Abstract

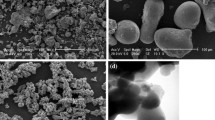

Alumina nanoparticles were added to a Cu−Zn alloy to investigate their effect on the microstructural, tribological, and corrosion properties of the prepared alloys. Alloying was performed using a mixture of copper and zinc powders with 0vol% and 5vol% of α-Al nanopowder in a satellite ball mill. The results showed that the Cu−Zn solid solution formed after 18 h of mechanical alloying. The mechanically alloyed powder was compacted followed by sintering of the obtained green compacts at 750°C for 30 min. Alumina nanoparticles were uniformly distributed in the matrix of the Cu−Zn alloy. The tribological properties were evaluated by pin-on-disk wear tests, which revealed that, upon the addition of alumina nanoparticles, the coefficient of friction and the wear rate were reduced to 20% and 40%, respectively. The corrosion properties of the samples exposed to a 3.5wt% NaCl solution were studied using the immersion and potentiodynamic polarization methods, which revealed that the addition of alumina nanoparticles reduced the corrosion current of the nanocomposite by 90%.

Similar content being viewed by others

References

P. Webster, The Brasses: Properties & Applications, Copper Development Association, Hertfordshire, 2005.

J.R. Davis, Copper and Copper Alloys, ASM International, Materials Park, Ohio, 2001.

S.K. Pabi and B.S. Murty, Mechanism of mechanical alloying in Ni Al and Cu Zn systems, Mater. Sci. Eng. A, 214(1996), No. 1-2, p. 146.

S.D. Beattie and J.R. Dahn, Comparison of electrodeposited copper−zinc alloys prepared individually and combinatorially, J. Electrochem. Soc., 150(2003), No. 11, p. C802.

Y. Guan and X. Peng, A novel electrodeposited Cu–Zn–Bi film with increased corrosion resistance in a 0.05 MK2SO4 solution, Appl. Surf. Sci., 258(2011), No. 2, p. 822.

M.R.H.D. Almeida, E.P. Barbano, M.F.D. Carvalho, P.C. Tulio, and I.A. Carlos, Copper–zinc electrodeposition in alkaline-sorbitol medium: electrochemical studies and structural, morphological and chemical composition characterization, Appl. Surf. Sci., 333(2015), p. 13.

D.Y. Ying and D.L. Zhang, Processing of Cu−Al2O3 metal matrix nanocomposite materials by using high energy ball milling, Mater. Sci. Eng. A, 286(2000), No. 1, p. 152.

K.S. Zuo, S.Q. Xi, and J.E. Zhou, Effect of temperature on mechanical alloying of Cu−Zn and Cu−Cr system, Trans. Nonferrous Met. Soc. China, 19(2009), No. 5, p. 1206.

T. Yamane, H. Okubo, N. Oki, K. Hisayuki, M. Kiritani, and M. Komatsu, Consolidation of mechanically alloyed powder mixture of Cu−Zn alloy and graphite, Mater. Sci. Eng. A, 350(2003), No. 1-2, p. 173.

F. Cardellini, V. Contini, G. Mazzone, and M. Vittori, Phase Transformations and chemical reactions in mechanically alloyed Cu−Zn powders, Scripta Metall. Mater., 28(1993), No. 9, p. 1035.

V. Rajkovic, D. Bozic, and M.T. Jovanovic, Effects of copper and Al2O3 particles on characteristics of Cu−Al2O3 composites, Mater. Des., 31(2010), No. 4, p. 1962.

M.F. Zawrah, H.A. Zayed, R.A. Essawy, A.H. Nassar, and M.A. Taha, Preparation by mechanical alloying, characterization and sintering of Cu−20wt.% Al2O3 nanocomposites, Mater. Des., 46(2013), p. 485.

L.H. Hihara and R.M. Latanision, Corrosion of metal matrix composites, Int. Mater. Rev., 39(1994), No. 6, p. 245.

B.D. Cullity, Elements of X-ray Diffraction, 2nd Ed., Addison-Wesley Publishing Company, USA, 1978.

J.B. Fogagnolo, F. Velasco, M.H. Robert, and J.M. Torralba, Effect of mechanical alloying on the morphology, microstructure and properties of aluminium matrix composite powders, Mater. Sci. Eng. A, 342(2003), No. 1-2, p. 131.

H.P. Klung and L.E. Alexander, X-ray Diffraction Procedures, Wiley, New York, 1962.

C. Suryanarayana and M.G. Norton, X-ray Diffraction: A Practical Approach, Springer Science & Business Media, New York, 2013.

J. Eckert, J.C. Holzer, C.E. Krill, and W.L. Johnson, Reversible grain size changes in ball-milled nanocrystalline Fe−Cu alloys, J. Mater. Res., 7(1992), No. 8, p. 1980.

