Abstract

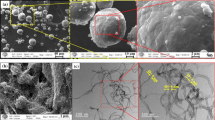

The potential difference between positive and negative ions was utilized to improve the homogenized dispersion of nanoscale Al2O3 whiskers in Mg matrix composites. The Mg powders were decorated with sodium dodecylbenzene sulfonate (C18H29NaO3S, SDBS) and were introduced to the cathode group on their surface. The Al2O3 whiskers were modified by the cetyl trimethyl ammonium bromide (C19H42BrN, CTAB) and were featured in the anode group. The suitable contents of CTAB and SDBS, the application atmosphere, and the type of solvents were investigated. Dispersion results showed that adding 2wt% SDBS into Mg powders and adding 2wt% CTAB into Al2O3 whiskers promoted the formation of more uniformly mixed composite powders, compared to those of conventional ball milling via scanning electron microscopy (SEM) analysis. Meanwhile, the calculated results derived from first-principle calculations also demonstrated the stronger cohesion between Al2O3 whisker reinforcements and Mg matrix than undecorated composite powders. After preparation by powder metallurgy, the morphology, grain size, hardness, and standard deviation coefficient of composites were analyzed to evaluate the dispersed efficiency. The results indicated that the modification of homogenized dispersed Al2O3 whiskers in composites contributed to the refinement of 26% in grain size and the improvement of 20% in hardness compared with pure Mg, and the reduction of 32.5% in the standard deviation coefficient of hardness compared with the ball-milling sample.

Similar content being viewed by others

References

E. Karthick, J. Mathai, J.M. Tony, and S.K. Marikkannan, Processing, microstructure and mechanical properties of Al2O3 and SiC reinforced magnesium metal matrix hybrid composites, Mater. Today Proc., 4(2017), No. 6, p. 6750.

Y.W. Wu, K. Wu, K.K. Deng, et al., Effect of extrusion temperature on microstructures and damping capacities of Grp/AZ91 composite, J. Alloys Compd., 506(2010), No. 2, p. 688.

B. Lei, B. Jiang, H.B. Yang, et al., Effect of Nd addition on the microstructure and mechanical properties of extruded Mg—Gd—Zr alloy, Mater. Sci. Eng. A, 816(2021), art. No. 141320.

H.B. Yang, L. Wu, B. Jiang, et al., Clarifying the roles of grain boundary and grain orientation on the corrosion and discharge processes of α-Mg based Mg—Li alloys for primary Mg-air batteries, J. Mater. Sci. Technol., 62(2021), p. 128.

J.X. Yang, G.L. Koons, G. Cheng, L.H. Zhao, A.G. Mikos, and F.Z. Cui, A review on the exploitation of biodegradable magnesium-based composites for medical applications, Biomed. Mater., 13(2018), No. 2, art. No. 022001.

J.L. Su, J. Teng, Z.L. Xu, and Y. Li, Biodegradable magnesium-matrix composites: A review, Int. J. Miner. Metall. Mater., 27(2020), No. 6, p. 724.

W.J. Liu, B. Jiang, H.C. Xiang, et al., High-temperature mechanical properties of as-extruded AZ80 magnesium alloy at different strain rates, Int. J. Miner. Metall. Mater., 29(2022), No. 7, p. 1373.

C. He, Y.B. Zhang, M. Yuan, et al., Improving the room-temperature bendability of Mg—3Al—1Zn alloy sheet by introducing a bimodal microstructure and the texture re-orientation, Int. J. Miner. Metall. Mater., 29(2022), No. 7, p. 1322.

H. Yang, X.H. Chen, G.S. Huang, et al., Microstructures and mechanical properties of titanium-reinforced magnesium matrix composites: Review and perspective, J. Magnes. Alloys, 2022. https://doi.org/10.1016/j.jma.2022.07.008

J.H. Liang, H.J. Li, L.H. Qi, et al., Fabrication and mechanical properties of CNTs/Mg composites prepared by combining friction stir processing and ultrasonic assisted extrusion, J. Alloys Compd., 728(2017), p. 282.

H.M. Xie, Y.Y. Wei, B. Jiang, C.P. Tang, and C.Y. Nie, Tribological properties of carbon nanotube/SiO2 combinations as water-based lubricant additives for magnesium alloy, J. Mater. Res. Technol., 12(2021), p. 138.

