Abstract

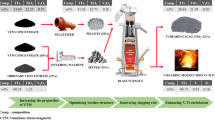

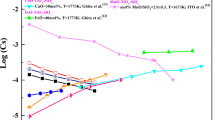

Aiming at the process of smelting ultra-high (>80%) or even full vanadium titanomagnetite in blast furnace, we are conducting a series of works on physics character of high TiO2 bearing blast furnace slag (BFS) for slag optimization. This work discussed the density and surface tension of high TiO2 bearing BFS using the Archimedean principle and the maximum bubble pressure method, respectively. The influence of TiO2 content and the MgO/CaO mass ratio on the density and surface tension of CaO-SiO2-TiO2-MgO-Al2O3 slags were investigated. Results indicated that the density of slags decreased with the TiO2 content increasing from 20wt% to 30wt%, but it increased slightly with the MgO/CaO mass ratio increasing from 0.32 to 0.73. In view of silicate network structure, the density and the degree of polymerization (DOP) of network structure have a consistent trend. The addition of TiO2 reduced (Q3)2/(Q2) ratio (Q2 and Q3 represent structural unit with bridge oxygen number of 2 and 3, respectively) and then decreased DOP, which led to the decrease of slag density. The surface tension of CaO-SiO2-TiO2-MgO-Al2O3 slags decreased dramatically with the TiO2 content increasing from 20wt% to 30wt%. Conversely, it increased with the MgO/CaO mass ratio increasing from 0.32 to 0.73. Furthermore, the iso-surface tension lines were obtained under 1723 K using the Tanaka developed model in view of Butler formula. It may be useful for slag optimization of ultra-high proportion (>80%) or even full vanadium titanomagnetite under BF smelting.

Similar content being viewed by others

References

M. Hino, T. Nagasaka, A. Katsumata, K.I. Higuchi, K. Yamaguchi, and N. Kon-No, Simulation of primary-slag melting behavior in the cohesive zone of a blast furnace, considering the effect of Al2O3, FetO, and basicity in the sinter ore, Metall. Mater. Trans. B, 30(1999), No. 4, p. 671.

N. Siddiqi, B. Bhoi, R.K. Paramguru, V. Sahajwalla, and O. Ostrovski, Slag-graphite wettability and reaction kinetics Part 1. Kinetics and mechanism of molten FeO reduction reaction, Ironmaking Steelmaking, 27(2000), No. 5, p. 367.

M. Wegener, L. Muhmood, S. Sun, and A.V. Deev, Surface tension measurements of calcia-alumina slags: A comparison of dynamic methods, Metall. Mater. Trans. B, 46(2015), No. 1, p. 316.

K. Ito and R.J. Fruehan, Study on the foaming of CaO-SiO2-FeO slags: Part I. Foaming parameters and experimental results, Metall. Trans. B, 20(1989), No. 4, p. 509.

K. Ito and R.J. Fruehan, Study on the foaming of CaO-SiO2-FeO slags: Part II. Dimensional analysis and foaming in iron and steelmaking processes, Metall. Trans. B, 20(1989), No. 4, p. 515.

H.L. George, R.J. Longbottom, S.J. Chew, and B.J. Monaghan, Flow of molten slag through a coke packed bed, ISIJ Int., 54(2014), No. 4, p. 820.

D.D. Geleta, M.I.H. Siddiqui, and J. Lee, Characterization of slag flow in fixed packed bed of coke particles, Metall. Mater. Trans. B, 51(2020), No. 1, p. 102.

L. Zhang, L.N. Zhang, M.Y. Wang, G.Q. Li, and Z.T. Sui, Recovery of titanium compounds from molten Ti-bearing blast furnace slag under the dynamic oxidation condition, Miner. Eng., 20(2007), No. 7, p. 684.

D.S. Chen, B. Song, L.N. Wang, T. Qi, Y. Wang, and W.J. Wang, Solid state reduction of Panzhihua titanomagnetite concentrates with pulverized coal, Miner. Eng., 24(2011), No. 8, p. 864.

F. Valighazvini, F. Rashchi, and R. Khayyam Nekouei, Recovery of titanium from blast furnace slag, Ind. Eng. Chem. Res., 52(2013), No. 4, p. 1723.

P. Liu, L.B. Zhang, B.G. Liu, G.J. He, J.H. Peng, and M.Y. Huang, Determination of dielectric properties of titanium carbide fabricated by microwave synthesis with Ti-bearing blast furnace slag, Int. J. Miner. Metall. Mater., 28(2021), No. 1, p. 88.

