Abstract

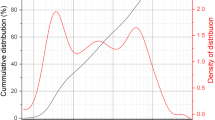

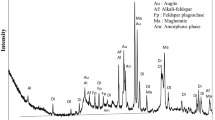

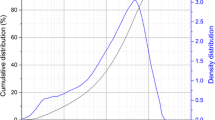

This study assesses the effects of curing temperatures (28 and 60 °C) and P2O5 / H2O molar ratio percentages (4 to 12 %) on initial setting time, microstructure and mechanical strength of volcanic ash-based phosphate inorganic polymers. The inorganic polymers along with the raw materials were characterized by X Ray Fluorescence (XRF), X Ray Diffraction (XRD), Fourier Transform Infra Red (FTIR) spectroscopy and Scanning Electron Microscopy (SEM). In addition, initial setting time of pastes was determined along with compressive strength and water absorption on specimens aged 28 days. The results showed that initial setting time decreases with the increase of P2O5 / H2O molar ratio percentage in the range of 126 − 20 Min (28 °C) and 20 − 10 Min (60 °C). Conversely, either at 28 or 60 °C curing, compressive strength increases with the increase of P2O5 / H2O molar ratio percentage. FTIR spectra show the presence of Ca-O and Fe-O and Al-O-P-O bonds. Dependent on curing temperature, new crystalline phases including hydroxyl apatite, brushite, sigloite, aluminium phosphate hydrate, potassium magnesium phosphate hydrate and silicon hydrogen phosphate were formed. Hence, initial setting time, microstructure and mechanical strength of volcanic ash-based phosphate inorganic polymers are P2O5 / H2O molar ratio percentage, curing temperature and chemical composition dependent.

Similar content being viewed by others

Data Availability

Not applicable.

References

Rishabh B, Kaislash C, Anshuman S, Kuldip SS, Manpreet S (2020) Environmental impact assessment of fly ash and silica fume based geopolymer concrete. J Clean Prod. https://doi.org/10.1016/j.jclepro.2020.120147

Hamdy AAG, Mona SM, Sahar EZ (2020) Preparation, performance and stability of alkali-activated-concrete xaste-lead-bearing sluge composite. J Clean Prod. https://doi.org/10.1016/j.jclepro.2020.12094

Ng H-T, Cheng-Yong H, Yung-Ming L, Al Bakri AMM, Hung KE, Razi HM, Ng YS (2021) Formulation, mechanical properties and phase analysis of fly ash geopolymer xhith leadle furnace slag replacement. J Mater Res Technol 12:1212–1226. https://doi.org/10.1016/j.mrt.2021.03.065

Kaze CR, Lemougna PN, Alomayri T, Assaedi H, Adesina A, Kumar DS, Lecomte-Nana GL, Kamseu E, Melo UC, Leonelli C (2021) Characterization and performance evaluation of laterite based geopolymr binder cured at different temperature. Conbuildmat 270:121443. https://doi.org/10.1016/j.conbuildmat.2020.121443

Akbar A, Farooq F, Shafique M, Aslam F, Alyousaf R, Abduljabar H (2021) Sugarcane bagasse ash-based engineered geopolymer motar incorporating propylene fiber. J Build Eng 33:101492. https://doi.org/10.1016/j.jobe.2020.101492

Tome S, Nana A, Kaze CR, Djobo YNJ, Alomayri T, Kamseu E, Etoh MA, Etame J, Kumar S (2021) Resistance of alkali-activated blended volcanic ash-MSXI-FA motar in sulphuric acid and artificial seawater. Silicon. https://doi.org/10.1007/s12633-021-01055-x

Wang L, Geddes DA, Walkley B, Provis JL, Mactchering V, Tsang DCW (2020) The role of zinc in metakaolin-based geopolymers. Cem Concr Res 136:106194. https://doi.org/10.1016/j.cemconrs.2020.106194

Pandaeng S, Sata V, Aguar JB, Pacheco-Torgal F, Chindaprasirt P (2015) apatite formation on calcined kaolin-white portland cement geopolymer. Mater Sci Eng C 51:1–6. https://doi.org/10.1016/j.mesc.2015.02.039