C. Suryanarayana, Mechanical alloying and milling, Prog. Mater. Sci., 46(2001), p. 1.

N.K. Mukhopadhyay, D. Mukherjee, S. Bera, I. Manna, and R. Manna, Synthesis and characterization of nano-structured Cu–Zn γ-brass alloy, Mater. Sci. Eng. A, 485(2008), No. 1-2, p. 673.

L. Lü and M.O. Lai, Mechanical Alloying, Springer Science & Business Media, New York, 2013.

H. Imai, K. Kondoh, Y. Kosaka, S. Li, J. Umeda, H. Atsumi, and A. Kojima, Characteristics of lead-free P/M Cu60−Zn40 brass alloys with graphite, Powder Technol., 198(2010), No. 3, p. 417.

S. Domsa, Sintered brass from mechanical Cu−Zn powder mixtures, J. Phys. IV, 3(1993), No. C7, p. 735.

R.M. German, Sintering Theory and Practice, Wiley-VCH, 1996, p. 568.

R.M. German, Powder Metallurgy and Particulate Materials Processing: the Processes, Materials, Products, Properties, and Applications, Metal Powder Industries Federation Princeton, NJ, 2005.

P.J.F. Harris, Growth and structure of supported metal catalyst particles, Int. Mater. Rev., 40(1995), No. 3, p. 97.

M. Korać1, Z. Anđić, M. Tasić, and Ž. Kamberović, Sintering of Cu–Al2O3 nano-composite powders produced by a thermochemical route, J. Serb. Chem. Soc., 72(2007), No. 11, p. 1115.

F. Shehata, M. Abdelhameed, A. Fathy, and M. Elmahdy, Preparation and characteristics of Cu−Al2O3 nanocomposite, Open J. Met., 1(2011), p. 25.

R. Ritasalo, X.W. Liua, O. Söderberg, A. Keski-Honkola, V. Pitkänen, and S.P. Hannula, The microstructural effects on the mechanical and thermal properties of pulsed electric current sintered Cu−Al2O3 composites, Procedia Eng., 10(2011), p. 124.

P.L. Mangonon, The Principles of Materials Selection for Engineering Design, Prentice Hall, London, 1999.

V. Rajković, D. Božić, A. Devečerski, S. Bojanić, and M.T. Jovanović, Strength and thermal stability of Cu−Al2O3 composite obtained by internal oxidation, Rev. Metal., 46(2010), No. 6, p. 520.

V. Rajković, D. Božić, M. Popović, and M.T. Jovanović, The influence of powder particle size on properties of Cu−Al2O3 composites, Sci. Sintering, 41(2009), p. 185.

A. Mukhtar, D.L. Zhang, C. Kong, and P. Munroe, Effect of processing condition and composition on the microhardness of Cu−(2.5−10) vol.% Al2O3 nanocomposite powder particles produced by high energy mechanical milling, Int. J. Mod. Phys. B, 24(2010), No. 15, p. 2308.

K. Jach, K. Pietrzak, A. Wajler, A. Sidorowicz, and U. Brykała, Application of ceramic preforms to the manufacturing of ceramic-metal composites, Arch. Metall. Mater., 58(2013), No. 4, p. 1425.

A. Vencl, V. Rajkovic, and F. Zivic, Friction and wear properties of copper-based composites reinforced with micro-and nano-sized Al2O3 particles, [in] Proceedings of the 8th International Conference on Tribology — BALKANTRIB’14, Sinaia, Romania, 2014, p. 30.

G.H. Zhou, H.Y. Ding, Y. Zhang, H. David, and A.H. Liu, Fretting behavior of nano-Al2O3 reinforced copper-matrix composites prepared by coprecipitation, Metalurgija, 15(2009), No. 3, p. 169.

A.M. Soleimanpour, P. Abachi, and K. Purazrang, Wear behaviour of in situ Cu–Al2O3 composites produced by internal oxidation of as cast alloys, Tribol. Mater. Surf. Interfaces, 3(2009), No. 3, p. 125.

Y.S. Zhang, K. Wang, Z. Han, and G. Liu, Dry sliding wear behavior of copper with nano-scaled twins, Wear, 262(2007), No. 11-12, p. 1463.

A. Fathy, F. Shehata, M. Abdelhameed, and M. Elmahdy, Compressive and wear resistance of nanometric alumina reinforced copper matrix composites, Mater. Des., 36(2012), p. 100.

J.W. Kaczmar, K. Granat, E. Grodzka, and A. Kurzawa, Tribological properties of Cu based composite materials strengthened with Al2O3 particles, Arch. Foundry Eng., 12(2012), No. 2, p. 33.

