Abstract

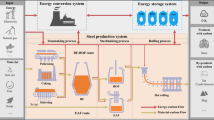

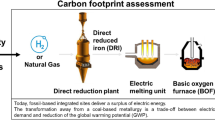

Decarbonization is a critical issue for peaking CO2 emissions of energy-intensive industries, such as the iron and steel industry. The decarbonization options of China’s ironmaking and steelmaking sector were discussed based on a systematic three-dimensional low-carbon analysis from the aspects of resource utilization (Y), energy utilization (Q), and energy cleanliness which is evaluated by a process general emission factor (PGEF) on all the related processes, including the current blast furnace (BF)—basic oxygen furnace (BOF) integrated process and the specific sub-processes, as well as the electric arc furnace (EAF) process, typical direct reduction (DR) process, and smelting reduction (SR) process. The study indicates that the three-dimensional aspects, particularly the energy structure, should be comprehensively considered to quantitatively evaluate the decarbonization road map based on novel technologies or processes. Promoting scrap utilization (improvement of Y) and the substitution of carbon-based energy (improvement of PGEF) in particular is critical. In terms of process scale, promoting the development of the scrap-based EAF or DR—EAF process is highly encouraged because of their lower PGEF. The three-dimensional method is expected to extend to other processes or industries, such as the cement production and thermal electricity generation industries.

Similar content being viewed by others

References

H. Wang, X. Lu, Y. Deng, et al., China’s CO2 peak before 2030 implied from characteristics and growth of cities, Nat. Sustainability, 2(2019), No. 8, p. 748.

Z. Liu, D.B. Guan, S. Moore, H. Lee, J. Su, and Q. Zhang, Climate policy: Steps to China’s carbon peak, Nature, 522(2015), No. 7556, p. 279.

D.B. Guan, Y.L. Shan, Z. Liu, and K.B. He, Performance assessment and outlook of China’s emission-trading scheme, Engineering, 2(2016), No. 4, p. 398.

K. Daehn, R. Basuhi, J. Gregory, M. Berlinger, V. Somjit, and E.A. Olivetti, Innovations to decarbonize materials industries, Nat. Rev. Mater., 7(2022), No. 4, p. 275.

D. Raabe, C.C. Tasan, and E.A. Olivetti, Strategies for improving the sustainability of structural metals, Nature, 575(2019), No. 7781, p. 64.

World Steel Association, Steel Statistical Yearbook 2021, Brussels, Belgium, 2021 [February 2, 2022]. http://www.worldsteel.org

Z.C. Guo and Z.X. Fu, Current situation of energy consumption and measures taken for energy saving in the iron and steel industry in China, Energy, 35(2010), No. 11, p. 4356.

W.Q. Wu, Y.J. Li, T.Y. Zhu, and W.J. Cao, CO2 emission in iron and steel making industry and its reduction prospect, Chin. J. Process Eng., 13(2013), p. 175.

J.C. Brunke and M. Blesl, A plant-specific bottom-up approach for assessing the cost-effective energy conservation potential and its ability to compensate rising energy-related costs in the German iron and steel industry, Energy Policy, 67(2014), p. 431.

N. Karali, T.F. Xu, and J. Sathaye, Reducing energy consumption and CO2 emissions by energy efficiency measures and international trading: A bottom-up modeling for the U.S. iron and steel sector, Appl. Energy, 120(2014), p. 133.

L. Price, J. Sinton, E. Worrell, D. Phylipsen, H. Xiulian, and L. Ji, Energy use and carbon dioxide emissions from steel production in China, Energy, 27(2002), No. 5, p. 429.

S. Siitonen, M. Tuomaala, and P. Ahtila, Variables affecting energy efficiency and CO2 emissions in the steel industry, Energy Policy, 38(2010), No. 5, p. 2477.

K. Tanaka, A comparison study of EU and Japan methods to assess CO2 emission reduction and energy saving in the iron and steel industry, Energy Policy, 51(2012), p. 578.

