Abstract

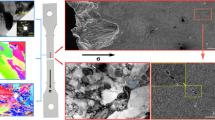

Tempering is an important process for T/P92 ferritic heat-resistant steel from the viewpoint of microstructure control, as it facilitates the formation of final tempered martensite under serving conditions. In this study, we have gained deeper insights on the mechanism underlying the microstructural evolution during tempering treatment, including the precipitation of carbides and the coarsening of martensite laths, as systematically analyzed by optical microscopy, transmission electron microscopy, and high-resolution transmission electron microscopy. The chemical composition of the precipitates was analyzed using energy dispersive X-ray spectroscopy. Results indicate the formation of M3C (cementite) precipitates under normalized conditions. However, they tend to dissolve within a short time of tempering, owing to their low thermal stability. This phenomenon was substantiated by X-ray diffraction analysis. Besides, we could observe the precipitation of fine carbonitrides (MX) along the dislocations. The mechanism of carbon diffusion controlled growth of M23C6 can be expressed by the Zener’s equation. The movement of Y-junctions was determined to be the fundamental mechanism underlying the martensite lath coarsening process. Vickers hardness was estimated to determine their mechanical properties. Based on the comprehensive analysis of both the micro-structural evolution and hardness variation, the process of tempering can be separated into three steps.

Similar content being viewed by others

References

F. Abe, Precipitate design for creep strengthening of 9% Cr tempered martensitic steel for ultra-supercritical power plants, Sci. Technol. Adv. Mater., 9(2008), art. No. 013002.

B.Q. Ning, Q.Z. Shi, Z.S. Yan, J.C. Fu, Y.C. Liu, and L.J. Bie, Variation of martensite phase transformation mechanism in minor-stressed T91 ferritic steel, J. Nucl. Mater., 393(2009), No. 1, p. 54.

P.J. Ennis and A. Czyrska-Filemonowicz, Recent advances in creep-resistant steels for power plant applications, Sadhana, 28(2003), No. 3–4, p. 709.

F. Abe, T. Horiuchi, M. Taneike, and K. Sawada, Stabilization of martensitic microstructure in advanced 9Cr steel during creep at high temperature, Mater. Sci. Eng. A, 378(2004), No. 1–2, p. 299.

F. Liu, G. Xu, Y.L. Zhang, H.J. Hu, L.X. Zhou, and Z.L. Xue, In situ observations of austenite grain growth in Fe-C-Mn-Si super bainitic steel, Int. J. Miner. Metall. Mater., 20(2013), No. 11, p. 1060.

J.Y. Li, P. Zhao, J. Yanagioto, S. Sugiyama, and Y.L. Chen, Effects of heat treatment on the microstructures and mechanical properties of a new type of nitrogen-containing die steel, Int. J. Miner. Metall. Mater., 19(2012), No. 6, p. 511.

Z. Lu, R.G. Faulkner, N. Riddle, F.D. Martino, and K. Yang, Effect of heat treatment on microstructure and hardness of Eurofer 97, Eurofer ODS and T92 steels, J. Nucl. Mater., 386–388(2009), p. 445.

F. Abe, H. Araki, and T. Noda, The effect of tungsten on dislocation recovery and precipitation behavior of low-activation martensitic 9Cr steels, Metall. Trans. A, 22(1991), No. 10, p. 2225.

F. Abe, Effect of quenching, tempering, and cold rolling on creep deformation behavior of a tempered martensitic 9Cr-1W steel, Metall. Mater. Trans. A., 34(2003), No. 4, p. 913.

H. Ghassemi-Armaki, R.P. Chen, K. Maruyama, M. Yoshizawa, and M. Igarashi, Static recovery of tempered lath martensite microstructures during long-term aging in 9–12% Cr heat resistant steels, Mater. Lett., 63(2009), No. 28, p. 2423.

G.R. Speich and W.C. Leslie, Tempering of steel, Mater. Trans., 3(1972), No. 5, p. 1043.

H. Sakasegawa, M. Tamura, S. Ohtsuka, S. Ukai, H. Tanigawa, A. Kohyama, and M. Fujiwara, Precipitation behavior of oxide particles in mechanically alloyed powder of oxide-dispersion-strengthened steel, J. Alloys Compd., 452(2008), No. 1, p. 2.

C.X. Liu, D.T. Zhang, Y.C. Liu, Q. Wang, and Z.S. Yan, Investigation on the precipitation behavior of M3C phase in T91 ferritic steels, Nucl. Eng. Des., 241(2011), p. 2411.

B. Hutchinson, J. Hagström, O. Karlsson, D. Lindell, M. Tornberg, F. Lindberg, and M. Thuvander, Microstructures and hardness of as-quenched martensites (0.1–0.5%C), Acta Mater., 59(2011), No. 14, p. 5845.

G. Ghosh and G.B. Olson, Precipitation of paraequilibrium cementite: Experiments, and thermodynamic and kinetic modeling, Acta Mater., 50(2002), No. 8, p. 2099.

Å. Gustafson and M. Hättestrand, Coarsening of precipitates in an advanced creep resistant 9% chromium steel quantitative microscopy and simulations, Materi. Sci. Eng. A., 333(2002), No. 1–2, p. 279.

Y.N. Wang, Y.P. Bao, M. Wang, and L.C. Zhang, Precipitation and control of BN inclusions in 42CrMo steel and their effect on machinability, Int. J. Miner. Metall. Mater., 20(2013), No. 9, p. 842.

K. Yamada, M. Igarashi, S. Muneki, and F. Abe, Creep properties affected by morphology of MX in high-Cr ferritic steels, ISIJ. Int., 41(2001), p. s116.

L.K. Singhal and J.W. Martin, The nucleation and growth of widmannstätten M23C6 precipitation in an austenitic stainless steel, Acta Metall., 16(1968), p. 1159.

C. Zener, Theory of growth of spherical precipitates from solid solution, J. Appl. Phys., 20(1949), p. 950.

L.Q. Xu, D.T. Zhang, Y.C. Liu, B.Q. Ning, Z.X. Qiao, Z.S. Yan, and H.J. Li, Precipitation kinetics of M23C6 in T/P92 heat-resistant steel by applying soft-impingement correction, J. Mater. Res., 28(2013), No. 11, p. 1529.

E.A. Brandes, Smithells Metals Reference Book, Butterworths, London, 1983, p. 13.

J. Guo, H.W. Qu, L.G. Liu, Y.L. Sun, Y. Zhang, and Q.X. Yang, Study on stable and meta-stable carbides in a high speed steel for rollers during tempering processes, Int. J. Miner. Metall. Mater., 20(2013), No. 2, p. 146.

K. Sawada, M. Taneike, K. Kimura, and F. Abe, In situ observation of recovery of lath structure in 9% chromium creep resistant steel, Mater. Sci. Technol., 19(2003), p. 739.

F. Abe, Coarsening behavior of lath and its effect on creep rates in tempered martensitic 9Cr-W steels, Mater. Sci. Eng. A, 387–389(2004), p. 565.

G. Krauss, Martensite in steel: strength and structure, Mater. Sci. Eng. A, 273–275(1999), p. 40.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, Lq., Zhang, Dt., Liu, Yc. et al. Precipitation behavior and martensite lath coarsening during tempering of T/P92 ferritic heat-resistant steel. Int J Miner Metall Mater 21, 438–447 (2014). https://doi.org/10.1007/s12613-014-0927-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-014-0927-4