Abstract

Objectives

Al 6061 alloys are being used in vast industrial applications. The dry sliding wear behavior of SiC based Al6061 composites has been thoroughly explored in recent decade while its fretting wear behavior at high temperatures has not been studied well. In this work, the fretting wear parameters of Al6061 alloy and Al 6061 reinforced with 2 wt% SiC have been optimized and high temperature fretting wear behavior analyzed.

Methods

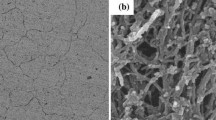

Ultrasonic assisted stir casting method has been employed to prepare Al6061-2SiC composite. Integrated Taguchi and TOPSIS methods have been used to optimize the input parameters viz. temperature, material type, applied load, time and frequency of strokes.

Results

It is observed that out of temperature, applied load, time and frequency of strokes, temperature proves out to be the most critical parameter affecting the wear behavior of the matrix alloy and its composite the most. Through integrated Taguchi and TOPSIS optimization technique, it is found that the most optimal combination of parameters for minimal wear rate and friction coefficient is Al6061 + 2 wt% SiC composite at 200 N load, 100 °C temperature, 10 min time, and 40 Hz frequency of fretting strokes.

Conclusions

The microscopic analysis of the samples revealed that fretting wear operates in partial slip regime in the composite tested at optimum combination of parameters. Wear regime changes from partial slip to mixed fretting with rise in temperature in the composite. In the alloy, the transition from mixed fretting to gross slip regime takes place with the rise in temperature. Al6061 alloy reinforced with 2 wt% SiC at optimum combination of parameters can prove to be a good replacement of conventional materials used in machinery prone to fretting wear.

Similar content being viewed by others

Data Availability

Not applicable.

Code Availability

Not applicable.

References

Vardhaman BSA, Amarnath M, Ramkumar J, Mondal K (2020) Enhanced tribological performances of zinc oxide/MWCNTs hybrid nanomaterials as the effective lubricant additive in engine oil. Mater Chem Phys 253:123447. https://doi.org/10.1016/j.matchemphys.2020.123447

Pratap V, Kumar S, Ranjan A, Kuriachen B (2020) Recent research progress in solid state friction-stir welding of aluminium – magnesium alloys : a critical review. Integr Med Res 9:6217–6256. https://doi.org/10.1016/j.jmrt.2020.01.008

Ul Haq MI, Anand A (2018) Dry sliding friction and wear behavior of AA7075-Si3N4 composite. Silicon 10:1819–1829. https://doi.org/10.1007/s12633-017-9675-1

Radha A, Vijayakumar KR (2016) An investigation of mechanical and wear properties of AA6061 reinforced with silicon carbide and graphene nano particles-particulate composites. Mater Today Proc 3:2247–2253. https://doi.org/10.1016/j.matpr.2016.04.133

Hariharasakthisudhan P, Sathickbasha K, Surya Rajan B, Jeyanthram V (2020) Steady-state wear behavior of multi-scale hybrid composite—AA6061/Al2O3 (μm)/Si3N4 (nm)/graphite—EN31 steel tribo system. J Tribol 142:1–16. https://doi.org/10.1115/1.4044853

Bharath V, Nagaral M, Auradi V, Kori SA (2014) Preparation of 6061Al-Al 2 O 3 MMC’s by stir casting and evaluation of mechanical and wear properties. Procedia Mater Sci 6:1658–1667. https://doi.org/10.1016/j.mspro.2014.07.151

Jun D, Yao-Hui L, Si-Rong Y, Wen-Fang L (2004) Dry sliding friction and wear properties of Al2O3 and carbon short fibres reinforced Al-12Si alloy hybrid composites. Wear 257:930–940. https://doi.org/10.1016/j.wear.2004.05.009

Sharma VK, Kumar V (2019) Development of rare-earth oxides based hybrid AMCs reinforced with SiC/Al2O3: mechanical & metallurgical characterization. J Mater Res Technol 8:1971–1981. https://doi.org/10.1016/j.jmrt.2019.01.013

Patel SK, Singh VP, Kumar N et al (2020) Wear behaviour of al-silicon (LM13) alloy composite reinforcement with TiC and ZrSiO4 particles. Silicon 12:211–221. https://doi.org/10.1007/s12633-019-00114-8

Chen R, Iwabuchi A, Shimizu T (2000) The effect of a T6 heat treatment on the fretting wear of a SiC particle-reinforced A356 aluminum alloy matrix composite. Wear 238(2):110–119. https://doi.org/10.1016/S0043-1648(99)00328-2