Sayed M, Gao RA, Naga SM, Colombo P, El Sayed H (2020) Influence of the thermal treatment on the characteristics of porous geopolymers as potential biomaterial. Mater Sci Eng C Mater Biol Appl 116:111171. https://doi.org/10.1016/j.msec.2020.111171

Luhar S, Ta-Wui C, Nicolaides D, Luhar I, Panias D, Sakkas K (2019) Valorization of glass wastes for the development of geopolymer composites-Durability, thermal and microstructural properties: A review. Conbuildmat 222:673–687. https://doi.org/10.1016/j.conbuildmat.2019.06.169

Xiao R, Ma Y, Jiang X, Zhang M, Zhang Y, Wang Y, Huang B, He Q (2020) Strength, microstructure, efflorescence behavior and environmental impacts of waste glass geopolymers cured at ambient temperature. J Clean Prod 252:119610. https://doi.org/10.1016/jclepro.2019-119610

Si R, Dai Q, Guo S, Wang J (2020) Mechanical property, nanopore structure and drying shrinkage of metalaolins-based geopolymer with waste glass powder. J Clean Prod 242:118502. https://doi.org/10.1016/j.clepro.2019.118502

Kaze CR, Lecomte-Nana GL, Kamseu E, Comacho PS, Yorkshire AS, Provis JL, Duttine M, Wattiaux A, Melo UC (2021) Mechanical and physical properties of inorganic polymer cement made of iron-rich laterite and lateritic clay: A comparative study. Cem Concr Res 140:106320. https://doi.org/10.1016/j.ce.conres.2020.106320

Bewa CN, Tchakouté HK, Banenzoue C, Cakanou L, Mbakop TT, Kamseu E, Ruscher CL (2020) Acid-based geopolymers using waste fired brick and differents metakaolin as raw materials. App Clay Sci 198:105813. https://doi.org/10.1016/j.clay.2020.105813

Mimboe AG, Abo MT, Djobo YJN, Tome S, Kaze CR, Deutou JGN (2020) Lateritic soil based-compressed earths bricks stabilized with phosphate binder. J Build Eng. https://doi.org/10.1016/j.jobe.éàéà.101465

Davidovits J (2002) Environnentally driven geopolymer cements applications. Geopolymer 2002 Conference, october 28–29, Melbourne, Australia

Elimbi A, Tchakoute HK, Njopwouo D (2011) Effects of calcination temperature of kaolinite clays on the properties of geopolymer cements. Constr Build Mater 25:2805–2812. https://doi.org/10.1016/j.conbuildmat.2010.12.055

Tchakoute HK, Elimbi A, Yanne E, Djangang CN (2013) Utilization of volcanic ashes for the production of geopolymers cured at ambient temperature. Cem Concr Comp 38:75–81. https://doi.org/10.1016/j.cemconcomp.2013.03.010

Djon Li Ndjock BI, Elimbi A, Cyr M (2017) Rational utilization of volcanic ashes based on factors affecting their alkaline activation. J Non-Cryst Solids 463:31–39. https://doi.org/10.1016/j.noncrysol.2017.02.024

Bondar D, Lynsdale CJ, Milestone NB, Hassani N, Ramezanianpour AA (2011) Effect of heat treatment on reactivity-strength of alkali-activated natural pozzolans. Constr Build Mater 25:4065–4071. https://doi.org/10.1016/j.conbuildmat.2011.04.044

Bondar D, Lynsdale CJ, Milestone NB, Hassani N, Ramezanianpour AA (2010) Geopolymer cement from alkali-activated natural pozzolans: Effect of addition of minerals. In: Second International Conference on Sustainable Construction Materials and Technologies, Ancona, Italy

Bondar D, Lynsdale CJ, Milestone NB, Hassani N, Ramezanianpour AA (2011) Effect of adding mineral additives to alkali-activated natural pozzolan paste. Constr Build Mater 25:2906–2910. https://doi.org/10.1016/j.conbuildmat.2010.12.031

