Abstract

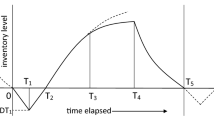

In this paper, we developed both crisp and fuzzy EOQ models with proportionate discount (discount increases when number of defects decrease in each lot) for items with imperfect quality. First, we construct an optimal order quantity of crisp case. Next, proposed three different fuzzy inventory models where in the first case the defective rate is fuzzified, in the next case, both defective rate and annual demand rate are fuzzified and finally in the case of the third model all costs, defective rate and annual demand are taken to be fuzzy. Lastly, we developed the model for items with imperfect quality with inspection errors, as the inspector may commit errors while screening the lot. The probability of misclassification errors is assumed to be known. The inspection process may consist of three costs: (a) cost of inspection (b) cost of Type I errors and (c) cost of Type II errors. The defective items, classified by the inspector and the buyer, would be salvaged as a single batch that is sold at a discounted price. The objective is to find the optimal lot size for models to maximize the total profit (both for crisp and fuzzy models) and used fuzzy numbers for defective items, demand rate and/or all types of costs (exclusively for fuzzy models). We considered the triangular fuzzy numbers to represent the fuzziness of all types of costs, defective items and annual demand. Finally, the optimum order quantity is obtained using the signed distance method. A numerical example is provided to illustrate the results of the proposed models and the sensitivity analysis is conducted to know the effect of changes made for the values of different parameters on the actual lot size and the profit respectively.

Similar content being viewed by others

References

Karlin, S.: One stage inventory models with uncertainty. In: Karlin, S., Scarf, H.E (eds.) Studies in the mathematical theory of inventory and production. Stanford University Press, Stanford (1958)

Porteus, E.L.: Optimal lot sizing, process quality improvement and setup cost reduction. Oper. Res. 34, 137–144 (1986)

Rossenblatt, M.J., Lee, H.L.: Economic production cycles with imperfect production processes. IIE Trans. 18, 48–55 (1986)

Kim, C.H., Hong, Y.: An optimal run length in deteriorating production process. Int. J. Prod. Econ. 58(2), 183–189 (1999)

Bhojak, A., Gothi, U.B.: An EOQ model with time dependent demand and Weibull distributed deterioration. Int. J. Eng. Res. Technol. (IJERT) 4(09), 1 (2015)

Gothi, U.B., Chatterji, D.: EPQ model for imperfect quality items under constant demand rate and varying IHC. SankhyaVignan NSV 11(1), 7–19 (2015)

Salameh, M.K., Jaber, M.Y.: Economic production quantity model for items with imperfect quality. Int. J. Prod. Econ. 64, 59–64 (2000)

Zadeh, L.: Fuzzy sets. Inf. Control 8, 338–353 (1965)

Shekarian, E., Olugu, E.U., Abdul-Rashid, S.H., Bottani, E.: A fuzzy reverse logistics inventory system integrating economic order/production quantity models. Int. J. Fuzzy Syst. 18(6), 1141–1161 (2016)

Shekarian, E., Olugu, E.U., Abdul-Rashid, S.H., Kazemi, N.: An economic order quantity model considering different holding costs for imperfect quality items subject to fuzziness and learning. J. Intell. Fuzzy Syst. 30(5), 2985–2997 (2016)

Kahraman, C., Gulbay, M., Kabak, O.: “Applications of Fuzzy Sets in Industrial Engineering: A Topical Classification”, Fuzzy Applications in Industrial Engineering, pp. 1–5. Springer, Berlin (2006)

Yao, J.S., Chang, S.C., Su, J.S.: Fuzzy inventory without backorder for fuzzy order quantity and fuzzy total demand quantity. Comput. Oper. Res. 27(10), 935–962 (2000)

Yao, J.S., Chiang, J.: Inventory without backorder with fuzzy total cost and fuzzy storing cost defuzzified by centroid and signed distance. Eur. J. Oper. Res. 148(2), 401–409 (2003)

Lee, H.M., Lin, L.: Applying signed distance method for fuzzy inventory without backorder. Int. J. Innov. Comput. Inf. Control 7(6), 3523–3531 (2011)

Samal, N., Pratihar, D.: Optimization of variable demand fuzzy economic order quantity inventory models without and with backordering. Comput. Ind. Eng. 78, 148–162 (2014)

Shekarian, E., Rashid, S.H.A., Bottan, E., Kumar, S.D.: Fuzzy inventory models: a comprehensive review. Appl. Soft Comput. 55, 588–621 (2017)

Chang, H.C.: An implication of fuzzy sets theory to the EOQ model with imperfect quality items. Comput. Oper. Res. 31, 2079–2092 (2004)

Chen, S.H., Chang, S.M.: Optimization of fuzzy production inventory model with unrepairable defective products. Int. J. Prod. Econ. 113(2), 887–894 (2008)

Bellman, R.E., Zadeh, L.A.: Decision-making in a fuzzy environment. Manag. Sci. 17(4), B141–B164 (1970)

Halim, K.A., Giri, B.C., Chaudhuri, K.S.: Fuzzy economic order quantity model for perishable items with stochastic demand, partial backlogging and fuzzy deterioration rate. Int. J. Oper. Res. 3(1–2), 77–96 (2008)

Lee, H.M., Yao, J.S.: Economic production quantity for fuzzy demand quantity and fuzzy production quantity. Eur. J. Oper. Res. 109(1), 203–211 (1998)

De, P.K., Rawat, A.: A fuzzy inventory model without shortages using triangular fuzzy number. Fuzzy Inf. Eng. 3, 59–68 (2011)

Jaggi, C.K., Pareek, S., Sharma, A., Nidhi, : Fuzzy inventory model for deteriorating items with time varying demand and shortages. Am. J. Oper. Res. 2, 81–92 (2012)

Dutta, D., Kumar, P.: Optimal ordering policy for an inventory model for deteriorating items without shortages by considering fuzziness in demand rate, ordering cost and holding cost. Int. J. Adv. Innov. Res. 2, 320–325 (2013)

Raouf, A., Jain, J.K., Sathe, P.T.: A cost-minimization model for multi characteristic component inspection. IIE Trans. 15(3), 187–194 (1983)

Duffuaa, S.O., Khan, M.: An optimal repeat inspection plan with several classifications. J. Oper. Res. Soc. 53(9), 1016–1026 (2002)

Duffuaa, S.O., Khan, M.: Impact of inspection errors on the performance measures of a general repeat inspection plan. Int. J. Prod Res 43(23), 4945–4967 (2005)

Khan, M., Jaber, M.Y., Bonney, M.: An economic order quantity (EOQ) for items with imperfect quality and inspection errors. Int. J. Prod. Econ. 133(1), 113–118 (2011)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Patro, R., Nayak, M.M. & Acharya, M. An EOQ model for fuzzy defective rate with allowable proportionate discount. OPSEARCH 56, 191–215 (2019). https://doi.org/10.1007/s12597-018-00352-1

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12597-018-00352-1