Abstract

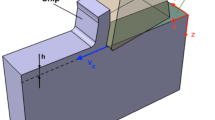

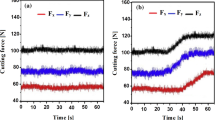

Titanium alloys are widely applied to the aerospace and bio component industries due to their good properties such as high specific strength, low density, chemical stability, etc. However, they are representative difficult-to-machine materials which cause the deterioration the cut quality and tool lifetime due to the local temperature increase, generation of serrated chips and large amplitude modulation in cutting force during their cutting. Accordingly, the cutting simulation of titanium alloys is necessary to improve machining characteristics. This study analyzed limits of Johnson-Cook material model which is widely applied to the finite elements method for the cutting simulation of titanium alloys, and carried out simulation where the supplemented Johnson-Cook material model is applied. Validation is also carried out by analyzing cutting force and chip shape which were obtained from experiments for the purpose of validation on such simulation results.

Similar content being viewed by others

References

Ezugwu, E. O. and Wang, Z. M., “Titanium Alloys and their Machinability -A Review,” Journal of Materials Processing Technology, Vol. 68, No. 3, pp. 262–274, 1997.

Hou, Z. B. and Komanduri, R., “On a Thermomechanical Model of Shear Instability in Machining,” CIRP Annals-Manufacturing Technology, Vol. 44, No. 1, pp. 69–73, 1995.

Komanduri, R. and Von Turkovich, B. F., “New Observations on the Mechanism of Chip Formation when Machining Titanium Alloys,” Wear, Vol. 69, No. 2, pp. 179–188, 1981.

Nemat-Nasser, S., Guo, W.-G., Nesterenko, V. F., Indrakanti, S., and Gu, Y.-B., “Dynamic Response of Conventional and Hot Isostatically Pressed Ti-6Al-4V Alloys: Experiments and Modeling,” Mechanics of Materials, Vol. 33, No. 8, pp. 425–439, 2001.

Vyas, A. and Shaw, M., “Mechanics of Saw-Tooth Chip Formation in Metal Cutting,” Journal of Manufacturing Science and Engineering, Vol. 121, No. 2, pp. 163–172, 1999.

Hua, J. and Shivpuri, R., “Prediction of Chip Morphology and Segmentation during the Machining of Titanium Alloys,” Journal of Materials Processing Technology, Vol. 150, No. 1, pp. 124–133, 2004.

Bäker, M., Rösler, J., and Siemers, C., “A Finite Element Model of High Speed Metal Cutting with Adiabatic Shearing,” Computers & Structures, Vol. 80, No. 5, pp. 495–513, 2002.

Yen, Y.-C., Jain, A., and Altan, T., “A Finite Element Analysis of Orthogonal Machining using Different Tool Edge Geometries,” Journal of Materials Processing Technology, Vol. 146, No. 1, pp. 72–81, 2004.

Umbrello, D., “Finite Element Simulation of Conventional and High Speed Machining of Ti-6Al-4V Alloy,” Journal of Materials Processing Technology, Vol. 196, No. 1, pp. 79–87, 2008.

Zhang, Y. C., Mabrouki, T., Nelias, D., and Gong, Y. D., “Chip Formation in Orthogonal Cutting Considering Interface Limiting Shear Stress and Damage Evolution based on Fracture Energy Approach,” Finite Elements in Analysis and Design, Vol. 47, No. 7, pp. 850–863, 2011.

Barge, M., Hamdi, H., Rech, J., and Bergheau, J.-M., “Numerical Modelling of Orthogonal Cutting: Influence of Numerical Parameters,” Journal of Materials Processing Technology, Vols. 164-165, pp. 1148–1153, 2005.

Pantalé, O., Bacaria, J.-L., Dalverny, O., Rakotomalala, R., and Caperaa, S., “2D and 3D Numerical Models of Metal Cutting with Damage Effects,” Computer Methods in Applied Mechanics and Engineering, Vol. 193, No. 39, pp. 4383–4399, 2004.

