Abstract

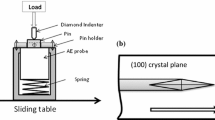

This paper reports an approach to use the acoustic emission (AE) technology for monitoring the surface/subsurface damage in twodimensional pre-stress scratching of SiC ceramics, in which the two-dimensional pre-stress is used to decrease the scratch-induced damage. Experiments in this study were conducted on a UMT-2 machine (CETR USA) utilizing a designed pre-stressing device under pressures of 0 MPa, 300 MPa and 500 MPa. The experimental results demonstrate that average frequency and magnitude of AE signals have a good correlation with the scratching tangential force and the scratch-induced surface /subsurface damage of materials. For a given normal load, the average frequency and magnitude of AE signals are observed to decrease with the increase in pre-stress, which indicates that surface/subsurface damage of SiC ceramics induced by two-dimensional pre-stress scratching is less than that induced by conventional scratching. The findings provide fundamental information for developing a practical on-line AE monitoring system that is effective in detecting surface/subsurface damage in scratching or grinding of ceramics. These results also demonstrate that two-dimensional pre-stress method contributes to decreasing the machining damage of brittle materials.

Similar content being viewed by others

Abbreviations

- AE:

-

Acoustic Emission

References

Xie, J., Li, Q., Sun, J., and Li, Y., “Study on Ductile-Mode Mirror Grinding of SiC Ceramic Freeform Surface using an Elliptical Torus-Shaped Diamond Wheel,” Journal of Materials Processing Technology, Vol. 222, pp. 422–433, 2015.

Zhang, B., Zheng, X. L., Tokura, H., and Yoshikawa, M., “Grinding Induced Damage in Ceramics,” Journal of Materials Processing Technology, Vol. 132, No. 1, pp. 353–364, 2003.

Li, B., Ni, J., Yang, J., and Liang, S. Y., “Study on High-Speed Grinding Mechanisms for Quality and Process Efficiency,” The International Journal of Advanced Manufacturing Technology, Vol. 70, No. 5-8, pp. 813–819, 2014.

Sarwar, M. S., Dahmardeh, M., Nojeh, A., and Takahata, K., “Batch-Mode Micropatterning of Carbon Nanotube Forests Using UV-LIGA Assisted Micro-Electro-Discharge Machining,” Journal of Materials Processing Technology, Vol. 214, No. 11, pp. 2537–2544, 2014.

Peng, Y., Wu, Y. B., Liang, Z. Q., Guo, Y. B., and Lin, X., “An Experimental Study of Ultrasonic Vibration-Assisted Grinding of Polysilicon Using Two-Dimensional Vertical Workpiece Vibration,” The International Journal of Advanced Manufacturing Technology, Vol. 54, No. 9-12, pp. 941–947, 2011.

Adalarasan, R., Santhanakumar, M., and Rajmohan, M., “Optimization of Laser Cutting Parameters for Al6061/SiCp/Al2O3 Composite using Grey based Response Surface Methodology (GRSM),” Measurement, Vol. 73, pp. 596–606, 2015.

Salonitis, K. and Vatousianos, S., “Experimental Investigation of the Plasma Arc Cutting Process,” Procedia CIRP, Vol. 3, pp. 287–292, 2012.

Yoshino, M., Ogawa, Y., and Aravindan, S., “Machining of Hard-Brittle Materials by a Single Point Tool under External Hydrostatic Pressure,” Journal of Manufacturing Science and Engineering, Vol. 127, No. 4, pp. 837–845, 2005.

Yoshino, M., Higashi, E., and Kawade, K., “Development of a Machining Tester for Two Dimensional Machining Test under External Hydrostatic Pressure,” JSME International Journal Series C Mechanical Systems, Machine Elements and Manufacturing, Vol. 49, No. 2, pp. 329–333, 2006.

Yoshino, M., Aoki, T., and Shirakashi, T., “Scratching Test of Hard-Brittle Materials under High Hydrostatic Pressure,” Journal of Manufacturing Science and Engineering, Vol. 123, No. 2, pp. 231–239, 2001.

Tan, Y., Jiang, S., Nie, S., Yang, D., Zhang, G., and Peng, R., “Prestress Scratching on SiC Ceramic,” International Journal of Applied Ceramic Technology, Vol. 9, No. 2, pp. 322–328, 2012.

Tan, Y., Jiang, S., Yang, D., and Sheng, Y., “Scratching of Al2O3 under Pre-Stressing,” Journal of Materials Processing Technology, Vol. 211, No. 7, pp. 1217–1223, 2011.

Liu, Q., Chen, X., and Gindy, N., “Investigation of Acoustic Emission Signals under a Simulative Environment of Grinding Burn,” International Journal of Machine Tools and Manufacture, Vol. 46, No. 3, pp. 284–292, 2006.

Zhang, D., Bi, G., Sun, Z., and Guo, Y., “Online Monitoring of Precision Optics Grinding using Acoustic Emission based on Support Vector Machine,” The International Journal of Advanced Manufacturing Technology, Vol. 80, No. 5-8, pp. 761–774, 2015.

Marinescu, I. and Axinte, D. A., “A Critical Analysis of Effectiveness of Acoustic Emission Signals to Detect Tool and Workpiece Malfunctions in Milling Operations,” International Journal of Machine Tools and Manufacture, Vol. 48, No. 10, pp. 1148–1160, 2008.

Marinescu, I. and Axinte, D., “A Time-Frequency Acoustic Emissionbased Monitoring Technique to Identify Workpiece Surface Malfunctions in Milling with Multiple Teeth Cutting Simultaneously,” International Journal of Machine Tools and Manufacture, Vol. 49, No. 1, pp. 53–65, 2009.

