Abstract

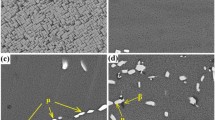

The aim of the present study was to investigate the effect of element segregation on the microstructure and γ′ phase in a γ/γ′ cobalt- based superalloy. Several samples were prepared from a cast alloy and homogenized at 1300°C for different times, with a maximum of 24 h. A microstructural study of the cast alloy using wavelength-dispersive spectroscopic analysis revealed that elements such as Al, Ti, and Ni segregated mostly within interdendritic regions, whereas W atoms were segregated within dendrite cores. With an increase in homogenization time, segregation decreased and the initial dendritic structure was eliminated. Field-emission scanning electron microscopy micrographs showed that the γ′ phases in the cores and interdendritic regions of the as-cast alloy were 392 and 124 nm, respectively. The size difference of γ′ was found to be due to the different segregation behaviors of constituent elements during solidification. After homogenization, particularly after 16 h, segregation decreased; thus, the size, chemical composition, and hardness of the precipitated γ′ phase was mostly uniform throughout the samples.

Similar content being viewed by others

References

V.A. Wills and D.G. McCartney, A comparative study of solidification features in nickel-base superalloys: Microstructural evolution and microsegregation, Mater. Sci. Eng. A, 145(1991), No. 2, p. 223.

N. Warnken, D. Ma, A. Drevermann, R.C. Reed, S.G. Fries, and I. Steinbach, Phase-field modelling of as-cast microstructure evolution in nickel-based superalloys, Acta Mater., 57(2009), No. 19, p. 5862.

G.D. Merz, T.Z. Kattamis, and A.F. Giamei, Microsegration and homogenization of Ni-7.5wt%Al-2.0wt%Ta dendritic monocrystals, J. Mater. Sci., 14(1979), No. 3, p. 663.

M.S.A. Karunaratne, D.C. Cox, P. Carter, and R.C. Reed, Modelling of the microsegregation in CMSX-4 superalloy and its homogenisation during heat treatment, Superalloys, 2000, p. 263.

Z.J. Miao, A.D. Shan, Y.B. Wu, J. Lu, W.l. Xu, and H.W. Song, Quantitative analysis of homogenization treatment of INCONEL718 superalloy, Trans. Nonferrous Met. Soc. China, 21(2011), No. 5, p. 1009.

Y.J. Li, Y.F. Teng, X.H. Feng, and Y.S. Yang, Effects of pulsed magnetic field on microsegregation of solute elements in a Ni-based single crystal superalloy, J. Mater. Sci. Technol., 33(2017), No. 1, p. 105.

J.B. le Graverend, J. Cormier, P. Caron, S. Kruch, F. Gallerneau, and J. Mendez, Numerical simulation of γ/γ′ microstructural evolutions induced by TCP-phase in the MC2 nickel base single crystal superalloy, Mater. Sci. Eng. A, 528(2011), No. 6, p. 2620.

A.S. Golezani, M. Bageri, and R. Samadi, Microstructural change, and impact toughness property of Inconel 738LC after 12 years of service, Eng. Fail. Anal., 59(2016), p. 624.

M.R. Jahangiri, S.M.A. Boutorabi, and H. Arabi, Study on incipient melting in cast Ni base IN939 superalloy during solution annealing and its effect on hot workability, Mater. Sci. Technol., 28(2012), No. 12, p. 1402.

S.H. Fu, J.X. Dong, M.C. Zhang, and X.S. Xie, Alloy design and development of INCONEL718 type alloy, Mater. Sci. Eng. A, 499(2009), No. 1–2, p. 215.

Y.Z. Zhou and A. Volek, Effect of carbon additions on hot tearing of a second generation nickel-base superalloy, Mater. Sci. Eng. A, 479(2008), No. 1–2, p. 324.

C.N. Wei, H.Y. Bor, and L. Chang, The effects of carbon content on the microstructure and elevated temperature tensile strength of a nickel-base superalloy, Mater. Sci. Eng. A, 527(2010), No. 16–17, p. 3741.

F. Long, Y.S. Yoo, C.Y. Jo, S.M. Seo, Y.S. Song, T. Jin, and Z.Q. Hu, Formation of η and σ phase in three polycrystalline superalloys and their impact on tensile properties, Mater. Sci. Eng. A, 527(2009), No. 1–2, p. 361.

J. Zhang and R.F. Singer, Effect of Zr and B on castability of Ni-based superalloy IN792, Metall. Mater. Trans. A, 35(2004), No. 4, p. 1337.

A. Epishin, T. Link, U. Brückner, B. Fedelich, and P. Portella, Effects of segregation in nickel-base superalloys: Dendritic stresses, Superalloys, 2004, p. 537.

P. Li, S.S. Li, and Y.F. Han, Influence of solution heat treatment on microstructure and stress rupture properties of a Ni3Al base single crystal superalloy IC6SX, Intermetallics, 19(2011), No. 2, p. 182.

