Abstract

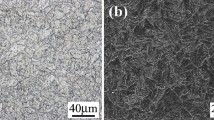

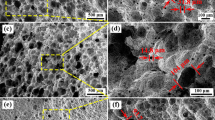

This study aims at providing systematically insights to clarify the impact of cathodic polarization on the stress corrosion cracking (SCC) behavior of 21Cr2NiMo steel. Slow-strain-rate tensile tests demonstrated that 21Cr2NiMo steel is highly sensitive to hydrogen embrittlement at strong cathodic polarization. The lowest SCC susceptibility occurred at −775 mV vs. SCE, whereas the SCC susceptibility was remarkably higher at potentials below −950 mV vs. SCE. Scanning electron microscopy (SEM) and electron backscattered diffraction (EBSD) revealed that the cathodic potential decline caused a transition from transgranular to intergranular mode in the fracture path. The intergranular mode transformed from bainite boundaries separation to prior austenitic grain boundaries separation under stronger cathodic polarization. Furthermore, corrosion pits promoted the nucleation of SCC cracks. In conclusion, with the decrease in the applied potential, the SCC mechanism transformed from the combination of hydrogen embrittlement and anodic dissolution to typical hydrogen embrittlement.

Similar content being viewed by others

References

P.R. Thies, L. Johanning, I. Bashir, T. Tuk, M. Tuk, M. Marta, and S. Müller-Schütze, Accelerated reliability testing of articulated cable bend restrictor for offshore wind applications, Int. J. Mar. Energy, 16(2016), p. 65.

P. Mabelly, P. Bourges, and G. Pont, Effect of metallurgical transformations on weld residual stresses—Application to E690 steel grade, Mar. Struct., 14(2001), No. 4–5, p. 553.

M.H. Mohd and J.K. Paik, Investigation of the corrosion progress characteristics of offshore subsea oil well tubes, Corros. Sci., 67(2013), p. 130.

M. Sun, K. Xiao, C.F. Dong, X.G. Li, and P. Zhong, Effect of stress on electrochemical characteristics of pre-cracked ultrahigh strength stainless steel in acid sodium sulphate solution, Corros. Sci., 89(2014), p. 137.

J. Ćwiek, Hydrogen assisted cracking of high-strength weld-able steels in sea-water, J. Mater. Process. Technol., 164–165(2005), p. 1007.

H. Alawi, A. Ragab, and M. Shaban, Stress corrosion cracking of some steels in various environments, Eng. Fract. Mech., 32(1989), No. 1, p. 29.

N.R. Raykar, R.K. Singh Raman, S.K. Maiti, and L. Choudhary, Investigation of hydrogen assisted cracking of a high strength steel using circumferentially notched tensile test, Mater. Sci. Eng. A, 547(2012), p. 86.

J.H. Bulloch, Some effects of yield strength on the stress corrosion cracking behaviour of low alloy steels in aqueous environments at ambient temperatures, Eng. Fail. Anal., 11(2004), No. 6, p. 843.

M.Q. Zhang, M. Beer, S.T. Quek, and Y.S. Choo, Comparison of uncertainty models in reliability analysis of offshore structures under marine corrosion, Struct. Saf., 32(2010), No. 6, p. 425.

Y.L. Zhou, J. Chen, and Z.Y. Liu, Corrosion behavior of rusted 550 MPa grade offshore platform steel, J. Iron Steel Res. Int., 20(2013), No. 3, p. 66.

DNV GL, Offshore standard DNV-OS-E302: Offshore Mooring Chain, DNV GL, Oslo, 2018.

G. Artola, A. Arredondo, A. Fernández-Calvo, and J. Aldazabal, Hydrogen embrittlement susceptibility of R4 and R5 high-strength mooring steels in cold and warm seawater, Metals., 8(2018), No. 9, art. No. 700.

