Abstract

Frequency-doubled light at 532 nm from the microchip Nd:YVO4 lasers is a promising candidate to replace the widely used He-Ne lasers in length metrology due to their superior characteristics, low-cost and rugged structure. In this paper, the spectral characteristics of a commercial microchip Nd:YVO4 laser are investigated. The laser temperature is initially controlled to facilitate the study of longitudinal mode structure of the laser at different pumping current and temperatures. Additionally, a simple method is suggested to obtain a single-mode operation at a relatively wide temperature range, namely from 20 to 25.8 °C, and pumping currents from 300 to 385 mA. The frequency stability is evaluated after controlling the laser temperature to be 1.9 × 10–8 at 1 s. Additionally, parameters that are important for locking the frequency of the laser to a molecular reference transition are investigated such as laser linewidth and the relation between current/temperature and wavelength.

Similar content being viewed by others

Introduction

Lasers with superior characteristics, such as narrow-linewidth, single longitudinal mode operation, enhanced frequency stability, are important in several applications including length metrology, Doppler wind lidar, coherent optical communication, gravitational wave detection, holography, and interferometry [1, 2, 3, 4, 5, 6, 7]. The development of more compact Nd:YVO4 lasers with frequency-doubled output at 532 nm is also progressing. Due to their attractive spectral characteristics, they are expected to replace the He-Ne lasers, which have been the backbone of length metrology for several decades.

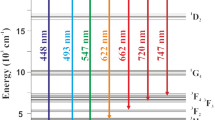

A Nd:YVO4 crystal has several superior characteristics over Nd:YAG crystal since it has a high pump absorption coefficient that pave the way to manufacture efficient lasers with short cavities [8, 9]. Figure 1a shows the structure of a microchip laser which consists mainly of a pump diode laser at 808 nm and two crystals bonded together are; the laser gain crystal (Nd:YVO4), and a frequency-doubling crystal, potassium titanyl phosphate (KTP). Although the crystals are coated in such a way to allow only light at 532 nm (green) to exit the cavity while keeping the fundamental lasing wavelength at 1064 nm (NIR) to resonate in the cavity, some traces of 1064 nm remain with green output light. Therefore, we have exploited this advantage in our test schemes using optical bandpass filters. Figure 1b shows the atomic energy level diagram of the transition at NIR of neodymium. The compact structure and rigidity of microchip Nd: YVO4 lasers enable the employment of such lasers in several instruments [1, 2, 5, 7, 10, 11]. It is worth mentioning here that the green laser pointers are made from Nd: YVO4 laser due its rigid structure [12].

a Microchip Nd:YVO4 green laser module structure, LD: laser diode, AR: Anti Reflection, HR: High Reflection,b Atomic energy levels and the operation of laser [12]

The Spatial Hole-Burning (SHB) in (inactive materials) of the Nd:YVO4 laser leads to multi- longitudinal mode operation [13]. But since single longitudinal mode (SLM) operation is a perquisite for several applications (including optical length metrology), several techniques have been developed to attain such desired behaviour [3, 4, 8, 9, 11, 14, 15, 16, 17, 18, 19, 20, 21]. The most common technique for obtaining the SLM operation is the insertion of a selective element (such as a Bragg grating or a polarization separator) inside the laser cavity [11, 14, 21]. However, insertion of selective elements inside the cavity will affect the compactness of the laser cavity and its rigidity. SLM operation can be also achieved by carefully controlling the laser diode current and temperature under certain conditions [16]. Although this technique seems to be simple, it could be easily affected by the surrounding environmental conditions. In the present work, a simple method is proposed to obtain a SLM operation by using an external polarization element together with controlling the laser current and temperature over a wide operation range. In order to employ this laser in length metrology, some other factors should be thoroughly investigated. For example, the effect of laser temperature and current on laser wavelength and mode structure is investigated. The wavelength stability after applying temperature and current control will also be evaluated. Furthermore, the linewidth of the laser will be measured by beating its frequency with an Optical Frequency Comb (OFC) since the resolution of the available optical spectrum analyzer is not sufficient to resolve the narrow linewidth of this laser. The measurement of these characteristics will help to investigate the suitable methods for stabilizing the Nd:YVO4 laser to an atomic/ molecular transition reference or even to use its wavelength directly for application in length metrology.

