Abstract

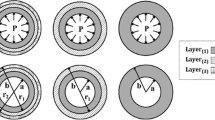

Achieving sharp corners without defects such as thinning and fractures is a primary objective in the manufacturing of double-stepped tubes. Therefore, selecting the optimal tube hydroforming (THF) process is crucial for improving the formability when manufacturing complex components. In this study, experimental and numerical study was conducted to analyze the radius of the corner and the thickness of the sample in the hydroforming process for double-stepped tubes. The pressure, axial feed, and friction coefficient were considered as input parameters, while the thinning ratio and corner filling were considered as output responses. The optimal hydroforming parameter combination for the corner filling ratio and the minimum thinning ratio was determined based on artificial neural networks. The values of the process parameters obtained from the finite element (FE) simulation and the artificial neural network (ANN) have a good correlation. The proposed method combining FE model and ANN is a precious tool for designing the THF process. Based on the results, it was confirmed that the feed rate has significant influence on the thinning ratio and corner filling.

Similar content being viewed by others

References

Zhang, S. H. (1999). Developments in hydroforming. Journal of Materials Processing Technology, 91(1), 236–244. https://doi.org/10.1016/S0924-0136(98)00423-3

Ghorbani-Menghari, H., Kim, J. H., Mohammadhosseinzadeh, M., Gorji, A., & Ghasempour-Mouziraji, M. (2020). Manufacturing of bent tubes with non-uniform curvature and cross-section using a novel hydroforming die: Experimental, finite element analysis and optimization. International Journal of Advanced Manufacturing Technology, 107, 1683–1695. https://doi.org/10.1007/s00170-020-05133-z

Wang, X. S., Yuan, S., Song, P., & Xie, W. (2012). Plastic deformation on hydroforming of aluminum alloy tube with rectangular sections. Transactions of the Nonferrous Metals Society of China, 22, s350–s356. https://doi.org/10.1016/S1003-6326%2812%2961730-0

Aue-U-Lan, Y., Ngaile, G., & Altan, T. (2004). Optimizing tube hydroforming using process simulation and experimental verification. Journal of Materials Processing Technology, 146, 137–143. https://doi.org/10.1016/S0924-0136(03)00854-9

Mirzaali, M., Liaghat, G. H., Moslemi Naeini, H., Seyedkashi, S. M. H., & Shojaee, K. (2011). Optimization of tube hydroforming process using simulated annealing algorithm. Procedia Engineering, 10, 3012–3019. https://doi.org/10.1016/j.proeng.2011.04.499

Li, B., Nye, T. J., & Metzger, R. D. (2005). Multi-objective optimization of forming parameters for tube hydroforming process based on the Taguchi method. International Journal of Advanced Manufacturing Technology, 28, 23–30. https://doi.org/10.1007/s00170-004-2338-6

Abbassi, F., Belhadj, T., Mistou, S., & Zghal, A. (2013). Parameter identification of a mechanical ductile damage using artificial neural networks in sheet metal forming. Materials and Design, 45, 605–615. https://doi.org/10.1016/j.matdes.2012.09.032

Zhou, C.-C., Yin, G.-F., & Hu, X.-B. (2009). Multi-objective optimization of material selection for sustainable products: Artificial neural networks and genetic algorithm approach. Materials and Design, 30(4), 1209–1215. https://doi.org/10.1016/j.matdes.2008.06.006

Elyasi, M., Bakhshi-Jooybari, M., Gorji, A., Hosseinipour, S. J., & Nourouzi, S. (2009). New die design for improvement of die corner filling in hydroforming of cylindrical stepped tubes. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 223(7), 821–827. https://doi.org/10.1243/09544054JEM1344

Ghorbani Menghari, H., Ziaeipoor, H., Farzin, M., & Alves De Sousa, R. J. (2014). An approach to improve thickness distribution and corner filling of copper tubes during hydro-forming processes. Structural Engineering and Mechanics, 50(4), 563–573. https://doi.org/10.12989/sem.2014.50.4.563

Ziaeipoor, H., Ghorbani Menghari, H., Alves De Sousa, R. J., Moosavi, H., Parastarfeizabadi, M., Farzin, M., & Sanaei, H. (2014). A novel approach in manufacturing two-stepped tubes using a multi-stage die in tube hydroforming process. International journal of precision engineering and manufacturing, 15(11), 2343–2350. https://doi.org/10.1007/s12541-014-0599-z

Katayama, T., Nakamachi, E., Nakamura, Y., Ohata, T., Morishita, Y., & Murase, H. (2004). Development of process design system for press forming—multi-objective optimization of intermediate die shape in transfer forming. Journal of Materials Processing Technology, 155–156, 1564–1570. https://doi.org/10.1016/j.jmatprotec.2004.04.253

Sobol, I. M. (1967). On the distribution of points in a cube and the approximate evaluation of integrals. USSR Computational Mathematics and Mathematical Physics, 7(4), 86–112. https://doi.org/10.1016/0041-5553(67)90144-9

Ponce P. Inteligencia artificial con aplicaciones a la ingeniería. Alfaomega Grupo Editor, S.A. de C.V., México., ISBN: 978-607-7854-83-8.

Marquardt, D. W. (1963). An Algorithm for least-squares estimation of nonlinear parameters. Journal of the Society for Industrial and Applied Mathematics, 11(2), 431. https://doi.org/10.1137/0111030

Hiroyasu, T., Miki, M., Kamiura, J., Watanabe, S., & Hiroyasu, H. (2002). Multi-objective optimization of diesel engine emissions and fuel economy using genetic algorithms and phenomenological model. SAE Technical Paper. https://doi.org/10.4271/2002-01-2778

Deb, K., Pratap, A., Agarwal, S., & Meyarivan, T. (2002). A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Transactions on Evolutionary Computation, 6(2), 182–197. https://doi.org/10.1109/4235.996017

Konak, A., Coit, D. W., & Smith, A. E. (2006). Multi-objective optimization using genetic algorithms: A tutorial. Reliability Engineering and System Safety, 91(9), 992–1007. https://doi.org/10.1016/j.ress.2005.11.018

Deb, K., Pratap, A., Agarwal, S., Meyarivan, T. (2000). A Fast Elitist Non-dominated Sorting Genetic Algorithm for Multi-objective Optimization: NSGA-II. Parallel Problem Solving from Nature PPSN VI 2000. Springer. https://doi.org/10.1007/3-540-45356-3_83

Goldberg, D. E. (1989). Genetic algorithms in search, optimization and machine learning. Addison-Wesley Longman. Reading.

Harish Ram, D. S., Bhuvaneswari, M. C., Prabhu, S. S. (2012). A Novel Framework for Applying Multiobjective GA and PSO Based Approaches for Simultaneous Area, Delay, and Power Optimization in High Level Synthesis of Datapaths. VLSI Des. https://doi.org/10.1155/2012/273276

Garson, G. D. (1991). Interpreting neural network connection weights. AI Expert, 6(4), 46–51.

Acknowledgements

This work was supported by the Korean government (MSIT) through the National Research Foundation of Korea (NRF) [grant number 2019R1A5A6099595].

Author information

Authors and Affiliations

Contributions

All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ghorbani-Menghari, H., Kahhal, P., Jung, J. et al. Multi-Objective Evolutionary Neural Network Optimization of Process Parameters for Double-Stepped Tube Hydroforming. Int. J. Precis. Eng. Manuf. 24, 915–929 (2023). https://doi.org/10.1007/s12541-023-00802-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-023-00802-x