W.K. Hao, Z.Y. Liu, W. Wu, X.G. Li, C.W. Du, and D.W. Zhang, Electrochemical characterization and stress corrosion cracking of E690 high strength steel in wet-dry cyclic marine environments, Mater. Sci. Eng. A, 710(2018), p. 318.

H.Y. Tian, X. Wang, Z.Y. Cui, Q.K. Lu, L.W. Wang, L. Lei, Y. Li, and D.W. Zhang, Electrochemical corrosion, hydrogen permeation and stress corrosion cracking behavior of E690 steel in thiosulfate-containing artificial seawater, Corros. Sci., 144(2018), p. 145.

Q.K. Lu, L.W. Wang, J.C. Xin, H.Y. Tian, X. Wang, and Z.Y. Cui, Corrosion evolution and stress corrosion cracking of E690 steel for marine construction in artificial seawater under potentiostatic anodic polarization, Constr. Build. Mater., 238(2020), art. No. 117763.

C.F. Dong, Z.Y. Liu, X.G. Li, and Y.F. Cheng, Effects of hydrogen-charging on the susceptibility of X100 pipeline steel to hydrogen-induced cracking, Int. J. Hydrogen Energy, 34(2009), No. 24, p. 9879.

S.J. Kim, S.K. Jang, and J.I. Kim, Electrochemical study of hydrogen embrittlement and optimum cathodic protection potential of welded high strength steel, Met. Mater. Int., 11(2005), No. 1, p. 63.

C. Batt, J. Dodson, and M.J. Robinson, Hydrogen embrittlement of cathodically protected high strength steel in sea water and seabed sediment, Br. Corros. J., 37(2002), No. 3, p. 194.

H.Y. Tian, J.C. Xin, Y. Li, X. Wang, and Z.Y. Cui, Combined effect of cathodic potential and sulfur species on calcareous deposition, hydrogen permeation, and hydrogen embrittlement of a low carbon bainite steel in artificial seawater, Corros. Sci., 158(2019), art. No. 108089.

W. Zheng, X. Zhu, and L. Su, Effect of cathodic protection on fracture behavior of low-alloy steels in seawater, Acta Metall. Sinca, 2(1989), No. 1, p. 57.

A. Zielinski and P. Domzalicki, Hydrogen degradation of high-strength low-alloyed steels, J. Mater. Process. Technol., 133(2003), No. 1–2, p. 230.

X.S. Du, Y.J. Su, J.X. Li, L.J. Qiao, and W.Y. Chu, Stress corrosion cracking of A537 steel in simulated marine environments, Corros. Sci., 65(2012), p. 278.

H.C. Ma, Z.Y. Liu, C.W. Du, H.R. Wang, C.Y. Li, and X.G. Li, Effect of cathodic potentials on the SCC behavior of E690 steel in simulated seawater, Mater. Sci. Eng. A, 642(2015), p. 22.

J.S. Kang, J.B. Seol, and C.G. Park, Three-dimensional characterization of bainitic microstructures in low-carbon high-strength low-alloy steel studied by electron backscatter diffraction, Mater. Charact., 79(2013), p. 110.

D. Delafosse and T. Magnin, Hydrogen induced plasticity in stress corrosion cracking of engineering systems, Eng. Fract. Mech., 68(2001), No. 6, p. 693.

Z.Y. Cui, Z.Y. Liu, L.W. Wang, X.G. Li, C.W. Du, and X. Wang, Effect of plastic deformation on the electrochemical and stress corrosion cracking behavior of X70 steel in near-neutral pH environment, Mater. Sci. Eng. A, 677(2016), p. 259.

G.A. Zhang and Y.F. Cheng, Micro-electrochemical characterization of corrosion of welded X70 pipeline steel in near-neutral pH solution, Corros. Sci., 51(2009), No. 8, p. 1714.

R.O. Ritchie, M.H.C. Cedeno, V.F. Zackay, and E.R. Parker, Effects of silicon additions and retained austenite on stress corrosion cracking in ultrahigh strength steels, Metall. Trans. A, 9(1978), No. 1, p. 35.