F. Shehata, A. Fathy, M. Abdelhameed, and S.F. Moustafa, Fabrication of copper−alumina nanocomposites by mechano-chemical routes, J. Alloys Compd., 476(2009), No. 1-2, p. 300.

C.S. Ramesh, R.N. Ahmed, M.A. Mujeebu, and M.Z. Abdullah, Development and performance analysis of novel cast copper−SiC−Gr hybrid composites, Mater. Des., 30(2009), No. 6, p. 1957.

G. Yuan, J.C. Jie, P.C. Zhang, J. Zhang, T.M. Wang, and T.J. Li, Wear behavior of high strength and high conductivity Cu alloys under dry sliding, Trans. Nonferrous Met. Soc. China, 25(2015), No. 7, p. 2293.

S. Alirezaei, S.M. Monirvaghefi, M. Salehi, and A. Saatchi, Wear behavior of Ni−P and Ni−P−Al2O3 electroless coatings, Wear, 262(2007), No. 7-8, p. 978.

R. Ravichandran and N. Rajendran, Influence of benzotriazole derivatives on the dezincification of 65–35 brass in sodium chloride, Appl. Surf. Sci., 239(2005), No. 2, p. 182.

G.A. El-Mahdy, A.K.F. Dyab, A.M. Atta, and H.A. Al-Lohedan, Brass Corrosion under a single droplet of NaCl, Int. J. Electrochem. Sci., 8(2013), p. 9858.

M.M. Antonijevic, G.D. Bogdanovic, M.B. Radovanovic, M.B. Petrovic, and A.T. Stamenkovic, Influence of pH and chloride ions on electrochemical behavior of brass in alkaline solution, Int. J. Electrochem. Sci., 4(2009), p. 654.

G.A. El-Mahdy, Electrochemical impedance study on brass corrosion in NaCl and (NH4)2SO4 solutions during cyclic wet−dry conditions, J. Appl. Electrochem., 35(2005), No. 3, p. 347.

I. Milošev and T. Kosec, Electrochemical and spectroscopic study of benzotriazole films formed on copper, copper−zinc alloys and zinc in chloride solution, Chem. Biochem. Eng. Q, 23(2009), No. 1, p. 53.

Z.S. Smialowska, Pitting corrosion of metals, Corros. Sci., 41(1999), No. 9, p. 1743.

B. Szczygieł and M. Kołodziej, Composite Ni/Al2O3 coatings and their corrosion resistance, Electrochim. Acta, 50(2005), No. 20, p. 4188.

A.C. Ciubotariu, L. Benea, M.L. Varsanyi, and V. Dragan, Electrochemical impedance spectroscopy and corrosion behaviour of Al2O3−Ni nano composite coatings, Electrochim. Acta, 53(2008), No. 13, p. 4557.

P. Berçot, E. Peña-Muñoz, and J. Pagetti, Electrolytic composite Ni−PTFE coatings: an adaptation of Guglielmi’s model for the phenomena of incorporation, Surf. Coat. Technol., 157(2002), No. 2-3, p. 282.

H. Koivuluoto and P. Vuoristo, Effect of powder type and composition on structure and mechanical properties of Cu+Al2O3 coatings prepared by using low-pressure cold spray process, J. Therm. Spray Technol., 19(2010), No. 5, p. 1081.

T. Lampke, A. Leopold, D. Dietrich, G. Alisch, and B. Wielage, Correlation between structure and corrosion behaviour of nickel dispersion coatings containing ceramic particles of different sizes, Surf. Coat. Technol., 201(2006), No. 6, p. 3510.

A.S.M.A. Haseeb, H.H. Masjuki, L.J. Ann, and M.A. Fazal, Corrosion characteristics of copper and leaded bronze in palm biodiesel, Fuel Process. Technol., 91(2010), No. 3, p. 329.

M.A. Almomani, W.R. Tyfour, and M.H. Nemrat, Effect of silicon carbide addition on the corrosion behavior of powder metallurgy Cu−30Zn brass in a 3.5 wt% NaCl solution, J. Alloys Compd., 679(2016), p. 104.

K.K. Alaneme and M.O. Bodunrin, Corrosion behavior of alumina reinforced aluminium (6063) metal matrix composites, J. Miner. Mater. Charact. Eng., 10(2011), No. 12, p. 1153.

B.M. Praveen and T.V. Venkatesha, Electrodeposition and properties of Zn-nanosized TiO2 composite coatings, Appl. Surf. Sci., 254(2008), No. 8, p. 2418.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Baghani, M., Aliofkhazraei, M. & Askari, M. Cu−Zn−Al2O3 nanocomposites: study of microstructure, corrosion, and wear properties. Int J Miner Metall Mater 24, 462–472 (2017). https://doi.org/10.1007/s12613-017-1427-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-017-1427-0