Abstract

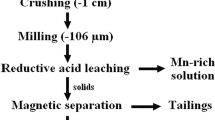

In the present investigation, magnetic separation studies using an induced roll magnetic separator were conducted to beneficiate low-grade ferruginous manganese ore. The feed ore was assayed to contain 22.4% Mn and 35.9% SiO2, with a manganese-to-iron mass ratio (Mn:Fe ratio) of 1.6. This ore was characterized in detail using different techniques, including quantitative evaluation of minerals by scanning electron microscopy, which revealed that the ore is extremely siliceous in nature and that the associated gangue minerals are more or less evenly distributed in almost all of the size fractions in major proportion. Magnetic separation studies were conducted on both the as-received ore fines and the classified fines to enrich their manganese content and Mn:Fe ratio. The results indicated that the efficiency of separation for deslimed fines was better than that for the treated unclassified bulk sample. On the basis of these results, we proposed a process flow sheet for the beneficiation of low-grade manganese ore fines using a Floatex density separator as a pre-concentrator followed by two-stage magnetic separation. The overall recovery of manganese in the final product from the proposed flow sheet is 44.7% with an assay value of 45.8% and the Mn:Fe ratio of 3.1.

Similar content being viewed by others

References

K.S. Mani and D. Subrahmanyam, Utilisation of low grade/off grade ores and mine waste, Proc. Indian Natn. Sci. Acad., 50A(1984), p. 509.

P.K. Naik, P.S.R. Reddy, and V.N. Misra, Floc flotation studies of ultra fine siliceous manganese ore by linear orthogonal saturated design, J. Min. Metall., 41A(2005), p. 11.

S. Roy, Ancient manganese deposits, [in] K.H. Wolf, Handbook of Strata-Bound and Stratiform Ore Deposits, Elsevier Scientific Publishing Company, Amsterdam, 1976, p. 395.

B.C. Acharya, D.S. Rao, and R.K. Sahoo, Nishikhal manganese deposit, Koraput District, Orissa, J. Geo. Soc. India, 36(1990), No. 6, p. 644.

B.C. Acharya, D.S. Rao, and R.K. Sahoo, Mineralogy and genesis of Kutinga manganese deposit, South Orissa, India, J. Mineral. Petrol. Econ. Geol., 89(1994), No. 8, p. 317.

S. Roy, Classification of manganese deposits, Acta Mineral. Petrol., 19(1969), p. 67.

P. Mishra, B.K. Mvohapatra, and P.P. Singh, Mode of occurrence and characteristics of Mn-ore bodies in iron ore group of rocks, North Orissa, India and its significance in resource evaluation, Res. Geol., 56(2006), No. 1, p. 55.

B.K. Mohapatra, S. Mishra, and P.P. Singh, Biogenic wad in Iron Ore Group of rocks of Bonai-Keonjhar belt, Orissa, J. Geol Soc. India, 80(2012), No. 1, p. 89.

K.V.G.K. Gokhale and T.C. Rao, Ore Deposits of India, Affiliated East West Press, New Delhi, 1983.

P.I.A. Narayan and N.N. Subrhmanyan, Beneficiation of Low Grade Manganese Ores of India, CSIR, New Delhi, 1957.

V. Singh, S.M. Rao, T.K. Ghosh, C.R. Kumar, and T.C. Rao, Beneficiation of low grade manganese ore fines to recover ferromanganese grade concentrate, Tata Search, 2009, No. 1, p. 155.

V. Singh, S.M. Rao, A. Dixit, and B.K. Das, Developing process flow sheet for reducing the alumina content in lumpy manganese ore feed for ferromanganese plant, Tata Search, 2006, No. 1, p. 47.

G.V. Rao, B.K. Mohapatra, and A.K. Tripathy, Enrichment of the manganese content by wet high intensity magnetic separation from Chikla manganese ore, India, Magn. Electr. Sep., 9(1998), No. 2, p. 69.

T. Sharma, Physico-chemical processing of low grade manganese ore, Int. J. Miner. Process., 35(1992), No. 3-4, p. 191.

Y.V. Swamy, B. Bhoi, S. Prakash, and H.S. Ray, Enrichment of the manganese to iron ratio of ferruginous low-grade manganese ore using solid reductant, Miner. Metall. Process., 15(1998), p. 34.

V. Kivinen, H. Krogerus, and J. Daavittila, Upgradation of Mn:Fe ratio of low grade manganese ore for ferromanganese production, [in] Proceedings of XII International Ferro Alloys Congress. Helsinki, 2010, p. 467.

