Abstract

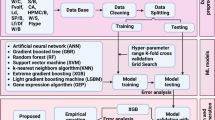

A futuristic class of concrete that has ductile nature with zeroed cement and eco-friendly materials is popularly known as Engineered Geopolymer Composites (EGC). Research on strain-hardening geopolymer composites have started a decade back and there is an extensive opportunity for utilizing this kind of eco-material in the construction sector for sustainable development. The focus of this article is to develop predictive models for the compressive strength of EGC with the objective of assisting the experimental researches and to analyze the type of locally available eco-materials that could be adopted in developing the novel ductile geopolymer composites for structural applications. A database has been created with ten mix-design factors, including material contents and curing conditions as inputs. Three soft-computing tools viz., Artificial Neural Networks (ANN), Response Surface Methodology (RSM) and Gene-Expression Programming (GEP) have been exercised to create, train and validate the predictive models. Also, a critical comparative analysis has been performed. The accuracy of predictive models is tested with regression tools. Among these artificial intelligence tools, the RSM model has shown an accuracy level of 96% with the least RMSE of 2.8 and the ANN [10:8:1] model has shown 93% accuracy with RMSE 3.4. Only 80% accuracy has been shown for the GEP model with RMSE 6.2. The sensitive parameter in concrete composites is compressive strength where the prediction error should be minimum. This article concludes that the developed ANN and RSM models worked effectively in prediction whereas GEP is comparatively less accurate, which can be improved when influencing mix-design parameters are lesser.

Similar content being viewed by others

Data Availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

References

Li VC (2016) Bendable concrete. Innov Const:11–15

Li VC (2003) Engineered cementitious composites (ecc): a review of the material and its applications. J Adv Concr Technol 1(3):215–230

Felekoglu B, Keskinates M (2016) Multiple cracking analysis of HTPP-ECC by digital image correlation method. Comput Concr 17(6):831–848

Chen C, Habert G, Bouzidi Y, Jullien A (2010) Environmental impact of cement production: detail of the different processes and cement plant variability evaluation. J Clean Prod 18:478–485. https://doi.org/10.1016/j.jclepro.2009.12.014

Ahmaruzzaman M (2010) A review on the utilization of fly ash. Prog Energy Combust Sc 36(3):327–363

Rangan BV (2008) Fly ash-based geopolymer concrete. Curtin University of Technology, Perth

Sakthidoss DD, Senniappan T (2020) A study on high strength geopolymer concrete with alumina-silica materials using manufacturing sand. Silicon. 12:735–746. https://doi.org/10.1007/s12633-019-00263-w

Chandrasekhar Reddy K (2020) Investigation of mechanical and microstructural properties of fiber-reinforced geopolymer concrete with ggbfs and metakaolin: novel raw material for geopolymerisation. Silicon. https://doi.org/10.1007/s12633-020-00780-z

Raijiwala DB, Patil HS (2010) Geopolymer concrete a green concrete. In 2010 2nd International Conference on Chemical, Biological and Environmental Engineering: 202–206. IEEE

Pan Z, Sanjayan JG, Rangan BV (2011) Fracture properties of geopolymer paste and concrete. Mag Concr Res 63(10):763–771

Yu J, Leung CKY (2017) Strength improvement of strain-hardening cementitious composites with ultrahigh-volume fly ash. J Mater Civ Eng 29(9):1–10

Nurdeen Altwair M, Megat Johari MA, Saiyid Hashim SF (2012) Flexural performance of green engineered cementitious composites containing high volume of palm oil fuel ash. Constr Build Mater 37:518–525

Pillay DL, Olalusi OB, Mostafa MM (2020) A review of the engineering properties of concrete with paper mill waste ash—towards sustainable rigid pavement construction. Silicon. https://doi.org/10.1007/s12633-020-00664-2

Xiaoyan Huang, Ravi Ranade, Qian Zhang, Wen Ni, Victor C Li (2013) Mechanical and thermal properties of green lightweight engineered cementitious composites. Constr Build Mater 48: 954–960

Shanour AS, Sai M, Arafa AI, Maher A (2018) Flexural performance of concrete beams containing engineered cementitious composites. Constr Build Mater 180:23–34

Yu J, Yao J, Lin X, Li H, Jeffery YK, Christopher KY, Ivan ML (2018) Tensile performance of sustainable strain-hardening cementitious composites with hybrid PVA and recycled PET fibers. Cem Concr Res 107:110–123

Kan LI, Wang WS, Liu WD, Wu M (2020) Development and characterization of fly ash based pva fiber reinforced engineered geopolymer composites incorporating metakaolin. Cem Concr Compos 108:103521. https://doi.org/10.1016/j.cemconcomp.2020.103521

Ekaputri JJ, Junaedi S, Wijaya (2017) Effect of curing temperature and fiber on metakaolin-based geopolymer. Procedia engineering 171:572–583. https://doi.org/10.1016/j.proeng.2017.01.376

