Abstract

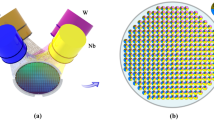

High-entropy alloys (HEAs) generally possess complex component combinations and abnormal properties. The traditional methods of investigating these alloys are becoming increasingly inefficient because of the unpredictable phase transformation and the combination of many constituents. The development of compositionally complex materials such as HEAs requires high-throughput experimental methods, which involves preparing many samples in a short time. Here we apply the high-throughput method to investigate the phase evolution and mechanical properties of novel HEA film with the compositional gradient of (Cr,Fe,V)-(Ta,W). First, we deposited the compositional gradient film by co-sputtering. Second, the mechanical properties and thermal stability of the (Cr0.33Fe0.33V0.33)x(Ta0.5W0.5)100−x (x = 13–82) multiple-based-elemental (MBE) alloys were investigated. After the deposited wafer was annealed at 600°C for 0.5 h, the initial amorphous phase was transformed into a body-centered cubic (bcc) structure phase when x = 33. Oxides were observed on the film surface when x was 72 and 82. Finally, the highest hardness of as-deposited films was found when x = 18, and the maximum hardness of annealed films was found when x = 33.

Similar content being viewed by others

References

Y. Tian and C.Y. Zhao, A review of solar collectors and thermal energy storage in solar thermal applications, Appl. Energy, 104(2013), p. 538.

N. Selvakumar and H.C. Barshilia, Review of physical vapor deposited (PVD) spectrally selective coatings for mid- and high-temperature solar thermal applications, Sol. Energy Mater. Sol. Cells, 98(2012), p. 1.

S. Suman, M.K. Khan, and M. Pathak, Performance enhancement of solar collectors—A review, Renewable Sustainable Energy Rev., 49(2015), p. 192.

M. Thirugnanasambandam, S. Iniyan, and R. Goic, A review of solar thermal technologies, Renewable Sustainable Energy Rev., 14(2010), No. 1, p. 312.

D.Y. Li and Y. Zhang, The ultrahigh charpy impact toughness of forged AlxCoCrFeNi high entropy alloys at room and cryogenic temperatures, Intermetallics, 70(2016), p. 24.

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Dahmen, P.K. Liaw, and Z.P. Lu, Microstructures and properties of high-entropy alloys, Prog. Mater. Sci., 61(2014), p. 1.

O.N. Senkov, G.B. Wilks, D.B. Miracle, C.P. Chuang, and P.K. Liaw, Refractory high-entropy alloys, Intermetallics, 18(2010), No. 9, p. 1758.

O.N. Senkov, G.B. Wilks, J.M. Scott, and D.B. Miracle, Mechanical properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20-W20 refractory high entropy alloys, Intermetallics, 19(2011), No. 5, p. 698.

Z.D. Han, N. Chen, S.F. Zhao, L.W. Fan, G.N. Yang, Y. Shao, and K.F. Yao, Effect of Ti additions on mechanical properties of NbMoTaW and VNbMoTaW refractory high entropy alloys, Intermetallics, 84(2017), p. 153.

Y.D. Wu, Y.H. Cai, T. Wang, J.J. Si, J. Zhu, Y.D. Wang, and X.D. Hui, A refractory Hf25Nb25Ti25Zr25 high-entropy alloy with excellent structural stability and tensile properties, Mater. Lett., 130(2014), p. 277.

Z.F. Lei, X.J. Liu, Y. Wu, H. Wang, S.H. Jiang, S.D. Wang, X.D. Hui, Y.D. Wu, B. Gault, P. Kontis, D. Raabe, L. Gu, Q.H. Zhang, H.W. Chen, H.T. Wang, J.B. Liu, K. An, Q.S. Zeng, T.G. Nieh, and Z.P. Lu, Enhanced strength and ductility in a high-entropy alloy via ordered oxygen complexes, Nature, 563(2018), No. 7732, p. 546.

Y. Zhang, Y. Liu, Y.X. Li, X. Chen, and H.W. Zhang, Micro-structure and mechanical properties of a refractory HfNbTiVSi0.5 high-entropy alloy composite, Mater. Lett., 174(2016), p. 82.