P.P. Mishra, B.K. Mohapatra, and K. Mahanta, Upgradation of low-grade siliceous manganese ore from Bonai-Keonjhar belt, Orissa, India, J. Miner. Mater. Charact. Eng., 8(2009), No. 1, p. 47.

N. Dash, B.K. Mohapatra, and D.S. Rao, Petro-minerographical studies of off-grade Mn-ores from two contrasting occurrences in Gangpur Group of rocks, India, and their influence on beneficiation, World Metall. Erzmetall, 63(2010), No. 2, p. 5.

G.V. Rao, B.C. Acharya, B.V.R. Murty, J.N. Mohanty, Y.V. Swamy, P. Chattopadhay, and A.K. Tripathy, Removal of phosphorus and enrichment of manganese from a complex ferruginous manganese ore, Magn. Electr. Sep., 9(1998), No. 2, p. 109.

S.B. Kanungo, S.K. Mishra, and D. Biswal, Beneficiation of low-grade, high phosphorous manganese ores of Andhra Pradesh, India, by wet high-intensity magnetic separation plus jigging or hydrocyclone classification, Miner. Metall. Process., 17(2000), No. 4, p. 269.

S.B. Kanungo, S.K. Mishra, and D. Biswal, Beneficiation of low grade, high phosphorous manganese ores of Andhra Pradesh, India, by wet high intensity magnetic separation, Miner. Metall. Process., 17(2000), No. 3, p. 181.

V. Singh, T.K. Ghosh, Y. Ramamurthy, and V. Tathavadkar, Beneficiation and agglomeration process to utilize low-grade ferruginous manganese ore fines, Int. J. Miner. Process., 99(2011), No. 1-4, p. 84.

G. Grieco, S. Kastrati, and M. Pedrotti, Magnetic enrichment of braunite-rich manganese ore at different grain sizes, Miner. Process. Extr. Metall. Rev., 35(2014), No.4, p.257.

T.V. Dendyuk, New reagent systems for flotation of low-grade manganese products of combined beneficiation, Powder Technol., 71(1992), No. 1, p. 47.

M. Oliazadeh, M. Noaparast, and R. Dehghan, Beneficiation of low grade fine manganese ores, [in] Proceeding of the XXIII International Mineral Processing Congress, Istanbul, 2006, p. 347.

A.M. Abeidu, The feasibility of activation of manganese minerals flotation, Trans. JIM, 14(1973), p. 45.

E.L. Chanturiya, T.V. Bashlykova, N.I. Potkonen, and A.R. Makavetskas, Poor manganese ore dressing on the basis of mineralogical–technological studies, [in] Proceedings of the XXI International Mineral Processing Congress, Rome, 13(2000), p. C2–1.

M.R. Hosseini, A. Bahrami, and M. Pazouki, Influence of shaking table parameters on manganese grade and recovery, [in] Proceedings of the XXIV International Mineral Processing Congress (IMPC), Beijing, 2008, p. 783.

U. Malayoglu, Study on the gravity processing of manganese ores, Asia J. Chem., 22(2010), No. 4, p. 3292.

S.K. Tripathy, P.K. Banerjee, and N. Suresh, Separation analysis of dry high intensity induced roll magnetic separator for concentration of hematite fines, Powder Technol., 264(2014), p. 527.

S.K. Tripathy, M.K. Mallick, V. Singh, and Y.R. Murthy, Preliminary studies on teeter bed separator for separation of manganese fines, Powder Technol., 239(2013), p. 284.

S. Roy, S.K. Mandal, and A. Das, Segregation and process features in a teeter bed separator as revealed by high-speed videography and image processing, Miner. Process. Extr. Metall. Rev., 35(2014), No.1, p.15.

B. Sarkar, A. Das, S. Roy, and S.K. Rai, In depth analysis of alumina removal from iron ore fines using teetered bed gravity separator, Miner. Process. Extr. Metall., 117(2008), No. 1, p. 1.

C.R. Kumar, S. Mohanan, S.K. Tripathy, Y. Ramamurthy, T. Venugopalan, and N. Suresh, Prediction of process input interactions of Floatex Density Separator performance for separating medium density particles, Int. J. Miner. Process., 100(2011), No. 3-4, p. 136.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tripathy, S.K., Banerjee, P.K. & Suresh, N. Effect of desliming on the magnetic separation of low-grade ferruginous manganese ore. Int J Miner Metall Mater 22, 661–673 (2015). https://doi.org/10.1007/s12613-015-1120-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-015-1120-0