X.L. Wang and B.Q. Lin, How to reduce CO2 emissions in China’s iron and steel industry, Renewable Sustainable Energy Rev., 57(2016), p. 1496.

X.C. Zhao, H. Bai, X. Lu, Q. Shi, and J.H. Han, A MILP model concerning the optimisation of penalty factors for the short-term distribution of byproduct gases produced in the iron and steel making process, Appl. Energy, 148(2015), p. 142.

X.C. Zhao, H. Bai, Q. Shi, X. Lu, and Z.H. Zhang, Optimal scheduling of a byproduct gas system in a steel plant considering time-of-use electricity pricing, Appl. Energy, 195(2017), p. 100.

H.M. Na, J.C. Sun, Z.Y. Qiu, et al., A novel evaluation method for energy efficiency of process industry—A case study of typical iron and steel manufacturing process, Energy, 233(2021), art. No. 121081.

W.Q. Long, S.S. Wang, C.Y. Lu, et al., Quantitative assessment of energy conservation potential and environmental benefits of an iron and steel plant in China, J. Cleaner Prod., 273(2020), art. No. 123163.

J.L. Suer, M. Traverso, and F. Ahrenhold, Carbon footprint of scenarios towards climate-neutral steel according to ISO 14067, J. Cleaner Prod., 318(2021), art. No. 128588.

K.H. Ma, J.Y. Deng, G. Wang, Q. Zhou, and J. Xu, Utilization and impacts of hydrogen in the ironmaking processes: A review from lab-scale basics to industrial practices, Int. J. Hydrogen Energy, 46(2021), No. 52, p. 26646.

J.C. Sun, H.M. Na, T.Y. Yan, et al., A comprehensive assessment on material, exergy and emission networks for the integrated iron and steel industry, Energy, 235(2021), art. No. 121429.

X.Y. Zhang, K.X. Jiao, J.L. Zhang, and Z.Y. Guo, A review on low carbon emissions projects of steel industry in the World, J. Cleaner Prod., 306(2021), art. No. 127259.

J. Tang, M.S. Chu, F. Li, C. Feng, Z.G. Liu, and Y.S. Zhou, Development and progress on hydrogen metallurgy, Int. J. Miner. Metall. Mater., 27(2020), No. 6, p. 713.

M. Fischedick, J. Marzinkowski, P. Winzer, and M. Weigel, Techno-economic evaluation of innovative steel production technologies, J. Cleaner Prod., 84(2014), p. 563.

C.Q. Hu, X.W. Han, Z.H. Li, and C.X. Zhang, Comparison of CO2 emission between COREX and blast furnace iron-making system, J. Environ. Sci., 21(2009), p. S116.

M.A. Quader, S. Ahmed, R.A.R. Ghazilla, S. Ahmed, and M. Dahari, A comprehensive review on energy efficient CO2 breakthrough technologies for sustainable green iron and steel manufacturing, Renewable Sustainable Energy Rev., 50(2015), p. 594.

A. Hasanbeigi, M. Arens, and L. Price, Alternative emerging ironmaking technologies for energy-efficiency and carbon dioxide emissions reduction: A technical review, Renewable Sustainable Energy Rev., 33(2014), p. 645.

R. Zhu, B.C. Han, K. Dong, and G.S. Wei, A review of carbon dioxide disposal technology in the converter steelmaking process, Int. J. Miner. Metall. Mater., 27(2020), No. 11, p. 1421.

V. Strezov, A. Evans, and T. Evans, Defining sustainability indicators of iron and steel production, J. Cleaner Prod., 51(2013), p. 66.

S.H. Zhang, E. Worrell, W. Crijns-Graus, F. Wagner, and J. Cofala, Co-benefits of energy efficiency improvement and air pollution abatement in the Chinese iron and steel industry, Energy, 78(2014), p. 333.

T. Ariyama and M. Sato, Optimization of ironmaking process for reducing CO2 emissions in the integrated steel works, ISIJ Int., 46(2006), No. 12, p. 1736.

