Abstract

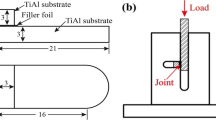

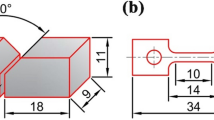

Vacuum brazing of Zr and 316 stainless steels (316L) was conducted using a Zr74Cu13Fe13 (at%) amorphous filler. A comprehensive investigation was carried out to examine the interfacial microstructure and mechanical properties of Zr/316L joints under varying brazing temperatures and extended holding times. The reaction products in Zr/316L joints brazed at 980 °C for 10 min consisted of Zr2Fe + Zrss/Zr(Fe,Cr)2 + (Zr,Cu)/α-(Fe,Cr). As the temperature increased and the duration of holding was extended, both Zr(Fe,Cr)2 and α-(Fe,Cr) layers adjacent to 316L thickened. Particularly, the growth kinetics analysis of the diffusion zone revealed that the growth coefficient of Zr(Cr,Fe)2 and α-(Fe,Cr) were 0.0291 μm2/s and 0.0058 μm2/s, respectively, indicating that Zr(Cr,Fe)2 exhibited a higher thickening rate than α-(Fe,Cr). The shear strength of Zr/316L joints initially increased and then deteriorated with higher brazing temperatures or longer holding times. The Zr/Zr–Cu–Fe/316L joints achieved a maximum strength of 93.5 MPa at a brazing parameter of 980 °C/15 min. Additionally, the joints initially failed at the interface of Zr(Fe,Cr)2/316L, with cracks propagating along the brittle Zr2Fe phase within the brazing seam.

Graphical Abstract

Similar content being viewed by others

References

A. Fattah-Alhosseini, R. Chaharmahali, M.K. Keshavarz, K. Babaei, Surf. Interfaces. 25, 101283 (2021). https://doi.org/10.1016/j.surfin.2021.101283

Y. Zheng, W. Liu, Z.Y. Su, Z.H. Zhao, G.C. Ren, W. Niu, Z.Y. Yu, L.B. Zang, Z.Z. Yu, Mater. Charact. 199, 112826 (2023). https://doi.org/10.1016/j.matchar.2023.112826

W.S. Jeon, A. Sharma, J.P. Jung, Metals 10, 787 (2020). https://doi.org/10.3390/met10060787

S.S. Guo, L.B. Sun, J. Fang, J. Zhang, Z. Zheng, C.F. Liu, Y. Wen, T.P. Shan, Mater. Charact. 193, 112270 (2022). https://doi.org/10.1016/j.matchar.2022.112270

Y. Gao, K. Zhang, C. Zhang, Y. Wang, W. Chen, Metals 13, 1475 (2023). https://doi.org/10.3390/met13081475

J. Ning, L.J. Zhang, M.X. Xie, H.X. Yang, X.Q. Yin, J.X. Zhang, J. Alloy. Compd. 698, 835–851 (2017). https://doi.org/10.1016/j.jallcom.2016.12.213

M. Slobodyan, Nucl. Eng. Technol. 53, 1049–1078 (2021). https://doi.org/10.1016/j.net.2020.10.005

Y. Zheng, G. Ren, L. Li, Mater. Lett. 348, 134710 (2023). https://doi.org/10.1016/j.matlet.2023.134710

M.S. Slobodyan, Prog. Nucl. Energ. 133, 103630 (2021). https://doi.org/10.1016/j.pnucene.2021.103630

S. Zeng et al., J. Mater. Res. Technol. 18, 2699–2710 (2022). https://doi.org/10.1016/j.jmrt.2022.03.157

H.T. Xu, L. Shi, C. Lu, H. Li, Y. He, W. Chen, Z. Gao, Mater. Charact. 179, 111368 (2021). https://doi.org/10.1016/j.matchar.2021.111368

W.L. Wang, D.Y. Fan, J.H. Huang, C.L. Li, J. Yang, S.H. Chen, Mat. Sci. Eng. A 728, 1–9 (2018). https://doi.org/10.1016/j.msea.2018.04.091

D.Y. Lin, J.X. Hu, X. Xi, Z. Liu, J.Q. Wen, Z.P. Wang, X.G. Song, H. Bian, Z.X. Tang, W. Fu, S.P. Hu, Mater. Chem. Phys. 295, 127079 (2023). https://doi.org/10.1016/j.matchemphys.2022.127079

C.H. Lee, R.K. Shiue, J. Mater. Sci. Technol. 29, 283–286 (2013). https://doi.org/10.1016/j.jmst.2013.01.010

Y.J. Jing, X.S. Yue, X.Q. Gao, Mat. Sci. Eng. A 678, 190–196 (2016). https://doi.org/10.1016/j.msea.2016.09.115

Y.Q. Xia, H.G. Dong, X.H. Hao, P. Li, S. Li, J. Mater. Process. Tech. 269, 35–44 (2019). https://doi.org/10.1016/j.jmatprotec.2019.01.020

K.H. Kim, C.H. Lim, J.G. Lee, M.K. Lee, C.K. Rhee, J. Nucl. Mater. 441, 59–66 (2013). https://doi.org/10.1016/j.jnucmat.2013.05.029

