Abstract

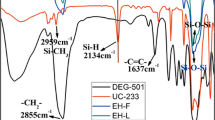

The oligosiloxane resins were synthesized through hydrolytic sol-gel reaction and remained many hydroxyl groups, which did great harm to the curing process and resulted in poor performance of the cured products. In previous works, epoxy-modified silicone resins were synthesized by dealcoholization, a reaction between 3-glycidoxypropylmethyldimethoxysilane and terminal hydroxyl groups in phenyl silicone resins. Although this method eliminated the hydroxyl groups, it caused a large loss of vinyl groups inevitably and a poor stability of cured products. In this study, methyltrimethoxysilane (MTMS) was used to eliminate hydroxyl groups containing in vinyl methyl phenyl silicone resins, which were synthesized through hydrolytic sol-gel reaction. Most of residual hydroxyl groups were deleted effectively and the great loss of vinyl groups were avoided in the dealcoholization reaction. Then, the methyl phenyl silicone materials were fabricated by hydrosilylation reaction between the synthesized vinyl methyl phenyl silicone resins and hydrogen-containing ones. The cured silicone materials showed excellent optical performance (~ 89.1% at 450 nm) and good adhesion performance. In addition, due to less vinyl loss in the vinyl methyl phenyl silicone resins, the cured methyl phenyl silicone materials exhibited higher cross-linking density, better thermal resistance (5% mass loss at 435 °C) and better mechanical properties (50 shore D) compared with the epoxy-modified phenyl silicone materials. The lumen depreciation (working 168 h at 50 mA) and reflow soldering tests further demonstrated the methyl phenyl silicone materials possessed good thermal stability. These results indicated that the methyl phenyl silicone materials could be used as a LED encapsulant with a good performance.

Similar content being viewed by others

References

Chen Z, Zhang Q, Wang K (2011). J Semicond 32:014007

Singh P, Tan CM (2016). Sci Rep 6:24052

Yang SC, Lin P, Wang CP (2010). Microelectron Reliab 50:959–964

Wen R, Huo J, Lv J (2017). J Mater Sci Mater Electron 28:14522–14535

Yang SC, Kwak SY, Jin JH (2012). J Mater Chem 22:8874–8880

Gao N, Liu WQ, Yan ZL (2013). Opt Mater 35:567–575

Kim YH, Lim YW, Lee D (2016). J Mater Chem C 4:10791–10796

Ryu HS, Kim DG, Lee JC (2010). Macromol Res 18:1021–1029

Kim JS, Yang SC, Bae BS (2010). Chem Mater 22:3549–3555

Yang XF, Cao C, Chen ZH (2015). Chin J Polym Sci 33:1305–1312

Li DD, Li S, Zhang S (2014). IEEI Trans Compon Pack Manuf Technol 4:190–197

Kuo CFJ, Chen JB, Shih CY (2014). J Appl Polym Sci 131:169–172

Shane OB, Opuro LM (2007). Appl Surf Sci 253:7969–7972

Kim JS, Yang SC, Kwak SY (2012). J Mater Chem 22:7954

Zhao M, Feng Y, Li Y (2014). J Macromol Sci A Pure Appl Chem 51:653–658

Pan Z, Zhu S, Huang B (2019). J Electron Mater 48:2865–2875

Judeinstein P, Sanchez C (1996). J Mater Chem 6:511

Hay JN, Raval HM (2001). Chem Mater 13:3396–3403

Bae JY, Kim YH, Kim HY (2013). RSC Adv 3:8871

Singh P, Tan CM (2018). Opt Mater 86:148–154

Acknowledgements

This project was supported by Department of education’s Production-Study-Research combined innovation Funding -- “Blue fire plan (Huizhou)”.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The author declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pan, Z., Zeng, K., Huang, B. et al. A New Dealcoholization Method in the Synthesis of Vinyl Methyl Phenyl Silicone Resins for LED Encapsulation. Silicon 12, 3005–3013 (2020). https://doi.org/10.1007/s12633-020-00396-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-020-00396-3