Abstract

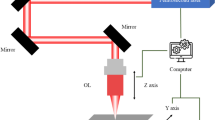

Recently, ultrafast laser machining has been used to machine hard materials. Ultrafast laser machining can be precisely machined without a non-thermal effect or damage to machining tools. However, their morphologies differed depending on the pulse energy. Generally, to machine difficult-to-machine materials, hard materials are irradiated by laser pulses with high pulse energy. Laser pulses with high pulse energy remove large volumes. However, burrs are formed at the top surface, and the large volumes removed remain empty. These burrs and empty spaces reduce the efficiency of the process. Owing to these problems, the formation of burrs must be restricted during laser ablation. Accordingly, this work aimed to reduce the formation of burrs and improve the machining efficiency. In this study, to overcome the aforementioned undesirable effects, the position of a focused laser beam with a high pulse energy was altered when irradiating cemented tungsten carbides; the laser had a pulse duration of 190 fs, wavelength of 1026 nm, frequency of 6 kHz, and pulse energy of 100 µJ. When focused laser beam was irradiated at the ablated bottom surface, the laser machining efficiency increased. Moreover, the position of the focused laser beam affected the morphology of burrs. On focusing the laser beam at the surface, burrs with shorter heights and larger lengths were formed. The morphologies of these burrs and the ablated space affected the laser passing rate and machining efficiency.

Similar content being viewed by others

References

Yang, L., Wei, J., Ma, Z., Song, P., Ma, J., Zhao, Y., Huang, Z., Zhang, M., Yang, F., & Wang, X. (2019). The fabrication of micro/nano structures by laser machining. Nanomaterials, 9, 1789. https://doi.org/10.3390/nano9121789

Nakajima, A., & Yan, J. (2022). Response of resin coating films containing fine metal particles to ultrashort laser pulses. International Journal of Precision Engineering and Manufacturing, 23, 385–393. https://doi.org/10.1007/s12541-022-00629-y

Dumitru, G., Romano, V., Weber, H. P., Sentis, M., & Marine, W. (2002). Femtosecond ablation of ultrahard materials. Applied Physics A: Materials Science & Processing, 74, 729–739. https://doi.org/10.1007/s003390101183

Gu, B. (2004). Ultrafast laser applications in semiconductor industry. Proceedings of SPIE Photon Processing in Microelectronics and Photonics, III(5339), 226. https://doi.org/10.1117/12.529794

Jia, K., Fischer, T. E., & Gallois, B. (1998). Microstructure, hardness and toughness of nanostructured and conventional WC-Co composites. Nanostructured Materials, 10, 875–891. https://doi.org/10.1016/S0965-9773(98)00123-8

Prakash, L. J. (1995). Application of fine grained tungsten carbide based cemented carbides. International Journal of Refractory Metals and Hard Materials, 13, 257–264. https://doi.org/10.1016/0263-4368(95)92672-7

Eberle, G., & Wegener, K. (2014). Ablation study of WC and PCD composites using 10 picosecond and 1 nanosecond pulse durations at green and infrared wavelengths. Physics Procedia, 56, 951–962. https://doi.org/10.1016/j.phpro.2014.08.115

Guimarães, B., Figueiredo, D., Fernandes, C. M., Silva, F. S., Miranda, G., & Carvalho, O. (2019). Laser machining of WC-Co green compacts for cutting tools manufacturing. International Journal of Refractory Metals and Hard Materials, 81, 316–324. https://doi.org/10.1016/j.ijrmhm.2019.03.018

Wang, X., & Zheng, H. (2018). Picosecond laser micro-drilling, engraving and surface texturing of tungsten carbide. Journal of Laser Applications, 30, 032203. https://doi.org/10.2351/1.5040602

Wu, H., Zou, P., Cao, J., & Ehmann, K. F. (2020). Vibrating-lens-assisted laser drilling. Journal of Manufacturing Processes, 55, 389–398. https://doi.org/10.1016/j.jmapro.2020.03.005

Chen, J., An, Q., Ming, W., & Chen, M. (2021). Investigations on continuous-wave laser and pulsed laser induced controllable ablation of SiCf/SiC composites. Journal of the European Ceramic Society, 41, 5835–5849. https://doi.org/10.1016/j.jeurceramsoc.2021.04.061

Link, S., Burda, C., Mohamed, M. B., Nikoobakht, B., & El-Sayed, M. A. (1999). Laser photothermal melting and fragmentation of gold nanorods: Energy and laser pulse-width dependence. Journal of Physical Chemistry A, 103, 1165–1170. https://doi.org/10.1021/jp983141k