M.T. Kim, D.S. Kim, and O.Y. Oh, Effect of γ′ precipitation during hot isostatic pressing on the mechanical property of a nickel-based superalloy, Mater. Sci. Eng. A, 480(2008), No. 1–2, p. 218.

D.L. Sponseller, Differential thermal analysis of nickel-base superalloys, Superalloys, 1996, p. 259.

D.A. Porter and K.E. Easterling, Phase Transformations in Metals and Alloys, 2nd Ed., CRC Press, State of Florida, 1992, p. 61.

F.J. Humphreysand M. Hatherly, Recrystallization and Related Annealing Phenomena, Elsevier, The Netherlands, 2004, p. 137.

J. Sato, T. Omori, K. Oikawa, I. Ohnuma, R. Kainuma, and K. Ishida, Cobalt-base high-temperature alloys, Science, 312(2006), No. 5770, p. 90.

K. Tanaka, M. Ooshima, N. Tsuno, A. Sato, and H. Inui, Creep deformation of single crystals of new Co-Al-W-based alloys with fcc/L12 two-phase microstructures, Philos. Mag., 92(2012), No. 32, p. 4011.

M.S. Titus, A. Suzuki, and T.M. Pollock, Creep and directional coarsening in single crystals of new γ-γ′ cobalt-base alloys, Scripta Mater., 66(2012), No. 8, p. 574.

F. Xue, H.J. Zhou, X.H. Chen, Q.Y. Shi, H. Chang, M.L. Wang, X.F. Ding, and Q. Feng, Creep behavior of a novel Co-Al-W-base single crystal alloy containing Ta and Ti at 982°C, MATEC Web of Conferences, 14(2014), p. 15002.

A. Bauer, S. Neumeier, F. Pyczak, R.F. Singer, and M. Göken, Creep properties of different γ′-strengthened Co-base superalloys, Mater. Sci. Eng. A, 550(2012), p. 333.

S. Neumeier, L.P. Freund, and M. Göken, Novel wrought γ/γ′ cobalt base superalloys with high strength and improved oxidation resistance, Scripta Mater., 109(2015), p. 104.

A. Suzuki and T.M. Pollock, High-temperature strength and deformation of γ/γ′ two-phase Co-Al-W-base alloys, Acta Mater., 56(2008), No. 6, p. 1288.

M. Tsunekane, A. Suzuki, and T.M. Pollock, Single-crystal solidification of new Co-Al-W-base alloys, Intermetallics, 19(2011), No. 5, p. 636.

X.F. Ding, T. Mi, F. Xue, H.J. Zhou, and M.L. Wang, Microstructure formation in γ-γ′ Co-Al-W-Ti alloys during directional solidification, J. Alloys Compd., 599(2014), p. 159.

E.T. McDevitt, Feasibility of cast and wrought Co-Al-WX gamma-prime superalloys, Mater. Sci. Forum, 783–786(2014), p. 1159.

I. Lopez-Galilea, C. Zenk, S. Neumeier, S. Huth, W. Theisen, and M. Göken, The thermal stability of intermetallic compounds in an as-cast SX Co-base superalloy, Adv. Eng. Mater., 17(2015), No. 6, p. 741.

J. Koßmann, C.H. Zenk, I. Lopez-Galilea, S. Neumeier, A. Kostka, S. Huth, W. Theisen, M. Göken, R. Drautz, and T. Hammerschmidt, Microsegregation and precipitates of an as-cast Co-based superalloy—microstructural characterization and phase stability modelling, J. Mater. Sci., 50(2015), No. 19, p. 6329.

P.J. Bocchini, E.A. Lass, K.W. Moon, M.E. Williams, C.E. Campbell, U.R. Kattner, D.C. Dunand, and D.N. Seidman, Atom-probe tomographic study of γ/γ′ interfaces and compositions in an aged Co-Al-W superalloy, Scripta Mater., 68(2013), No. 8, p. 563.

F. Pyczak, A. Bauer, M. Göken, U. Lorenz, S. Neumeier, M. Oehring, J. Paul, N. Schell, A. Schreyer, A. Stark, and F. Symanzik, The effect of tungsten content on the properties of L12-hardened Co-Al-W alloys, J. Alloys Compd., 632(2015), p. 110.

H.Y. Yan, V.A. Vorontsov, and D. Dye, Alloying effects in polycrystalline γ′ strengthened Co-Al-W base alloys, Intermetallics, 48(2014), p. 44.

K. Shinagawa, T. Omori, J. Sato, K. Oikawa, I. Ohnuma, R. Kainuma, and K. Ishida, Phase equilibria and microstructure on γ′ phase in Co-Ni-Al-W system, Mater. Trans., 49(2008), No. 6, p. 1474.

R.C. Kramb, M.M. Antony, and S.L. Semiatin, Homogenization of a nickel-base superalloy ingot material, Scripta Mater., 54(2006), No. 9, p. 1645.