L.Z. Gao, T.X. Ma, M.J. Hu, Z.M. Yan, X.W. Lü, and M.L. Hu, Effect of titanium content on the precipitation behavior of carbon-saturated molten pig iron, Int. J. Miner. Metall. Mater., 26(2019), No. 4, p. 483.

J.Y. Xiang, Q.Y. Huang, X. Lv, and C.G. Bai, Effect of mechanical activation treatment on the recovery of vanadium from converter slag, Metall. Mater. Trans. B, 48(2017), No. 5, p. 2759.

G.Q. Ma and M. Cheng, Technological study of titanium slag production from titanium-bearing blast furnace slag, Adv. Mater. Res., 962–965(2014), p. 793.

T.Q. Jiang, H.G. Dong, Y.F. Guo, G.H. Li, and Y.B. Yang, Study on leaching Ti from Ti bearing blast furnace slag by sulphuric acid, Miner. Process. Extr. Metall., 119(2010), No. 1, p. 33.

Z.D. Pang, X.W. Lv, J.W. Ling, Y.Y. Jiang, Z.M. Yan, and J. Dang, Blast furnace ironmaking process with super high TiO2 in the slag: High-temperature structure of the slag, Metall. Mater. Trans. B, 51(2020), No. 5, p. 2348.

Z.M. Yan, X.W. Lv, Z.D. Pang, X.M. Lv, and C.G. Bai, Transition of blast furnace slag from silicate based to aluminate based: Density and surface tension, Metall. Mater. Trans. B, 49(2018), No. 3, p. 1322.

Y.H. Liu, X.W. Lv, C.G. Bai, and B. Yu, Surface tension of the molten blast furnace slag bearing TiO2: Measurement and evaluation, ISIJ Int., 54(2014), No. 10, p. 2154.

V.B. Fainerman, R. Miller, and P. Joos, The measurement of dynamic surface tension by the maximum bubble pressure method, Colloid Polym. Sci., 272(1994), No. 6, p. 731.

N. Ono, T. Kaneko, S. Nishiguchi, and M. Shoji, Measurement of temperature dependence of surface tension of alcohol aqueous solutions by maximum bubble pressure method, J. Therm. Sci. Technol., 4(2009), No. 2, p. 284.

H.A. Friedrichs, L.W. Ronkow, P. Vermot, and S.A. Bliznjukow, New method for simultaneous measurement of viscosity, density and surface tension of metallic melts at high temperatures, Steel Res., 66(1995), No. 12, p. 509.

G. Liu, J.M. Toguri, and N.M. Stubina, Surface tension and density of the molten LaCl3-NaCl binary system, Can. J. Chem., 65(1987), No. 12, p. 2779.

T. Fujisawa, T. Utigard, and J.M. Toguri, Surface tension and density of the molten PbCl2-KCl-NaCl ternary system, Can. J. Chem., 63(1985), No. 5, p. 1132.

A. Pamies, C. Garcia Cordovilla, and E. Louis, The measurement of surface tension of liquid aluminium by means of the maximum bubble pressure method: The effect of surface oxidation, Scripta Metall., 18(1984), No. 9, p. 869.

O. Takeda, H. Iwamoto, R. Sakashita, C. Iseki, and H.M. Zhu, Development of maximum bubble pressure method for surface tension measurement of high viscosity molten silicate, Int. J. Thermophys., 38(2017), No. 7, art. No. 109.

F.A. Oliveira, A. Miller, and J. Madías, Surface tension, densities and viscosities of some CaO-Al2O3 slags, Rev. Metal., 35(1999), No. 2, p. 91.

P. Vadász, M. Havlík, and V. Danêk, Density and surface tension of calcium-ferritic slags I. The systems Cao-FeO-Fe2O3-SiO2 and CaO-FeO-Fe2O3-Al2O3, Can. Metall. Q., 39(2000), No. 2, p. 143.

K.C. Mills, Slag Atlas, 2nd ed., Verlag Stahleisen, Germany, 1995.

S. Sukenaga, S. Haruki, Y. Nomoto, N. Saito, and K. Nakashima, Density and surface tension of CaO-SiO2-Al2O3-R2O (R=Li, Na, K) melts, ISIJ Int., 51(2011), No. 8, p. 1285.

A.I. Bochorishvili and S.B. Yakobashvili, Effect of metal oxide on the surface tension of lime-alumina slags, Svar. Proiz., 10(1968), No. 1, p. 13.

S. Sukenaga, T. Higo, H. Shibata, N. Saito, and K. Nakashima, Effect of CaO/SiO2 ratio on surface tension of CaO-SiO2-Al2O3-MgO melts, ISIJ Int., 55(2015), No. 6, p. 1299.

