Abstract

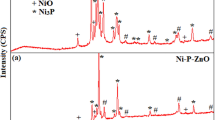

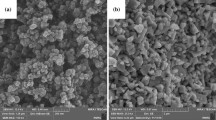

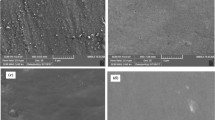

This paper describes an investigation of the effect of ZrO2 nanoparticles on the abrasive properties, crystalline texture developments, and tribocorrosion behavior of Ni-P nanostructured coatings. In the investigation, Ni-P and Ni-P-ZrO2 nanostructured coatings are deposited on St52 steel via the electroless method. Transmission electron microscopy (TEM), field emission scanning electron microscopy (FE-SEM), X-ray diffraction (XRD), energy dispersive spectroscopy (EDS), cyclic-static polarization lests in 3.5wt% NaCl solution, the tribocorrosion test (by back-and-forth wear in electrochemical cell), and the microhardness test using the Vickers method were performed to characterize and analyze the deposited coatings. The results of this study showed that the addition of ZrO2 nanoparticles to the Ni-P electro-less bath produced the following: a sharp increase in wear and hardness resistance, the change of the wear mechanism from sheet to adhesive mode, the reduction of pitting corrosion resistance, significant reduction in the tribocorrosion protective properties, change in the preferred orientation of the crystalline texture coating from (111) to (200), increase in the sedimentation rate during the deposit process, and a sharp increase in the thickness of the Ni-P nanostructured coatings.

Similar content being viewed by others

References

S.H.M. Anijdan, M. Sabzi, M.R. Zadeh, and M. Farzam, The effect of electroless bath parameters and heat treatment on the properties of Ni-P and Ni-P-Cu composite coatings, Mater. Res., 21(2018), No. 2, p. 1.

M. Sabzi, S.H.M. Anijdan, M.R. Zadeh, and M. Farzam, The effect of heat treatment on corrosion behaviour of Ni-P-3 gr/lit Cu nano-composite coating, Can. Metall. Q., 57(2018), No. 3, p. 350.

M. Sabzi, S.H.M. Anijdan, and M. Asadian, The effect of substrate temperature on microstructural evolution and hardenability of tungsten carbide coating in hot filament chemical vapor deposition, Int. J. Appl. Ceram. Technol., 15(2018), No. 6, p. 1350.

M. Sabzi, S.M. Far, and S.M. Dezfuli, Characterization of bioactivity behavior and corrosion responses of hydroxyapatite-ZnO nanostructured coating deposited on NiTi shape memory alloy, Ceram. Int., 44(2018), No. 17, p. 21395.

S.H.M. Anijdan and M. Sabzi, The evolution of microstructure of an high Ni HSLA X100 forged steel slab by thermomechanical controlled processing, [in] TMS 2018 147th Annual Meeting & Exhibition Supplemental Proceedings, 2018, p. 145.

S.H.M. Anijdan, M. Sabzi, M.R. Zadeh, and M. Farzam, The influence of pH, rotating speed and Cu content reinforcement nano-particles on wear/corrosion response of Ni-P-Cu nano-composite coatings, Tribol. Int., 127(2018), p. 108.

K. Zielińska, A. Stankiewicz, and I. Szczygiel, Electroless deposition of Ni-P-nano-ZrO2 composite coatings in the presence of various types of surfactants, J. Colloid Interface Sci., 377(2012), No. 1, p. 362.

C. Gao, L. Dai, W. Meng, Z.G. He, and L. Wang, Electrochemically promoted electroless nickel-phosphorous plating on titanium substrate, Appl. Surf. Sci., 392(2017), p. 912.

X. Shu, Y.X. Wang, C.M. Liu, A. Aljaafari, and W. Gao, Double-layered Ni-P/Ni-P-ZrO2 electroless coatings on AZ31 magnesium alloy with improved corrosion resistance, Surf. Coat. Technol., 261(2015), p. 161.

C. Hodge and M.M. Stack, Tribo-corrosion mechanisms of stainless steel in soft drinks, Wear, 270(2010), No. 1–2, p. 104.

M. Sabzi and S.M. Dezfuli, Post weld heat treatment of hypereutectoid hadfield steel: characterization and control of microstructure, phase equilibrium, mechanical properties and fracture mode of welding joint, J. Manuf. Processes, 34(2018), p. 313.

M. Sabzi and S.M. Dezfuli, Drastic improvement in mechanical properties and weldability of 316L stainless steel weld joints by using electromagnetic vibration during GTAW process, J. Manuf. Processes, 33(2018), p. 74.

S.H.M. Anijdan, M. Sabzi, M. Ghobeiti-Hasab, and A. Roshan-Ghiyas, Optimization of spot welding process parameters in dissimilar joint of dual phase steel DP600 and AISI 304 stainless steel to achieve the highest level of shear-tensile strength, Mater. Sci. Eng. A, 726(2018), p. 120.