Experimental setup

As shown in Fig. 2, the experimental setup consists of a low-cost commercial microchip (Nd:YVO4) green laser which emits (NIR and Green) optical radiation. To maintain the temperature of the laser crystal during the experiment and hence obtain a moderate wavelength stability, the laser is mounted on a heat sink that is fixed on a Peltier element (TEC thermoelectric cooler). A temperature sensor (AD590) is fixed at the heat sink and connected with the Peltier element to a PID temperature controller (TED 200 C). A current controller (LDC 220) is used to adjust the laser current during the experiment at the specific values that we need to perform the required tests. A small cubic beam splitter is used to split the laser beam into two parts, the first part is directed toward a wavemeter (EXFO WA-1500) which is connected to a computer to measure the laser wavelength stability before and after controlling its temperature. A bandpass filter at 1064 nm is used before the wavemeter to block the green beam and to ensure passing only the NIR beam into the wavemeter (since it can only measure down to 600 nm). A Glan Thompson polarizer is used to filter the two orthogonally polarized longitudinal modes and hence obtaining the SLM operation. The second beam is directed toward the optical spectrum analyzer (OSA), model AQ6370C, that works in the wavelength range 600–1700 nm and with a resolution of 0.02 nm to detect the longitudinal oscillating modes (at NIR) of the microchip laser and the mode spacing between the two longitudinal modes. The green beam should follow exactly the NIR beam from the phase matching condition of the second harmonic generation process. The long-term stability of green output from the laser is measured using a power meter (Newport 1835-C) for five hours when the laser is operating at SLM (a green filter is used instead of a NIR filter).

SLM operation, longitudinal-mode analysis (at NIR), thermal control, wavelength measurement (at NIR), and power measurement (at green) of the Microchip Nd:YVO4 laser. PE: Peltier element, HS: Heat sink, P: Polarizer, F1: 1064 nm filter, F2: 532 nm filter, BS: Beam splitter, C: Collimator, OSA: Optical spectrum analyzer, M: Mirror, D: power meter detector

Results and discussion

Wavelength dependence on current and temperature

Laser wavelength dependence on laser injection current and temperature are investigated here since they are very important parameters for laser stabilization to atomic or molecular absorptions. The wavelength measurement is made using the wavemeter at the NIR wavelength since the wavemeter cannot operate at the green wavelength and it is known for sure that the green is double the NIR frequency from the phase matching at the second-harmonic generation crystal [3]. The laser is initially adjusted to run in a single-mode (SLM) operation (see Sect. 3.2), afterwards, the temperature is set to 23 °C while changing the injection current from 300.9 to 375.4 mA. As demonstrated in Fig. 3(a), a linear relation exists between the wavelength and laser injection current with a coefficient of \(\Delta \lambda /\Delta I\)=0.22 pm/mA. Then, the current is kept constant at 309 mA and the temperature is changed from 20 to 25.8 °C. It is clearly seen that wavelength changes linearly with changing the temperature with a coefficient of \(\Delta \lambda /\Delta T\) = 12.9 pm/°C, as shown in Fig. 3b.

In addition, it would be helpful also to know laser power dependence on the laser current and temperature in order to avoid introducing intensity fluctuations into our beam while stabilizing the laser in a later stage. A dependence coefficient of 0.06 mW/mA and of 0.37 mW/°C are measured for current and temperature, respectively. While the power dependence on current is clear but the power dependence on temperature is related to the dependence of the efficiency of the second harmonic conversion on the temperature of the KTP crystal (the KTP crystal is bonded to the laser crystal inside the laser cavity).