W.D. Kingery, Surface tension of some liquid oxides and their temperature coefficients, J. Am. Ceram. Soc., 42(1959), No. 1, p. 6.

J.A.V. Butler, The thermodynamics of the surfaces of solutions, Proc. R. Soc. London A, 135(1932), No. 827, p. 348.

B.O. Mysen, F.J Ryerson, and D. Virgo, The influence of TiO2 on the structure and derivative properties of silicate melts, Am Miner., 65(1980), No. 11-1, p. 1150.

B.O. Mysen, D. Virgo, C.M. Scarfe, and D.J. Cronin, Relations between the anionic structure and viscosity of silicate melts; a Raman spectroscopic study, Am. Mineral., 65(1980), No. 7–8, p. 690.

B.O. Mysen, D. Virgo, and I. Kushiro, The structural role of aluminium in silicate melts—A Raman spectroscopic study at 1 atmosphere, Am. Mineral., 66(1981), No. 7, p. 678.

B.O. Mysen, D. Virgo, and F.A. Seifert, The structure of silicate melts: Implications for chemical and physical properties of natural magma, Rev. Geophys. Space Phys., 20(1982), No. 3, p. 353.

B.O. Mysen, L.W. Finger, D. Virgo, and F.A. Seifert, Curve-fitting of Raman spectra of silicate glasses, Am. Mineral., 67(1982), No. 7, p. 686.

K.C. Mills, M. Hayashi, L.J. Wang, and T. Watanabe, The structure and properties of silicate slags, [in] Treatise on Process Metallurgy, Elsevier, Amsterdam, 2014, p. 149.

K.C. Mills, The estimation of slag properties, [in] Southern African Pyrometallurgy 2011 International Conference, Southern African, 2011.

K.C. Mills, L. Yuan, and R.T. Jones, Estimating the physical properties of slags, J. South Afr. Inst. Min. Metall., 111(2011), p. 649.

T. Tanaka, K. Hack, T. Iida, and S. Hara, Application of thermodynamic databases to the evaluation of surface tensions of molten alloys, salt mixtures and oxide mixtures, Int. J. Mater. Res., 87(1996), No. 5, p. 380.

T. Tanaka, T. Kitamura, and I.A. Back, Evaluation of surface tension of molten ionic mixtures, ISIJ Int., 46(2006), No. 3, p. 400.

M. Nakamoto, A. Kiyose, T. Tanaka, L. Holappa, and M. Hämäläinen, Evaluation of the surface tension of ternary silicate melts containing Al2O3, CaO, FeO, MgO or MnO, ISIJ Int., 47(2007), No. 1, p. 38.

M. Nakamoto, M. Hanao, T. Tanaka, M. Kawamoto, L. Holappa, and M. Hämäläinen, Estimation of surface tension of molten silicates using neural network computation, ISIJ Int., 47(2007), No. 8, p. 1075.

M. Hanao, T. Tanaka, M. Kawamoto, and K. Takatani, Evaluation of surface tension of molten slag in multi-component systems, ISIJ Int., 47(2007), No. 7, p. 935.

R.D. Shannon, Revised effective ionic radii and systematic studies of interatomic distances in halides and chalcogenides, Acta Crystallogr. Sect. A, 32(1976), No. 5, p. 751.

I. Sohn and D.J. Min, A review of the relationship between viscosity and the structure of calcium-silicate-based slags in ironmaking, Steel Res. Int., 83(2012), No. 7, p. 611.

R. Knoche, D.B. Dingwell, and S.L. Webb, Melt densities for leucogranites and granitic pegmatites: Partial molar volumes for SiO2, Al2O3, Na2O, K2O, Li2O, Rb2O, Cs2O, MgO, CaO, SrO, BaO, B2O3, P2O5, F2O−1, TiO2, Nb2O5, Ta2O5, and WO3, Geochim. Cosmochim. Acta, 59(1995), No. 22, p. 4645.

Acknowledgements

This work was financially supported by the National Key R&D Program of China (No. 2018YFC1900500) and the Key Fund of Natural Science (No. 51974048).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors have no relevant financial or non-financial interests to disclose.

Rights and permissions

About this article

Cite this article

Pang, Z., Jiang, Y., Ling, J. et al. Blast furnace ironmaking process with super high TiO2 in the slag: Density and surface tension of the slag. Int J Miner Metall Mater 29, 1170–1178 (2022). https://doi.org/10.1007/s12613-021-2262-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-021-2262-x