Abstract

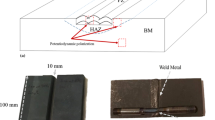

The weldability of the ZhS6U nickel-based superalloy, which is prone to solidification cracking during electron-beam welding (EBW) repair processes, was investigated. The effects of two different pre-weld heat-treatment cycles on the final microstructure before and after welding were examined. Welds were made on flat coupons using an EBW machine, and the two heat-treatment cycles were designed to reduce γ′ liquation before welding. Microstructural features were also examined by optical and scanning electron microscopy. The results showed that the change in the morphology and size of the γ′ precipitates in the pre-weld heat-treatment cycles changed the ability of the superalloy to release the tensile stresses caused by the matrix phase cooling after EBW. The high hardness in the welded coupons subjected to the first heat-treatment cycle resulted in greater resistance to stress release by the base alloy, and the concentration of stress in the base metal caused liquation cracks in the heat-affected zone and solidification cracks in the weld area.

Similar content being viewed by others

References

M.A. Godovanets, B.A. Prusakov, and I.I. Lysenko, Regenerative heat treatment of blades of high-temperature nickel alloys, Met. Sci. Heat. Treat., 38(1996), No. 5, p. 202.

M.F. Chiang and C. Chen, Induction-assisted laser welding of IN-738 nickel-base superalloy, Mater. Chem. Phys., 114(2009), No. 1, p. 415.

A.T. Egbewande, R.A. Buckson, and O.A. Ojo, Analysis of laser beam weldability of Inconel 738 superalloy, Mater. Charact., 61(2010), No. 5, p. 569.

Y. Danis, C. Arvieu, E. Lacoste, T. Larrouy, and J.M. Quenisset, An investigation on thermal, metallurgical and mechanical states in weld cracking of Inconel 738LC superalloy, Mater. Des., 31(2010), No. 1, p. 402.

M. Montazeri and F.M. Ghaini, The liquation cracking behavior of IN738LC superalloy during low power Nd:YAG pulsed laser welding, Mater. Charact., 67(2012), p. 65.

M. Prager, Welding of Precipitation-Hardening Nickel-Base Alloys, Welding Research Council, New York, 1968.

H.A. Shahsavari, A.H. Kokabi, and S. Nategh, Effect of preweld microstructure on HAZ liquation cracking of Rene 80 superalloy, Mater. Sci. Technol., 23(2007), No. 5, p. 547.

O.A. Ojo, Intergranular liquation cracking in heat affected zone of a welded nickel based superalloy in as cast condition, Mater. Sci. Technol., 23(2007), No. 10, p. 1149.

T. Böllinghaus, H. Herold, C.E. Cross, and J.C. Lippold, Hot Cracking Phenomena in Welds II, Springer, Berlin, 2008.

M. Qian and J.C. Lippold, The effect of annealing twin-generated special grain boundaries on HAZ liquation cracking of nickel-base superalloys, Acta Mater., 51(2003), No. 12, p. 3351.

O.A. Ojo, N.L. Richards, and M.C. Chaturvedi, Contribution of constitutional liquation of gamma prime precipitate to weld HAZ cracking of cast Inconel 738 superalloy, Scripta Mater., 50(2004), No. 5, p. 641.

O.A. Ojo, N.L. Richards, and M.C. Chaturvedi, Microstructural study of weld fusion zone of TIG welded IN 738LC nickel-based superalloy, Scripta Mater., 51(2004), No. 7, p. 683.

J.M. Kalinowski, Weldability of a Nickel-Based Superalloy, NASA Contractor Report 195376, 1994.

V.M. Polyanskii, V.V. Gavrilyuk, V.Z. Zagorskii, A.V. Logunov, A.M. Polyanskii, and M.I. Silis, Structure, properties, and fracture mechanism of cast refractory nickel alloy, Met. Sci. Heat Treat., 46(2004), No. 9–10, p. 392.

M.J. Donachie and S.J. Donachie, Superalloys: A Technical Guide, 2nd Ed., ASM International, Ohio, 2002.

O. Hunziker, D. Dye, and R.C. Reed, On the formation of a centreline grain boundary during fusion welding, Acta Mater., 48(2000), No. 17, p. 4191.

Acknowledgements

The authors would like to express their appreciation for Mr. Mehdi Talebipoor’s support in this research for the provision of alloys and other laboratory equipment.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khakzadshahandashti, A., Rahimipour, M.R., Shirvani, K. et al. Weldability and liquation cracking behavior of ZhS6U superalloy during electron-beam welding. Int J Miner Metall Mater 26, 251–259 (2019). https://doi.org/10.1007/s12613-019-1730-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-019-1730-z