S.R. Hegde, R.M. Kearsey, and J.C. Beddoes, Designing homogenization-solution heat treatments for single crystal superalloys, Mater. Sci. Eng. A, 527(2010), No. 21–22, p. 5528.

A. Janotti, M. Krčmar, C.L. Fu, and R.C. Reed, Solute diffusion in metals: Larger atoms can move faster, Phys. Rev. Lett., 92(2004), No. 8, p. 85901.

S.S. Naghavi, V.I. Hegde, and C. Wolverton, Diffusion coefficients of transition metals in fcc cobalt, Acta Mater., 132(2017), p. 467.

L. Gong, B. Chen, Z.H. Du, M.S. Zhang, R.C. Liu, and K. Liu, Investigation of solidification and segregation characteristics of cast Ni-base superalloy K417G, J. Mater. Sci. Technol., 34(2016), No. 3, p. 541.

X.L. Pan, H.Y. Yu, G.F. Tu, W.R. Sun, and Z.Q. Hu, Segregation and diffusion behavior of niobium in a highly alloyed nickel-base superalloy, Trans. Nonferrous Met. Soc. China, 21(2011), No. 11, p. 2402.

Y. Minamino, Y. Koizumi, N. Tsuji, T. Yamada, and T. Takahashi, Interdiffusion in Co solid solutions of Co-Al-Cr-Ni system at 1423 K, Mater. Trans., 44(2003), No. 1, p. 63.

S. Obata, M. Moniruzzaman, and Y. Murata, Interdiffusion in Co-based Co-Al-W ternary alloys at elevated temperatures, ISIJ Int., 54(2014), No. 10, p. 2129.

H. Chang, G.L. Xu, X.G. Lu, L. Zhou, K. Ishida, and Y.W. Cui, Experimental and phenomenological investigations of diffusion in Co-Al-W alloys, Scripta Mater., 106(2015), p. 13.

J. Chen, L. Zhang, J. Zhong, W. Chen, and Y. Du, High-throughput measurement of the composition-dependent interdiffusivity matrices in Ni-rich fcc Ni-Al-Ta alloys at elevated temperatures, J. Alloys Compd., 688(2016), p. 320.

S. Neumeier, H.U. Rehman, J. Neuner, C.H. Zenk, S. Michel, S. Schuwalow, J. Rogal, R. Drautz, and M. Göken, Diffusion of solutes in fcc cobalt investigated by diffusion couples and first principles kinetic Monte Carlo, Acta Mater., 106(2016), p. 304.

A. Green and N. Swindells, Measurement of interdiffusion coefficients in Co-AI and Ni-AI systems between 1000 and 1200°C, Mater. Sci. Technol., 1(1985), No. 2, p. 101.

I. Povstugar, P.P. Choi, S. Neumeier, A. Bauer, C.H. Zenk, M. Göken, and D. Raabe, Elemental partitioning and mechanical properties of Ti- and Ta-containing Co-Al-W-base superalloys studied by atom probe tomography and nanoindentation, Acta Mater., 78(2014), p. 78.

I. Povstugar, C.H. Zenk, R. Li, P.P. Choi, S. Neumeier, O. Dolotko, M. Hoelzel, M. Göken, and D. Raabe, Elemental partitioning, lattice misfit and creep behaviour of Cr containing γ′ strengthened Co base superalloys, Mater. Sci. Technol., 32(2016), No. 3, p. 220.

V.A. Vorontsov, J.S. Barnard, K.M. Rahman, H.Y. Yan, P.A. Midgley, and D. Dye, Coarsening behaviour and interfacial structure of γ′ precipitates in Co-Al-W based superalloys, Acta Mater., 120(2016), p. 14.

C.H. Zenk, S. Neumeier, H.J. Stone, and M. Göken, Mechanical properties and lattice misfit of γ/γ′ strengthened Co-base superalloys in the Co-W-Al-Ti quaternary system, Intermetallics, 55(2014), p. 28.

A. Bauer, S. Neumeier, F. Pyczak, and M. Göken, Microstructure and creep strength of different γ/γ′-strengthened Co-base superalloy variants, Scripta Mater., 63(2010), No. 12, p. 1197.

M.J. Donachie and S.J. Donachie, Superalloys: A Technical Guide, ASM international, New York, 2002, p. 82.

R.C. Reed, The Superalloys: Fundamentals and Applications, Cambridge University Press, Cambridge, 2008, p. 216.

Acknowledgement

The authors would like to appreciate the support of Dr. Jahanafrooz for this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sani, S.A., Arabi, H., Kheirandish, S. et al. Investigation on the homogenization treatment and element segregation on the microstructure of a γ/γ′-cobalt-based superalloy. Int J Miner Metall Mater 26, 222–233 (2019). https://doi.org/10.1007/s12613-019-1727-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-019-1727-7