L.L. Meng, X.S. Hu, X.J. Wang, et al., Graphene nanoplatelets reinforced Mg matrix composite with enhanced mechanical properties by structure construction, Mater. Sci. Eng. A, 733(2018), p. 414.

S. Jabbarzare, H.R. Bakhsheshi-Rad, A.A. Nourbakhsh, T. Ahmadi, and F. Berto, Effect of graphene oxide on the corrosion, mechanical and biological properties of Mg-based nanocomposite, Int. J. Miner. Metall. Mater., 29(2022), No. 2, p. 305.

P. Xiao, Y.M. Gao, F.X. Xu, et al., An investigation on grain refinement mechanism of TiB2 particulate reinforced AZ91 composites and its effect on mechanical properties, J. Alloys Compd., 780(2019), p. 237.

M.Y. Zheng, K. Wu, and C.K. Yao, Effect of interfacial reaction on mechanical behavior of SiCw/AZ91 magnesium matrix composites, Mater. Sci. Eng. A, 318(2001), No. 1–2, p. 50.

H. Tsukamoto, Enhancement of mechanical properties of SiCw/SiCp-reinforced magnesium composites fabricated by spark plasma sintering, Results Mater., 9(2021), art. No. 100167.

X.P. Zhang, H.X. Wang, L.P. Bian, et al., Microstructure evolution and mechanical properties of Mg—9Al—1Si—1SiC composites processed by multi-pass equal-channel angular pressing at various temperatures, Int. J. Miner. Metall. Mater., 28(2021), No. 12, p. 1966.

Y.C. Yu, S.W. Tang, Z.L. Wang, and J. Hu, Effects of coating contents on the interfacial reaction and tensile properties of Al2O3 coated-A118B4O33w/Al—Mg matrix composites, Mater. Charact., 107(2015), p. 327.

X.S. Zeng, Y. Liu, Q.Y. Huang, G. Zeng, and G.H. Zhou, Effects of carbon nanotubes on the microstructure and mechanical properties of the wrought Mg—2.0Zn alloy, Mater. Sci. Eng. A, 571(2013), p. 150.

Q.H. Yuan, G.H. Zhou, L. Liao, Y. Liu, and L. Luo, Interfacial structure in AZ91 alloy composites reinforced by graphene nanosheets, Carbon, 127(2018), p. 177.

P. Xiao, Y.M. Gao, F.X. Xu, et al., Tribological behavior of in situ nanosized TiB2 particles reinforced AZ91 matrix composite, Tribol. Int., 128(2018), p. 130.

Y.P. Zhu, P.P. Jin, W.D. Fei, S.C. Xu, and J.H. Wang, Effects of Mg2B2O5 whiskers on microstructure and mechanical properties of AZ31B magnesium matrix composites, Mater. Sci. Eng. A, 684(2017), p. 205.

S. Arai, Y. Suzuki, J. Nakagawa, T. Yamamoto, and M. Endo, Fabrication of metal coated carbon nanotubes by electroless deposition for improved wettability with molten aluminum, Surf. Coat. Technol., 212(2012), p. 207.

W.M. Tucho, H. Mauroy, J.C. Walmsley, S. Deledda, R. Holmestad, and B.C. Hauback, The effects of ball milling intensity on morphology of multiwall carbon nanotubes, Scripta Mater., 63(2010), No. 6, p. 637.

H. Yu, Y. Sun, L.X. Hu, Z.P. Wan, and H.P. Zhou, The effect of Ti addition on microstructure evolution of AZ61 Mg alloy during mechanical milling, J. Alloys Compd., 704(2017), p. 537.

M. Estili and A. Kawasaki, An approach to mass-producing individually alumina-decorated multi-walled carbon nanotubes with optimized and controlled compositions, Scripta Mater., 58(2008), No. 10, p. 906.

W. Gong, X.C. Li, and B.Q. Zhu, Modeling calculation and synthesis of alumina whiskers based on the vapor deposition process, Materials, 10(2017), No. 10, art. No. 1192.

F. Zuo, F. Meng, D.T. Lin, et al., Influence of whisker-aspect-ratio on densification, microstructure and mechanical properties of Al2O3 whiskers-reinforced CeO2-stabilized ZrO2 composites, J. Eur. Ceram. Soc., 38(2018), No. 4, p. 1796.

