Abstract

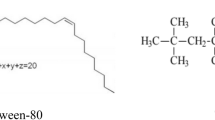

Mild steel panels were subjected to zinc phosphate conversion coating accelerated by environment friendly nano silicon dioxide using a series of cationic surfactants as additives. Four cationic surfactants have been synthesized in the absence of solvent using triethylamine and four different long chain alkyl halides. From 1H NMR and 13C NMR spectra the chemical structures of the synthesized surfactants were confirmed. The nano silicon dioxide accelerator provided a highly porous phosphate coating ensuring good adhesion to the consecutive top coating. The incorporation of cationic surfactants as additives led to fine-grained coatings which enhanced adherence and excellent corrosion resistance property to the phosphate coating. The performance of the surfactants as a corrosion inhibitor increases with the increase in the hydrophobicity of the side-chain length. Accelerator and additive incorporation effectively reduced the extent of zinc dissolution during phosphating and exhibited the highest polarization resistance. The good dispersability of additives and increased hydrophobicity yielded coatings with improved protection against corrosion. The corrosion inhibition performance of the coated steel has been studied by Open Circuit Potential (OCP), Potentiodynamic Polarization Curve, Electrochemical Impedance Spectroscopy (EIS) and salt spray test.

Similar content being viewed by others

References

Palraj S, Selvaraj M, Jayakrishnan P (2005) Effect of phosphate coatings on the performance of epoxy polyamide red oxide primer on galvanized steel. Progress Organ Coat 54:5–9

Zhou M, Yang Q, Troczynski T (2006) Effect of substrate surface modification on alumina composite sol–gel coatings. Surf Coat Technol 200:2800–2804

Ruhi G, Modi OP, Sinha ASK, Singh IB (2008) Effect of sintering temperatures on corrosion and wear properties of sol–gel alumina coatings on surface pre-treated mild steel. Corros Sci 50:639– 649

Jegannathan S, Sankara Narayanan TSN, Ravichandran K, Rajeswari S (2006) Formation of zinc–zinc phosphate composite coatings by cathodic electrochemical treatment. Surf Coat Technol 200:4117–4126

Raja Gopal C, Vasu KI (2000) Conversion coatings: a reference for phosphating chromating and anodizing. Tata McGraw-Hill Publishing Company Ltd, New Delhi

Sinha PK, Feser R (2002) Phosphate coating on steel surfaces by an electrochemical method. Surf Coat Technol 161:158–168

Sheng M, Wang Y, Zhong Q, Wu H, Zhou Q, Lin H (2011) The effects of nano-SiO2 additive on the zinc phosphating of carbon steel. Surf Coat Technol 205:3455–3460

Namazu T, Isono Y (2003) Quasi-static bending test of Nano-scale SiO2 wire at intermediate temperature using AFM-based technique. Sensor Actuat A Phys 104:78–85

Benjaram Reddy M, Lakshmanan Pandian, Bharali Pankaj, Pranjal Saikia J (2006) Dehydration of 4-methylpentan-2-ol over Ce x Zr1 − xO2/SiO2 nano-composite catalyst. Mol Catal A Chem 258:355–360

Lee KN, Kim KS, Kim NH, Roh Y (2008) Fabrication of SiO2 nano-dots by block copolymer lithography and liquid phase deposition. Mat Sci Eng B Solid 147:209–212

Ramnani SP, Sabharwal S, Vinod Kumar J, Hari Prasad Reddy K, Rama Rao KS, Sai Prasad PS (2008) Advantage of radiolysis over impregnation method for the synthesis of SiO2 supported nano-Ag catalyst for direct decomposition of N2O. Catal Commun 9:756–761

Shehata HA, Abd El-wahab AA, Hafiz AA, Aiad I, Hegazy MA (2008) Syntheses and characterization of some cationic surfactants. J Surfact Deterg 11:139–144

Negm NA, Kandile NG, Aiad IA, Mohammad MA (2011) New eco-friendly cationic surfactants: Synthesis, characterization and applicability as corrosion inhibitors for carbon steel in 1 N HCl. Colloids Surf A Physiochem Eng Asp 391:224–233

Yurt A, Balaban A, Kandemir SU, Bereket G, Erk B (2004) Investigation on some Schiff bases as HCl corrosion inhibitors for carbon steel. Mater Chem Phys 85:420–426