Djobo YJN, Elimbi A, Dika Manga J, Djon Li Ndjock BI (2016) Partial replacement of volcanic ash by bauxite and calcined oyster shell in synthesis of volcanic ash-based geopolymers. Constr Build Mater 113:673–681. https://doi.org/10.1016/j.conbuilmat.2016.03.104

Baenla J, Bike Mbah JB, Djon Li Ndjock IB, Elimbi A (2019) Partial replacement of low reactive volcanic ash by cassava pell ash in the synthesis of volcanic ash based geopolymer. Constr Build Mater. https://doi.org/10.1016/j.conbuildmater.2019.116689

Tchakouté HK, Rüscher CH (2017) Mechanical and microstructural properties of metakaolin-based geopolymer cements from sodium water glass and phosphoric acid solution as hardeners: a comparative study. Appl Clay Sci 140:81–87. https://doi.org/10.1016/j.clay.2017.02.002

Katsiki A (2019) Aluminosilicate phosphate cements – a critical review. Adv Appl Ceram 118:274–286. https://doi.org/10.1080/17436753.2019.1572339

Le-ping L, Xue-min C, Shu-heng Q, Jun-li Y, Zhang L (2010) Preparation of phosphoric acid-based porous geopolymers. Appl Clay Sci 50:600–603. https://doi.org/10.1016/j.clay.2010.10.004

Khabbouchi M, Hosni K, Mezni M, Zanelli C, Doggy M, Dondi M, Srasra E (2017) Interaction of metakaolin - phosphoric acid and their structural evolution at high temperature. Appl Clay Sci 146:510–516. https://doi.org/10.1016/j.clay.2017.07.006

Katsiki A, Hertel T, Tysmans T, Pontikes Y, Rahier H (2019) Metakaolinite phosphate cementious matrix: inorganic polymer obtained by acidic activation. Materials. https://doi.org/10.3390/ma12030442

Djon Li Ndjock BI, Baenla J, Bike Mbah JB, Elimbi A, Cyr M (2020) Amorphous phase of volcanic ash and microstructure of cement product obtained from phosphoric acid activation. SN Appl Sci 2:720. https://doi.org/10.1007/s42452-020-2496-7

Djobo JNY, Elimbi A, Stephan D (2020) Phase and dimensional stability of volcanic ash-based phosphate inorganic polymers at elevated temperatures. SN Appl Sci 2:828. https://doi.org/10.1007/s42452-020-2616-4

Djobo YJN, Stephan D, Elimbi A (2020) Setting and harderning behavior of volcanic ash phosphate cement. J Build Eng 31:101427. https://doi.org/10.1016/j.jobe.2020.101427

Djon Li Ndjock BI, Robayo-salazar RA, Mejia de Gutierrez R, Baenla J, Mbey JA, Cyr M, Elimbi A (2021) Phosphoric acid activation of volcanic ashes: Influence of the molar ratio R = (MgO + CaO) / P2O5 on reactivity of volcanic ash and strength of obtained cementatious materials. J Build Eng. https://doi.org/10.1016/j.jobe.2020.101879

EN 196-3 Standard (2005) Methods of testing cement. Part 3: Determination of setting time and Soundness

ASTM C-642 Standard. Test Methods for (1995) apparent porosity, water absorption, apparent specific gravity and bulk density of burned refractory brick and shapes by boiling water 2000. Pennsylvania

Fernandez-Jiménez A, Palomo A (2005) Characterization of fly ash cements. Fuel 82:2259–2265

Davidovits J (1991) Geopolymers inorganic polymeric new materials. J Thermal Anal 37:1633–1656. https://doi.org/10.1007/BF01912193

Davidovits J (2017) Geopolymers: ceramic-like inorganic polymers. J Ceram Sci Technol 08(3):335–350. https://doi.org/10.4416/JCST2017-00038

