Abstract

Nowadays, porous Si3N4 ceramics are fabricated by high purity α-Si3N4 powders, resulting in a higher cost of production. To reduce cost and save energy, in this research, high levels of β-Si3N4 powders were effectively utilized to produce excellent and low-cost porous Si3N4 ceramics. The effects of high levels of β-Si3N4 powders on the microstructural evolution and properties were investigated in detail. The results suggested that, with the increase in β-Si3N4 powders from 0 wt.% to 80 wt.%, the aspect ratio of β-Si3N4 grains gradually decreased because of the anisotropic growth of grains significantly impinged by adjacent other β-Si3N4 grains. Additionally, the bending strength and dielectric constant of porous silicon nitride ceramics declined and their values were 685 MPa - 220 MPa, and 7.58–5.57, respectively, while the porosity increased from 5.9% to 28.5%. Similarly, the residual bending strength of Si3N4 ceramics degraded from 615 MPa to 172 MPa at 1000 °C for 20 h owing to the formation of SiO2 on the surface of silicon nitride ceramics after oxidizing.

Similar content being viewed by others

Data Availability

The datasets used or analysed during the current study are available from the corresponding author on reasonable request.

References

Wang C, Chen M, Wang HJ, Fan XY (2016) Fabrication and thermal shock resistance of multilayer γ-Y2Si2O7 environmental barrier coating on porous Si3N4 ceramic. J Eur Ceram Soc 36:689–695

Liu K, Zhang CR, Li B, Wang SQ, Cao F (2014) Synthesis of porous silicon nitride-boron nitride composites by gel-casting and PIP. J Mater Eng Perform 23:2829–2833

Li D, Li B, Yang XJ, Gao ST, Zheng YY (2018) Fabrication and properties of in situ silicon nitride nanowires reinforced porous silicon nitride (SNNWs/SN) composites. J Eur Ceram Soc 38:2671–2675

Liu W, Tong WX, He RX, Wu HD, Wu SH (2016) Effect of the Y2O3 additive concentration on the properties of a silicon nitride ceramic substrate. Ceram Int 42:18641–18647

Zou CR, Zhang CR, Li B, Wang SQ, Cao F (2013) Microstructure and properties of porous silicon nitride ceramics prepared by gel-casting and gas pressure sintering. Mater Design 44:114–118

Riley FL (2000) Silicon nitride and related materials. J Am Ceram Soc 83:245–265

Ganesh I (2011) Development of β-SiAlON based ceramics for radome applications. Process Appl Ceram 5:113–138

Li XM, Yin XW, Zhang LT, Cheng LF, Qi YC (2019) Mechanical and dielectric properties of porous Si3N4–SiO2 composite ceramics. Mater Sci Eng A 500:63–69

Yu JL, Yang JL, Li S, Li HX, Huang Y (2012) Preparation of Si3N4 foam ceramics with nest-like cell structure by particle-stabilized foams. J Am Ceram Soc 95:1229–1233

Chen F, Shen Q, Yan FQ, Zhang LM (2007) Pressureless sintering of α-Si3N4 porous ceramics using a H3PO4 pore-forming agent. J Am Ceram Soc 90:2379–2383

Fukasawa T, Deng ZY, Ando M, Ohji T, Kanzaki S (2002) Synthesis of porous silicon nitride with Unidirectionally aligned channels using freeze-drying process. J Am Ceram Soc 85:2151–2155

Wan T, Yao DX, Hu HL, Xia YF, Zuo KH, Zeng YP (2014) Fabrication of porous Si3N4 ceramics through a novel gelcasting method. Mater Lett 133:190–192

Arnaldo JM, Nieto MI, Moreno R (2001) Aqueous gel-forming of silicon nitride using Carrageenans. J Am Ceram Soc 84:62–64

Zhang Y, Yao DX, Yin JW, Zuo KH (2019) Fabrication and mechanical properties of porous Si3N4 ceramics prepared via SHS. Ceram Int 45:14867–14872

Yao, X.D., Zeng Y.P (2011) High flexural strength porous silicon nitride prepared via Nitridation of silicon powder. J Inorg Mater 26:422–426

Golla BR, Ko JW, Kim HD (2017) Processing and characterization of sintered reaction bonded Si3N4 ceramics. Int J of Refract Met H 68:75–83

Liu CC (2003) Microstructure characterization of gas-pressure-sintered α-silicon nitride containing β-phase seeds. Ceram Int 29:841–846

Wang B, Yang J, Guo R, Gao JQ (2009) Microstructure characterization of hot-pressed β-silicon nitride containing β-Si3N4 seeds. Mater Charact 60:894–899

Yu JJ, Guo WM, Wei WX, Lin HT, Wang CY (2018) Fabrication and wear behaviors of graded Si3N4 ceramics by the combination of two-step sintering and β-Si3N4 seeds. J Eur Ceram Soc 38:3457–3462

Lee HM, Tatami J, Kim DK (2016) Mirostructural evolution of Si3N4 ceramics from starting powders with different α-to-β ratios. J Ceram Soc Jpn 124:800–807