H. Bai, P. Liu, H.X. Li, L.H. Zhao, and D.Q. Cang, Analysis of carbon emission reduction of China’s integrated steelworks, [in] N.R. Neelameggham, C.K. Belt, M. Jolly, R.G. Reddy, and J.A. Yurko, eds., Energy Technology 2011: Carbon Dioxide and Other Greenhouse Gas Reduction Metallurgy and Waste Heat Recovery, John Wiley & Sons, Inc., Hoboken, 2011, p. 253.

L.M. Germeshuizen and P.W.E. Blom, A techno-economic evaluation of the use of hydrogen in a steel production process, utilizing nuclear process heat, Int. J. Hydrogen Energy, 38(2013), No. 25, p. 10671.

A.R. da Costa, D. Wagner, and F. Patisson, Modelling a new, low CO2 emissions, hydrogen steelmaking process, J. Cleaner Prod., 46(2013), p. 27.

M.T. Johansson, Bio-synthetic natural gas as fuel in steel industry reheating furnaces — A case study of economic performance and effects on global CO2 emissions, Energy, 57(2013), p. 699.

D.B. Guo, L.D. Zhu, S. Guo, et al., Direct reduction of oxidized iron ore pellets using biomass syngas as the reducer, Fuel Process. Technol., 148(2016), p. 276.

H. Helle, M. Helle, H. Saxén, and F. Pettersson, Mathematical optimization of ironmaking with biomass as auxiliary reductant in the blast furnace, ISIJ Int., 49(2009), No. 9, p. 1316.

P. Sodsai and P. Rachdawong, The Current situation on CO2 emissions from the steel industry in Thailand and mitigation options, Int. J. Greenhouse Gas Control, 6(2012), p. 48.

H. Suopajärvi, E. Pongrácz, and T. Fabritius, Bioreducer use in Finnish blast furnace ironmaking — Analysis of CO2 emission reduction potential and mitigation cost, Appl. Energy, 124(2014), p. 82.

W.D. Judge, J. Paeng, and G. Azimi, Electrorefining for direct decarburization of molten iron, Nat. Mater., 21(2022), 10, p. 1130.

M. Asanuma, T. Ariyama, M. Sato, et al., Development of waste plastics injection process in blast furnace, ISIJ Int., 40(2000), No. 3, p. 244.

A. Ziębik and W. Stanek, Forecasting of the energy effects of injecting plastic wastes into the blast furnace in comparison with other auxiliary fuels, Energy, 26(2001), No. 12, p. 1159.

M. Meng, D.X. Niu, and W. Shang, CO2 emissions and economic development: China’s 12th five-year plan, Energy Policy, 42(2012), p. 468.

R.G.D. Pinto, A.S. Szklo, and R. Rathmann, CO2 emissions mitigation strategy in the Brazilian iron and steel sector — From structural to intensity effects, Energy Policy, 114(2018), p. 380.

W.Y. Chen, X. Yin, and D. Ma, A bottom-up analysis of China’s iron and steel industrial energy consumption and CO2 emissions, Appl. Energy, 136(2014), p. 1174.

A. Hasanbeigi, L. Price, C.X. Zhang, N. Aden, X.P. Li, and F.Q. Shangguan, Comparison of iron and steel production energy use and energy intensity in China and the U.S., J. Cleaner Prod., 65(2014), p. 108.

A. Hasanbeigi, W. Morrow, J. Sathaye, E. Masanet, and T.F. Xu, A bottom-up model to estimate the energy efficiency improvement and CO2 emission reduction potentials in the Chinese iron and steel industry, Energy, 50(2013), p. 315.

Y. Li and L. Zhu, Cost of energy saving and CO2 emissions reduction in China’s iron and steel sector, Appl. Energy, 130(2014), p. 603.

E. Worrell, L. Price, and N. Martin, Energy efficiency and carbon dioxide emissions reduction opportunities in the US iron and steel sector, Energy, 26(2001), No. 5, p. 513.