J. Corrochano, C. Cerecedo, V. Valcárcel, M. Lieblich, and F. Guitián, Whiskers of Al2O3 as reinforcement of a powder metallurgical 6061 aluminium matrix composite, Mater. Lett., 62(2008), No. 1, p. 103.

X.Y. Qu, F.C. Wang, C.S. Shi, et al., In situ synthesis of a gamma-Al2O3 whisker reinforced aluminium matrix composite by cold pressing and sintering, Mater. Sci. Eng. A, 709(2018), p. 223.

L. Wang, Q.G. Fu, and F.L. Zhao, Improving oxidation resistance of MoSi2 coating by reinforced with Al2O3 whiskers, Intermetallics, 94(2018), p. 106.

H.W. Zhang, D.G. Zhu, S. Grasso, and C.F. Hu, Tunable morphology of aluminum oxide whiskers grown by hydrothermal method, Ceram. Int., 44(2018), No. 13, p. 14967.

D.S. Zhu, X.F. Li, N. Wang, X.J. Wang, J.W. Gao, and H. Li, Dispersion behavior and thermal conductivity characteristics of Al2O3—H2O nanofluids, Curr. Appl. Phys., 9(2009), No. 1, p. 131.

S.J. Clark, M.D. Segall, C.J. Pickard, et al., First principles methods using CASTEP, Z. Kristallogr., 220(2005), No. 5–6, p. 567.

M. Marlo and V. Milman, Density-functional study of bulk and surface properties of titanium nitride using different exchange-correlation functionals, Phys. Rev. B, 62(2000), No. 4, p. 2899.

X.J. Wang, D.S. Zhu, and S. Yang, Investigation of pH and SDBS on enhancement of thermal conductivity in nanofluids, Chem. Phys. Lett., 470(2009), No. 1–3, p. 107.

P.L. Chen, Z.X. Zhong, F. Liu, and W.H. Xing, Cleaning ceramic membranes used in treating desizing wastewater with a complex-surfactant SDBS-assisted method, Desalination, 365(2015), p. 25.

X.L. Tan, M. Fang, C.L. Chen, S.M. Yu, and X.K. Wang, Counterion effects of nickel and sodium dodecylbenzene sulfonate adsorption to multiwalled carbon nanotubes in aqueous solution, Carbon, 46(2008), No. 13, p. 1741.

S.L. Xiang, X.J. Wang, M. Gupta, K. Wu, X.S. Hu, and M.Y. Zheng, Graphene nanoplatelets induced heterogeneous bimodal structural magnesium matrix composites with enhanced mechanical properties, Sci. Rep., 6(2016), art. No. 38824.

A. Nevarez-Rascon, A. Aguilar-Elguezabal, E. Orrantia, and M.H. Bocanegra-Bernal, Compressive strength, hardness and fracture toughness of Al2O3 whiskers reinforced ZTA and ATZ nanocomposites: Weibull analysis, Int. J. Refract. Met. Hard Mater., 29(2011), No. 3, p. 333.

R.A. Saravanan and M.K. Surappa, Fabrication and characterisation of pure magnesium—30 vol.% SiCp particle composite, Mater. Sci. Eng. A, 276(2000), No. 1–2, p. 108.

D.G. Altman and J.M. Bland, Standard deviations and standard errors, BMJ, 331(2005), No. 7521, art. No. 903.

Acknowledgements

The authors gratefully acknowledge the Fundamental Research Funds for the National Natural Science Foundation of China (Nos. 52101123 and 52004227), the Fundamental Research Funds for the Central Universities-Interdisciplinary Research (No. 2682021ZTPY001), and the Dongguan Scitech Commissioner (No. 20211800500102). We also thank the Analytical and Testing Center of Southwest Jiaotong University for assistance with EBSD and TEM experiments.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Conflict of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Rights and permissions

About this article

Cite this article

Qian, X., Yang, H., Hu, C. et al. Effect of potential difference between nano-Al2O3 whisker and Mg matrix on the dispersion of Mg composites. Int J Miner Metall Mater 30, 104–111 (2023). https://doi.org/10.1007/s12613-022-2550-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-022-2550-0