Laser longitudinal modes

Single longitudinal mode operation is necessary for using the laser in length metrology. An optical spectrum analyzer (OSA) is used to perform this investigation, see Fig. 2. The NIR wavelength is selected using bandpass filter due to the limited range of the OSA from 600 to 1700 nm. The laser is found to operate at two or three longitudinal modes depending on the laser injection current (of the pump laser) and laser temperature, see Fig. 4. The two-mode operation is obtained by operating the laser at current and temperature values of 381 mA and 23 °C, respectively. The two modes are found to be orthogonally polarized; therefore, a Glan Thompson polarizer is used to obtain a single mode from the laser which oscillates at two modes, see Fig. 5a. The single mode power is measured to be 7.1 mW at green wavelength. The length of the laser cavity is calculated from the measured mode spacing between the two oscillating modes (55.6 GHz) to be around 2.7 mm.

The power of the single longitudinal mode is measured to be 7.1 mW at the green wavelength with long-term stability of ± 0.01 mW during 5 h as shown in Fig. 5b. The laser current was at 381 mA and the temperature at 23 °C and a Glan Thompson polarizer is used. This power and wavelength stability allow to implement the laser in many interferometers.

Wavelength stability measurement

Wavelength stability is crucial for several applications like length metrology measurements where stability less than 10−7 is required to allow length metrology with accuracy of 0.1 µm in a one-meter range. Consequently, different techniques are introduced to stabilize the frequency of solid-state lasers. The most commonly used technique is the stabilization of the laser frequency to the doppler-free molecular transition lines in Iodine. However, such stabilization technique does not allow a rigid structure of the stabilized laser and it needs a careful search for the locking transition. It is worth to investigate here if the thermal stabilization of the Nd:YVO4 laser is sufficient to obtain the required frequency stability needed for interferometric application. To perform this investigation, a single longitudinal mode is obtained from the laser as discussed in Sect. 3.2, then the NIR wavelength of this mode is sent to the wavemeter to check its stability. Laser stability is measured without applying the temperature stabilization for 6 h at room temperature of 21 °C. Allan deviation reaches around 5 × 10−7 at 100 s, see Fig. 6 (open circles). After applying the PID temperature control to thermally stabilize the laser temperature, the wavelength stability is improved to the limit of our wavemeter. Allan deviation of the laser stability is obtained from the measured data to reach around 1 × 10−8 at 1000 s (closed diamonds), which mostly reflects the stability of the wavemeter and not our laser which is expected to be more stable than 1 × 10−8. Therefore, we believe that it can be used in length metrology even without stabilization to a doppler-free atomic or molecular absorption. Even with stabilization to absorption reference, it can be actively controlled with current and temperature to achieve stability sufficient for length metrology.

Linewidth measurement

Laser linewidth is of great importance for length metrology since it determines the coherence length of the laser to which the laser interferometer could be used. Several methods could be used for linewidth measurement such as self-heterodyne, phase discrimination at a Fabry–Perot interferometer and beating with another laser that has the same wavelength and a narrower linewidth [22]. Among these methods, beating with another laser method is the most accurate means of linewidth measurement since it is a direct method for linewidth measurement. However, to find a laser at exactly the same wavelength so that the difference is small enough to be detected as a beat note at a high-speed photodetector is very difficult. The candidate laser also should be with a narrower linewidth and a better frequency stability to avoid the fast drift of the beat note while measuring the wavelength. Another superior alternative candidate to fulfill this task that is already available in our lab is to beat the laser frequency of the laser to one mode of a femtosecond laser optical frequency comb. The advantage of this technique is that to beat the laser with any mode from the frequency comb within 250 MHz frequency range is easy even if the laser is drifting. This method was not suitable for the measurement of the stability of the laser since the stability of the laser was not sufficient to keep the beat within the bandwidth of the amplifier that is needed for the frequency counter. The Optical frequency comb used here is a Menlo System, FC1500-2500-WG fiber-based comb with a repetition rate of 250 MHz and a linewidth of around 70 kHz. The green wavelength of the laser was made to beat with the green output from the frequency comb which is obtained from the frequency-doubled output from the comb after passing through the self-phase modulation photonic crystal, see Fig. 7.