H. Bai, X. Lu, H.X. Li, et al., The relationship between energy consumption and CO2 Emissions in iron and steel making, [in] M.D. Salazar-Villalpando, N.R. Neelameggham, D.P. Guillen, S. Pati, and G.K. Krumdick, eds., Energy Technology 2012: Carbon Dioxide Management and Other Technologies, John Wiley & Sons, Inc., Hoboken, 2012, p. 125.

X. Lu, H. Bai, L.H. Zhao, X.T. Liu, and D.Q. Cang, Relationship between energy consumption and CO2 emission of iron and steel plant, J. Univ. Sci. Technol. Beijing, 34(2012), p. 1445.

R.L. Milford, S. Pauliuk, J.M. Allwood, and D.B. Müller, The roles of energy and material efficiency in meeting steel industry CO2 targets, Environ. Sci. Technol., 47(2013), No. 7, p. 3455.

B. Yu, X. Li, L. Shi, and Y. Qian, Quantifying CO2 emission reduction from industrial symbiosis in integrated steel Mills in China, J. Cleaner Prod., 103(2015), p. 801.

H. Zhang, L. Dong, H.Q. Li, T. Fujita, S. Ohnishi, and Q. Tang, Analysis of low-carbon industrial symbiosis technology for carbon mitigation in a Chinese iron/steel industrial park: A case study with carbon flow analysis, Energy Policy, 61(2013), p. 1400.

Y.L. Shan, Z. Liu, and D.B. Guan, CO2 emissions from China’s lime industry, Appl. Energy, 166(2016), p. 245.

H. Li, L.F. Guo, Z.Q. Li, W.C. Song, and Y.Q. Li, Research of low-carbon mode and on limestone addition instead of lime in the BOF steelmaking, J. Iron Steel Res. Int., 17(2010), Suppl. 2, p. 23.

A. Ziebik, K. Lampert, and M. Szega, Energy analysis of a blast-furnace system operating with the COREX process and CO2 removal, Energy, 33(2008), No. 2, p. 199.

H. Xu, H. Qian, Y.S. Zhou, and Z.Y. Li, MIDREX shaft technology in COREX—DR combined process at SALDANHA steel, World Iron Steel, 10(2010), No. 2, p. 6.

X.D. Jin, Choice of non-coking ironmaking process, Iron Steel, 33(1998), No. 4, p. 11.

Z.H. Kuang, J.J. Lin, and X.Q. Li, Performance of Coal used in COREX Technological Process, Ironmaking, 27(2008), No. 4, p. 60.

L. Wang, L.H. Chen, H.O. Lv, Development situation of COREX smelting reduction process, J. Shenyang Inst. Eng. Nat. Sci., 2(2006), p. 373.

L.Y. Liu, H.G. Ji, X.F. Lü, et al., Mitigation of greenhouse gases released from mining activities: A review, Int. J. Miner. Metall. Mater., 28(2021), No. 4, p. 513.

S. Pauliuk, R.L. Milford, D.B. Müller, and J.M. Allwood, The steel scrap age, Environ. Sci. Technol., 47(2013), No. 7, p. 3448.

D. Kushnir, T. Hansen, V. Vogl, and M. Åhman, Adopting hydrogen direct reduction for the Swedish steel industry: A technological innovation system (TIS) study, J. Cleaner Prod., 242(2020), art. No. 118185.

V. Vogl, M. Åhman, and L.J. Nilsson, Assessment of hydrogen direct reduction for fossil-free steelmaking, J. Cleaner Prod., 203(2018), p. 736.

Acknowledgements

This research was financially supported by the State Key Laboratory of Advanced Metallurgy, China (Project Code: 41603006). Mr. Hongfu Li from JIGANG Group Co., Ltd., China is gratefully acknowledged for his helpful comments and discussion.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Conflict of Interest

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Lu, X., Tian, W., Li, H. et al. Decarbonization options of the iron and steelmaking industry based on a three-dimensional analysis. Int J Miner Metall Mater 30, 388–400 (2023). https://doi.org/10.1007/s12613-022-2475-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-022-2475-7