Gómez, M. P., Hey, A. M., Ruzzante, J. E., and D’Attellis, C. E., “Tool Wear Evaluation in Drilling by Acoustic Emission,” Physics Procedia, Vol. 3, No. 1, pp. 819–825, 2010.

Li, X., “A Brief Review: Acoustic Emission Method for Tool Wear Monitoring during Turning,” International Journal of Machine Tools and Manufacture, Vol. 42, No. 2, pp. 157–165, 2002.

Neslušan, M., Micieta, B., Micietová, A., Cilliková, M., and Mrkvica, I., “Detection of tool Breakage during Hard Turning through Acoustic Emission at Low Removal Rates,” Measurement, Vol. 70, pp. 1–13, 2015.

Webster, J., Marinescu, I., Bennett, R., and Lindsay, R., “Acoustic Emission for Process Control and Monitoring of Surface Integrity during Grinding,” CIRP Annals-Manufacturing Technology, Vol. 43, No. 1, pp. 299–304, 1994.

Akbari, J., Saito, Y., Hanaoka, T., Higuchi, S., and Enomoto, S., “Effect of Grinding Parameters on Acoustic Emission Signals while Grinding Ceramics,” Journal of Materials Processing Technology, Vol. 62, No. 4, pp. 403–407, 1996.

Hwang, T. W., Whitenton, E. P., Hsu, N. N., Blessing, G. V., and Evans, C., “Acoustic Emission Monitoring of High Speed Grinding of Silicon Nitride,” Ultrasonics, Vol. 38, No. 1, pp. 614–619, 2000.

Guo, Y. B. and Ammula, S. C., “Real-Time Acoustic Emission Monitoring for Surface Damage in Hard Machining,” International Journal of Machine Tools and Manufacture, Vol. 45, No. 14, pp. 1622–1627, 2005.

Lee, D.-E., Hwang, I., Valente, C. M., Oliveira, J., and Dornfeld, D. A., “Precision Manufacturing Process Monitoring with Acoustic Emission,” International Journal of Machine Tools and Manufacture, Vol. 46, No. 2, pp. 176–188, 2006.

Han, X. and Wu, T., “Analysis of Acoustic Emission in Precision and High-Efficiency Grinding Technology,” The International Journal of Advanced Manufacturing Technology, Vol. 67, No. 9-12, pp. 1997–2006, 2013.

Torres, F. and Griffin, J., “Control with Micro Precision in Abrasive Machining through the Use of Acoustic Emission Signals,” Int. J. Precis. Eng. Manuf., Vol. 16, No. 3, pp. 441–449, 2015.

Griffin, J. and Chen, X., “Real-Time Fuzzy-Clustering and Cart Rules Classification of the Characteristics of Emitted Acoustic Emission during Horizontal Single-Grit Scratch Tests,” The International Journal of Advanced Manufacturing Technology, Vol. 74, No. 1-4, pp. 481–502, 2014.

Cruz, C. E. D., De Aguiar, P. R., Machado, Á. R., Bianchi, E. C., Contrucci, J. G., and Neto, F. C., “Monitoring in Precision Metal Drilling Process using Multi-Sensors and Neural Network,” The International Journal of Advanced Manufacturing Technology, Vol. 66, No. 1-4, pp. 151–158, 2013.

Rabani, A., Marinescu, I., and Axinte, D., “Acoustic Emission Energy Transfer Rate: A Method for Monitoring Abrasive Waterjet Milling,” International Journal of Machine Tools and Manufacture, Vol. 61, No. pp. 80–89, 2012.

Yi, L., Yan, Z., Xiaojian, X., Yang, Z., and Rui, W., “Effect of Welding Heat Input to Metal Droplet Transfer Characterized by Structure-Borne Acoustic Emission Signals Detected in GMAW,” Measurement, Vol. 70, pp. 75–82, 2015.

Öpöz, T. T. and Chen, X., “Experimental Investigation of Material Removal Mechanism in Single Grit Grinding,” International Journal of Machine Tools and Manufacture, Vol. 63, pp. 32–40, 2012.

Klecka, M. and Subhash, G., “Grain Size Dependence of Scratch-Induced Damage in Alumina Ceramics,” Wear, Vol. 265, No. 5, pp. 612–619, 2008.

Yang, Z., Yu, Z., Xie, C., and Huang, Y., “Application of Hilbert–Huang Transform to Acoustic Emission Signal for Burn Feature Extraction in Surface Grinding Process,” Measurement, Vol. 47, pp. 14–21, 2014.

Griffin, J. M., “Traceability of Acoustic Emission Measurements for Micro and Macro Grinding Phenomena-Characteristics and Identification through Classification of Micro Mechanics with Regression to Burn using Signal Analysis,” The International Journal of Advanced Manufacturing Technology, Vol. 81, No. 9-12, pp. 1463–1474, 2015.

Ruff, A. W., Shin, H., and Evans, C. J., “Damage Processes in Ceramics Resulting from Diamond Tool Indentation and Scratching in Various Environments,” Wear, Vol. 181, pp. 551–562, 1995.

Lawn, B. and Swain, M., “Microfracture Beneath Point Indentations in Brittle Solids,” Journal of Materials Science, Vol. 10, No. 1, pp. 113–122, 1975.

Conway, J. and Kirchner, H., “The Mechanics of Crack Initiation and Propagation Beneath a Moving Sharp Indentor,” Journal of Materials Science, Vol. 15, No. 11, pp. 2879–2883, 1980.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, G., Zeng, Y., Zhang, W. et al. Monitoring for damage in two-dimensional pre-stress scratching of SiC ceramics. Int. J. Precis. Eng. Manuf. 17, 1425–1432 (2016). https://doi.org/10.1007/s12541-016-0168-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-016-0168-8