Figure 8 depicts the spectrum of the beat note with the comb at the green wavelength. After we have applied a Gaussian fit, we deduced a linewidth of 2 MHz ± 0.3 MHz which corresponds to coherence length of around 150 m [23].

Spatial beam profile

Spatial beam profile is also an important parameter when the laser will be deployed in an interferometer. The beam profile of the output laser green output beam is measured as shown in Fig. 9. by using beam profile (Thorlabs, BP209-VIS). It is found that the beam operates at a TEM00 transverse mode. A cross-section of the output beam in X and Y directions shows that the power distribution inside the measured beam is characterized by a Gaussian shape.

Conclusion

In this work, a commercial microchip Nd:YVO4 laser that is available at very cheap prices in the market is characterized to be used in length metrology. The wavelength dependence on pump laser current and the temperature of the cavity is found to be (\(\Delta \lambda /\Delta I\)= 0.22 pm/mA and \(\Delta \lambda /\Delta T\) =12.9 pm/°C), respectively. By adjusting the current and temperature over relatively wide ranges of 300 mA to 385 mA and 20 °C to 25.8 °C) and by using an external polarizer the laser can operate in a single longitudinal mode with output power of around 7 mW. In addition, the wavelength stability of the laser is measured using a high-resolution wavemeter before and after applying thermal stabilization to the laser cavity. The stability is found to be lower than that of the wavemeter after applying the thermal control, namely less than 10−7, which is sufficient for most length metrological applications to reach length accuracy of 0.1 µm for a measured length of one meter without stabilization to any Doppler-free atomic or molecular transitions. The linewidth of the laser is also measured by beating its frequency with an optical frequency comb line to be around 2 MHz ± 0.3 MHz which corresponds to a coherence length around of 150 m. In addition, the spatial beam profile is measured for the green laser and is found to be Gaussian TM00. Therefore, we believe that the microchip Nd:YVO4 laser could be used for length metrology after selecting the single mode from the laser.

Data availability

Data will be made available on request.

References

C. Tian-Xiang, Y. Hai-Jun, L. Cheng, High-precision absolute coordinate measurement using frequency scanned interferometry. J. Instrum. 9(03), P03001 (2014)

M. Frede, B. Schulz, R. Wilhelm, P. Kwee, F. Seifert, B. Willke, D. Kracht, Fundamental mode, single-frequency laser amplifier for gravitational wave detectors. Opt. Express 15, 459 (2007)

A.J. Antoñczak, J.Z. Sotor, K.M. Abramski, Single-frequency microchip solid state diode pumped lasers. Bull. Polish Acad. Sci. Tech. Sci. 56, 113–116 (2008)

G. Dudzik, J. Sotor, K. Krzempek, G. Sobon, K.M. Abramski, Single-frequency, fully integrated, miniature DPSS laser based on monolithic resonator. Solid State Lasers XXIII Technol. Dev. 8959, 89591F (2014)

J.Z. Sotor, A.J. Antończak, K.M. Abramski, Single frequency monolithic solid state green laser as a potential source for vibrometry systems. AIP Conf. Proc. 1253, 313–316 (2010)

S.P. Perfetto, M. Roederer, Increased immunofluorescence sensitivity using 532 nm laser excitation. Cytom. Part A 71, 73–79 (2007)

H.J. Yang, J. Deibel, S. Nyberg, K. Riles, High-precision absolute distance and vibration measurement with frequency scanned interferometry. Appl. Opt. 44, 3937–3944 (2005)