Bityurin, N., & Malyshev, A. (2002). Bulk photothermal model for laser ablation of polymers by nanosecond and subpicosecond pulses. Journal of Applied Physics, 92, 605–613. https://doi.org/10.1063/1.1486040

Pinkerton, A. J., & Li, L. (2004). Modelling the geometry of a moving laser melt pool and deposition track via energy and mass balances. Journal of Physics D Applied Physics, 37, 1885–1895. https://doi.org/10.1088/0022-3727/37/14/003

Malinauskas, M., Žukauskas, A., Hasegawa, S., Hayasaki, Y., Mizeikis, V., Buividas, R., & Juodkazis, S. (2016). Ultrafast laser processing of materials: From science to industry. Light: Science and Applications, 5, e16133. https://doi.org/10.1038/lsa.2016.133

Sugioka, K., & Cheng, Y. (2014). Ultrafast lasers—reliable tools for advanced materials processing. Light: Science and Applications, 3, e149. https://doi.org/10.1038/lsa.2014.30

Dausinger, F. (2001). Laser drilling with short pulses. XIII International Symposium on Gas Flow and Chemical Lasers and High-power Laser Conference, 4184, 519. https://doi.org/10.1117/12.413990

Kononenko, T. V., Garnov, S. V., Klimentov, S. M., Konov, V. I., Loubnin, E. N., Dausinger, F., Raiber, A., & Taut, C. (1997). Laser ablation of metals and ceramics in picosecond-nanosecond pulsewidth in the presence of different ambient atmospheres. Applied Surface Science, 109–110, 48–51. https://doi.org/10.1016/S0169-4332(96)00905-1

Bian, Q., Yu, X., Zhao, B., Chang, Z., & Lei, S. (2013). Femtosecond laser ablation of indium tin-oxide narrow grooves for thin film solar cells. Optics & Laser Technology, 45, 395–401. https://doi.org/10.1016/j.optlastec.2012.06.018

Zhao, W., Liu, H., Shen, X., Wang, L., & Mei, X. (2020). Percussion drilling hole in Cu, Al Ti and Ni alloys using ultra-short pulsed laser ablation. Materials (Basel). https://doi.org/10.3390/ma13010031

Wang, H., Lin, H., Wang, C., Zheng, L., & Hu, X. (2017). Laser drilling of structural ceramics—a review. Journal of the European Ceramic Society, 37, 1157–1173. https://doi.org/10.1016/j.jeurceramsoc.2016.10.031

Perry, M. D., Stuart, B. C., Banks, P. S., Feit, M. D., Yanovsky, V., & Rubenchik, A. M. (1999). Ultrashort-pulse laser machining of dielectric materials. Journal of Applied Physics, 85, 6803–6810. https://doi.org/10.1063/1.370197

Liu, J. M. (1982). Simple technique for measurements of pulsed Gaussian-beam spot sizes. Optics Letters, 7, 196. https://doi.org/10.1364/ol.7.000196

Tani, G., Orazi, L., Fortunato, A., & Cuccolini, G. (2008). Laser ablation of metals: A 3D process simulation for industrial applications. Journal of Manufacturing Science and Engineering, Transactions of the ASME, 130, 0311111–03111111. https://doi.org/10.1115/1.2917326

Di Niso, F., Gaudiuso, C., Sibillano, T., Mezzapesa, F. P., Ancona, A., & Lugarà, P. M. (2014). Role of heat accumulation on the incubation effect in multi-shot laser ablation of stainless steel at high repetition rates. Optics Express, 22, 12200. https://doi.org/10.1364/oe.22.012200

Colombier, J. P., Combis, P., Stoian, R., & Audouard, E. (2007). High shock release in ultrafast laser irradiated metals: Scenario for material ejection. Physical Review B: Condensed Matter and Materials Physics, 75, 1–11. https://doi.org/10.1103/PhysRevB.75.104105

Kautek, W., Rudolph, P., Daminelli, G., & Krüger, J. (2005). Physico-chemical aspects of femtosecond-pulse-laser-induced surface nanostructures. Applied Physics A: Materials Science & Processing, 81, 65–70. https://doi.org/10.1007/s00339-005-3211-7

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shin, YG., Choi, J. & Cho, SH. Morphologies of Cemented Tungsten Carbides Irradiated by Femtosecond Laser with High Pulse Energy for Machining Enhanced Cutting Tools. Int. J. Precis. Eng. Manuf. 24, 547–553 (2023). https://doi.org/10.1007/s12541-022-00746-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-022-00746-8