Huang W, Hou B, Pang Y, Zhou Z (2006) Fretting wear behavior of AZ91D and AM60B magnesium alloys. Wear 260:1173–1178. https://doi.org/10.1016/j.wear.2005.07.023

Chen GX, Zhou ZR (2001) Study on transition between fretting and reciprocating sliding wear. Wear 250–251:665–672. https://doi.org/10.1016/S0043-1648(01)00675-5

Zhu MH, Zhou ZR (2011a) On the mechanisms of various fretting wear modes. Tribol Int 44:1378–1388. https://doi.org/10.1016/j.triboint.2011.02.010

Stachowiak GW (2006) Wear: materials, mechanisms and practice. Wiley, Chichester

Patil NA, Pedapati SR, Mamat O Bin, Syah Lubis AMH (2019) Optimization of friction stir process parameters for enhancement in surface properties of Al 7075-SiC/Gr hybrid surface composites. Coatings 9:. https://doi.org/10.3390/coatings9120830

Daoud A, Abou El-khair MT (2010) Wear and friction behavior of sand cast brake rotor made of A359-20 vol% SiC particle composites sliding against automobile friction material. Tribol Int 43:544–553. https://doi.org/10.1016/j.triboint.2009.09.003

Walczak M, Pieniak D, Zwierzchowski M (2015) The tribological characteristics of SiC particle reinforced aluminium composites. Arch Civ Mech Eng 15:116–123. https://doi.org/10.1016/j.acme.2014.05.003

Kalra CS, Kumar V, Manna A (2019) The wear behavior of Al/(Al 2 O 3 + SiC + C) hybrid composites fabricated stir casting assisted squeeze. Part Sci Technol 37:303–313. https://doi.org/10.1080/02726351.2017.1369475

Mosleh-Shirazi S, Akhlaghi F, Li DY (2016) Effect of graphite content on the wear behavior of Al/2SiC/Gr hybrid nano-composites respectively in the ambient environment and an acidic solution. Tribol Int 103:620–628. https://doi.org/10.1016/j.triboint.2016.08.016

Jojith R, Radhika N (2019) Mechanical and tribological properties of LM13/TiO2/MoS2 hybrid metal matrix composite synthesized by stir casting. Part Sci Technol 37:566–578. https://doi.org/10.1080/02726351.2017.1407381

Kumar S, Virendra P, Singh P, Kuriachen B (2019) Microstructural , tribological and mechanical properties evolution of ZrSiO 4 / A4047 surface composite fabricated through friction stir processing. Trans Indian Inst Metals 72:1765–1774. https://doi.org/10.1007/s12666-019-01647-7

Kumar S, Nateriya R, Saha B, Kuriachen B (2020) Microstructural and mechanical behaviour of WC reinforced particles A3003 surface composite fabricated through friction stir processing 56:998–1007. https://doi.org/10.1134/S2070205120050226

Liu S, Wang Y, Muthuramalingam T, Anbuchezhiyan G (2019) Effect of B4C and MOS2 reinforcement on micro structure and wear properties of aluminum hybrid composite for automotive applications. Compos Part B Eng 176:107329. https://doi.org/10.1016/j.compositesb.2019.107329

Hu Q, Mccoll IR, Harris SJ, Waterhouse RB (2000) The role of debris in the fretting wear of a SiC reinforced aluminium alloy matrix composite 245:10–21

Jr CHH, Sanders JH, Sharma S et al (2006) Effect of high temperature on the characterization of fretting wear regimes at Ti6Al4V interfaces 260:493–508. https://doi.org/10.1016/j.wear.2005.03.011

Rybiak R, Fouvry S, Bonnet B (2010) Fretting wear of stainless steels under variable temperature conditions : introduction of a ‘ composite ’ wear law. Wear 268:413–423. https://doi.org/10.1016/j.wear.2009.08.029

Prakash NA, Gnanamoorthy R, Kamaraj M (2012) Fretting wear behavior of fine grain structured aluminium alloy formed by oil jet peening process under dry sliding condition. Wear 294–295:427–437. https://doi.org/10.1016/j.wear.2012.07.026

Venkateswaran T, Sarkar D, Basu B (2006) WC-ZrO2 composites: processing and unlubricated tribological properties. Wear 260:1–9. https://doi.org/10.1016/j.wear.2004.11.005