Guo, Y. B. and Yen, D. W., “A FEM Study on Mechanisms of Discontinuous Chip Formation in Hard Machining,” Journal of Materials Processing Technology, Vols. 155-156, pp. 1350–1356, 2004.

Calamaz, M., Coupard, D., and Girot, F., “A New Material Model for 2D Numerical Simulation of Serrated Chip Formation when Machining Titanium Alloy Ti-6Al-4V,” International Journal of Machine Tools and Manufacture, Vol. 48, No. 3, pp. 275–288, 2008.

Kassner, M. E., Wang, M. Z., Perez-Prado, M.-T., and Alhajeri, S., “Large-Strain Softening of Aluminum in Shear at Elevated Temperature,” Metallurgical and Materials Transactions A, Vol. 33, No. 10, pp. 3145–3153, 2002.

Xu, Y., Zhang, J., Bai, Y., and Meyers, M. A., “Shear Localization in Dynamic Deformation: Microstructural Evolution,” Metallurgical and Materials Transactions A, Vol. 39, No. 4, pp. 811–843, 2008.

Miller, R. M., Bieler, T. R., and Semiatin, S. L., “Flow Softening during Hot Working of Ti-6Al-4V with a Lamellar Colony Microstructure,” Scripta Materialia, Vol. 40, No. 12, pp. 1387–1393, 1999.

Ding, R. and Guo, Z. X., “Microstructural Evolution of a Ti-6Al-4V Alloy during ß-Phase Processing: Experimental and Simulative Investigations,” Materials Science and Engineering: A, Vol. 365, No. 1, pp. 172–179, 2004.

Sima, M. and Özel, T., “Modified Material Constitutive Models for Serrated Chip Formation Simulations and Experimental Validation in Machining of Titanium Alloy Ti-6Al-4V,” International Journal of Machine Tools and Manufacture, Vol. 50, No. 11, pp. 943–960, 2010.

Karpat, Y., “Temperature Dependent Flow Softening of Titanium Alloy Ti-6Al-4V: An Investigation using Finite Element Simulation of Machining,” Journal of Materials Processing Technology, Vol. 211, No. 4, pp. 737–749, 2011.

Li, L. and He, N., “A FEA Study on Mechanisms of Saw-Tooth Chip Deformation in High Speed Cutting of Ti-6Al-4V Alloy,” Proc. of 5th International Conference on High Speed Machining (HSM), Metz, France, pp. 759–767, 2006.

Lee, W.-S. and Lin, C.-F., “Plastic Deformation and Fracture Behaviour of Ti-6Al-4V Alloy Loaded with High Strain Rate under Various Temperatures,” Materials Science and Engineering: A, Vol. 241, No. 1, pp. 48–59, 1998.

Lee, W.-S. and Lin, C.-F., “High-Temperature Deformation Behaviour of Ti-6Al-4V Alloy Evaluated by High Strain-Rate Compression Tests,” Journal of Materials Processing Technology, Vol. 75, No. 1, pp. 127–136, 1998.

Meyer, H. W. and Kleponis, D. S., “Modeling the High Strain Rate Behavior of Titanium Undergoing Ballistic Impact and Penetration,” International Journal of Impact Engineering, Vol. 26, No. 1, pp. 509–521, 2001.

Seo, S., Min, O., and Yang, H., “Constitutive Equation for Ti-6Al-4V at High Temperatures Measured using the SHPB Technique,” International Journal of Impact Engineering, Vol. 31, No. 6, pp. 735–754, 2005.

Liu, R., Melkote, S., Pucha, R., Morehouse, J., Man, X., and Marusich, T., “An Enhanced Constitutive Material Model for Machining of Ti-6Al-4V Alloy,” Journal of Materials Processing Technology, Vol. 213, No. 12, pp. 2238–2246, 2013.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Choi, HJ., Park, CW., Kang, IS. et al. Material model application considering strain softening for cutting simulation of Ti-6Al-4V alloy and its experimental validation. Int. J. Precis. Eng. Manuf. 17, 1651–1658 (2016). https://doi.org/10.1007/s12541-016-0191-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-016-0191-9