Abstract

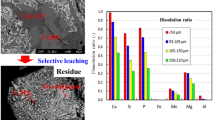

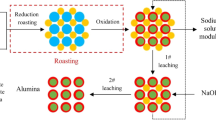

The phosphorus production industry is energy-intensive, which is one of the major reasons phosphorus has lower yields through furnace production. In this study, phosphorus conversion rate from phosphorus ore was investigated using four different fluxing agents: silica, potassium shale, potassium feldspar, and nepheline. Different holding times (10, 20, 30, and 40 min), acidity values (0.68, 0.88, 1.02, 1.42, and 2.02), coal surplus coefficients (1.05, 1.25, 1.5, 2, and 2.5), and calcination temperatures (1250 °C, 1300 °C, 1350 °C, 1400 °C, and 1450 °C) were studied. The results demonstrated that potassium shale, potassium feldspar, and nepheline as new fluxing agents improved phosphorus conversion rate under the same experimental conditions. To further ensure the significance of the experiment, the conversion rate of phosphorus from phosphorus ore was also investigated without an additive and with the addition of Na2CO3 and K2CO3. The slag viscosity of different fluxing agents and different additives at high temperatures was analyzed via the spread area method. To investigate the mechanism of phosphorus conversion, silica and nepheline as fluxing slag at different calcination temperatures were analyzed using X-ray diffraction.

Similar content being viewed by others

References

Vaccari DA (2009) Phosphorus famine: the threat to our food supply. Sci Am 300:54–59

Wang XJ, Tang L, Jiang Z (2014) Numerical simulation of Venturi ejector reactor in yellow phosphorus purification system. Nucl Eng Des 268:18–23

Wang Z, Jiang M, Ning P, Xie G (2011) Thermodynamic modeling and gaseous pollution prediction of the yellow phosphorus production. Ind Eng Chem Res 50:12194–12202

Withers PJA, Elser JJ, Hilton J, Ohtake H, Schipper WJ, Van Dijk KC (2015) ChemInform abstract: greening the global phosphorus cycle: how green chemistry can help achieve planetary P sustainability. Green Chem 17:2087–2099

Chen M, Graedel TE (2016) A half-century of global phosphorus flows, stocks, production, consumption, recycling, and environmental impacts. Glob Environ Chang 36:139–152

Okano K, Yamamoto Y, Takano H, Aketo T, Honda K, Ohtake H (2016) A simple technology for phosphorus recovery using acid-treated concrete sludge. Sep Purif Technol 165:173–178

Kuroda A, Takiguchi N, Gotanda T, Nomura K, Kato J, Ikeda T, Ohtake H (2002) A simple method to release polyphosphate from activated sludge for phosphorus reuse and recycling. Biotechnol Bioeng 78:333–338

Elser JJ (2012) Phosphorus: a limiting nutrient for humanity? Curr Opin Biotechnol 23:833–838

Geng R, Chen ZJ, Xia JP, Yang J, Li Y, Cao RF (2017) Experimental study of various fluxing agents in a phosphorus furnace. Phosphorus Sulfur Silicon Relat Elem 192:1048–1053

Brunner PH (2010) Substance flow analysis as a decision support tool for phosphorus management. J Ind Ecol 14:870–873

Wu H, Gao L, Wang S, Yuan Z (2016) Life cycle assessment of phosphorus use efficiency in crop production system of three crops in Chaohu Watershed. China. J Clean Prod 139:1298–1307

Chen SJ (1978) Yellow phosphorus by electric furnace method1st edn. Chemical Industry Press, Beijing

Geng RX, Xia JP, Chen ZJ, Yang J, Zheng S, Liu HL (2017) Effects of potassium feldspar on slagging and fluxing in phosphorus produced via electric furnace. Phosphorus Sulfur Silicon Relat Elem 192:475–480

Wang X, Ning P, Chen W (2011) Studies on purification of yellow phosphorus off-gas by combined washing, catalytic oxidation, and desulphurization at a pilot scale. Sep Purif Technol 80:519–525

Karshigina Z, Abisheva Z, Bochevskaya Y, Akcil A, Sargelova E (2015) Recovery of rare earth metals and precipitated silicon dioxide from phosphorus slag. Miner Eng 77:159–166

Cordell D, Rosemarin A, Schroder JJ, Smit AL (2011) Towards global phosphorus security: a systems framework for phosphorus recovery and reuse options. Chemosphere 84:747–758

Mayer BK, Baker LA, Boyer TH, Drechsel P, Gifford MM, Hanjra A, Prathap P, Jared S, Paul W, Bruce ER (2016) Total value of phosphorus recovery. Environ Sci Technol 50:6606–6620