Emregul KC, Akay AA, Atakol O (2005) The corrosion inhibition of steel with schiff base compounds in 2 M HCl. Mater Chem Phys 93:325–329

Negm NA, Morsy SMI (2005) Corrosion inhibition of triethanolammonium bromide mono - and dibenzoate as cationic inhibitors in an acidic medium. J Surf Det 8:283–287

Negm NA Aiad IA (2007) Synthesis and characterization of multifunctional surfactants in oil-field protection applications. J Surfact Deterg 10:87–92

Quraishi MA, Sardar R, Jamal D (2001) Corrosion inhibition of mild steel in hydrochloric acid by some aromatic hydrazides. Mater Chem Phys 71:309–313

Behpour M, Ghoreishi SM, Gandomi-Niasar A, Soltani N, Salavati-Niasari M (2009) The inhibition of mild steel corrosion in hydrochloric acid media by two Schiff base compounds. J Mater Sci 44:2444–2453

Rafiquee MZA, Khan Sadaf, Saxena Nidhi, Quraishi MA (2009) Investigation of some oleochemicals as green inhibitors on mild steel corrosion in sulfuric acid. J Appl Electrochem 39:1409–1417

Thomas R, Umapathy MJ (2014) Nano silicon dioxide accelerated zinc phosphate conversion coating on mild steel using decyltriethylammonium bromide as an additive. Silicon, 6, 4. doi:10.1007/s12633-014-9231-1

Simescu F, Idrissi H (2009) Corrosion behaviour in alkaline medium of zinc phosphate coated steel obtained by cathodic electrochemical treatment. Corros Sci 51:833–840

Totik Y (2006) The corrosion behaviour of manganese phosphate coatings applied to AISI steel subjected to different heat treatments. Surf Coat Technol 200:2711–2717

Ying liang CHENG, Hai lan WU, Zhen hua CHEN, Hui min WANG, Ling ling LI (2006) Phosphating process of AZ31 magnesium alloy and corrosion resistance of coatings. Trans Nonferrous Met SOCC Hina 16:1086–1091

Weng D, Jokiel P, Uebleis A, Boehni H (1996) Corrosion and protection characteristics of zinc and manganese phosphate coatings. Surf Coat Technol 88:147–156

Shibli SMA, Chacko F (2011) Development of nano TiO2-incorporated phosphate coatings on hot dip zinc surface for good paintability and corrosion resistance. Appl Surf Sci 257:3111–3117

Phanasgaonkar A, Raja VS (2009) Influence of curing temperature, silica nanoparticles and cerium on surface morphology and corrosion behaviour of hybrid silane coatings on mild steel. Surf Coat Technol 203:2260–2271

Ananda Kumar S, Sasikumar A (2010) Studies on novel silicone/phosphorus/sulphur containing nano-hybrid epoxy anticorrosive and antifouling coatings. Progress Organ Coat 68:189–200

Hosseini MG, Sabouri M, Shahrabi T (2007) Corrosion protection of mild steel by polypyrrole phosphate composite coating. Progress Organ Coat 60:178–185

Li GY, Lian JS, Niu LY, Jiang ZHA (2005) Zinc and manganese phosphate coating on automobile iron castings. ISIJ Int 45:1326–1330

Thi Xuan Hang T, Truc TA, Nam TH, Vu KO, Jorcin JB, Pebere N (2007) Corrosion protection of carbon steel by an epoxy resin containing organically modified clay. Surf Coat Technol 201:7408–7415

Tsai Cheng Yang, Liu Jen Shou, Chen Pei Li, Lin Chao Sung (2010) Effect of Mg2 + on the microstructure and corrosion resistance of the phosphate conversion coating on hot-dip galvanized sheet steel. Corros Sci 52:3907–3916

Acknowledgments

We thank the Department of Chemistry, College of Engineering, Anna University, and Chennai-600 025 for providing the laboratory and chemical facilities for this research work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Thomas, R., Umapathy, M.J. Environment Friendly Nano Silicon Dioxide Accelerated Zinc Phosphate Coating on Mild Steel Using a Series of Surfactants as Additives. Silicon 9, 675–688 (2017). https://doi.org/10.1007/s12633-016-9460-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-016-9460-6