Belmonte M, González-Julián J, Miranzo P, Osendi MI (2010) Spark plasma sintering: a powerful tool to develop new silicon nitride-based materials. J Eur Ceram Soc 30:2937–2946

Jones AH, Dobedoe RS, Lewis MH (2001) Mechanical properties and tribology of Si3N4–TiB2 ceramic composites produced by hot pressing and hot isostatic pressing. J Eur Ceram Soc 21:969–980

Awais Q, Zsolt F, Zsolt EH, Katalin B, Gsaba B (2018) Effect of the oxidation of Si3N4 powder on the microstructural and mechanical properties of hot isostatic pressed silicon nitrdie. Ceram Int 44:14601–14609

Kovalčíkováa A, Cs B, Dusza J, Tapasztób O (2012) Mechanical properties and electrical conductivity in a carbon nanotube reinforced silicon nitride composite. Ceram Int 38:527–533

Pasupuleti S, Peddetti R, Santhanam S, Jen KP, Wing ZN, Hecht M, Halloran JP (2008) Toughening behavior in a carbon nanotube reinforced silicon nitride composite. Mater Sci Eng A 491:224–229

Ryshkewitch E (1993) Compression strength of porous sintered alumina and zirconia. J A Ceram Soc 36:65–68

Chao LY, Shetty KD (1992) Extreme-value statistics analysis of fracture strengths of a sintered silicon nitride failing from pores. J Am Ceram Soc 75:2116–2124

Kalemtas A, Topates G, Özcoban H, Mandal H, Kara F, Janssen R (2013) Mechanical characterization of highly porous β-Si3N4 ceramics fabricated via partial sintering & starch addition. J Eur Ceram Soc 33:1507–1515

Xu X, Huang LP, Liu XJ, Fu XR (2002) Effects of α/β ratio in starting powder on microstructure and mechanical properties of silicon nitride ceramics. Ceram Int 28:279–281

Lin SJ, Ye F, Ma J, Ding JJ, Liu Q, Dong SL (2015) Fabrication and properties of porous boron nitride/silicon oxynitride ceramic composites via gas pressure sintering. Mater Design 87:272–277

Zhao YJ, Zhang YJ, Gong HY, Wang XL, Sun HB (2015) Effects of Y2O3–MgO nanopowders content on mechanical and dielectric properties of porous BN/Si3N4 composites. Ceram Int 41:3618–3623

Logesh G, Mohammed R, Mangesh L, Ummen S (2018) Mechanical and dielectric properties of carbon fiber reinforced reaction bonded silicon nitride composites. J Alloy Compd 767:1083–1093

Yang WL, Shi ZQ, Wang HL, Qiao GJ, Li YF, Yang JF, Jin ZH (2014) Effects of ZrO2 on the Nitridation behavior and mechanical properties of reaction-bonded Si3N4/h-BN composite. J Mater Eng Perform 23:3436–3443

Xia YF, Zeng YP, Jiang DL (2011) Mechanical and dielectric properties of porous Si3N4 ceramics using PMMA as pore former. Ceram Int 37:3775–3779

Lee SJ, Baek S (2016) Effect of SiO2 content on the microstructure, mechanical and dielectric properties of Si3N4 ceramics. Ceram Int 42:9921–9925

Penn SJ, Alford NM, Templeton A, Wang XR (2005) Effect of porosity and grain size on the microwave dielectric properties of sintered alumina. J Am Ceram Soc 80:1885–1888

Liang HQ, Yao XM, Huang ZR, Zeng YP, Su BZ (2016) The relationship between microstructure and flexural strength of pressureless liquid phase sintered SiC ceramics oxidized at elevated temperatures. Ceram Int 42:13256–13261

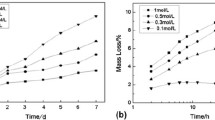

Liang HQ, Zeng YP, Zuo KH, Xia YF, Yao DX, Yin JW (2017) The effect of oxidation on the mechanical properties and dielectric properties of porous Si3N4 ceramics. Ceram Int 43:5517–55233

Acknowledgments

The work is supported by National Natural Science Foundation of China (project number: 50872108).

Author information

Authors and Affiliations

Contributions

Dr. Haiqiang Ma: Investigation and Validation, Writing-original draft preparation. Prof. Chonggao Bao: Supervision, Methodology, Validation and Writing-review.

Corresponding authors

Ethics declarations

Conflicts of Interest

The authors declared that they have no conflicts of interest to this work.

Consent to Participate

Participants provide their written or verbal informed consent to participate in this study.

Consent for Publication

Written informed consent for publication was obtained from all participants.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ma, H., Bao, C. Preparation, Properties and Growth Mechanism of Low-Cost Porous Si3N4 Ceramics with High Levels of β-Si3N4 Powders. Silicon 14, 1357–1367 (2022). https://doi.org/10.1007/s12633-021-00941-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-021-00941-8