Roy ED (2017) Phosphorus recovery and recycling with ecological engineering: a review. Ecol Eng 98:213–227

Le Corre KS, Valsami-Jones E, Hobbs P, Parsons SA (2009) Phosphorus recovery from wastewater by struvite crystallization: a review. Crit Rev Environ Sci Technol 39:433–477

Bradford-Hartke Z, Lane J, Lant P, Leslie G (2015) Environmental benefits and burdens of phosphorus recovery from municipal wastewater. Environ Sci Technol 49:8611–8622

Ansari AJ, Hai FI, Price WE, Long DN (2016) Phosphorus recovery from digested sludge centrate using seawater-driven forward osmosis. Sep Purif Technol 163:1–7

Linderholm K, Tillman AM, Mattsson JE (2012) Life cycle assessment of phosphorus alternatives for Swedish agriculture. Resour Conserv Recycl 66:27–39

Tran ATK, Zhang Y, Corte DD, Hannes JB, Ye W, Mondal Jullok PN, Meesschaert B, Pinoy L, Van der Bruggen B (2014) P-recovery as calcium phosphate from wastewater using an integrated selectrodialysis/crystallization process. J Clean Prod 77:140–151

Xie M, Long DN, Price WE, Elimelech M (2014) Toward resource recovery from wastewater: extraction of phosphorus from digested sludge using a hybrid forward osmosis–membrane distillation process. Environ Sci Technol Lett 1:191–195

Karunanithi R, Szogi AA, Bolan N, Naidu R, Loganathan P, Hunt PG, Vanotti MB, Saint CP, Ok YS, Krishnamoorthy S (2015) Phosphorus recovery and reuse from waste streams. Adv Agron 131:173–250

Egle L, Rechberger H, Zessner M (2015) Overview and description of technologies for recovering phosphorus from municipal waste water. Resour Conserv Recycl 105:325–346

Dwarapudi S, Banerjee PK, Chaudhary P, Sinha S, Chakraborty U, Sekhar C, Venugopalan T, Venugopal R (2014) Effect of fluxing agents on the swelling behavior of hematite pellets. Int J Miner Process 126:76–89

Yang LL, Wang HM, Zhu X, Li GR (2014) Effect of boron mud and CaF2 on surface tension and density of CaO-SiO2-B2O3 ternary slag systems. J Iron Steel Res Int 21:745–748

Wang C, Zhang C, Zhang SJ, Guo LJ (2015) The effect of CaF2 on the magnesium production with silicothermal process. Int J Miner Process 142:147–153

Sokolář R, Šveda M (2016) The use of zeolite as fluxing agent for whitewares. Procedia Eng 151:229–235

Ding Z, Ma WH, Wei KX, Wu JJ, Zhou Y, Xie KQ (2012) Boron removal from metallurgical-grade silicon using lithium containing slag. J Non-Cryst Solids 358:2708–2712

Guo YJ, Li JY, Han SJ, Wang YZ, Boughton R (2011) Growth and characterization of Ga3PO7 single crystals in different fluxing system. J Chin Ceram Soc 39:1339–1343

Li X, Hu B, Wu YX (2014) Process parameters and kinetics of smelting reduction technology for low-grade phosphate ore reduction. J Chem Eng Chin Univ 28:905–910

Xia GH, Lu M, Su XL, Zhao XD (2012) Iron removal from kaolin using thiourea assisted by ultrasonic wave. Ultrason Sonochem 19:38–42

Cao RF, Xia JP, Li WL, Han YW (2018) Effects of alkali metal carbonates on carbothermal reduction of phosphate rock. J Chem Eng Chin Univ 32:568–576

Karimi A, Semagina N, Gray MR (2011) Kinetics of catalytic steam gasification of bitumen coke. Fuel 90:1285–1291

Coetzee S, Neomagus HWJP, Bunt JR, Everson RC (2013) Improved reactivity of large coal particles by K2CO3, addition during steam gasification. Fuel Process Technol 114:75–80

Zhang J, Li J, Mao Y, Bi J, Zhu M, Zhang Z, Zhang L, Zhang D (2017) Effect of CaCO3 addition on ash sintering behaviour during K2CO3, catalysed steam gasification of a Chinese lignite. Appl Thermal Eng 111:503–509

Acknowledgments

The authors are grateful for financial support from the National Natural Science Foundation of China (No. 51804147 and 21566018).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, Z., Li, Y. & Xia, J. Silica, Alkali Carbonate and Alkali Rich Metal Ore as Additive Effect on the Carbothermic Reduction Process of Phosphorus Ore. Silicon 12, 613–620 (2020). https://doi.org/10.1007/s12633-019-00171-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-019-00171-z