Coppola L, Bellezze T, Belli A, Bignozzi MC, Bolzoni F, Brenna A, Cabrini M, Candamano S, Cappai M, Caputo D, Carsana M, Casnedi L, Cioffi R, Cocco O, Coffetti D, Colangelo F, Coppola B, Corinaldesi V, Crea F, Crotti E, Daniele V, De Gisi S, Delogu F, Diamanti MV, Di Matio L, Di Mundo R, Di Palma L, Donnini J, Farina I, Ferone C, Frontera P, Castaldi M, Giossuè C, Incarnato L, Liguori B, Lollini F, Lorenzi S, Manzi S, Martino O, Marroccoli M, Mascolo MC, Mavilia L, Mazzoli A, Medici F, Meloni P, Merlonetti G, Mobili A, Notarricola M, Ormellese M, Pasrore T, Pedeferri MP, Petrella A, Pia G, Redaelli E, Roviello G, Scarfato P, Scoccia G, Tagheri G, Telesca A, Tittarelli F, Torado F, Vilardi G, Yang F (2018) Binder alternative to Portland cement and waste management for sustainable construction-Part1. J Appl BiomaterFunct Mater 16:186–202. https://doi.org/10.1177/2280800018782845

Nkwaju RY, Djobo JNY, Nouping JNF, Huisken PWM, Detou JGN, Couard L (2019) Iron-rich laterite-bagasse fibers based geopolymer composite: Mechanical, durability and insulating properties. Appl Clay Sci 183:105333.https://doi.org/10.1016/j.clay.2019.105333

Djobo JNY, Elimbi A, Tchakouté HK, Kumar S (2016) Reactivity of volcanic ash in alkaline medium, microstructural and strength characteristics of resulting geopolymers under differents synthesis conditions. J Mater Sci 51:10301–10317. https://doi.org/10.1007/s10853-016-0257-1

Louati S, Baklouti S, Samet B (2016) Geopolymers based on phosphoric acid and illito-kaolinitic clay. Adv Mater Sci Eng. https://doi.org/10.1155/2016/2359759

Khabbouchi M, Hosni K, Srasra E (2018) Physico-chemical characterization of modified tunisian kaolin by phosphoric acid. Surf Eng Appl Electrochem 54:219–226. https://doi.org/10.3203/S1068375518020072

Leogodi MA, De Waal D (2007) The preparation of magnetite, goethite, hematite and maghemite of pigment quality from mill scale iron waste. Dyes Pigments 74:161–168. https://doi.org/10.1016/j.dyepig.2006.01.038

Bewa CN, Tchakouté HK, Ruscher CH, Kamseu E, Leonelli C (2019) Influence of the curing temperature on the properties of poly(phospho-ferro-siloxo) networks from laterite. SN Appl Sci 1:1–12. https://doi.org/10.1007/s42452-019-0975-5

Kaze R, Beuleuk à Moungam L, Cannio M, Rosa R, Kamseu E, Melo UC, Leonelli C (2018) Microstructure and engineering properties of Fe2O3 (FeO) - Al2O3 - SiO2 based geopolymers composites. J Clean Prod 199:849–859. https://doi.org/10.1016/j.jclepro.2018.07.171

Vempati RK, Loeppert RH (1989) Influence of structural and adsorbed Si on the transformation of synthetic ferrihydrite. Clays Clay Min 273–279. https://doi.org/10.1346/CCMN.1989.0370312

Gallup LD, Reiff WM (1991) Characterization of geothermal scale deposits by Fe-57 mossbauer spectroscopy and complementary x-ray diffraction and infrared studies. Geothermics. 20(4): 207–224. https://doi.org/10.1016/0375-6505(91)90033-R

Tchakouté HK, Fotio D, Ruscher CH, Kamseu E, Djobo JNY, Bignozzi MC, Leonelli C (2018) The effects of synthesized calcium phosphate compounds on the mechanical and microstructural properties of metakaolin-based geopolymer cements. Constr Build Mater 163:776–792. https://doi.org/10.1016/j.conbuildmat.2017.12.162

Mabah DET, Tchakouté HK, Ruscher CH, Kamseu E, Elimbi A, Leonelli C (2018) Design of low cost semi-crystalline calcium silicate from biomass for the improvement of the mechanical and microstructural properties of metakaolin-based geopolymers cement. Mater Chem Phys. https://doi.org/10.1016/j.mathchemphys.2018.10.061