Majzoobi GH, Abbasi F (2017) An investigation into the effect of normal load frequency on fretting fatigue behavior of Al7075-. 2004. https://doi.org/10.1080/10402004.2017.1371366

Zhai W, Lu W, Zhang P, Wang J, Liu X, Zhou L (2018) Applied surface science Wear-triggered self-healing behavior on the surface of nanocrystalline nickel aluminum bronze / Ti 3 SiC 2 composites. Appl Surf Sci 436:1038–1049. https://doi.org/10.1016/j.apsusc.2017.12.138

Jin C, Onuoha CC, Farhat ZN, Kipouros GJ, Plucknett KP (2017) Microstructural damage following reciprocating wear of TiC-stainless steel cermets. Tribol Int 105:201–218. https://doi.org/10.1016/j.triboint.2016.10.011

Xia M, Liu A, Lin Y, Li N, Ding H, Zhong C (2019) Densi fi cation behavior , microstructure evolution and fretting wear performance of in-situ hybrid strengthened Ti-based composite by laser powder-bed fusion. Vacuum 160:146–153. https://doi.org/10.1016/j.vacuum.2018.11.023

Wang M, Wang Y, Liu H, Wang J, Yan F (2019) Tribology international interrelated e ff ects of temperature and load on fretting behavior of SAF 2507 super duplex stainless steel. Tribiology Int 136:140–147. https://doi.org/10.1016/j.triboint.2019.03.042

Ferreira T, Koga GY, Oliveira IL de, et al (2020) Functionally graded aluminum reinforced with quasicrystal approximant phases – improving the wear resistance at high temperatures. Wear 462–463. https://doi.org/10.1016/j.wear.2020.203507

Prasad Reddy A, Vamsi Krishna P, Rao RN (2019) Tribological behaviour of Al6061–2SiC-xGr hybrid metal matrix nanocomposites fabricated through ultrasonically assisted stir casting technique. Silicon 11:2853–2871. https://doi.org/10.1007/s12633-019-0072-9

Roy RK (2010) A primer on the Taguchi method. Society of Manufacturing Engineers, Dearborn

Balasubramaniyan S, Selvaraj T (2017) Application of integrated Taguchi and TOPSIS method for optimization of process parameters for dimensional accuracy in turning of EN25 steel. J Chinese Inst Eng Trans Chinese Inst Eng A 40:267–274. https://doi.org/10.1080/02533839.2017.1308233

Harichandran R, Selvakumar N (2018) International Journal of Mechanical Sciences Microstructure and mechanical characterization of ( B 4 C + h-BN )/ Al hybrid nanocomposites processed by ultrasound assisted casting 144:814–826. https://doi.org/10.1016/j.ijmecsci.2017.08.039

Nimura K, Sugawara T, Jibiki T, Ito S, Shima M (2015) Tribology international surface modi fi cation of aluminum alloy to improve fretting wear properties. Tribiology Int:1–7. https://doi.org/10.1016/j.triboint.2015.01.022

Hirsch MR, Neu RW (2013) Influence of temperature on the fretting response between AISI 301 stainless steel and AISI 52100 steel. Tribol Int 68:77–84. https://doi.org/10.1016/j.triboint.2012.11.004

Wu PQ, Chen H, Van Stappen M et al (2000) Comparison of fretting wear of uncoated and PVD TiN coated high-speed steel under different testing conditions. Surf Coatings Technol 127:114–119. https://doi.org/10.1016/S0257-8972(00)00564-8

Acknowledgments

The authors would like to thank the staff of the foundry laboratory of the Department of Metallurgical and Materials Engineering NIT Srinagar for their help in the fabrication of composites. They would also like to thank colleagues and friends for their unconditional support for the realization of this project.

Author information

Authors and Affiliations

Contributions

Conceptualization: [Mehak Nisar]; Methodology: [Mehak Nisar]; Formal analysis and investigation: [Mehak Nisar]; Writing - original draft preparation: [Mehak Nisar]; Writing - review and editing: [Mehak Nisar]; Supervision: [Dr. M. S. Charoo].

Corresponding author

Ethics declarations

Consent to Participate

Yes.

Consent for Publication

Yes.

Conflicts of Interest/Competing Interests

The authors declare no conflicts of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nisar, M., Charoo, M.S. Optimization of Fretting Wear Parameters and Effect of High Temperature on Fretting Wear Behavior of Al6061 Alloy and Al6061-SiC Composite. Silicon 14, 3949–3961 (2022). https://doi.org/10.1007/s12633-021-01172-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-021-01172-7