C.S. Carter, Fracture toughness and stress corrosion characteristics of a high strength maraging steel, Metall. Trans., 2(1971), No. 6, p. 1621.

S.K. Banerji, C.J. McMahon, and H.C. Feng, Intergranular fracture in 4340-type steels: Effects of impurities and hydrogen, Metall. Trans. A, 9(1978), No. 2, p. 237.

Y. Lee and R.P. Gangloff, Measurement and modeling of hydrogen environment-assisted cracking of ultra-high-strength steel, Metall. Mater. Trans. A, 38(2007), No. 13, p. 2174.

H. Luo, C.F. Dong, Z.Y. Liu, M.T.J. Maha, and X.G. Li, Characterization of hydrogen charging of 2205 duplex stainless steel and its correlation with hydrogen-induced cracking, Mater. Corros., 64(2013), No. 1, p. 26.

J.L. Cabezas-Villa, J. Lemus-Ruiz, D. Bouvard, O. Jiménez, H.J. Vergara-Hernández, and L. Olmos, Sintering study of Ti6Al4V powders with different particle sizes and their mechanical properties, Int. J. Miner. Metall. Mater., 25(2018), No. 12, p. 1389.

Z.Y. Liu, L. Lu, Y.Z. Huang, C.W. Du, and X.G. Li, Mechanistic aspect of non-steady electrochemical characteristic during stress corrosion cracking of an X70 pipeline steel in simulated underground water, Corrosion, 70(2014), No. 7, p. 678.

Z.Y. Liu, X.G. Li, and Y.F. Cheng, Mechanistic aspect of near-neutral pH stress corrosion cracking of pipelines under cathodic polarization, Corros. Sci., 55(2012), p. 54.

S. Bechtle, M. Kumar, B.P. Somerday, M.E. Launey, and R.O. Ritchie, Grain-boundary engineering markedly reduces susceptibility to intergranular hydrogen embrittlement in metallic materials, Acta Mater., 57(2009), No. 14, p. 4148.

R.N. Parkins, Predictive approaches to stress corrosion cracking failure, Corros. Sci., 20(1980), No. 2, p. 147.

Z.Y. Liu, X.G. Li, C.W. Du, G.L. Zhai, and Y.F. Cheng, Stress corrosion cracking behavior of X70 pipe steel in an acidic soil environment, Corros. Sci., 50(2008), No. 8, p. 2251.

S.S. Kasana and O.P. Pandey, Effect of electroslag remelting and homogenization on hydrogen flaking in AMS-4340 ultra-high-strength steels, Int. J. Miner. Metall. Mater., 26(2019), No. 5, p. 611.

P.P. Bai, J. Zhou, B.W. Luo, S.Q. Zheng, P.Y. Wang, and Y. Tian, Hydrogen embrittlement of X80 pipeline steel in H2S environment: Effect of hydrogen charging time, hydrogen-trapped state and hydrogen charging-releasing-recharging cycles, Int. J. Miner. Metall. Mater., 27(2020), No. 1, p. 63.

R. Matsumoto, M. Riku, S. Taketomi, and N. Miyazaki, Hydrogen-grain boundary interaction in Fe, Fe-C, and Fe-N systems, Prog. Nucl. Sci. Technol., 2(2011), p. 9.

Acknowledgement

This work was financially supported by the National Science and Technology Major Project, China (No. 2017-VII-0012-0109).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Conflict of Interest

The authors declare no potential conflict of interest.

Rights and permissions

About this article

Cite this article

Liu, M., Liu, Z., Du, C. et al. Effect of cathodic potential on stress corrosion cracking behavior of 21Cr2NiMo steel in simulated seawater. Int J Miner Metall Mater 29, 263–270 (2022). https://doi.org/10.1007/s12613-020-2199-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-020-2199-5