4C/6061Al neutron absorber composite sheets fabricated by powder metallurgy. J Alloy Compd 730:342–351

Zhang Z-H, Wang F-C, JieLuo S-K, Lee Lu, Wang (2010) Microstructures and mechanical properties of spark plasma sintered Al–SiC composites containing high volume fraction of SiC. Mater Sci Eng A 527:7235–7240

Prasad DS, Ebenezer NS, Shoba C, Pujari SR (2018) Effect of nickel electroplating on the mechanical damping and storage modulus of metal matrix composites. Mater Res Express 5(11):116409

Prasad DS, Ebenezer NS, Shoba C (2017) The effect of nickel electroplating on corrosion behavior of metal matrix composites. Trans Indian Inst Met 70(10):2601–2607

Siva Prasad D, Shoba C (2014) Effect of heat treatment on the white layer and its effect on the damping behavior of metal matrix composites. Mater Sci Eng: A 599:25–27

Aydin F, Sun Y, Ahlatci H, Turen Y (2018) Investigation of microstructure, mechanical and wear behaviour of B4C particulate reinforced magnesium matrix composites by powder metallurgy. Trans Indian Inst Met 71(4):873–882

Kumar PRS, Kumaran S, Srinivasa Rao T, Siva Prasad K (2009) Microstructure and mechanical properties of fly ash particle reinforced AA6061 composites produced by press and extrusion. Trans Indian Inst Met 62:559–566

Chintada S, Dora SP, Prathipati R. (2019) Investigations on the machinability of Al/SiC/RHA hybrid metal matrix composites. Silicon 11:2907–2918

Venkatesh VSS, Ashish B, Deoghare (2021) Microstructural characterization and mechanical behaviour of SiC and kaoline reinforced aluminium metal matrix composites fabricated through powder metallurgy technique. Silicon. https://doi.org/10.1007/s12633-021-01154-9

Yu JH, Wang CB, Shen Q, Zhang LM (2012) Preparation and properties of Sip/Al composites by spark plasma sintering. Mater Des 41:198–202

Venkatesh VSS, Ashish B, Deoghare (2021) Modelling and optimisation of wear parameters for spark plasma sintered Al– SiC– Kaoline Hybrid Composite. Adv Mater Process Technol. https://doi.org/10.1080/2374068X.2021.1939561

Saud M, Almotairy A, FadaviBoostani M, Hassani D, Wei ZY, Jiang (2020) Effect of hot isostatic pressing on the mechanical properties of aluminium metal matrix nanocomposites produced by dual speed ball milling. J Mater Res Technol 9(2):1151–1161

Venkatesh VSS, Ashish B, Deoghare (2021) Effect of boron carbide and Kaoline reinforcements on the microstructural and mechanical characteristics of aluminium hybrid metal matrix composite fabricated through powder metallurgy technique. Adv Mater Process Technol https://doi.org/10.1080/2374068X.2021.1945314

Singh S, Gupta D, Jain V (2015) Recent applications of microwaves in materials joining and surface coatings. Proc Inst Mech Eng Part B J Eng Manuf 230:603–617

Leonelli C, Veronesi P, Denti L, Gatto A, Iuliano L (2008) Microwave assisted sintering of green metal parts. J Mater Proc Technol 205:489–496

Venkatesh VSS, Deoghare AB (2021) Microstructural characterization and mechanical behaviour of SiC and Kaoline reinforced aluminium metal matrix composites fabricated through powder metallurgy technique. Silicon. https://doi.org/10.1007/s12633-021-01154-9

Venkatesh VSS, Deoghare AB (2021) Effect of sintering mechanisms on the mechanical behaviour of SiC and Kaoline reinforced hybrid aluminium metal matrix composite fabricated through powder metallurgy technique. Silicon. https://doi.org/10.1007/s12633-021-01333-8

Zawrah MF, Abo Mostafa H, Taha MA (2019) Effect of SiC content on microstructure, mechanical and electrical properties of sintered Al-20Si-xSiC nanocomposites fabricated by mechanical alloying. Mater Res Express 6:1–27

Matli PR, Fareeha U, Shakoor RA, Mohamed AMA (2018) A comparative study of structural and mechanical properties of Al–Cu composites prepared by vacuum and microwave sintering techniques. J Mater Res Technol 7(2):165–172

Shoba Chintada, Dora SP, Kare D, Doddi PRV (2021) Developments in sintered aluminium based composites. Met Powder Rep https://doi.org/10.1016/j.mprp.2021.06.085

Ghasali Ehsan, Rahim Yazdani-rad A, Rahbari T, Ebadzadeh, (2016) Microwave sintering of aluminum-ZrB2 composite: Focusing on microstructure and mechanical properties. Mater Res 19(4):765–769

Shahrdami L, Sedghi A, Shaeri MH (2019) Microstructure and mechanical properties of Al matrix nanocomposites reinforced by different amounts of CNT and SiCW. Composites Part B 175:1–11

Khan A, Abdelrazeq MW, Mattli MR, Yusuf MM, Alashraf A, Matli PR, Shakoor RA (2020) Structural and mechanical properties of Al-SiC-ZrO2 nanocomposites fabricated by microwave sintering technique. Crystals, MDPI 10:1–12

Taylor RP, Mcclain ST, Berry JT (1999) Uncertainty analysis of metal-casting porosity measurements using Archimedes’ principle. Int J Cast Met Res 11(4):247–257

Chao Sun M, Song Z, Wang, He Y (2011) Effect of particle size on the microstructures and mechanical properties of SiC-reinforced pure aluminum Composites. J Mater Eng Perform 20(9):1606–1612