J.G. Lee, M.K. Lee, Mater. Des. 65, 265–271 (2015). https://doi.org/10.1016/j.matdes.2014.09.009

J.G. Lee, G.J. Lee, J.J. Park, M.K. Lee, J. Nucl. Mater. 488, 204–209 (2017). https://doi.org/10.1016/j.jnucmat.2017.03.020

Y.Q. Xia, H.G. Dong, P. Li, J. Alloy. Compd. 849, 156650 (2020). https://doi.org/10.1016/j.jallcom.2020.156650

H.S. Chen, C.S. Long, T.G. Wei, W. Gao, H.X. Xiao, Mater. Des. 60, 358–362 (2014). https://doi.org/10.1016/j.matdes.2014.03.055

S. Li, Z.Y. Liu, Y.Q. Xia, X.X. Wang, P. He, Y.T. Jiu, L.H. Jia, W.M. Long, J. Manuf. Process. 70, 484–493 (2021). https://doi.org/10.1016/j.jmapro.2021.09.001

Y.Q. Xia, P. Li, X.H. Hao, H.G. Dong, J. Manuf. Process. 35, 382–395 (2018). https://doi.org/10.1016/j.jmapro.2018.08.022

D. Aboudi, S. Lebaili, M. Taouinet, J. Zollinger, Mater. Design. 116, 386–394 (2017). https://doi.org/10.1016/j.matdes.2016.12.008

H.S. Chen, C.S. Long, T.G. Wei, W. Gao, H.X. Xiao, L. Chen, Mater. Des. 60, 358–362 (2014). https://doi.org/10.1016/j.matdes.2014.03.055

Z.W. Yang, F. Zhang, X. Yang, Y. Wang, D.P. Wang, Adv. Eng. Mater. 25, 2300279 (2023). https://doi.org/10.1002/adem.202300279

L. Li, X.Q. Li, K. Hu, S.G. Qu, C. Yang, Z.F. Li, Mat. Sci. Eng. A 634, 91–98 (2015). https://doi.org/10.1016/j.msea.2015.03.039

A. Sharma, B. Ahn, Sci. Rep. 11, 9345 (2021). https://doi.org/10.1038/s41598-021-87705-x

Y.Q. Xia, H.G. Dong, R.Z. Zhang, Y.Q. Wang, X.H. Hao, P. Li, C. Dong, Mater. Des. 187, 108380 (2020). https://doi.org/10.1016/j.matdes.2019.108380

S.H. Zhou, R.E. Napolitano, Acta Mater. 5, 2186–2196 (2010). https://doi.org/10.1016/j.actamat.2009.12.004

K.A. Terrani, C.M. Parish, D. Shin, B.A. Pint, J. Nucl. Mater. 438, 64–71 (2013). https://doi.org/10.1016/j.jnucmat.2013.03.006

H. Wang, Z. Wang, G. Chen, L.B. Ren, T.B. Tan, Y.Y. Guo, Y. Liu, H.H. Pan, Mater. Lett. 324, 132652 (2022). https://doi.org/10.1016/j.matlet.2022.132652

Q. Qi, J. Zhang, C.J. Lu, Q. Zhang, Y.H. Xuan, M.X. Liu, Prog. Nat. Sci. Nat. Sci. 28, 378–385 (2018). https://doi.org/10.1016/j.pnsc.2018.04.006

Z.Y. Luo, G. Wang, Y. Zhao, C.W. Tan, R.J. He, Ceram. Int. 48, 23325 (2022). https://doi.org/10.1016/j.ceramint.2022.04.320

K.K. Pandey, V.I. Levitas, Acta Mater. 196, 338–346 (2020). https://doi.org/10.1016/j.actamat.2020.06.015

T.P. Wang, J. Zhang, W.J. Lee, T. Ivas, L. Christian, Simul. Model. Pract. Theory 95, 49–59 (2019). https://doi.org/10.1016/j.simpat.2019.04.007

R. Haque, A. Olofinjana, B. Imasogie, Adv. Mater. Sci. Eng. 47, 1250154 (2020). https://doi.org/10.1155/2020/1250154

N. Jiang, H. Bian, J.C. Li, X.G. Song, Y.Z. Lei, W.M. Long, H.W. Niu, Y.Y. Pei, Vacuum 206, 111537 (2022). https://doi.org/10.1016/j.vacuum.2022.111537

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant Nos. 52275321 and 52205348), Shandong Natural Science Foundation (Grant: ZR2023JQ021), the Taishan Scholars Foundation of Shandong Province (NO. tsqn201812128), Innovation Scientists and Technicians Troop Projects of Henan Province (204200510031) and Heilongjiang Touyan Innovation Team Program (No. HITTY-20190013). This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIP) (NRF-2021R1A2C3006662, NRF-2022R1A5A1030054). And the authors also thank Li Yingchun from Shiyanjia Lab (www.shiyanjia.com) for the XRD test.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bian, H., Jiang, N., Lin, D. et al. Microstructure and Mechanical Property of Zr/316L Brazed Joints by Zr–Cu–Fe Amorphous Filler. Met. Mater. Int. 30, 1624–1634 (2024). https://doi.org/10.1007/s12540-023-01593-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-023-01593-6