Ling Y, Wang K, Li W, Shi G, Lu P (2019) Effect of slag on the mechanical properties and bond strength of fly ash-based engineered geopolymer composites. Composites Part B 164:747–757. https://doi.org/10.1016/j.compositesb.2019.01.092

Nematollahi B, Ranade R, Sanjayan J, Ramakrishnan S (2017) Thermal and mechanical properties of sustainable lightweight strain hardening geopolymer composites. Arch Civ Mech Eng 17:55–64. https://doi.org/10.1016/j.acme.2016.08.002

Farooq M, Bhutta A, Banthia N (2019) Tensile performance of eco-friendly ductile geopolymer composites (EDGC) incorporating different micro-fibers. Cem Concr Compos 103:183–192. https://doi.org/10.1016/j.cemconcomp.2019.05.004

Zurada JM (1992) Introduction to artificial neural systems. St. Paul West

Kim JI, Kim DK (2002) Application of neural networks for estimation of concrete strength. KSCE J Civ Eng 6:429–438. https://doi.org/10.1007/bf02841997

Bai J, Wild S, Ware J, Sabir B (2003) Using neural networks to predict workability of concrete incorporating metakaolin and fly ash. Adv Eng Softw 34:663–669. https://doi.org/10.1016/s0965-9978(03)00102-

Yang DS, Park SK, Lee JH (2003) A prediction on mix proportion factor and strength of concrete using neural network. KSCE J Civ Eng 7:525–536. https://doi.org/10.1007/bf02838318

Jithendra C, Elavenil S (2020) Influences of parameters on slump flow and compressive strength properties of aluminosilicate based flowable geopolymer concrete using taguchi method. Silicon 12:595–602. https://doi.org/10.1007/s12633-019-00166-w

Siddique R, Aggarwal P, Aggarwal Y (2011) Prediction of compressive strength of self-compacting concrete containing bottom ash using artificial neural networks. Adv Eng Softw 42:780–786. https://doi.org/10.1016/j.advengsoft.2011.05.016

Khosravani MR, Nasiri S, Anders D, Weinberg K (2019) Prediction of dynamic properties of ultra-high performance concrete by an artificial intelligence approach. Adv Eng Softw 127:51–58. https://doi.org/10.1016/j.advengsoft.2018.10.002

Liu JC, Zhang Z (2020) Neural network models to predict explosive spalling of PP fiber reinforced concrete under heating. J Build Eng 32:101472. https://doi.org/10.1016/j.jobe.2020.101472

Nagajothi S, Elavenil S (2020) Influence of aluminosilicate for the prediction of mechanical properties of geopolymer concrete – artificial neural network. Silicon 12:1011–1021. https://doi.org/10.1007/s12633-019-00203-8

Nagaraj Y, Jagannatha N, Sathisha N (2020) Prediction of material removal rate and surface roughness in hot air assisted hybrid machining on soda-lime-silica glass using regression analysis and artificial neural network. Silicon. https://doi.org/10.1007/s12633-020-00729-2

Bektas F, Bektas BA (2014) Analyzing mix parameters in ASR concrete using response surface methodology. Constr Build Mater 66:299–305. https://doi.org/10.1016/j.conbuildmat.2014.05.055

Mohammed BS, Fang OC, Anwar Hossain KM, Lachemi M (2012) Mix proportioning of concrete containing paper mill residuals using response surface methodology. Constr Build Mater 35:63–68. https://doi.org/10.1016/j.conbuildmat.2012.02.050

Yousefi A, Matavos Aramyan S (2018) Mix design optimization of silica fume-based pervious concrete for removal of heavy metals from wastewaters. Silicon 10:1737–1744. https://doi.org/10.1007/s12633-017-9663-5

Poorarbabi A, Ghasemi M, Azhdary Moghaddam M (2020) Concrete compressive strength prediction using non-destructive tests through response surface methodology. Ain Shams Eng J 11:939–949. https://doi.org/10.1016/j.asej.2020.02.009

Hammoudi A, Moussaceb K, Belebchouche C, Dahmoune F (2019) Comparison of artificial neural network (ANN) and response surface methodology (RSM) prediction in compressive strength of recycled concrete aggregates. Constr Build Mater 209:425–436. https://doi.org/10.1016/j.conbuildmat.2019.03.119

Elemam WE, Abdelraheem AH, Mahdy MG, Tahwia AM (2020) Optimizing fresh properties and compressive strength of self-consolidating concrete. Constr Build Mater 249:118781. https://doi.org/10.1016/j.conbuildmat.2020.118781

Busari AA, Kupolati WK, Ndambuki JM (2020) Correction to: response surface analysis of the corrosion effect of metakaolin in reinforced concrete. Silicon. https://doi.org/10.1007/s12633-020-00754-1

Shahmansouri AA, Akbarzadeh Bengar H, Ghanbari S (2020) Compressive strength prediction of eco-efficient GGBS-based geopolymer concrete using GEP method. J Build Eng 31:101326. https://doi.org/10.1016/j.jobe.2020.101326