M.C. Turk, M.J. Walters, and D. Roy, Tribo-electrochemical investigation of a slurry composition to reduce dissolution and galvanic corrosion during chemical mechanical planarization of Cu-Ru interconnects, Mater. Chem. Phys., 201(2017), p. 271.

M.M. Stack, W. Huang, G. Wang, and C. Hodge, Some views on the construction of bio-tribo-corrosion maps for Titanium alloys in Hank’s solution: Particle concentration and applied loads effects, Tribol. Int., 44(2011), No. 12, p. 1827.

A.V. Kobets and T.N. Vorobyova, Palladium catalyst synthesis through sol-gel processing for electroless nickel deposition on glass, Thin Solid Films, 616(2016), p. 793.

V. Ezhilselvi, J.N. Balaraju, and S. Subramanian, Chromate and HF free pretreatment for MAO/electroless nickel coating on AZ31B magnesium alloy, Surf. Coat. Technol., 325(2017), p. 270.

F. Liao, X.R. Han, Y.F. Zhang, C.J. Xu, and H.Y. Chen, Carbon fabrics coated with nickel film through alkaline electroless plating technique, Mater. Lett., 205(2017), p. 165.

Z.C. Shao, Z.Q. Cai, R. Hu, and S.Q. Wei, The study of electroless nickel plating directly on magnesium alloy, Surf. Coat. Technol., 249(2014), p. 42.

D. Li, F. Chen, Z.H. Xie, S.Y. Shan, and C.J. Zhong, Enhancing structure integrity and corrosion resistance of Mg alloy by a two-step deposition to avoid F ions etching to nano-SiO2 reinforcement, J. Alloys Compd., 705(2017), p. 70.

Z.W. Song, Z.H. Xie, L.F. Ding, and Y.K. Zhang, Corrosion resistance of super-hydrophobic coating on AZ31B Mg alloy, Int. J. Electrochem. Sci., 13(2018), p. 6190.

R. Hu, Y.Y. Su, and H.D. Liu, Deposition behaviour of nickel phosphorus coating on magnesium alloy in a weak corrosive electroless nickel plating bath, J. Alloys Compd., 658(2016), p. 555.

R. Kullaiah, L. Elias, and A.C. Hegde, Effect of TiO2 nano-particles on hydrogen evolution reaction activity of Ni coatings, Int. J. Miner. Metall. Mater., 25(2018), No. 4, p. 472.

S. Arulvel, A. Elayaperumal, and M.S. Jagatheeshwaran, Electroless nickel-phosphorus coating on crab shell particles and its characterization, J. Solid State Chem., 248(2017), p. 87.

L.P. Wu, Z.D. Yang, and G.W. Qin, Kinetic study of a novel electroless NiP deposition on AZ91D magnesium alloy using nickel hypophosphite as the metal salt, J. Alloys Compd., 694(2017), p. 1133.

H. Zhao and Y.X. Lu, Comparative study of electroless nickel film on different organic acids modified cuprammonium fabric (CF), Appl. Surf. Sci., 362(2016), p. 154.

L.Y. Li, N. Takahashi, K. Kaneko, T. Shimizu, and T. Takarada, A novel method for nickel recovery and phosphorus removal from spent electroless nickel-plating solution, Sep. Purif. Technol., 147(2015), p. 237.

L. Bonin, V. Vitry, and F. Delaunois, Corrosion behaviour of electroless high boron-mid phosphorous nickel duplex coatings in the as-plated and heat-treated states in NaCl, H2SO4, NaOH and Na2SO4 media, Mater. Chem. Phys., 208(2018), p. 77.

N. Guglielmi, Kinetics of the deposition of inert particles from electrolytic baths, J. Electrochem. Soc., 119(1972), No. 8, p. 1009.

M. Sabzi, A. Obeydavi, and S.H.M. Anijdan, The effect of joint shape geometry on the microstructural evolution, fracture toughness, and corrosion behavior of the welded joints of a Hadfield steel, Mech. Adv. Mater. Struct., 2018. https://doi.org/10.1080/15376494.2018.1430268.

M. Sabzi and S.M. Dezfuli, A study on the effect of compositing silver oxide nanoparticles by carbon on the electrochemical behavior and electronic properties of zinc-silver oxide batteries, Int. J. Appl. Ceram. Technol., 15(2018), No. 6, p. 1446.

S.M. Dezfuli and M. Sabzi, A study on the effect of presence of CeO2 and benzotriazole on activation of self-healing mechanism in ZrO2 ceramic-based coating, Int. J. Appl. Ceram. Technol., 15(2018), No. 5, p. 1248.