T. Sasaki, T. Kojima, A. Yokotani, O. Oguri, S. Nakai, Single-longitudinal-mode operation and second-harmonic generation of Nd:YVO4 microchip lasers. Opt. Lett. 16, 1665 (1991)

Y. Ma, L. Wu, H. Wu, W. Chen, Y. Wang, S. Gu, Single-longitudinal mode Nd:YVO4 microchip laser with orthogonal-polarization bidirectional traveling-waves mode. Opt. Express 16, 18702 (2008)

H. Talvitie, M. Merimaa, E. Ikonen, Frequency stabilization of a diode laser to Doppler-free spectrum of molecular iodine at 633 nm. Opt. Commun. 152, 182–188 (1998)

X. Zhang, Z. Wang, S. Liu, S. Gou, R. Fan, D. Jin, Z. Bai, Development of Single-Longitudinal-Mode Selection Technology for Solid-State Lasers. Int. J. Opt. 2021, 1–13 (2021). https://doi.org/10.1155/2021/6667015

J. Galang, A. Restelli, E. W. Hagley, J. Hadler, C.W. Clark, A green laser pointer hazard. in ILSC 2011 -International Laser Safety Conference 296–300 (2011)

J.J. Zayhowski, Limits imposed by spatial hole burning on the single-mode operation of standing wave laser cavities. in XVII International conference quantum electron. Dig. 148 (1990)

Y. Hui, Q. Li, X. Zhang, M. Jiang, Single frequency mode laser controlled by volume Bragg gratings. Zhongguo Jiguang/Chin. J. Lasers 36, 2805–2807 (2009)

G.J. Friel, A.J. Kemp, T.K. Lake, B.D. Sinclair, Compact and efficient Nd:YVO4 laser that generates a tunable single-frequency green output. Appl. Opt. 39, 4333 (2000)

J. Watanabe, T. Harimoto, Oscillating longitudinal-mode control of a microchip green laser by injection current. Opt. Express 15, 965 (2007)

J. Sotor, G. Dudzik, G. Sobon, K. Krzempek, K.M. Abramski, 0.5W single-longitudinal mode, monolithic Nd:YVO4 microchip laser. In: Conference lasers electro-optics, CLEO 2013 (2013)

J.Z. Sotor, A.J. Antończak, K.M. Abramski, Single-longitudinal mode Nd:YVO4/YVO4/KTP green solid state laser. Opto-Electron. Rev. 18, 75–79 (2010)

J.Z. Sotor, G. Dudzik, A.J. Antonczak, K.M. Abramski, Single-longitudinal mode, monolithic, green solid-state laser. Appl. Phys. B Lasers Opt. 103, 67–74 (2011)

J. Sotor, G. Dudzik, K. Abramski, A compact single-longitudinal mode microchip laser operating at 532 nm. Photonics Lett. Pol. 6, 2–4 (2014)

E. Wu, H. Pan, S. Zhang, H. Zeng, High power single-longitudinal-mode operation in a twisted-mode-cavity laser with a c-cut Nd:GdVO4 crystal. Appl. Phys. B Lasers Opt. 80, 459–462 (2005)

Z. Bai, Z. Zhao, Y. Qi, J. Ding, S. Li, X. Yan, Y. Wang, Z. Lu, Narrow-linewidth laser linewidth measurement technology. Front. Phys. 9, (2021). https://doi.org/10.3389/fphy.2021.768165

R.S. Quimby, Photonics and lasers: an introduction (Wiley, Newyork, 2006)

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB). No funding was received for conducting this study.

Author information

Authors and Affiliations

Contributions

All the authors have accepted full responsibility for the content of this manuscript and have given their approval for its submission.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Elsafty, A.S., Terra, O., Sobee, M. et al. Spectral characteristics of a microchip Nd:YVO4 laser. J Opt 52, 1717–1723 (2023). https://doi.org/10.1007/s12596-022-00968-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12596-022-00968-z