Abstract

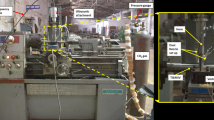

Flow field is one of the crucial factors that influence the surface quality in electrochemical machining (ECM). In this study, to eliminate the flow marks on aero engine blades, the distribution of flow field is optimized by adjusting the turning profile on the cathode at the electrolyte inlet. To observe the flow situation, a simulation model is proposed with varying turning radii by using the finite element method. Then, the turning radius is optimized dynamically. When the radius is 0 mm, cavitation occurs at the inlet near the cathode side and the electrolyte velocity is very small at the turning location, which might produce the flow mark. However, when the radius increases to 0.5 mm, the uniformity of the distribution of flow field in the machining gap is clearly improved. Furthermore, verification experiments are performed at radii of 0 and 0.5 mm for the ECM of blades. Major flow marks are observed on the machining profile at the radius of 0 mm, whereas the profile is smooth at the radius of 0.5 mm. The experimental results are consistent with the simulation results, which implies that the proposed optimization method is effective in improving the flow field.

Similar content being viewed by others

Abbreviations

- ECM:

-

Electrochemical Machining

References

Klocke, F., Zeis, M., and Klink, A., “Interdisciplinary Modelling of the Electrochemical Machining Process for Engine Blades,” CIRP Annals-Manufacturing Technology, Vol. 64, No. 1, pp. 217–220, 2015.

Xu, Z. Y., Sun, L. Y., Hu, Y., and Zhang, J. C., “Flow Field Design and Experimental Investigation of Electrochemical Machining on Blisk Cascade Passage,” The International Journal of Advanced Manufacturing Technology, Vol. 71, Nos. 1-4, pp. 459–469, 2014.

Qu, N. S., Hu, Y., Zhu, D., and Xu, Z. Y., “Electrochemical Machining of Blisk Channels with Progressive-Pressure Electrolyte Flow,” Materials and Manufacturing Processes, Vol. 29, No. 5, pp. 572–578, 2014.

Zuh, D., Zhang, J. C., Zhang, K. L., Liu, J., Chen, Z., and Qu, N. S., “Electrochemical Machining on Blisk Cascade Passage with Dynamic Additional Electrolyte Flow,” The International Journal of Advanced Manufacturing Technology, Vol. 80, Nos. 1-4, pp. 637–645, 2015.

Zhu, D., Wang, W., Fang, X. L., Qu, N. S., and Xu, Z. Y., “Electrochemical Drilling of Multiple Holes with Electrolyte-Extraction,” CIRP Annals-Manufacturing Technology, Vol. 59, No. 1, pp. 239–242, 2010.

Fang, X. L., Qu, N. S., Zhang, Y. D., Xu, Z. Y., and Zhu, D., “Effects of Pulsating Electrolyte Flow in Electrochemical Machining,” Journal of Materials Processing Technology, Vol. 214, No. 1, pp. 36–43, 2014.

Zaytsev, A. N., Zhitnikov, V. P., and Kosarev, T. V., “Formation Mechanism and Elimination of the Workpiece Surface Macro-Defects, Aligned Along the Electrolyte Stream at Electrochemical Machining,” Journal of Materials Processing Technology, Vol. 149, No. 1, pp. 439–444, 2004.

Singh, A., Anandita, S., and Gangopadhyay, S., “Microstructural Analysis and Multiresponse Optimization During ECM of Inconel 825 Using Hybrid Approach,” Materials and Manufacturing Processes, Vol. 30, No. 7, pp. 842–851, 2015.

Kai, S., Sai, H., Kunieda, M., and Izumi, H., “Study on Electrolyte Jet Cutting,” Procedia CIRP, Vol. 1, pp. 627–632, 2012.

Yang, C. T., Song, S. L., Yan, B. H., and Huang, F. Y., “Improving Machining Performance of Wire Electrochemical Discharge Machining by Adding SiC Abrasive to Electrolyte,” International Journal of Machine Tools and Manufacture, Vol. 46, No. 15, pp. 2044–2050, 2006.