Furko M, Havasi V, Konya Z, Grunewald A, Detsch R, Boccaccini A, Balazsi C (2018) Development and characterizarion of multi-element doped hydroxyapatite bioceramic coatings on metallic implants for orthopedic applications. Bol Soc Esp Ceram Vidrio 57:55–65. https://doi.org/10.1016/j.bsecv.2017.09.003

Frost RL, Xi Y, Scholz R, Belleti FM, Filho MC (2013) The phosphate mineral sigloite Fe3+Al2(PO4)2(OH)3.7(H2O), an exception to the paragenesis rule-a vibrational spectroscopic study. J Mol Struct 1033:258–264. https://doi.org/10.1016/j.molstruc.2012.10.020

Soudée E, Péra J (2000) Mechanism of setting reaction in magnesia-phosphate cements. Cem Concr Res 30(99):315–321. https://doi.org/10.1016/S0008-8846

Barandehfard F, Kianpour Rad M, Hosseinnia A, Khorroo K, Tahriri M, Jazaveri HE, Moharamzadeh K, Tayebi L (2016) The addition of synthesized hydroxyapatite and fluoroapatite nanoparticles to a glass- ionomer cements for dental restoration and its effects on mechanical properties. Ceram Int 42:17866–17875

Wagh AS, Jeong SY (2003) Chemically bonded phosphate ceramics: III, Reduction mechanism and its application to iron phosphate ceramics. J Am Ceram Soc 86(11):1850–1855. https://doi.org/10.1111/j.1151-2916.2003.tb03571.x

Wagh AS (2005) Chemically bonded phosphate ceramics-A novel class of geopolymers. Adv Ceram Mater Comp X:107-116. https://doi.org/10.1002/978111840353.ch10

Acknowledgements

The authors would like to thank Mrs Christoph Janiak and Alex Spiess of the Institute fur Anorganische Chemie und Strukturchemie I, Henrich Heine Universitat of Dusseldorf for the XRD and SEM analyses.

Author information

Authors and Affiliations

Contributions

This work was carried out in collaboration between all the authors.

-Joseph Dika Manga: one of co-supervisor of this study.

-Bernard Dickson Priso Missota : prepared the methodology, carried out the experimental part of this study and interpreted the results of XRD, FTIR and SEM analyzes. This co-author wrote the first version of this manuscript.

-Thierry Ebenizer Pougnong : made and interpreted the results relating to the mechanical measurements.

-Jean Baenla: Interpreted the results of the XRD and FTIR analyzes.

-Louise Ndongo Ebonguè ground and sieved the raw materials.

-Antoine Elimbi: other co-supervisor and revised the proposed manuscript and corrected before submitting this final version.

Corresponding author

Ethics declarations

Ethics Approval and Consent to Participate

We Authors of this study are sincere to confirm that the submitted paper whose title is “Effects of kinetic parameters on initial setting time, microstructure and mechanical strength of volcanic ash-based phosphate inorganic polymers” is from us and is an original one.

We confirm that this manuscript has been read and approved by all named Authors and there are no other persons who satisfied the criteria for authorship but are not listed. We further confirm that the order of the Authors listed in this manuscript has been approved by all of us.

We confirm that this submitted manuscript has not been published previously or is not under consideration for publication elsewhere.

We wish to confirm that there are not known conflicts of interest associated with this submitted paper and there has been no significant financial support for this work that could influence its outcome.

If this paper is accepted, we hereby confirm that it will be published elsewhere neither in the same form nor in any language without the written consent of the publisher.

We: Bernard Dickson Priso Missota; Joseph Dika Manga; Thierry Enenizer Pougnong; Jean Baenla; Louise Ndongo Ebongue; Antoine Elimbi.

Consent for Publication

Not Applicable.

Competing Interest

Not Applicable.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Missota Priso Dickson, B., Dika Manga, J., Pougnong, T.E. et al. Effects of Kinetic Parameters on Initial Setting Time, Microstructure and Mechanical Strength of Volcanic Ash-based Phosphate Inorganic Polymers. Silicon 14, 3693–3705 (2022). https://doi.org/10.1007/s12633-021-01140-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-021-01140-1