Shahmansouri AA, Akbarzadeh Bengar H, Jahani E (2019) Predicting compressive strength and electrical resistivity of eco-friendly concrete containing natural zeolite via GEP algorithm. Constr Build Mater 229:116883. https://doi.org/10.1016/j.conbuildmat.2019.116883

Beheshti Aval SB, Ketabdari H, Asil Gharebaghi S (2017) Estimating shear strength of short rectangular reinforced concrete columns using nonlinear regression and gene expression programming. Structures 12:13–23. https://doi.org/10.1016/j.istruc.2017.07.002

Ozcan F (2012) Gene expression programming based formulations for splitting tensile strength of concrete. Constr Build Mater 26:404–410. https://doi.org/10.1016/j.conbuildmat.2011.06.039

Jafari S, Mahini SS (2017) Lightweight concrete design using gene expression programing. Constr Build Mater 139:93–100. https://doi.org/10.1016/j.conbuildmat.2017.01.120

Awoyera PO, Kirgiz MS, Viloria A, Ovallos Gazabon D (2020) Estimating strength properties of geopolymer self-compacting concrete using machine learning techniques. J Mater Res Technol 9:9016–9028. https://doi.org/10.1016/j.jmrt.2020.06.008

Chen L, Kou CH, Ma SW (2014) Prediction of slump flow of high-performance concrete via parallel hyper-cubic gene-expression programming. Eng Appl Artif Intell 34:66–74. https://doi.org/10.1016/j.engappai.2014.05.005

Mangi SA, Wan Ibrahim MH, Jamaluddin N (2020) Establishment of strength prediction equation for concrete containing coal bottom ash exposed to aggressive environment. Silicon. https://doi.org/10.1007/s12633-020-00675-z

Awolusi TF, Oke LO, Akinkurolere OO (2020) The application of response surface methodology in understanding the compressive strength and water absorption capacity of sandcrete blocks. Silicon. https://doi.org/10.1007/s12633-020-00701-0

Nematollahi B, Sanjayan J, Ahmed Shaikh FU (2016) Matrix design of strain hardening fiber reinforced engineered geopolymer composite. Composites Part B 89:253–265. https://doi.org/10.1016/j.compositesb.2015.11.039

Ohno M, Li VC (2018) An integrated design method of engineered geopolymer composite. Cem Concr Compos 88:73–85. https://doi.org/10.1016/j.cemconcomp.2018.02.001

Li W, Du H (2018) Properties of PVA fiber reinforced geopolymer mortar. International congress on polymers in concrete (ICPIC 2018) https://doi.org/10.1007/978-3-319-78175-4_71

Al Mashhadani MM, Canpolat O, Aygormez Y, Uysal M, Erdem S (2018) Mechanical and microstructural characterization of fiber reinforced fly ash based geopolymer composites. Constr Build Mater 167:505–513. https://doi.org/10.1016/j.conbuildmat.2018.02.061

Zahid M, Shafiq N (2020) Effects of sand/fly ash and the water/solid ratio on the mechanical properties of engineered geopolymer composite and mix design optimization. Minerals 10. https://doi.org/10.3390/min10040333

Xu F, Deng X, Peng C, Zhu J, Chen J (2017) Mix design and flexural toughness of PVA fiber reinforced fly ash-geopolymer composites. Constr Build Mater 150:179–189. https://doi.org/10.1016/j.conbuildmat.2017.05.172

Nematollahi B, Sanjayan J, Shaikh FUA (2014) Comparative deflection hardening behavior of short fiber reinforced geopolymer composites. Constr Build Mater 70:54–64. https://doi.org/10.1016/j.conbuildmat.2014.07.085

Kan L, Zhang L, Zhao Y, Wu M (2020) Properties of polyvinyl alcohol fiber reinforced fly ash based engineered Geopolymer composites with zeolite replacement. Constr Build Mater 231:117161. https://doi.org/10.1016/j.conbuildmat.2019.117161

DattaChaudhuri T, Ghosh I (2015) Forecasting volatility in indian stock market using artificial neural network with multiple inputs and outputs. Int J Comput 120:7–15. https://doi.org/10.5120/21245-4034

Robiminer - Own work, CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=18558398

Acknowledgements

The Authors would like to express gratitude to B.S.Abdur Rahman Crescent Institute of Science & Technology for supporting the necessary facilities and permission for paper publication.

Authors‘Contributions

All authors in this article made substantial contributions to the conception, design of the work, acquisition, analysis, interpretation of data and writing/revision of the article.

Code Availability

Not applicable.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethical Approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed Consent

Not applicable.

Consent for Publication

Not Applicable.

Conflict of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yaswanth, K.K., Revathy, J. & Gajalakshmi, P. Soft Computing Techniques for the Prediction and Analysis of Compressive Strength of Alkali-Activated Alumino-Silicate Based Strain-Hardening Geopolymer Composites. Silicon 14, 1985–2008 (2022). https://doi.org/10.1007/s12633-021-00988-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-021-00988-7