Kuo, K. Y., Wu, K. L., Yang, C. K., and Yan, B. H., “Wire Electrochemical Discharge Machining (WECDM) of Quartz Glass with Titrated Electrolyte Flow,” International Journal of Machine Tools and Manufacture, Vol. 72, pp. 50–57, 2013.

Cheng, C. P., Wu, K. L., Mai, C. C., Hsu, Y. S., and Yan, B. H., “Magnetic Field-Assisted Electrochemical Discharge Machining,” Journal of Micromechanics and Microengineering, Vol. 20, No. 7, Paper No. 075019, 2010.

Skoczypiec, S., “Research on Ultrasonically Assisted Electrochemical Machining Process,” The International Journal of Advanced Manufacturing Technology, Vol. 52, Nos. 5-8, pp. 565–574, 2011.

Rebschläger, A., Kollmannsperger, R., and Bähre, D., “Video based Process Observations of the Pulse Electrochemical Machining Process at High Current Densities and Small Gaps,” Procedia CIRP, Vol. 14, pp. 418–423, 2014.

Ruszaj, A., Zybura, M., Zurek, R., and Skrabalak, G., “Some Aspects of the Electrochemical Machining Process Supported by Electrode Ultrasonic Vibrations Optimization,” Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, Vol. 217, No. 10, pp. 1365–1371, 2003.

Hackert-Oschätzchen, M., Paul, R., Martin, A., Meichsner, G., Lehnert, N., and Schubert, A., “Study on the Dynamic Generation of the Jet Shape in Jet Electrochemical Machining,” Journal of Materials Processing Technology, Vol. 223, pp. 240–251, 2015.

Dabrowski, L. and Paczkowski, T., “Computer Simulation of Two-Dimensional Electrolyte Flow in Electrochemical Machining,” Russian Journal of Electrochemistry, Vol. 41, No. 1, pp. 91–98, 2005.

Klocke, F., Zeis, M., Harst, S., Klink, A., Veselovac, D., and Baumgärtner, M., “Modeling and Simulation of the Electrochemical Machining (ECM) Material Removal Process for the Manufacture of Aero Engine Components,” Procedia CIRP, Vol. 8, No. pp. 265–270, 2013.

Zhu, D., Zhu, Di, Xu, Z. Y., Xu, Q., and Liu, J., “Investigation on the Flow Field of W-Shape Electrolyte Flow Mode in Electrochemical Machining,” Journal of Applied Electrochemistry, Vol. 40, No. 3, pp. 525–532, 2010.

Schnerr, G. H. and Sauer, J., “Physical and Numerical Modeling of Unsteady Cavitation Dynamics,” Proc. of 4th International Conference on Multiphase Flow, New Orleans, USA, 2001.

Shih, T. H., Liou, W., Shabbir, A., Yang, Z., and Zhu, J., “A New KEpsilon Eddy Viscosity Model for High Reynolds Number Turbulent Flows: Model Development and Validation,” Computer and Fluids, Vol. 24, No. 3, pp. 227–238, 1995.

Qian, Z. D., Hu, X. Q., Huai, W. X., and Amador, A., “Numerical Simulation and Analysis of Water Flow Over Stepped Spillways,” Science in China Series E: Technological Sciences, Vol. 52, No. 7, pp. 1958–1965, 2009.

Sharif, M. A. R. and Mothe, K. K., “Evaluation of Turbulence Models in the Prediction of Heat Transfer due to Slot Jet Impingement on Plane and Concave Surfaces,” Numerical Heat Transfer, Part B: Fundamentals, Vol. 55, No. 4, pp. 273–294, 2009.

Wolfshtein, M., “The Velocity and Temperature Distribution in One-Dimensional Flow with Turbulence Augmentation and Pressure Gradient,” International Journal of Heat and Mass Transfer, Vol. 12, No. 3, pp. 301–318, 1969.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhu, D., Zhang, R. & Liu, C. Flow field improvement by optimizing turning profile at electrolyte inlet in electrochemical machining. Int. J. Precis. Eng. Manuf. 18, 15–22 (2017). https://doi.org/10.1007/s12541-017-0002-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-017-0002-y