L. Bonin, N. Bains, V. Vitry, and A.J. Cobley, Electroless deposition of nickel-boron coatings using low frequency ultrasonic agitation: Effect of ultrasonic frequency on the coatings, Ultrasonics, 77(2017), p. 61.

P. Sahoo and S.K. Das, Tribology of electroless nickel coatings-A review, Mater. Des., 32(2011), No. 4, p. 1760.

F.J. He, Y.Z. Fang, and S.J. Jin, The study of corrosion-wear mechanism of Ni-W-P alloy, Wear, 311(2014), No. 1–2, p. 14.

B. Elsener, M. Crobu, M.A. Scorciapino, and A. Rossi, Electroless deposited Ni-P alloys: corrosion resistance mechanism, J. Appl. Electrochem, 38(2008), No. 7, p. 1053.

R.B. Diegle, N.R. Sorensen, C.R. Clayton, M.A. Helfand, and Y.C. Yu, An XPS investigation into the passivity of an amorphous Ni-20P alloy, J. Electrochem. Soc., 135(1988), No. 5, p. 1085.

Y. Sun and V. Rana, Tribocorrosion behaviour of AISI 304 stainless steel in 0.5M NaCl solution, Mater. Chem. Phys., 129(2011), No. 1–2, p. 138.

C. DellaCorte, The effect of counterface on the tribological performance of a high temperature solid lubricant composite from 25 to 650°C, Surf. Coat. Technol., 86–87(1996), p. 486.

S.H.M. Anijdan, and M. Sabzi, The effect of pouring temperature and surface angle of vortex casting on microstructural changes and mechanical properties of 7050Al-3wt%SiC composite, Mater. Sci. Eng. A, 737(2018), p. 230.

S.H.M. Anijdan and M. Sabzi, The effect of heat treatment process parameters on mechanical properties, precipitation, fatigue life, and fracture mode of an austenitic Mn Hadfield steel, J. Mater. Eng. Perform., 27(2018), No. 10, p. 5246.

M. Sabzi, S.M. Dezfuli, and S.M. Far, Deposition of Ni-tungsten carbide nanocomposite coating by TIG welding: Characterization and control of microstructure and wear/corrosion responses, Ceram. Int, 44(2018), No. 18, p. 22816.

S.H.M. Anijdan, M. Sabzi, M. Asadian, and H.R. Jafarian, Effect of sub-layer temperature during HFCVD process on morphology and corrosion behavior of tungsten carbide coating, Int. J. Appl. Ceram. Technol., 16(2019), No. 1, p. 243.

M. Sabzi, S.M. Dezfuli, and S.M. Mirsaeidghazi, The effect of pulse-reverse electroplating bath temperature on the wear/corrosion response of Ni-Co/tungsten carbide nanocomposite coating during layer deposition, Ceram. Int., 44(2018), No. 16, p. 19492.

S.M. Dezfuli and M. Sabzi, Effect of yttria and benzotriazole doping on wear/corrosion responses of alumina-based nanostructured film, Ceram. Int., 44(2018), No. 16, p. 20245.

M. Sabzi and S.M. Dezfuli, Deposition of Al2O3 ceramic film on copper-based heterostructured coatings by aluminizing process: Study of the electrochemical responses and corrosion mechanism of the coating, Int. J. Appl. Ceram. Technol., 16(2019), No. 1, p. 195.

M. Sabzi, S.H.M. Anijdan, M. Ghobeiti-Hasab, and M. Fatemi-Mehr, Sintering variables optimization, microstructural evolution and physical properties enhancement of nano-WC ceramics, J. Alloys Compd., 766(2018), p. 672.

M. Sabzi, S.M. Far, and S.M. Dezfuli, Effect of melting temperature on microstructural evolutions, behavior and corrosion morphology of Hadfield austenitic manganese steel in the casting process, Int. J. Miner. Metall. Mater., 25(2018), No. 12, p.1431.

M. Sabzi and S.H.M. Anijdan, Microstructural analysis and optical properties evaluation of sol-gel heterostructured NiO-TiO2 films used for solar panels, Ceram. Int., 45(2019), No. 3, p. 3250.

M. Sabzi, A. Kianpour-Barjoie, M. Ghobeiti-Hasab, and S.M. Dezfuli, Effect of high-frequency electric resistance welding (HF-ERW) parameters on metallurgical transformations and tensile properties of API X52 microalloy steel welding joint, Arch. Metall. Mater, 63(2018), No. 4, p. 1693.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sabzi, M., Dezfuli, S.M. & Balak, Z. Crystalline texture evolution, control of the tribocorrosion behavior, and significant enhancement of the abrasion properties of a Ni-P nanocomposite coating enhanced by zirconia nanoparticles. Int J Miner Metall Mater 26, 1020–1030 (2019). https://doi.org/10.1007/s12613-019-1805-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-019-1805-x