Abstract

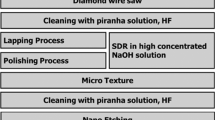

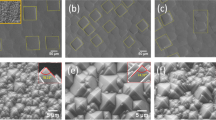

To minimize reflection from the flat surface, the multicrystalline silicon (mc-silicon) wafers were textured by low-temperature acid etching technique, which was optimized etching parameters (e.g. temperature and time) in HF-HNO3-H2O system. The textured surfaces and the light trapping property of wafers were analyzed by 3D microscope and reflection spectrum, respectively. It is found the low temperature etching process is more effective in controlling the reaction speed and obtaining favorable textured structure compared with the room temperature etching process. Moreover, the large difference exists for reaction rate affected by temperature with different etching environments. It shows the ice-bath etched wafers give rise to many deep pit textures in a short time, and was good at light trapping. The reflectance is 31% lower than that obtained from the RT etching environment. By ice-bath etching step, we achieved conversion efficiency, open circuit voltage, short circuit and fill factor as high as 17.24%, 0.617V, 8.529A and 0.81, respectively. This work establishes that it is possible to fabricate the multicrystal silicon solar cells of low cost and high efficiency using low-temperature acid etching technique.

Similar content being viewed by others

References

Yoo J, Cho JS, Ahn SJ, Gwak J, Cho A, Eo YJ, Yun JH, Yoon K, Yi J (2013) Random reactive ion etching texturing techniques for application of multicrystalline silicon solar cells. Thin Solid Films 546:275–278

Sio HC, Xiong Z, Trupke T, Macdonald D (2012) Imaging crystal orientations in multicrystalline silicon wafers via photoluminescence. Appl Phys Lett 101(8):082102–1-4

Srivastava SK, Singh P, Yameen M, Prathap P, Rauthan CMS, Vandana, Singh PK (2015) Antireflective ultra-fast nanoscale texturing for efficient multi-crystalline silicon solar cells. Sol Energy 115:656–666

Yan Y, Sun Y, Li J, Hu Z, Zhao X (2014) Controlled nanodot fabrication by rippling polycarbonate surface using an AFM diamond tip. Nanoscale Res Lett 9(1):1–7

Li T, Zhou CL, Wang WJ (2016) Comprehensive Study of SF6/O2 Plasma Etching for Mc-Silicon Solar Cells. Chinese Phys Lett 33(3):038801–1-3

Tang CS, Yang Y, Wang T, Wang J, Yu Y, Xin Y (2016) Surface oxidation of multicrystalline silicon using atmospheric pressure plasma jet driven by radio frequency of 2.0 MHz. Surf Coat Tech 304:537–541

Van Nieuwenhuysen K, Récaman Payo M, Kuzma-Filipek I, Van Hoeymissen J, Beaucarne G, Poortmans J (2010) Epitaxially grown emitters for thin film silicon solar cells result in 16% efficiency. Thin Solid Films 518:S80–S82

Nositschka WA, Beneking C, Voigt O, Kurz H (2003) Texturization of multicrystalline silicon wafers for solar cells by reactive ion etching through colloidal masks. Sol Energ Mat Sol C 76:155–166

Ha SH, Kim JH, Park SJ (2017) Anisotropic etching for laser texturing of multicrystalline silicon wafer. Mol Cryst Liq Cryst 645(1):231–238

Binetti S, Le Donne A, Rolfi A, Jaggi B, Neuenschwander B, Busto C, Frigeri C, Scorticati D, Longoni L, Pellegrino S (2016) Picosecond laser texturization of mc-silicon for photovoltaics:A comparison between 1064nm, 532nm and 355nm radiation wavelengths. Appl Surf Sci 371:196–202

Guo KW (2017) Surface Texturing for Silicon Solar Energy by Wet Acid. J Nanosci Adv Tech 2(1):24–29

Hamdi A, Amri C, Ouertani R, Ezzaouia H (2017) Effect of etching time on morphological, optical and structural properties of silicon nanowire arrays etched on multi-crystalline silicon wafer. J Mater Sci-Mater El 28(6):4807–4813

Dubois S, Turmagambetov T, Garandet JP, Lignier H, Enjalbert N (2016) Influence of the solar cells metallization firing treatment on carrier recombination and trapping in copper contaminated multicrystalline silicon: new insights into the role of the phosphorus-rich layers. Sol Energ Mat Sol C 157:558–564

Acknowledgements

This work was supported by National Natural Science Foundation of China (No. 51406069); China Postdoctoral Science Foundation Special Project (No.2016T90426); China Postdoctoral Science Foundation (No.2015M581733); Jiangsu Planned Projects for Postdoctoral Research Funds (No.1501107B); Training Project of Jiangsu University Youth Backbone Teacher.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Qiao, F., Liang, Q. & Jiang, Y. Efficient Ice-Bath Texturing Route for Multi-Crystalline Silicon Solar Cell Application. Silicon 11, 1611–1615 (2019). https://doi.org/10.1007/s12633-018-9982-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-018-9982-1