Abstract

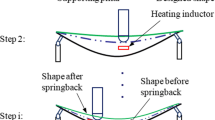

Large springback of high strength steels in progressive dies hinders accurate manufacturing because a proper prediction of elastic unloading is not possible due to material variations, tool wear, and varying ambient conditions. In order to compensate springback and enhance the forming limit when brittle materials are bent, a warm bending technology for progressive dies through inline induction heating is developed. Within a certain temperature range, there is a linear relation to the springback angle, which allows a direct influence on the final bending angle. Based on this principle, a closed loop control with a feedback of the angle after unloading is implemented, which adjusts the sheet temperature before bending. With the developed discrete controller, finally a stable and fast control mode is achieved so that an initial deviation from the target value is reduced to less than Δθ = ±0.30°.

Similar content being viewed by others

Abbreviations

- c :

-

Settling cycles

- d :

-

Damping factor

- e :

-

Error

- f :

-

Frequency

- f s :

-

Stroke rate

- n :

-

Number of dead cycles

- T :

-

Temperature

- v r :

-

Stroke velocity

- θ :

-

Bending angle

- θ n :

-

Nominal angle

- Θ :

-

Springback angle

References

Keeler, S. and Kimchi, M., “Advanced High-Strength Steels Application Guidelines Version 5.0.” WorldAutoSteel, pp. 2-1-2-15, 2014.

Wagoner, R. H., Lim, H., and Lee, M.-G., “Advanced Issues in Springback,” International Journal of Plasticity, Vol. 45, pp. 3–20, 2013.

West, J. S., “Adaptive Stroke Reversal Control in Brakeforming,” M.Sc. Thesis, Department of Mechanical Engineering, Massachusetts Institute of Technology, 1980.

Pourboghrat, F. and Stelson, K. A., “Pressbrake Bending in the Punch-Sheet Contact Region-Part 1: Modeling Nonuniformities,” Journal of Manufacturing Science and Engineering, Vol. 110, No. 2, pp. 124–130, 1988.

Kwok, S. K. and Lee, W. B., “The Design of an Intelligent Bending Machine,,” Proc. of International Conference on Manufacturing Automation, pp. 601–606, 1992.

Anokye-Siribor, K. and Singh, U. P., “A New Analytical Model for Pressbrake Forming using In-Process Identification of Material Characteristics,” Journal of Materials Processing Technology, Vol. 99, No. 1, pp. 103–112, 2000.

Gerritsen, G., “Method for Controlling the Stroke of a Press Brake,” EP Patent, 1120176A1, 2001.

Ridane, N., “FEM-Gestützte Prozessregelung des Freibiegens,” Shaker, pp. 24–38, 2008.

Welo, T. and Granly, B., “A New Adaptive Bending Method using Closed Loop Feedback Control,” Transactions of Nonferrous Metals Society of China, Vol. 20, No. 11, pp. 2111–2117, 2010.

Groche, P., Beiter, P., and Henkelmann, M., “Prediction and Inline Compensation of Springback in Roll Forming of High and Ultra-High Strength Steels,” Production Engineering, Vol. 2, No. 4, pp. 401–407, 2008.

Neugebauer, R., Altan, T., Geiger, M., Kleiner, M., and Sterzing, A., “Sheet Metal Forming at Elevated Temperatures,” CIRP Annals-Manufacturing Technology, Vol. 55, No. 2, pp. 793–816, 2006.

Bammer, F., Schumi, T., and Schuöcker, D., “Some Aspects of Laser-Assisted Bending,” Proc. of International Conference on Technology of Plasticity, 2011.

Yanagimoto, J. and Oyamada, K., “Mechanism of Springback-Free Bending of High-Strength Steel Sheets under Warm Forming Conditions,” CIRP Annals-Manufacturing Technology, Vol. 56, No. 1, pp. 265–268, 2007.

Löbbe, C., Becker, C., and Tekkaya, A. E., “Warm Bending of Microalloyed High-Strength Steel by Local Induction Heating,” Proc. of 7th Forming Technology Forum, pp. 99–104, 2014.

Lange, K. and Liewald, M., “Umformtechnik: Handbuch für Industrie und Wissenschaft-Band 3: Blechbearbeitung,” Springer, pp. 271–275, 1990.

Smith, O. J. M., “A Controller to Overcome Dead Time,” ISA Journal, Vol. 6, No. 2, pp. 28–33, 1959.

Fait, J., “Technologische Grundlagenuntersuchungen zur Erhöhung der Flexibilität des Schwenkbiegens,” VDI-Verlag, p. 32, 1990.

Rothstein, R., “Einsatz der Prozeßsimulation zur Analyse und Weiterentwicklung von Gesenkbiegeverfahren,” VDI-Verlag, pp. 80–84, 1990.

Müller-Duysing, M., “Die Berechnung und Adaptive Steuerung des Drei-Punkt-Biegens,” Ph.D. Thesis, Eidgenössische Technische Hochschule Zürich, 1993.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Löbbe, C., Hoppe, C., Becker, C. et al. Closed loop springback control in progressive die bending by induction heating. Int. J. Precis. Eng. Manuf. 16, 2441–2449 (2015). https://doi.org/10.1007/s12541-015-0314-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-015-0314-8