Z.N. An, H.L. Jia, Y.Y. Wu, P.D. Rack, A.D. Patchen, Y.Z. Liu, Y. Ren, N. Li, and P.K. Liaw, Solid-solution CrCoCuFeNi high-entropy alloy thin films synthesized by sputter deposition, Mater. Res. Lett., 3(2015), No. 4, p. 203.

X.H. Yan, J.S. Li, W.R. Zhang, and Y. Zhang, A brief review of high-entropy films, Mater. Chem. Phys., 210(2018), p. 12.

Y. Zou, H. Ma, and R. Spolenak, Ultrastrong ductile and stable high-entropy alloys at small scales, Nature Commun., 6(2015), art. No. 7748.

Y. Zou, S. Maiti, W. Steurer, and R. Spolenak, Size-dependent plasticity in an Nb25Mo25Ta25W25 refractory high-entropy alloy, Acta Mater., 65(2014), p. 85.

Y. Xiao, Y. Zou, H. Ma, A.S. Sologubenko, X. Maeder, R. Spolenak, and J.M. Wheeler, Nanostructured NbMoTaW high entropy alloy thin films: High strength and enhanced fracture toughness, Scripta Mater., 168(2019), p. 51.

H. Kim, S. Nam, A. Roh, M. Son, M.H. Ham, J.H. Kim, and H. Choi, Mechanical and electrical properties of NbMoTaW refractory high-entropy alloy thin films, Int. J. Refract. Met. Hard Mater., 80(2019), p. 286.

D.Y. Li, C.X. Li, T. Feng, Y.D. Zhang, G. Sha, J.J. Lewandowski, P.K. Liaw, and Y. Zhang, High-entropy Al0.3CoCrFe-Ni alloy fibers with high tensile strength and ductility at ambient and cryogenic temperatures, Acta Mater., 123(2017), p. 285.

Y. Zhang, X.H. Yan, W.B. Liao, and K. Zhao, Effects of nitrogen content on the structure and mechanical properties of (Al0.5CrFeNiTi0.25)Nx high-entropy films by reactive sputtering, Entropy, 20(2018), No. 9, art. No. 624.

N. Chawake, J. Zálešák, C. Gammer, R. Franz, M.J. Cordill, J.T. Kim, and J. Eckert, Microstructural characterization of medium entropy alloy thin films, Scripta Mater., 177(2020), p. 22.

W.R. Zhang, P.K. Liaw, and Y. Zhang, A novel low-activation VCrFeTaxWx (x = 0.1, 0.2, 0.3, 0.4, and 1) high-entropy alloys with excellent heat-softening resistance, Entropy, 20(2018), No. 12, art. No. 951.

Q.W. Xing, J. Ma, C. Wang, and Y. Zhang, High-throughput screening solar-thermal conversion films in a pseudobinary (Cr,Fe,V)-(Ta,W) system, ACS Comb. Sci, 20(2018), No. 11, p. 602.

Q.W. Xing, The Design and Property of Refractory Multiple-Basis-Element Alloy Films [Dissertation], University of Science and Technology Beijing, Beijing, 2019.

X.B. Feng, J.Y. Zhang, Y.Q. Wang, Z.Q. Hou, K. Wu, G. Liu, and J. Sun, Size effects on the mechanical properties of nano-crystalline NbMoTaW refractory high entropy alloy thin films, Int. J. Plast., 95(2017), p. 264.

J.A. Thornton, Structure-zone models of thin films, Model. Opt. Thin Films, 0821(1988), p. 95.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (No. 51671020) and the Fundamental Research Funds for the Central Universities (No. FRF-MP-19-013).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xing, Qw., Ma, J. & Zhang, Y. Phase thermal stability and mechanical properties analyses of (Cr,Fe,V)-(Ta,W) multiple-based elemental system using a compositional gradient film. Int J Miner Metall Mater 27, 1379–1387 (2020). https://doi.org/10.1007/s12613-020-2063-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-020-2063-7