Abstract

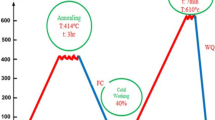

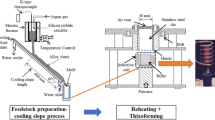

The effects of conform continuous extrusion and subsequent heat treatment on the mechanical and wear-resistance properties of high-alloying Al–13Si–7.5Cu–1Mg alloy were investigated. The microstructures of alloys before and after conform processing and aging were compared by transmission electron microscopy and scanning electron microscopy, respectively. The results reveal that the primary phases were broken and refined by intense shear deformation during conform processing. After the conform-prepared Al–13Si–7.5Cu–1Mg alloy was subjected to solid-solution treatment at 494°C for 1.5 h and aging at 180°C for 4 h, its hardness improved from HBS 115.8 to HBS 152.5 and its ultimate tensile strength increased from 112.6 to 486.8 MPa. Its wear resistance was also enhanced. The factors leading to the enhanced strength, hardness, and wear resistance of the alloy were discussed in detail.

Similar content being viewed by others

References

F.T. Xu, Y. Xu, and G. Li, The mechanism of PEO process on Al–Si alloys with the bulk primary silicon, Appl. Surf. Sci., 255(2009), No. 23, p. 9531.

M. Zamani and S. Seifeddine, Determination of optimum Sr level for eutectic Si modification in Al–Si cast alloys using thermal analysis and tensile properties, Int. J. Metalcast., 10(2016), No. 4, p. 457.

C.M. Cepeda-Jiménez, A Orozco-Caballero, J.M. García-Infanta, A.P. Zhilyaev, O.A. Ruano, and F. Carrenoa, Assessment of homogeneity of the shear-strain pattern in Al–7wt%Si casting alloy processed by high-pressure torsion, Mater. Sci. Eng. A, 597(2014), p. 102.

Z. Li, A.M. Samuel, F.H. Samuel, C. Ravindran, S. Valtierra, and H.W. Doty, Parameters controlling the performance of AA319-type alloys: Part I. Tensile properties, Mater. Sci. Eng. A, 367(2004), No. 1–2, p. 96.

K.Z. He, F.X. Yu, D.Z. Zhao, and L. Zuo, Characterization of precipitates in a hot-deformed hypereutectic Al–Si alloy, J. Alloys Compd., 539(2012), p. 74.

L Zuo and F.X. Yu, DC Casting, Deformation and Strengthening of Al–Si Alloys, Mater. Sci. Forum, 706–709(2012), p. 186.

H.B. Chen and B. Yang, Effect of heat treatment on microstructures and mechanical properties of a bulk nanostructured Al–Zn–Mg–Cu alloy, Int. J. Miner. Metall. Mater., 16(2009), No. 16, p. 672.

C. Xu, S. Schroeder, P.B. Berbon, and T.G. Langdon, Principles of ECAP-Conform as a continuous process for achieving grain refinement: Application to an aluminum alloy, Acta Mater., 58(2010), No. 4, p. 1379.

M. Murashkin, A. Medvedev, V. Kazykhanov, A. Krokhin, G. Raab, N. Enikeev, and R.Z. Valive, Enhanced mechanical properties and electrical conductivity in ultrafine-grained Al 6101 alloy processed via ECAP-Conform, Metals, 5(2015), No. 4, p. 2148.

H. Zhang, F.L. Jiang, X.Y. Shang, and L.X. Li, Flow stress and microstructural evolution of the horizontal continuous casting Al–0.96Mn–0.38Si–0.18Fe alloy during hot compression, Mater. Sci. Eng. A, 571(2013), p. 25.

X.Y. Zhang, H. Zhang, X.X. Kong, and D.F. Fu, Microstructure and properties of Al–0.70Fe–0.24Cu alloy conductor prepared by horizontal continuous casting and subsequent continuous extrusion forming, Trans. Nonferrous. Met. Soc. China, 25(2015), No. 6, p. 1763.

J.A. Pardoe, Conform continuous extrusion process — its contribution to energy conservation, Met. Technol., 11(1984), No. 1, p. 358.

L. Lasa and J.M. Rodriguez-Ibabe, Evolution of the main intermetallic phases in Al–Si–Cu–Mg casting alloys during solution treatment, J. Mater. Sci., 39(2004), No. 4, p. 1343.

E. Sjölander and S. Seifeddine, The heat treatment of Al–Si–Cu–Mg casting alloys, J. Mater. Process. Technol., 210(2010), p. 1249.

M.A. Moustafa, F.H. Samuel, H.W. Doty, and S. Valtierra, Effect of Mg and Cu additions on the microstructural characteristics and tensile properties of Sr-modified Al–Si eutectic alloys, Int. J. Cast Met. Res., 14(2002), No. 4, p. 235.

N. Raghukiran and R. Kumar, Effect of scandium addition on the microstructure, mechanical and wear properties of the spray formed hypereutectic aluminum-silicon alloys, Mater. Sci. Eng. A, 641(2015). p. 138.

S.K. Chaudhury and D. Apelian, Fluidized bed heat treatment of cast Al–Si–Cu–Mg alloys, Metall. Mater. Trans. A, 37(2006), p. 2295.

N. Kang, P. Coddet, H.L. Liao, T. Baur, and C. Coddet, Wear behavior and microstructure of hypereutectic Al–Si alloys prepared by selective laser melting, Appl. Surf. Sci., 378(2016), p. 142.

R.X. Li, R.D. Li, Y.H Zhao, L.Z. He, C.X. Li, H.R. Guan, and Z.Q. Hu, Age-hardening behavior of cast Al–Si base alloy, Mater. Lett., 58(2004), No. 15, p. 2096.

X. Pan, J.E. Morral, and H.D. Brody, Predicting the Q-phase in Al–Cu–Mg–Si alloys, J. Phase Equilib. Diffus., 31(2010), No. 2, p. 144.

D.J. Chakrabarti and D.E. Laughlin, Phase relations and precipitation in Al–Mg–Si alloys with Cu additions, Prog. Mater. Sci., 49(2004), No. 3–4, p. 389.

A.R Farkoosh and M. Pekguleryuz, Enhanced mechanical properties of an Al–Si–Cu–Mg alloy at 300°C: Effects of Mg and the Q-precipitate phase, Mater. Sci. Eng. A, 621(2015), p. 277.

M. Gazizov and R. Kaibyshev, Effect of pre-straining on the aging behavior and mechanical properties of an Al–Cu–Mg–Ag alloy, Mater. Sci. Eng. A, 625(2015), p. 119.

Acknowledgement

This study was financially supported by the National Natural Science Foundation of China (No. 51274245).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lin, Gy., Tan, X., Feng, D. et al. Effects of conform continuous extrusion and heat treatment on the microstructure and mechanical properties of Al–13Si–7.5Cu–1Mg alloy. Int J Miner Metall Mater 26, 1013–1019 (2019). https://doi.org/10.1007/s12613-019-1815-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-019-1815-8