Wąsik A, Leszczyńska-Madej B, Madej M (2017) The influence of SiC particle size on mechanical properties of aluminium matrix composites. Metall Foundry Eng 43(1):41–49

Prasad DS, Shoba Ch (2015) Experimental evaluation onto the damping behavior of Al/SiC/RHA hybrid composites. J Mater Res Technol 5(2):123–130

Prasad DS, Radha PT, Shoba Ch, Rao PS (2018) Dynamic mechanical behavior of WC-Co coated A356. 2 aluminum alloy. J Alloy Compd 767:988–993

Prasad DS, Ebenezer NS, Shoba Ch, Raju P, Rao PS (2019) The effect of T6 heat treatment on corrosion behavior of nickel electroplated metal matrix composites. Silicon 11(4):2025–2032

Prasad DS, Radha PT, Shoba Ch, Khurshid A, Kaustubh M (2018) Optimizing of wire EDM parameters for damping capacity of aluminum alloy. Mater Today: Proc 5(8):16832–16839

Hansen N (2004)Hall-Petch relation and boundary strengthening. Scr Mater 51:801–806

Zhang Z, Chen DL (2006) Consideration of Orowan strengthening effect in particulate-reinforced metal matrix nanocomposites: A model for predicting their yield strength. Scripta Mater 54:1321–1326

Shoba Ch, Prasad DS, Sucharita A, Abishek M, Koundinya MS (2018) Investigations of surface roughness, power consumption, MRR and tool wear while turning hybrid composites. Mater Today: Proc 5(8):16565–16574

Shoba Ch, Ramanaiah N, Rao DN (2014) Ageing behavior of aluminum hybrid metal matrix composites. Mater Sci 10(11):484–489

Shoba Ch, Ramanaiah N, Rao DN (2015) Influence of dislocation density on the residual stresses induced while machining Al/SiC/RHA hybrid composites J Mater Res Technol 4(3):273–277

Prasad DS, Shoba C (2015) Damping Behavior of Metal matrix composites. Trans Indian Inst Metals 68(2):161–167

Dora SP, Chintada S, Palukuri TR, Pujari SR (2020) Energy dissipation in WC-Co coated A356.2/RHA composites. Eng Sci Technol 23(5):1285–1290

Vogelsang M, Arsenault RJ, Fisher RM (1986) An in situ HVEM study of dislocation generation at Al/SiC interfaces in metal matrix composites. Mater Metall Trans A 17:379–389

Prasad DS, Shoba C, Ramanaiah N (2014) Investigations on mechanical properties of aluminum hybrid composites. J Mater Res Technol 3(1):79–85

Suryanarayana C, Mukhopadhyay D, Patankar SN, Froes FH (1992) Grain size effects in nanocrystalline materials. J Mater Res 7:2114–2118

Sudarshan, Surappa MK (2008) Synthesis of fly ash particle reinforced A356 Al composites and their characterization. Mater Sci Eng A 480:117–124

Manish Maurya NK, Maurya V, Bajpai (2019) Effect of SiC reinforced particle parameters in the development of aluminium based metal matrix composite. Joint Journal of Novel Carbon Resource Sciences & Green Asia Strategy (6):200–206

Najmeddin Arab (2020) Effects of SiC Wt% content on microstructure and mechanical properties of Al/SiC nano composite produced by mechanical alloying, sintering and milling. J Mater Environ Sci 11:2095–2105

Mohamed SS, Abdallah SA, Alazemi HH (2018) An Investigation on the mechanical and physical properties of AL6061/SiCp/Gr metal matrix composites. Int J Eng Appl Sci 5:1–5

Zulfia A, Zhakiah T, Dhaneswara D, Sutopo (2017) Characteristics of Al-Si-Mg reinforced SiC composites produced by stir casting route. IOP Conf. Series: Materials Science and Engineering, 202

Zakeria M, Vakili-Ahrari A, Rudi (2013) Effect of shaping methods on the mechanical properties of Al-SiC composite. Mater Res 16(5):1169–1174

Fathy A, Sadoun A, Abdelhameed M (2014) Effect of matrix/reinforcement particle size ratio (PSR) on the mechanical properties of extruded Al–SiC composites. Int J Adv Manuf Technol 73:1049–1056

El-Mahallawy NA, Zoalfakar SH, Maboud AAGA (2019) Microstructure and mechanical properties of Al/SiC surface composite with different volume fractions using friction stir process. IOP Conf. Series: Materials Science and Engineering, 634

Funding

The authors wish to thank the Science and Engineering Research Board, Department of Science and Technology, New Delhi, India for financial support (EEQ/2017/000276 dated 16th March 2018).

Author information

Authors and Affiliations

Contributions

Chintada Shoba: conceptualization, methodology, writing, D. Siva Prasad: Editing, Supervisor, Dorathi Kare: Experimentation and characterization.

Corresponding author

Ethics declarations

Conflict of Interest

All authors declare that there is no conflict of interest.

Ethics Approval and Consent to Participate

The manuscript does not report on or involve the use of any animal or human data or tissue and hence not applicable.

Consent for Publication

Yes.

Competing of Interest

All authors declare that they have no competing interests.

Consent to Participate

Not applicable.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chintada, S., Dora, S.P. & Kare, D. Mechanical Behavior and Metallographic Characterization of Microwave Sintered Al/SiC Composite Materials – an Experimental Approach. Silicon 14, 7341–7352 (2022). https://doi.org/10.1007/s12633-021-01409-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-021-01409-5